Epidermis needle and its preparing method

A technology of epidermal needle and needle body, applied in the field of epidermal needle, can solve problems such as narrow material range, and achieve the effects of low price, good durability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

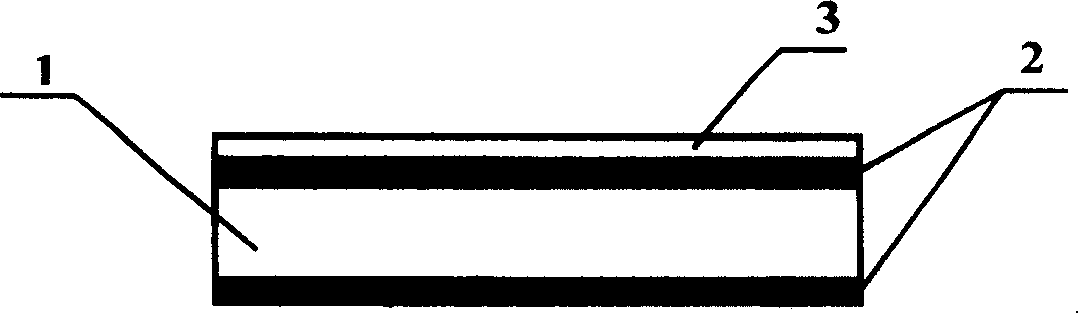

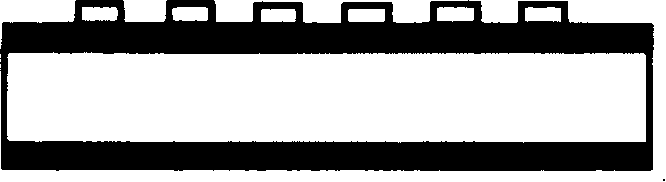

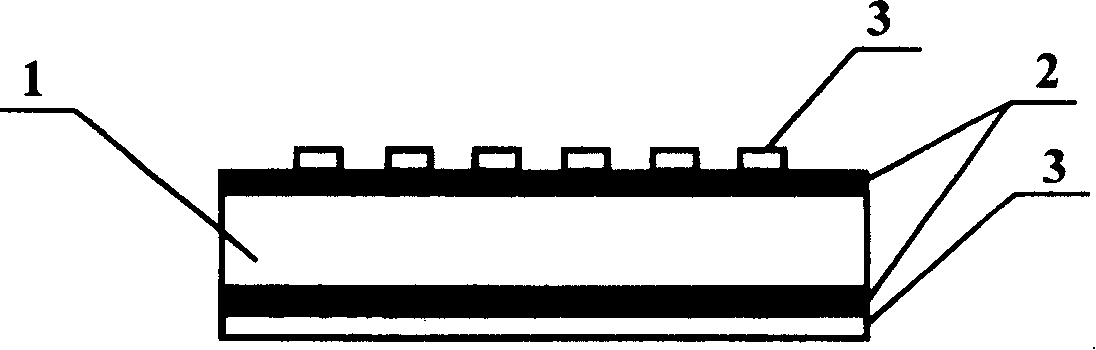

[0037] Embodiment one: see attached Figures 1a-1g , attached figure 2 Shown, a kind of manufacture method of metal epidermis needle, comprises the steps:

[0038] a) A stainless steel sheet with a thickness of 500 microns is taken as the metal substrate 1, after being washed with lotion, rinsed with deionized water and dried. Then use chemical vapor deposition to deposit a layer of silicon dioxide with a thickness of 1 micron on both surfaces of the metal as a protective layer 2 for the metal, and spin-coat Shipley 1818 photoresist 3 with a thickness of 2 microns on the silicon dioxide on one side. ( Figure 1a );

[0039] b) Pre-bake (soft bake) at 90°C for 5 minutes, and form a 20×20 array of solid circles with a diameter of 80 microns and a pitch of 200 microns in a unit of 4 square millimeters. The substrate with photoresist is exposed for 4 seconds, then developed and dried at 120°C for about 30 minutes ( Figure 1b );

[0040] c) Spin-coat Shipley 1818 photoresist...

Embodiment 2

[0045] Embodiment 2: A kind of manufacturing method of metal skin needle

[0046] 1) On a stainless steel sheet with a thickness of 1 mm, use a laser to cut square columns with a depth of 150 microns and a size of 200x120 microns.

[0047] 2) The above-mentioned metal sheet is ultrasonically cleaned in ethanol-water, and then placed in an electrolyte solution containing 30% concentrated sulfuric acid and 10% phosphoric acid at 50°C with a current density of 200A / dm 2 After electrolysis for a few minutes, a superficial and bright epidermis needle is obtained, see attached image 3 shown.

Embodiment 3

[0048] Example 3: Rat in vitro transdermal release curve using bovine serum albumin and botulinum toxin as model macromolecules

[0049] Bovine serum albumin and botulinum toxin solutions were used as model macromolecules.

[0050] Take a piece of rat skin without hair, place the cuticle upwards on the mouth of the diffusion cell, put the epidermis needles prepared in Example 1 (400 needles on an area of 4 square millimeters, and the distance between the needles is 200 microns) on it , lightly press the epidermal needle with your hand to make micropores on the skin, but do not penetrate the skin. The stratum corneum of the skin faces the drug supply chamber (the concentration of each substance in the supply chamber is 0.1mM, 1ml), and the dermis faces the drug receiving chamber. Fill the receiving chamber with phosphate buffer (pH7.4) preheated to 37°C, seal the sampling port with parafilm, and place it in a constant temperature water bath at 37°C. Under continuous stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com