Frequency changing electromagnetic wire and manufacturing method thereof

A production method and technology of electromagnetic wire, applied in the direction of circuits, insulated cables, electrical components, etc., can solve the problems of insufficient anti-pulse ability of variable frequency electromagnetic wire, low output of production method, poor quality of paint film, etc., and achieve improved anti-pulse electric aging and the ability of thermal aging of the coil, improving safety and reliability, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

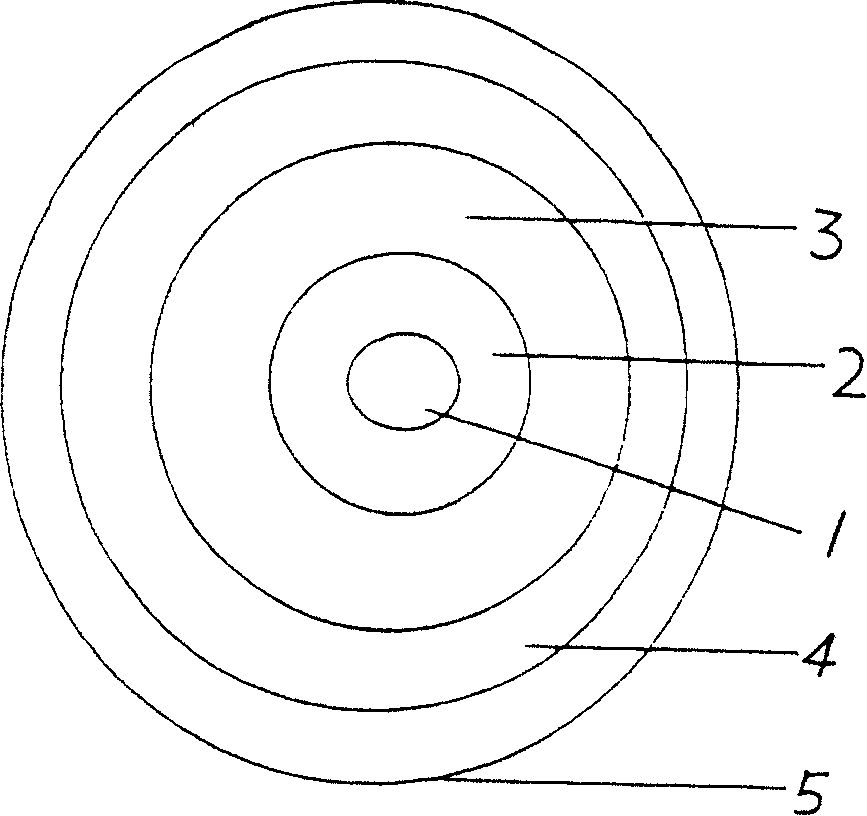

Image

Examples

Embodiment 1

[0015] The 2.6mm soft copper material is drawn to reach 1mm line, so that the surface of the copper material is smooth and seamless; the surface of the copper wire is cleaned with water with a flow rate of 2 cubic per minute, and then the copper wire is placed in a tubular annealing furnace for 15 Seconds of annealing, softening the copper surface and then using 250-degree steam protection to restore the copper wire lattice; use molds and nozzles to spray three layers of paint on the surface of the copper wire, the thickness of the primer is at least 0.06 mm, and the middle The thickness of the paint is at least 0.07 mm, and the thickness of the top coat is at least 0.02 mm; then bake the painted surface on the enamelling machine to make a smooth and complete paint film on the surface of the copper wire; then cool the copper wire to room temperature and collect it to It becomes a finished product on the reel.

Embodiment 2

[0017] The continuous casting and rolling high-purity low-oxygen copper is subjected to wire drawing treatment to make the surface of the copper material smooth and seamless; the surface of the copper wire is cleaned with 3 cubic meters of water per minute, and then the copper wire is tempered in an annealing furnace to make the copper surface After softening treatment, use 300-degree steam protection to restore the copper wire lattice; use molds and nozzles to paint the surface of the copper wire in three layers. Both the primer and the top coat are made of frequency conversion paint 981-M imported from the United States. -31TAM; bake the painted surface on the enamelling machine for 3 minutes at 680 degrees to make a smooth and complete paint film on the surface of the copper wire; finally cool the copper wire to close to room temperature, and then collect it on the reel to become the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com