A kind of electronic paste for patch fuse fuse and its manufacturing method

A technology of electronic paste and fuse, applied in the direction of conductive materials, circuits, electrical components, etc. dispersed in non-conductive inorganic materials, can solve the problems of easily oxidized resistivity, no protective components, increase, etc. Prevention of breaking failure, prevention of oxidation, good coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

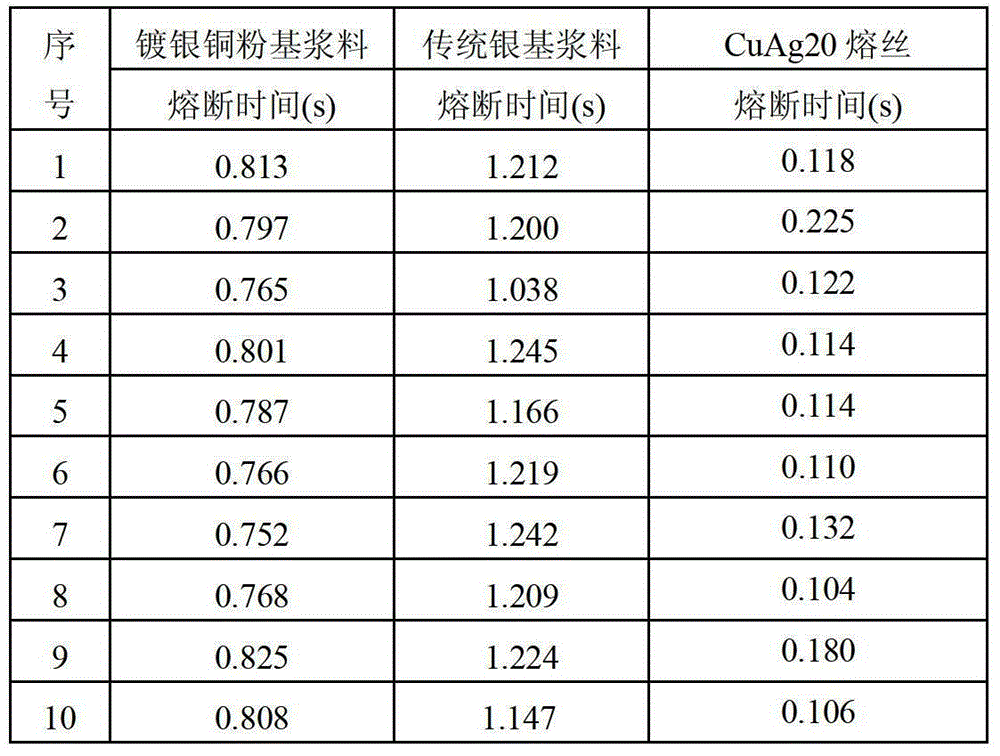

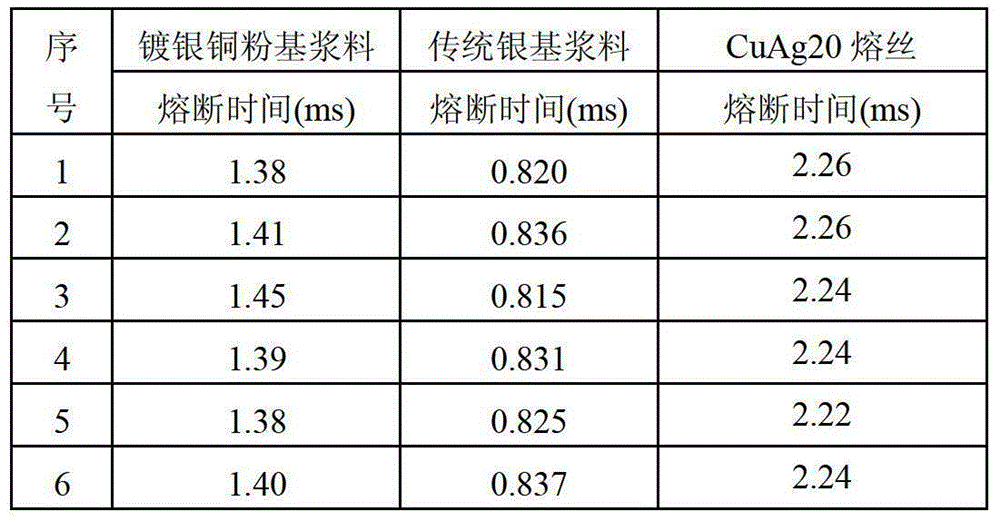

Embodiment 1

[0015] A kind of electronic paste, its weight percentage is composed of: silver plated copper powder (average particle diameter 8um, containing silver 10wt%) 60wt%, nanometer silver powder (particle diameter 5~100nm) 21wt%, terpineol 3~15wt%, Ethyl cellulose 5~12wt%, Ba-B-Si glass powder 2~10wt%. Silver-plated copper powder is a mixture of spherical and flake particles in any proportion. (1) Take macromolecular resin and organic solvent in the container according to the above ratio, then put the container into a constant temperature water bath, disperse and stir the resin and solvent for 120 ± 10 minutes, make it fully mixed, the water temperature of the water bath is 80±5°C, and finally an organic carrier solution is obtained; (2) Weigh silver-plated copper powder, nano-silver powder, and low-temperature glass powder in proportion and add them to the organic carrier prepared in step (1), and grind and disperse through a high-speed ball mill, The solid phase powders are unifo...

Embodiment 2

[0028] A kind of electronic paste, its weight percentage is composed of: silver-plated copper powder (average particle diameter 8um, containing silver 10wt%) 55wt%, silver nitrate 30wt%, triethanolamine 0.6wt%, terpineol 3~15wt%, ethyl alcohol Base cellulose 5~12wt%, Zn-B-Si glass powder 2~10wt%. Silver-plated copper powder is a mixture of spherical and flake particles in any proportion. (1) Add terpineol dropwise to triethanolamine, add precursor silver nitrate after stirring for 5 minutes, and ultrasonically disperse for 20 minutes at 30° C.; The preparation method is to obtain an organic carrier solution; (3) the organic carrier solution is prepared according to the preparation method of step (2) in Example 1 to obtain a kind of electronic paste according to the present invention. Finally, fuses were made by traditional thick-film printing process, and the anti-pulse ability and high-temperature life of the product were tested according to the experimental method and equip...

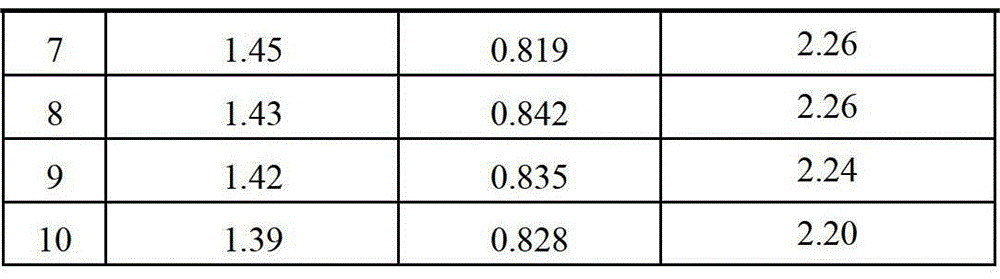

Embodiment 3

[0030] A kind of electronic paste, its weight percentage is composed of: silver plated nickel powder (average particle diameter 10um, containing silver 10wt%) 50wt%, nanometer silver powder (particle diameter 5~100nm) 36wt%, terpineol 3~15wt%, Ethyl cellulose 5~12wt%, Zn-B-Si glass powder 2~10wt%. Silver-plated nickel powder is a mixture of spherical and flake particles in any proportion. An electronic paste according to the present invention was obtained by the preparation method as in Example 1. Finally, fuses were made by traditional thick-film printing process, and the anti-pulse ability and high-temperature life of the product were tested according to the experimental method and equipment described in Example 1. The test results show that the anti-pulse ability of the product using silver-plated nickel powder-based electronic paste is about 50% higher than that of the corresponding product of silver-plated copper powder-based electronic paste, and its anti-pulse ability ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com