Method for making sample cell of solid phase white amino reflective layer

A manufacturing method and sample cell technology, which are applied in chemical instruments and methods, material testing products, other chemical processes, etc., to achieve the effects of superior practicability, easy amino acid, high activity and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

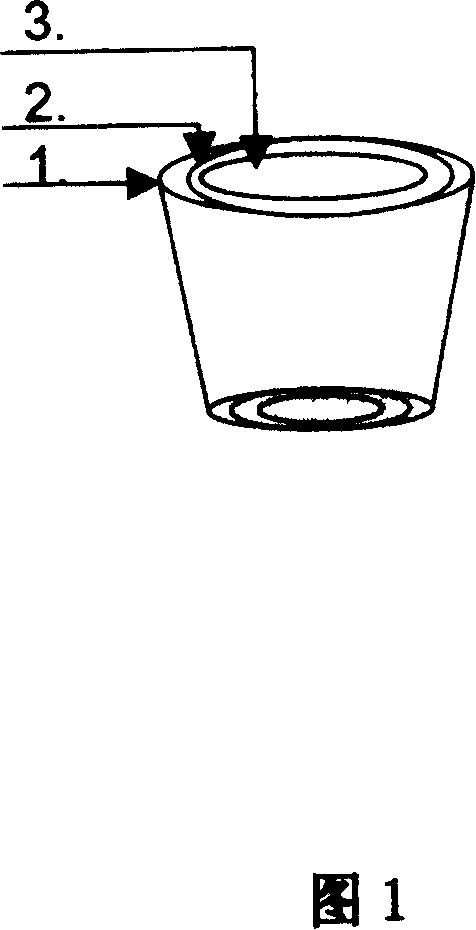

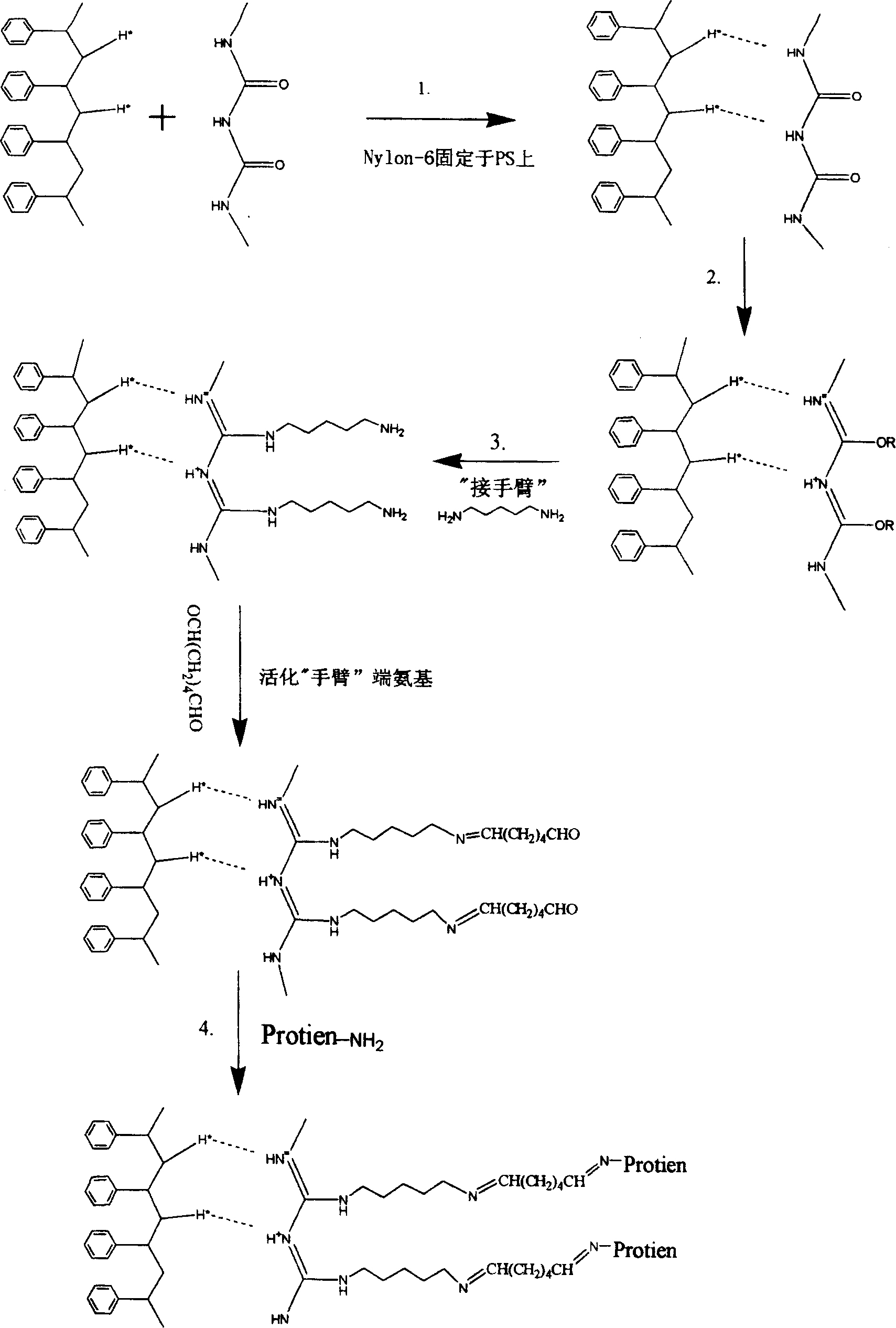

[0051] (1). Add 400 μl of matrix 1 activator to matrix 1 made of PS, leave it at room temperature for 1 minute, discard the solution and immediately add 200 μl of 12% nylon-6 solution dissolved by the middle layer 2 nylon-6 activator, along the central axis Rotate the substrate 1 at a slow speed (40 times / min), so that nylon-6 is quickly, firmly and uniformly combined with the inner surface of the substrate 1 to form a solid-phase white amino reflective layer sample with a nylon-6 film thickness of 0.1-0.2mm The middle layer of the pool is 2 nylon-6 film layers;

[0052] (2). Add 400 μl of 5% triethyloxonium tetrafluoroborate ester dichloromethane solution to the sample pool of the above step (1), leave it at room temperature for 4-10 minutes, discard it, and rinse it twice with dichloromethane , washed with dioxane once;

[0053] 3. Add 200 μl of 0.5 M glutaraldehyde into the sample pool of (2) above, incubate at 37° C. for 15 minutes, and discard. Add 0.2M pH=7.2 phosphate...

Embodiment 2

[0055] (1). Add 400 μl of matrix 1 activator to matrix 1 made of PS, leave it at room temperature for 1 minute, and immediately add 200 μl of 13% nylon-6 solution dissolved with middle layer 2 nylon-6 activator after discarding the solution. Slowly rotate (40 times / min) the substrate 1 along the central axis, so that nylon-6 is quickly, firmly and uniformly bonded to the inner surface of the substrate 1, forming a solid-phase white amino reflective layer of nylon-6 with a thickness of 0.1-0.2mm 2 nylon-6 film layers in the middle layer of the sample pool;

[0056] (2). Add 400l of 4% triethyloxonium tetrafluoroborate ester dichloromethane solution to the sample cell of the above step (1), leave it at room temperature for 4-10 minutes, discard. Rinse twice with dichloromethane , washed with dioxane once;

[0057] 3. Add 200 μl of 0.5 M glutaraldehyde borate buffer solution to the sample cell in the above step (2), incubate at 37° C. for 15 minutes, and discard. Add 0.2M pH=7....

Embodiment 3

[0059] (1). Add 400 μl of matrix 1 activator to matrix 1 composed of PS. Stand at room temperature for 1 minute, discard the solution and immediately add 200 μl of 14% nylon-6 solution dissolved by the middle layer 2 nylon-6 activator. Slowly rotate (40 times / min) the substrate 1 along the central axis, so that nylon-6 is quickly, firmly and uniformly combined with the inner surface of the substrate 1, forming a solid-phase white amino group with a nylon-6 film thickness of 0.1-0.2mm 2 nylon-6 film layers in the middle layer of the reflective layer sample pool;

[0060] (2). Add 400 μl of 3% triethyloxonium tetrafluoroborate ester in dichloromethane to the sample cell in the above step (1), leave it at room temperature for 4-10 minutes, and discard it. Rinse 2 times with dichloromethane, and rinse 1 time with dioxane; The synthetic method of described triethyloxonium tetrafluoroborate is according to the literature: (enzyme is fixed on the chemistry of nylon, biochemistry.J.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com