Boiler chimney body and method for forming its inner wall protection structure

A technology of chimney body and structure, applied in the field of chimney body and its inner wall protection structure, which can solve the problems of boiler pressure fluctuation, insufficient discharge rate, and drop of discharge rate, etc., to achieve improved firmness, improved binding force, and increased affinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

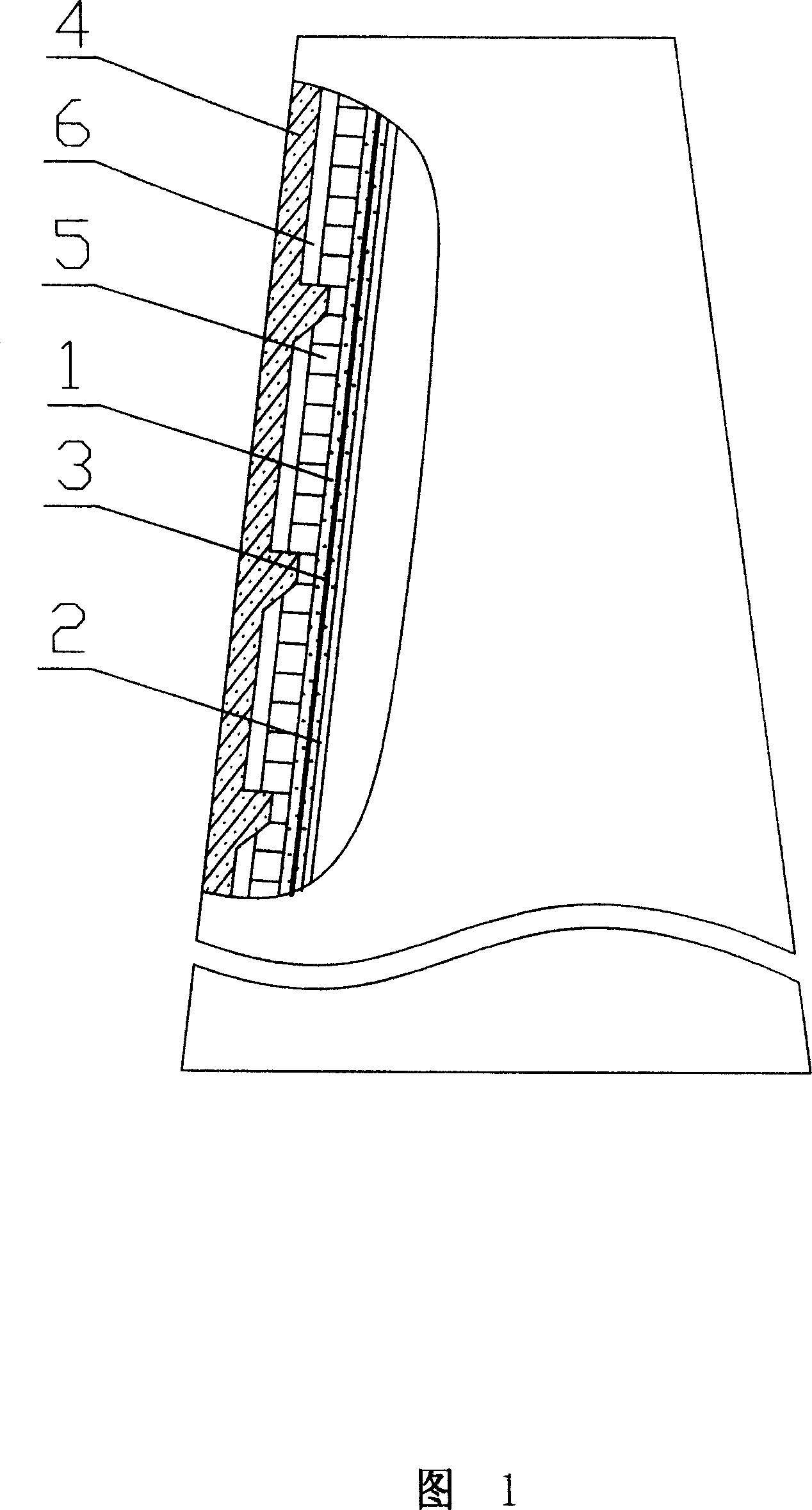

[0019] (Embodiment 1, for the new chimney body of the thermal power plant boiler)

[0020] As shown in Figure 1, the chimney body includes a simplified outer shell 4 and a liner 5, the liner 5 is arranged on the inner wall of the outer shell 4, and is fixedly connected with the outer shell, and there is air flow between the outer shell 4 and the liner 5 Channel 6; also has an inner wall protection structure, the inner wall protection structure is an acid-resistant, high-temperature-resistant polymerized silicate solidified layer 1, an acid-resistant, high-temperature-resistant epoxy coating cured layer 2 and reinforced The composite structure of layer 3, the polymeric silicate cured layer 1 is consolidated on the inner surface of the lining 5, the epoxy paint cured layer 2 is consolidated on the polymeric silicate cured layer 1, the reinforcing layer 3 is a glass fiber mesh cloth, The reinforcement layer 3 is buried and consolidated in the polymeric silicate solidified layer 1...

Embodiment 2

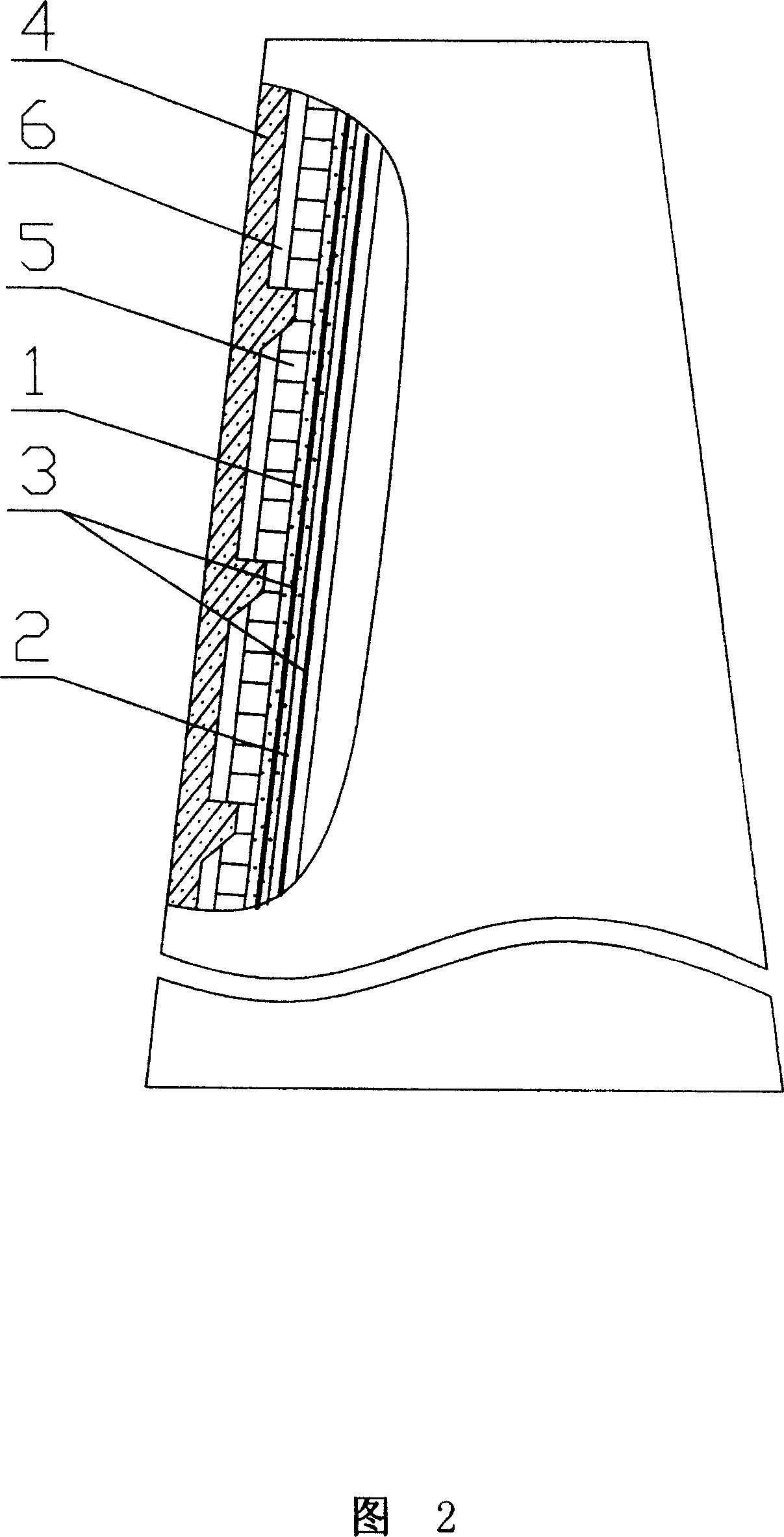

[0023] (Embodiment 2, being used for the new chimney body of boiler in thermal power plant)

[0024] The outer casing 4, the lining 5, the air flow channel 6 and the inner wall protection structure of the chimney body are basically the same as those in Embodiment 1, the difference is that the reinforcement layer 3 in the polymer silicate solidified layer 1 of the inner wall protection structure has two layer.

[0025] The specific steps of the method for forming the inner wall protection structure of the chimney body are basically the same as those in Example 1, the difference is that in step ①, the heating temperature during stirring is 80° C. and the corrosion resistance is added when the viscosity reaches Tu-4 cup for 50 seconds. Powder and curing coagulant. Step ② needs to be carried out twice, that is, after laying the first layer of glass fiber mesh cloth 3, smoothing with the paste-like polymeric silicate mixture, and drying the coated paste-like polymeric silicate mix...

Embodiment 3

[0026] (Embodiment 3, the old chimney that is used for factory coal-fired boiler)

[0027] The outer casing 4, the lining 5, the air flow channel 6 and the inner wall protection structure of the chimney body are basically the same as those in Example 2, the difference is that the reinforcement layer 3 in the polymeric silicate solidified layer 1 of the inner wall protection structure has three layers .

[0028] The specific steps of the method for forming the inner wall protection structure of the chimney body are basically the same as those in Example 2, the difference is that in step ①, the heating temperature during stirring is 100° C. and the corrosion resistance is added when the viscosity reaches Tu-4 cup for 50 seconds. Powder and curing coagulant. Step ② needs to be carried out three times, wherein the thickness of each layer of paste-like polymeric silicate mixture sprayed is 2mm, so that the thickness of the inner wall protection structure obtained at last is 9.2mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com