Small heat pipe and method for manufacturing the same

A manufacturing method and heat pipe technology, which are applied in cooling/ventilation/heating transformation, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of high cost, low yield, affecting the popularization and application of sintered small heat pipes, and achieve thermal conductivity. Fast speed, excellent performance, satisfying the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

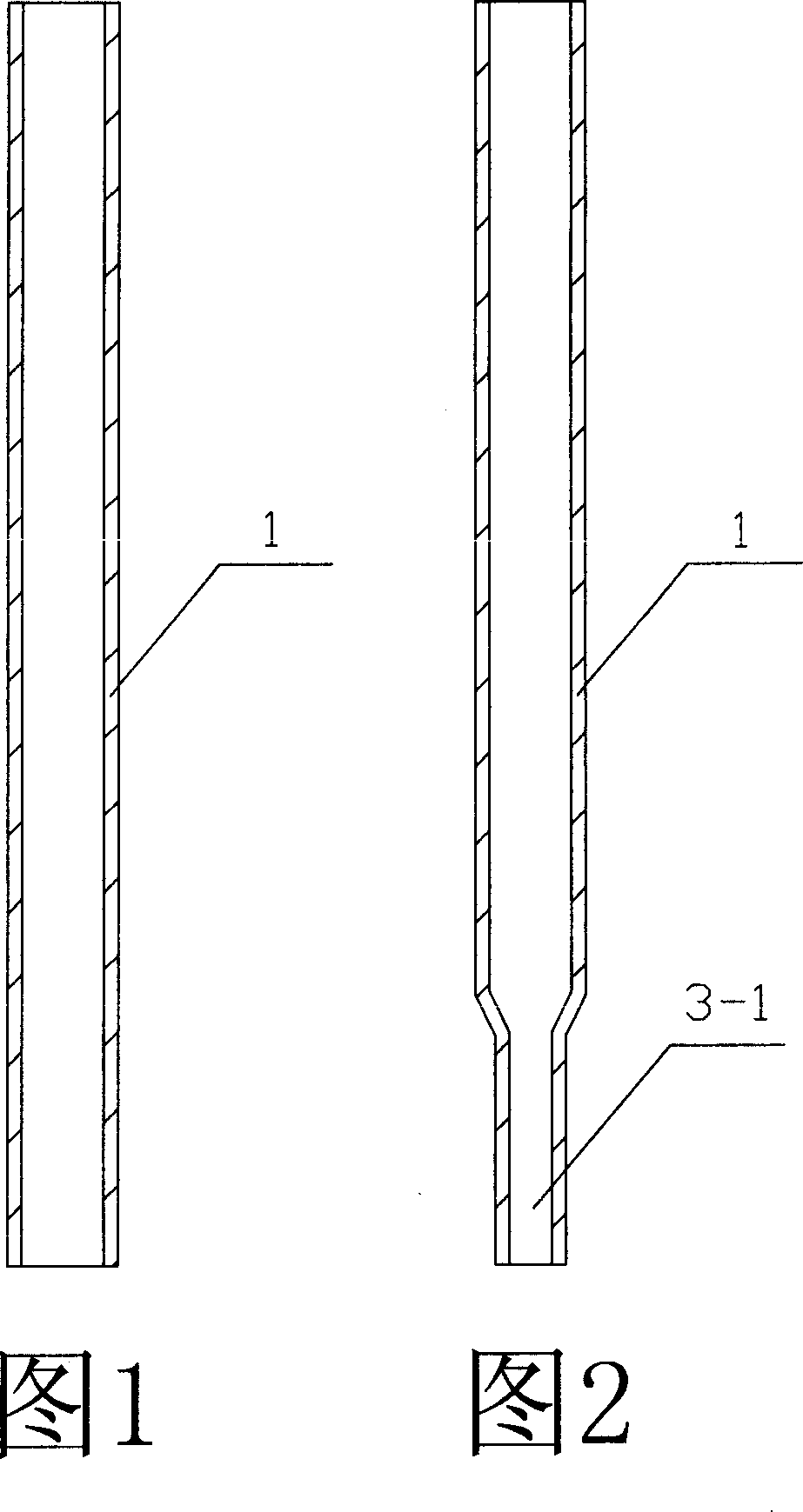

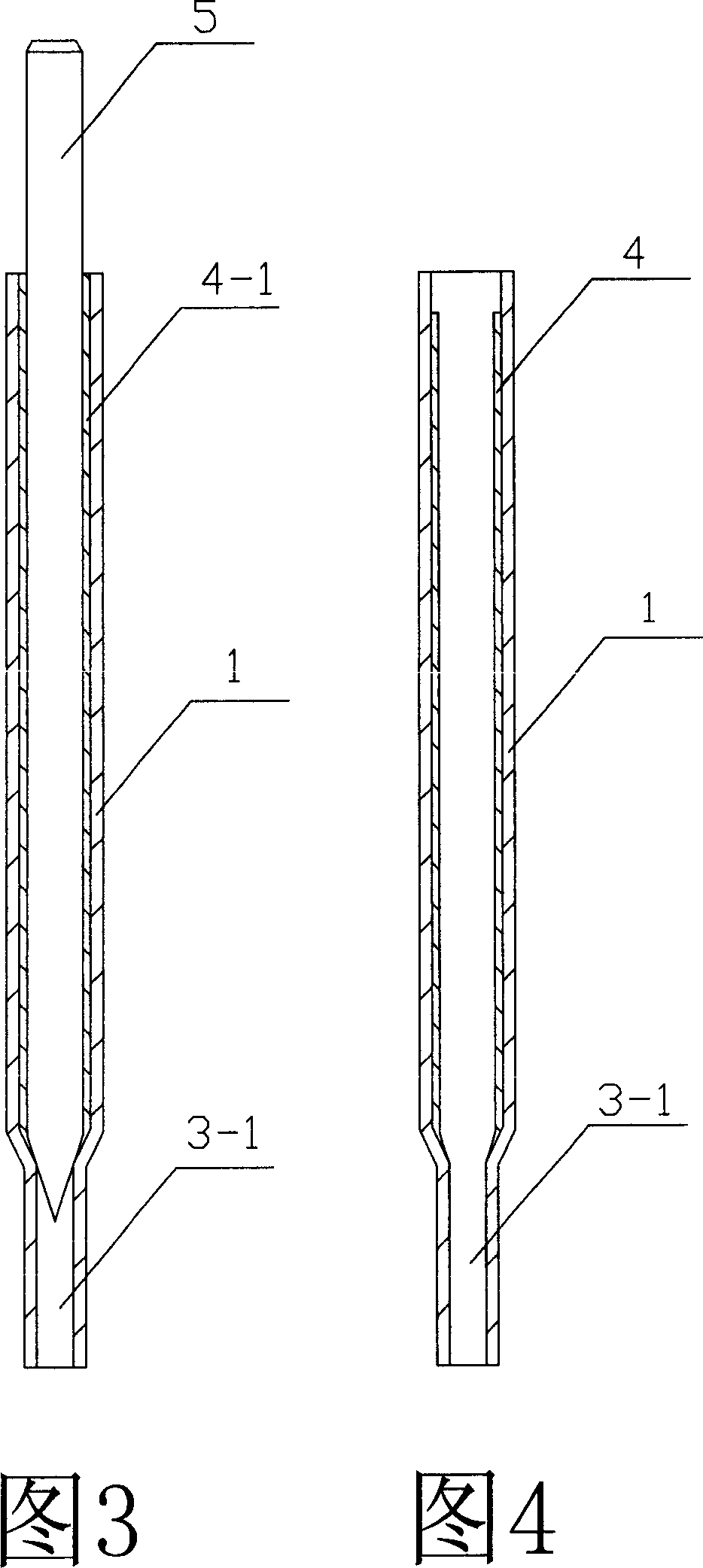

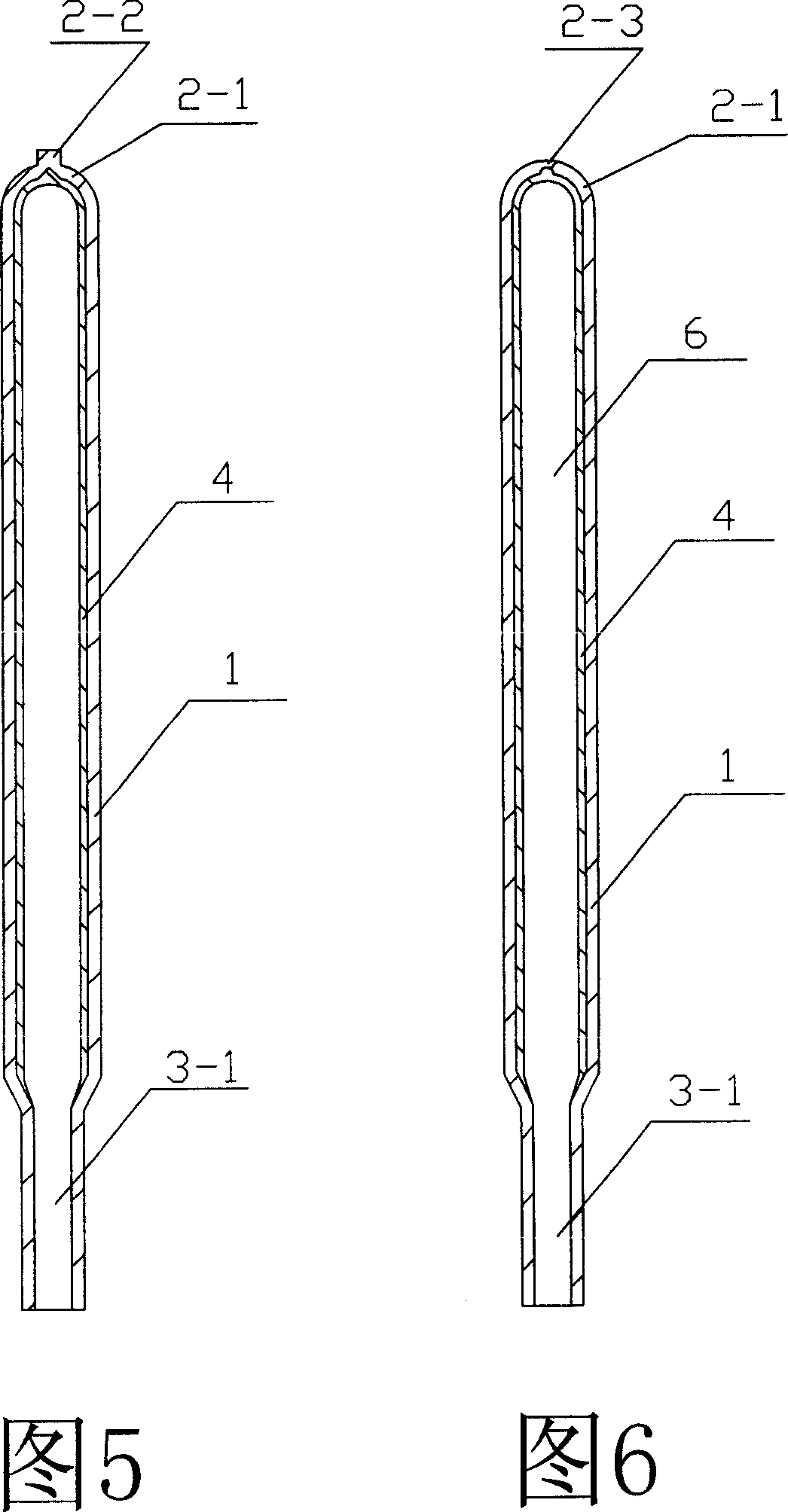

[0021] Referring to Fig. 7 and Fig. 8, this small heat pipe includes tail end 2, pipe body 1, sintered layer 4, and degassing end 3. The small heat pipe consists of tail end 2, pipe body 1, and degassing end 3 to form a sealed cavity 6. The interior is in a vacuum state; the tail end 2 of the tube body 1 is mechanically constricted and sealed by spot welding, and the degassing end 3 of the tube body 1 is squeezed into a degassing pipe 3-1 with a small diameter by mechanical blowing, and passes through the degassing pipe 3-1 Inject the working liquid into the sealed cavity 6, extract the air in the sealed cavity 6 through the degassing pipe 3-1, then pinch off the degassing pipe 3-1 and weld it in a sealed state; The upper sintering layer 4 has a certain thickness of porous capillary structure. The sintering layer 4 is sintered by a certain mesh of pure copper powder at high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com