Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92results about How to "Random shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Food packaging articles

ActiveUS20200063367A1High air permeabilityHigh thicknessFlexible coversWrappersSynthetic fiberFood packaging

Containers and lids made from cellulose fibers and cellulose ester fibers are provided that have enhanced air permeability, stiffness, R-heat insulation values, or thickness at equivalent grammage basis weights are provided, or alternatively, maintaining one or more of these properties while lowering the basis weight of the containers or lids. The container and lids with this synthetic fiber can be biodegradable when made with cellulose ester fibers having a degree of substitution of not more than 2.5. Examples of such containers are food packaging such as hot or cold delivery boxes.

Owner:EASTMAN CHEM CO

Cellulose and cellulose ester film

ActiveUS20200063353A1Reduce consistencyLow variabilityNon-fibrous pulp additionSpecial paperCellulose ester membranePolymer science

A film is made from a wet laid product containing cellulose fibers and cellulose ester fibers and a plasticizer. The film can be made by heat pressing the wet laid sheet to form a film having a continuous phase of cellulose ester resin and a discontinuous phase of cellulose fibers.

Owner:EASTMAN CHEM CO

Ultrasonic welding of wet laid nonwoven compositions

ActiveUS20200299900A1Reduce consistencyLow variabilitySpecial paperPaper/cardboardPolymer scienceUltrasonic welding

The present invention relates to ultrasonic welding of compositions, and wet laid articles made from the compositions, containing cellulose fibers and cellulose ester fibers, as well as wet laid processes using the compositions. More specifically, the present invention relates to a wet laid nonwoven comprising cellulose and cellulose ester fibers. The wet laid nonwoven is bonded to itself and / or to other substrates, and this bonding is accomplished at least in part by ultrasonic welding.

Owner:EASTMAN CHEM CO

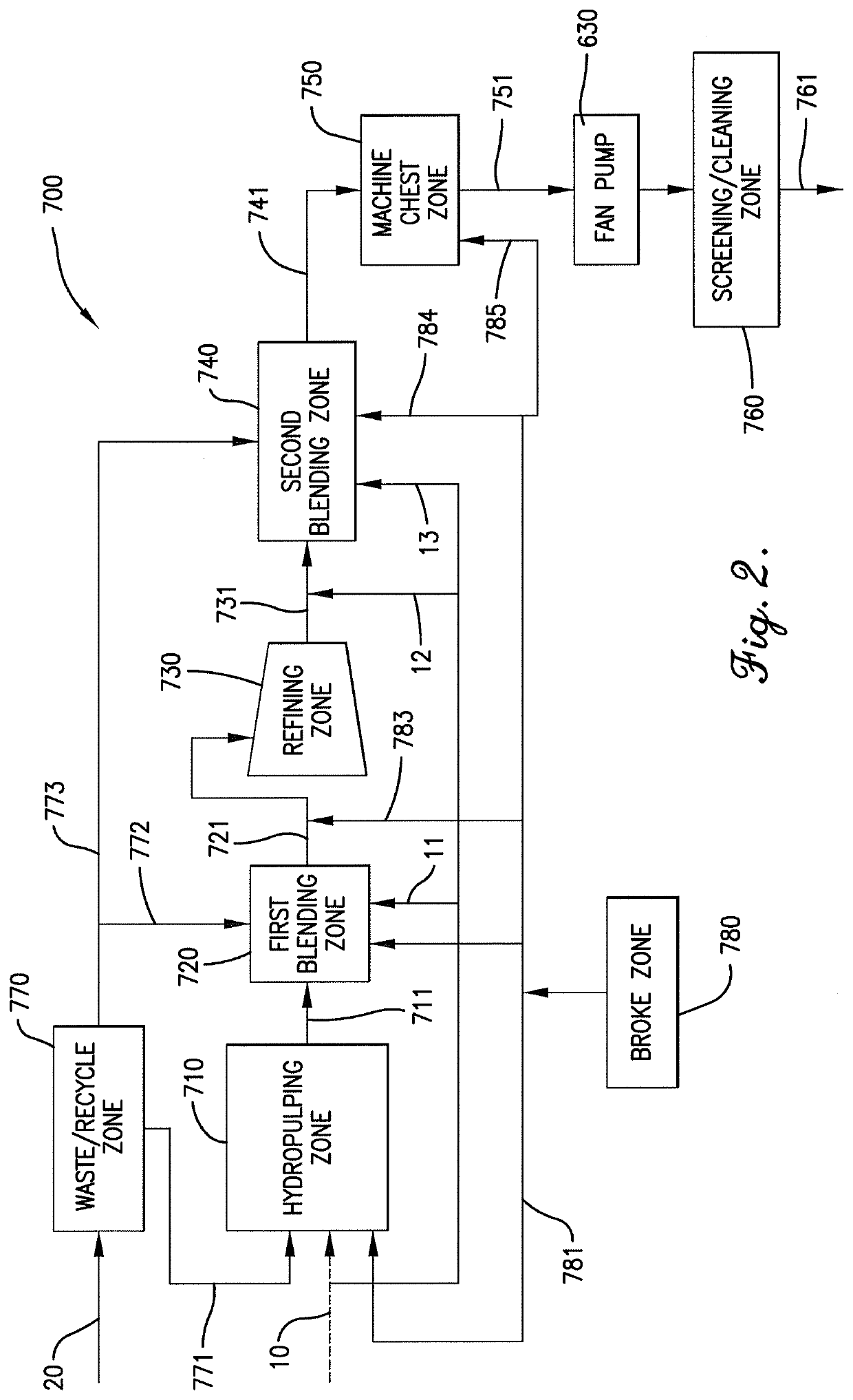

Composition of matter in a post-refiner blend zone

ActiveUS20200063358A1Reduce consistencyLow variabilityWater-repelling agents additionReinforcing agents additionPolymer scienceCellulose fiber

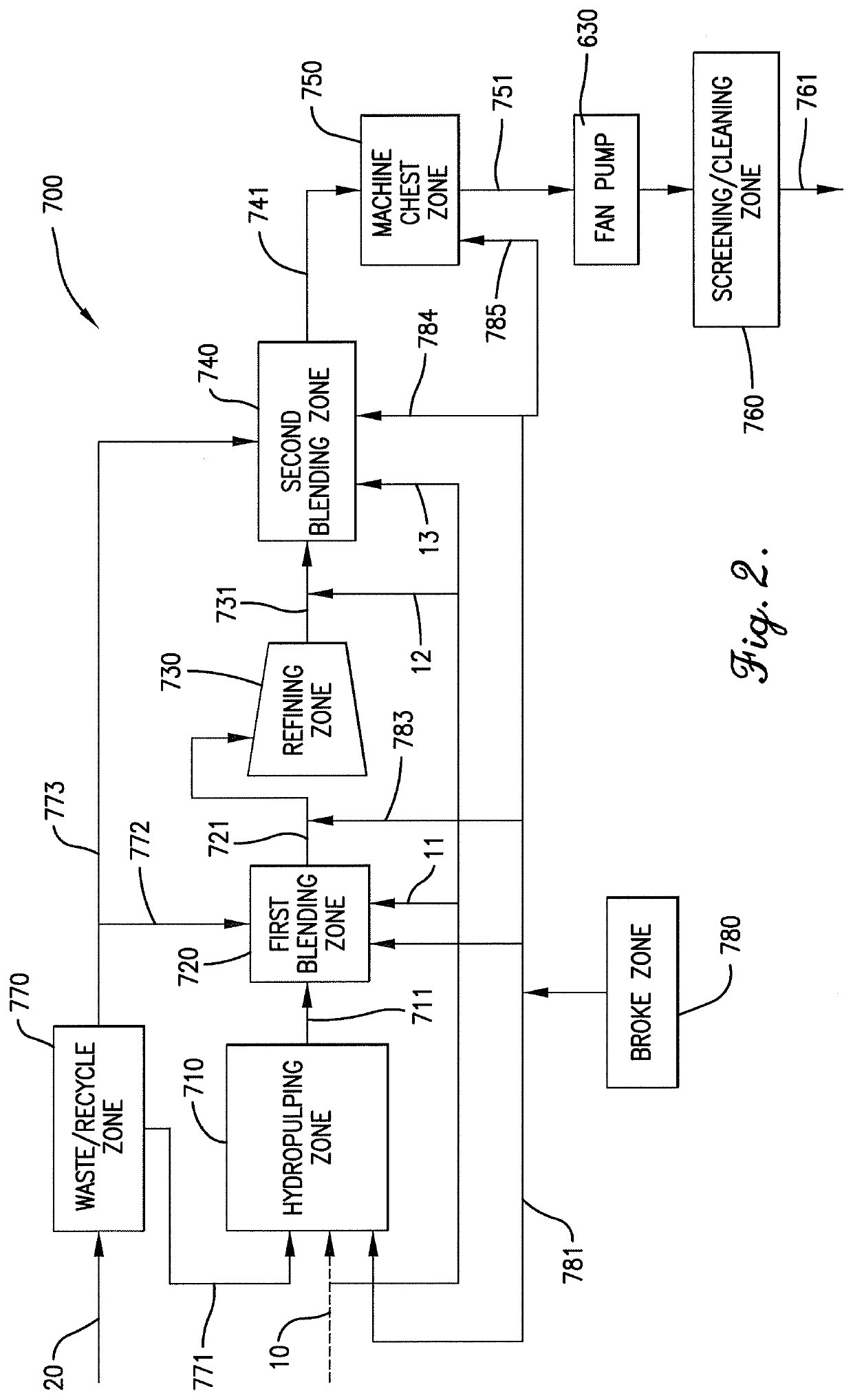

After cellulose fibers and cellulose ester fibers are co-refined, they are fed to a blend tank continuously feeds a wet laid process. The composition in the blend tank includes co-refined cellulose fibers and cellulose ester fibers and one or more additives, and the cellulose ester fibers have a denier per filament (DPF) of less than 3, a cut length of less than 6 mm, crimped, or non-round with a DPF of less than 3.

Owner:EASTMAN CHEM CO

Compostable wet-laid articles comprising cellulose and cellulose esters

InactiveUS20200063365A1Reduce consistencyLow variabilityFlexible coversWrappersPolymer scienceCellulose fiber

Wet laid products including packaging is obtained from co-refined cellulose fibers and synthetic fibers are made biodegradable, and can also be compostable and soil biodegradable. The synthetic fibers include staple cellulose ester fibers. Desirably, such staple cellulose ester fibers have a denier per filament of 3 or less, a cut length of 6 mm or less, are crimped, or are non-round and crimped, and have a degree of substitution of 2.5 or less.

Owner:EASTMAN CHEM CO

Paper bag

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many desired benefits. This invention also relates to a biodegradable bag.

Owner:EASTMAN CHEM CO

Elongated tubular articles from wet-laid webs

ActiveUS20200063349A1Reduce consistencyLow variabilitySpecial paperWater-repelling agents additionPolymer scienceCellulose fiber

Embodiments of the present invention relate to elongated tubular members that include at least one layer comprising a cellulose ester. In some cases, the cellulose ester may be in the form of staple fibers. The layer may be formed via a wet-laid fiber web that may also include cellulose fibers. The elongated tubular members may be suitable for use with food and / or beverage items as, for example, drinking straws or other similar items.

Owner:EASTMAN CHEM CO

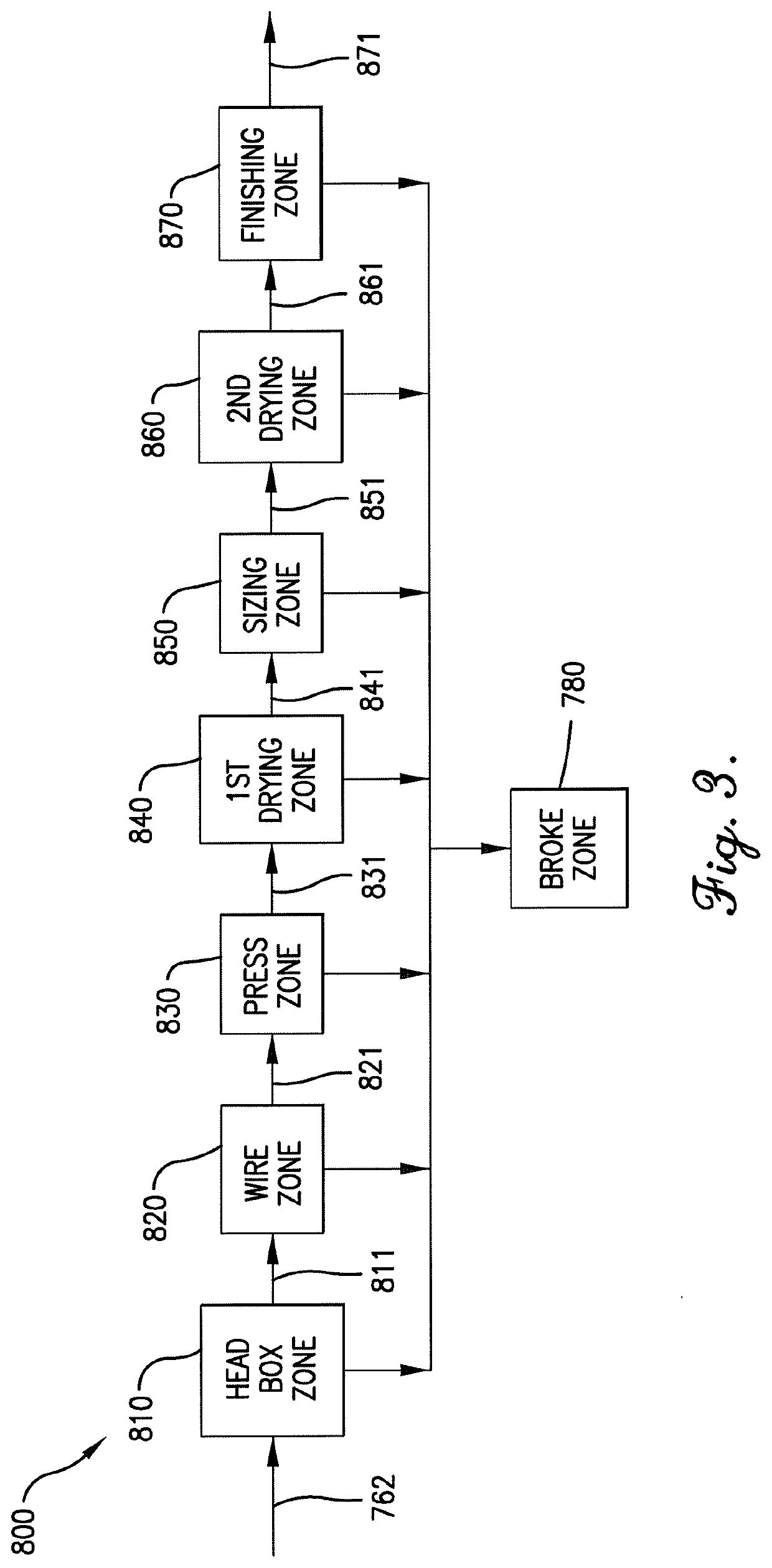

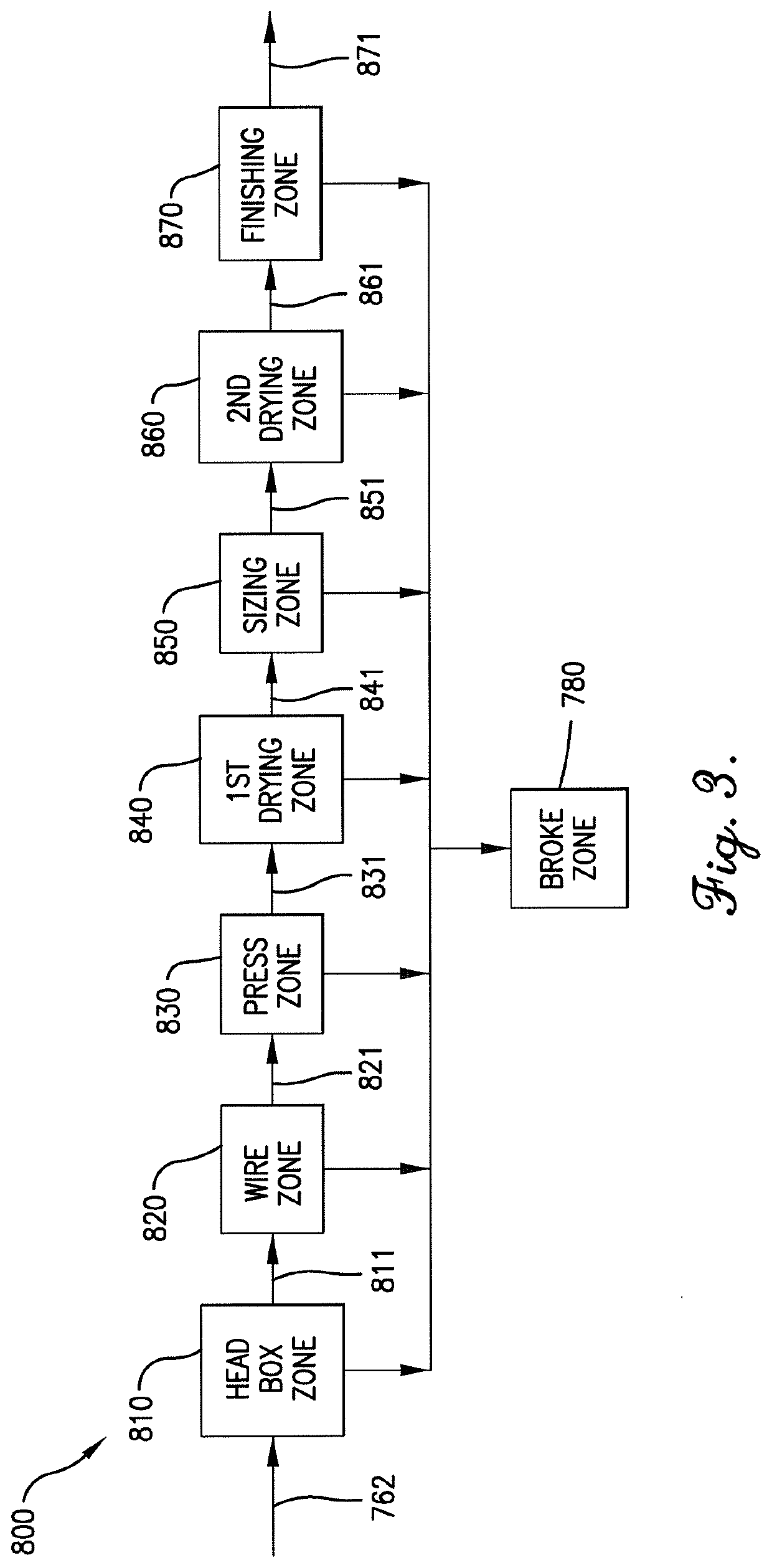

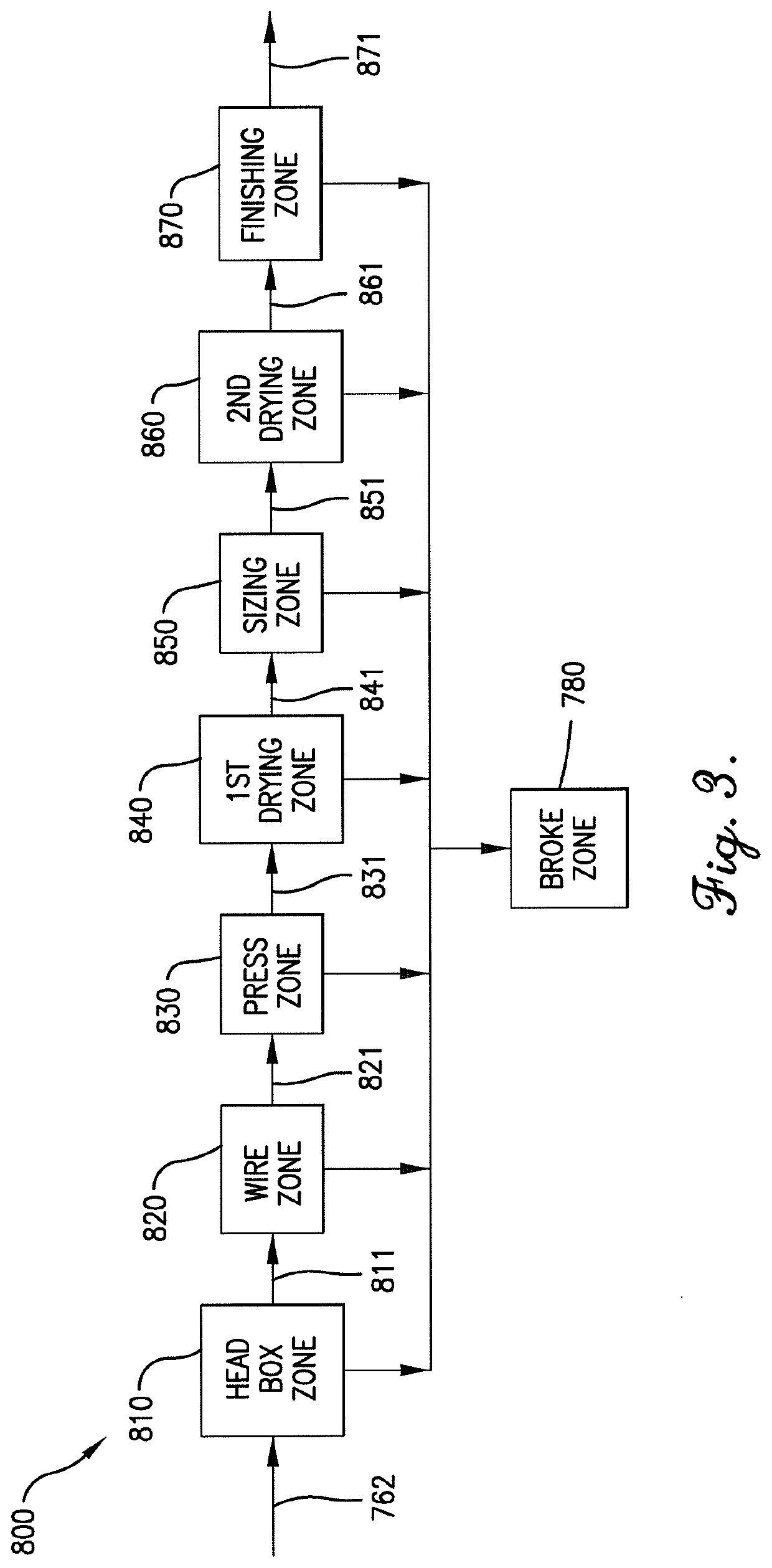

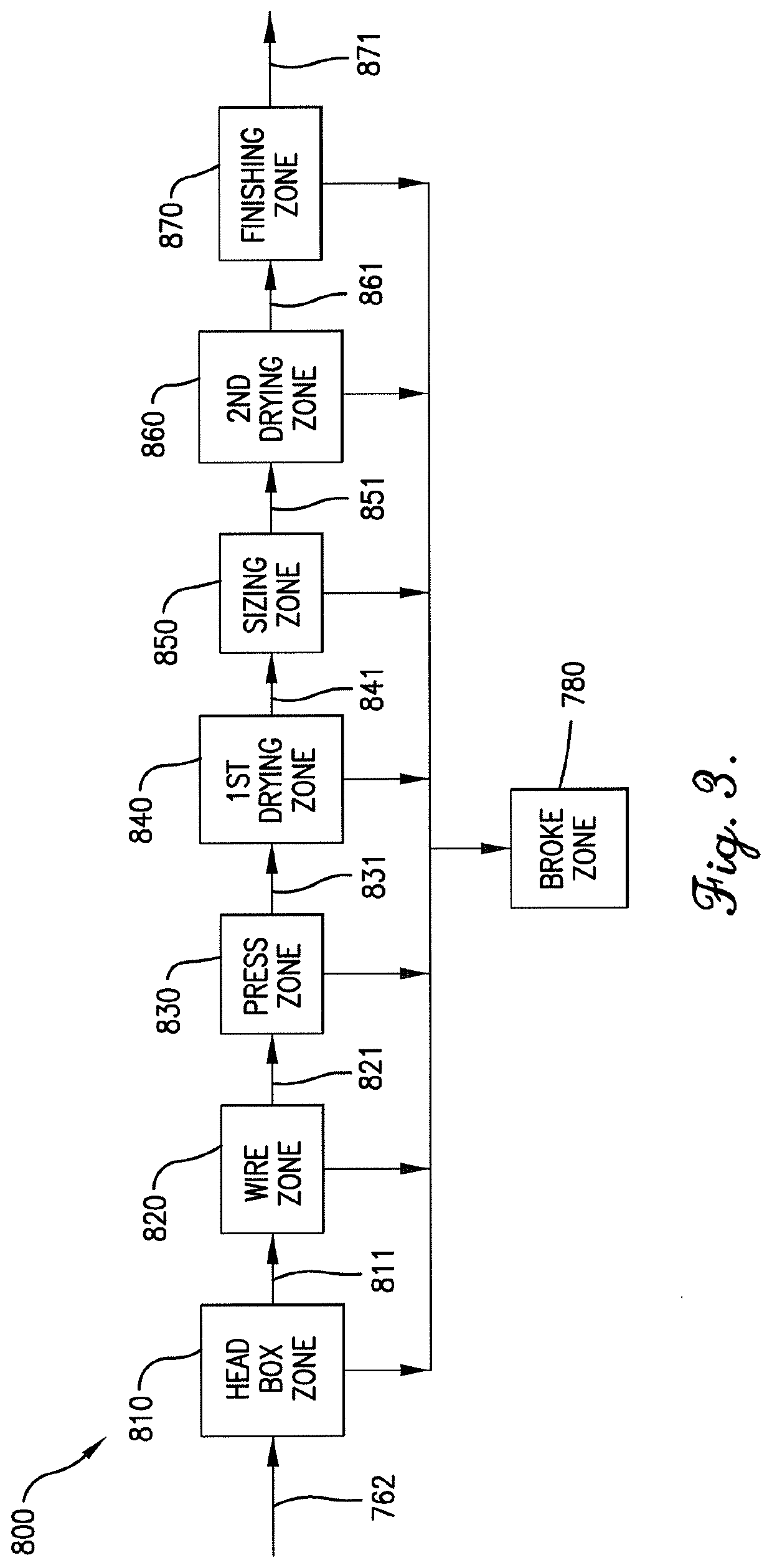

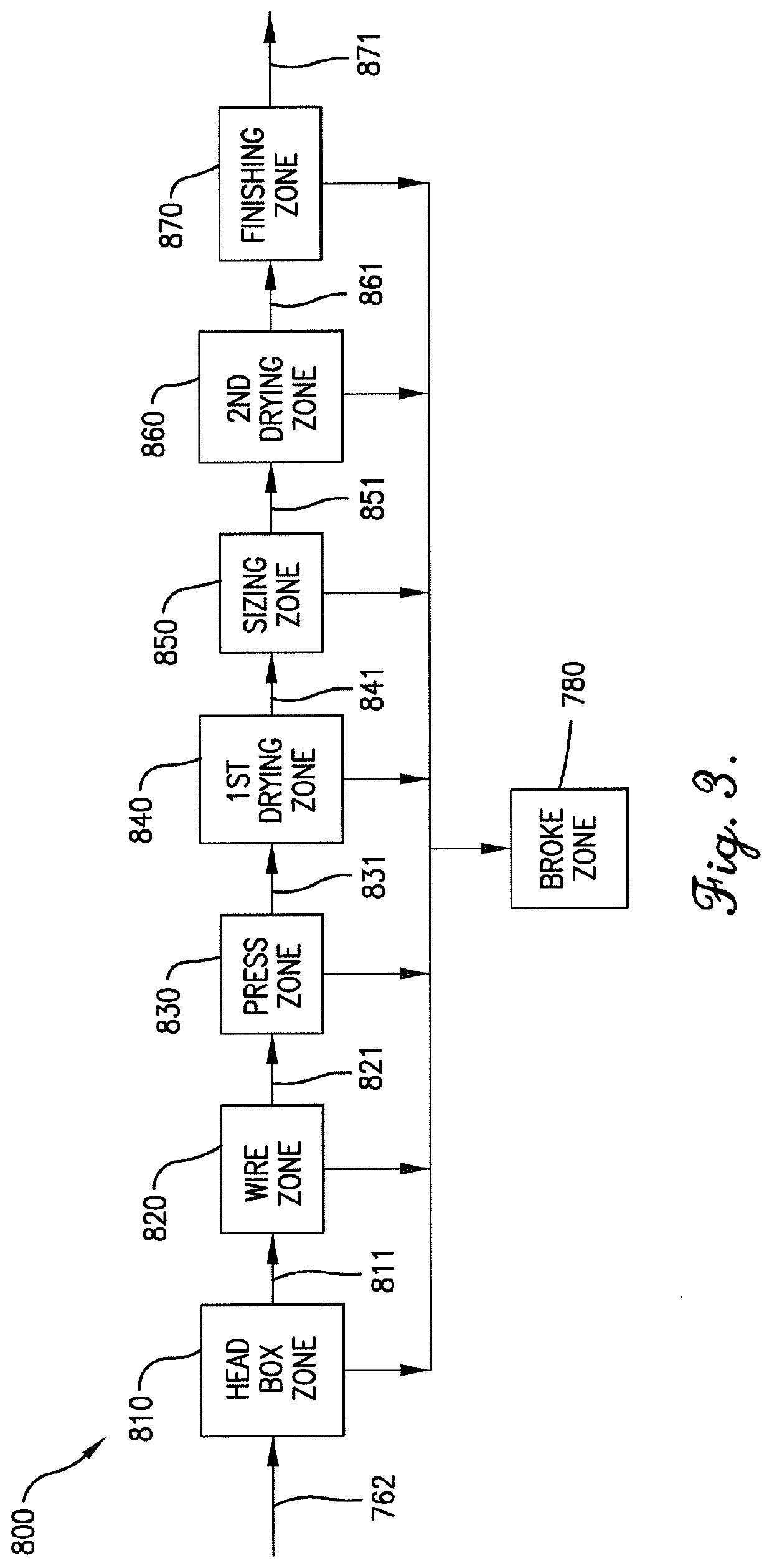

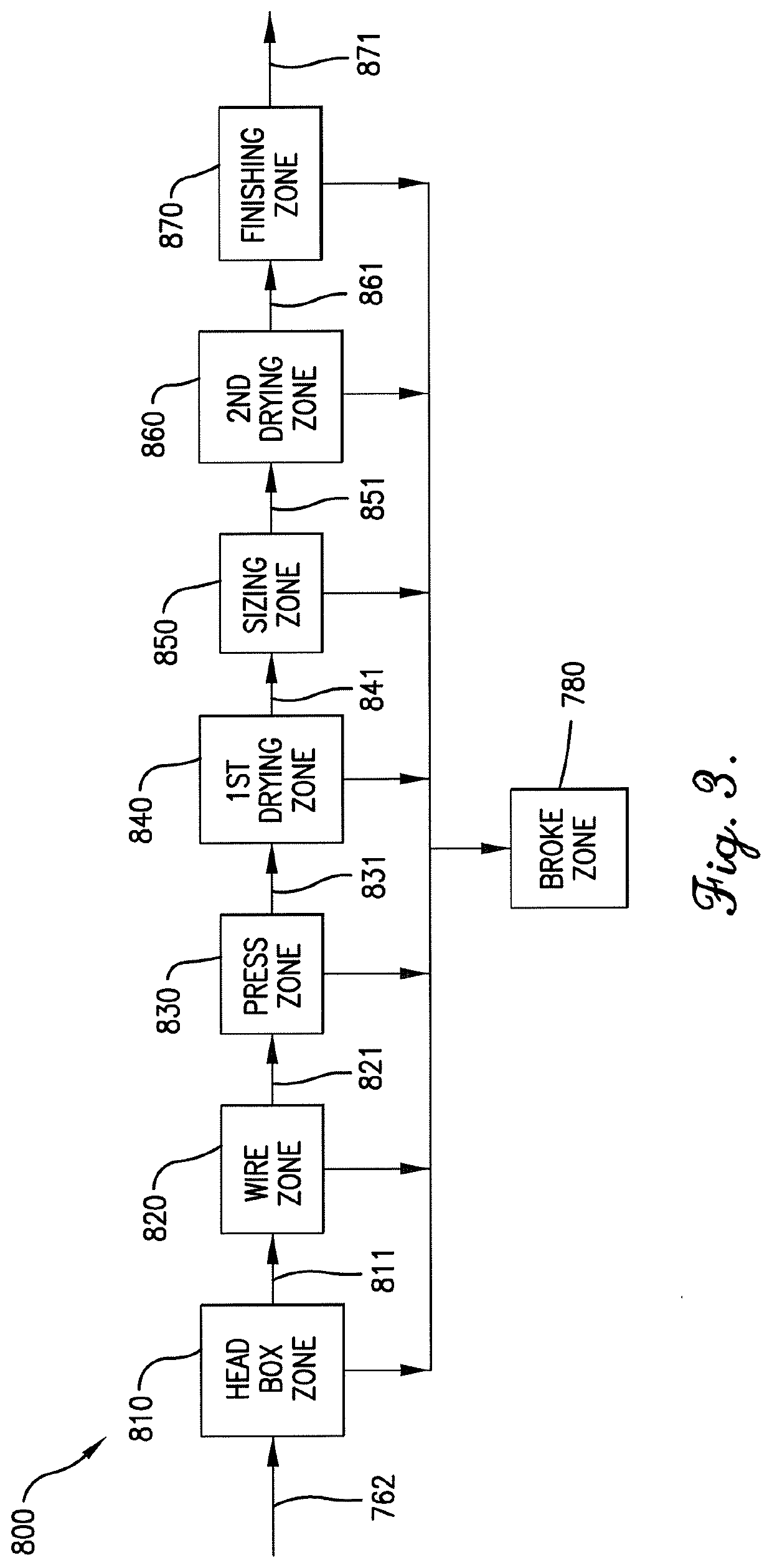

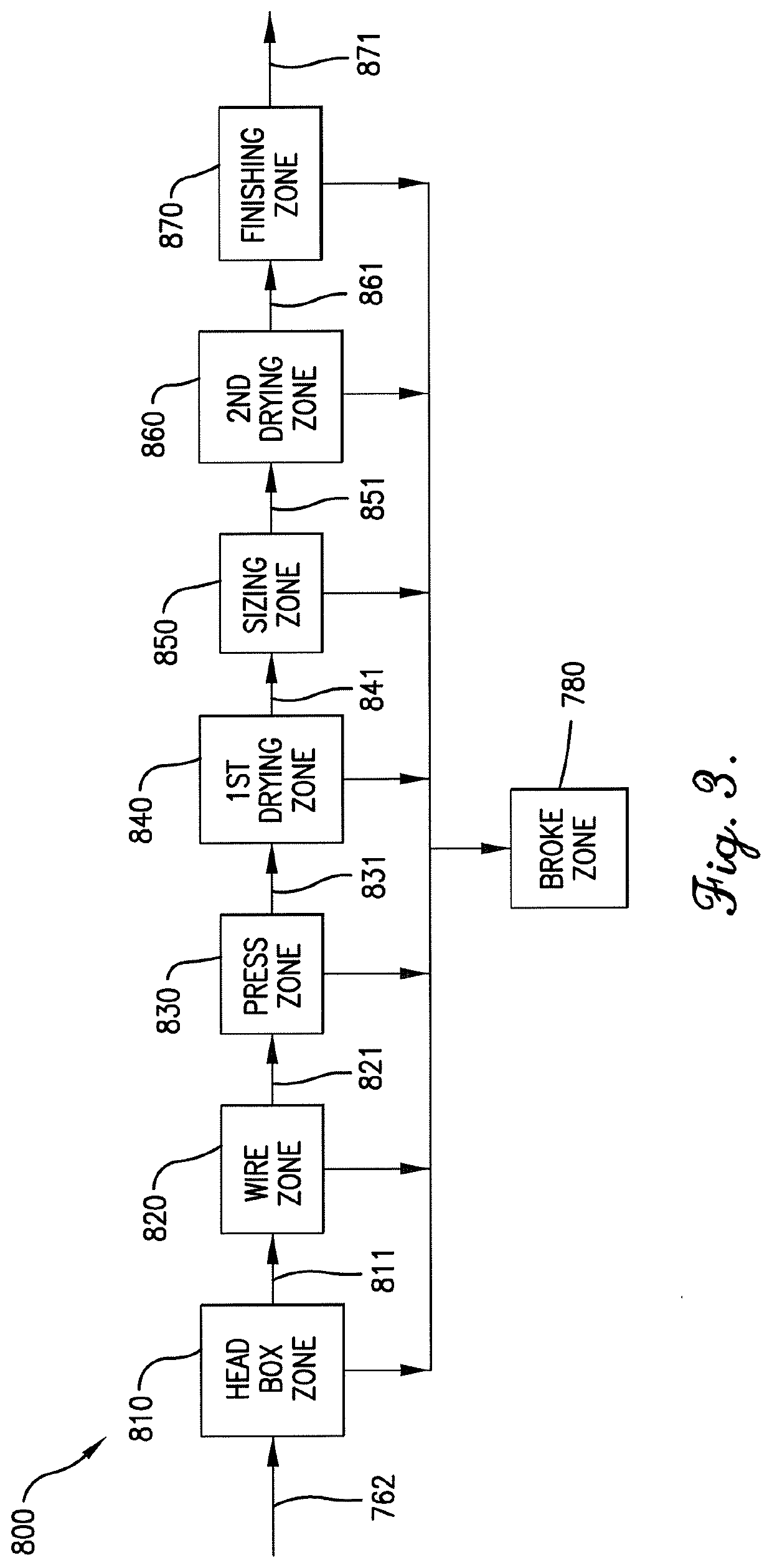

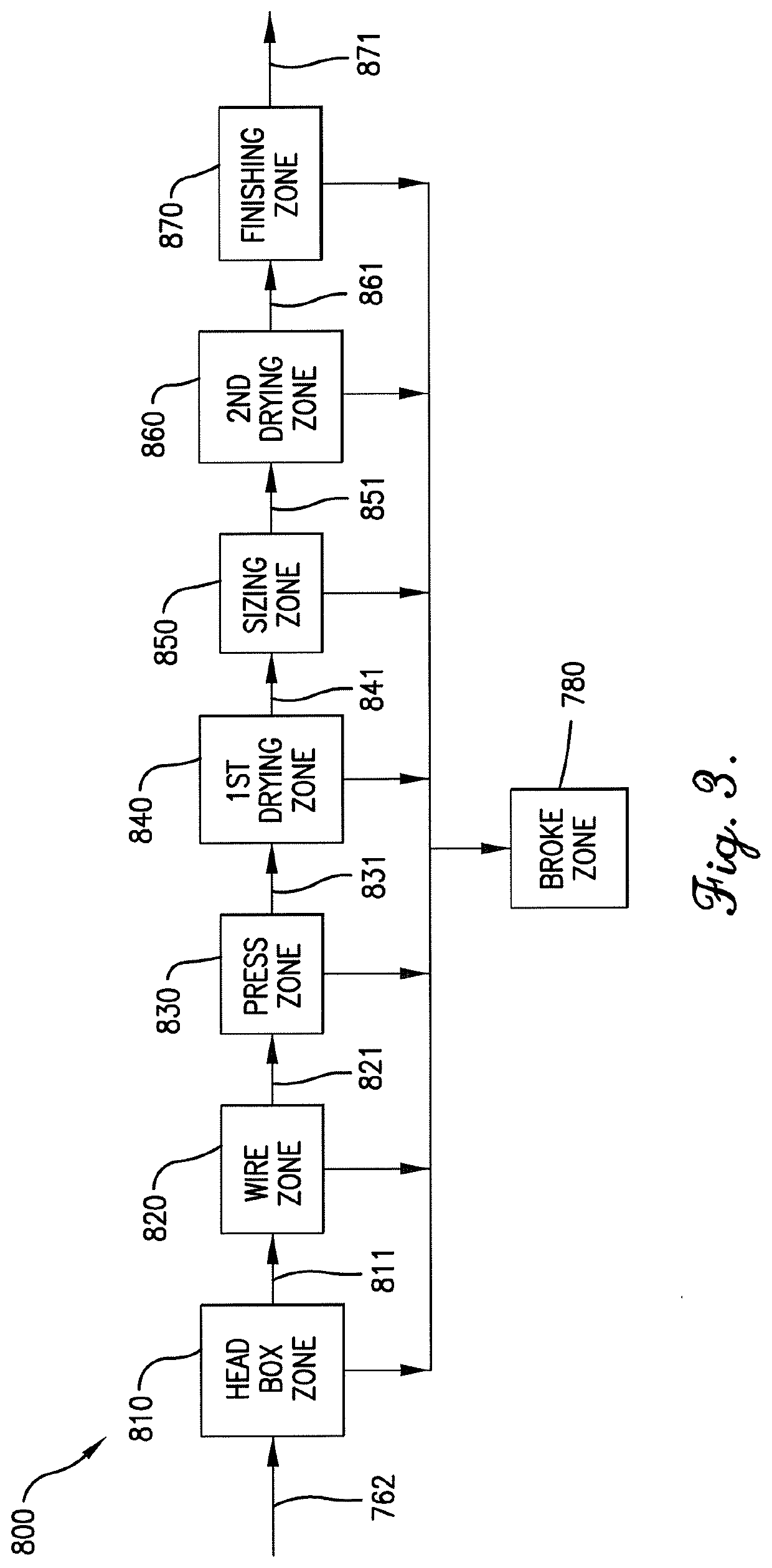

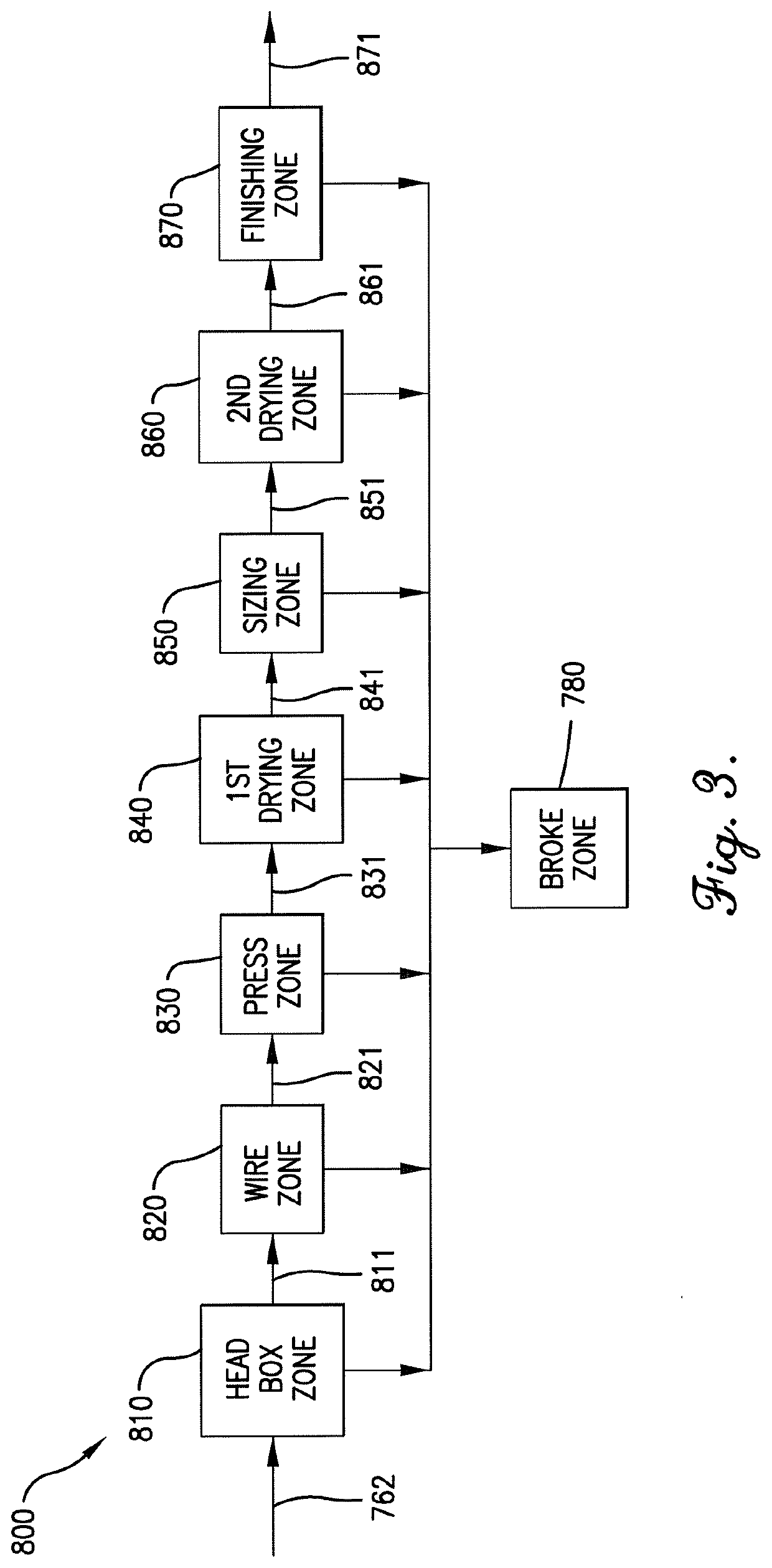

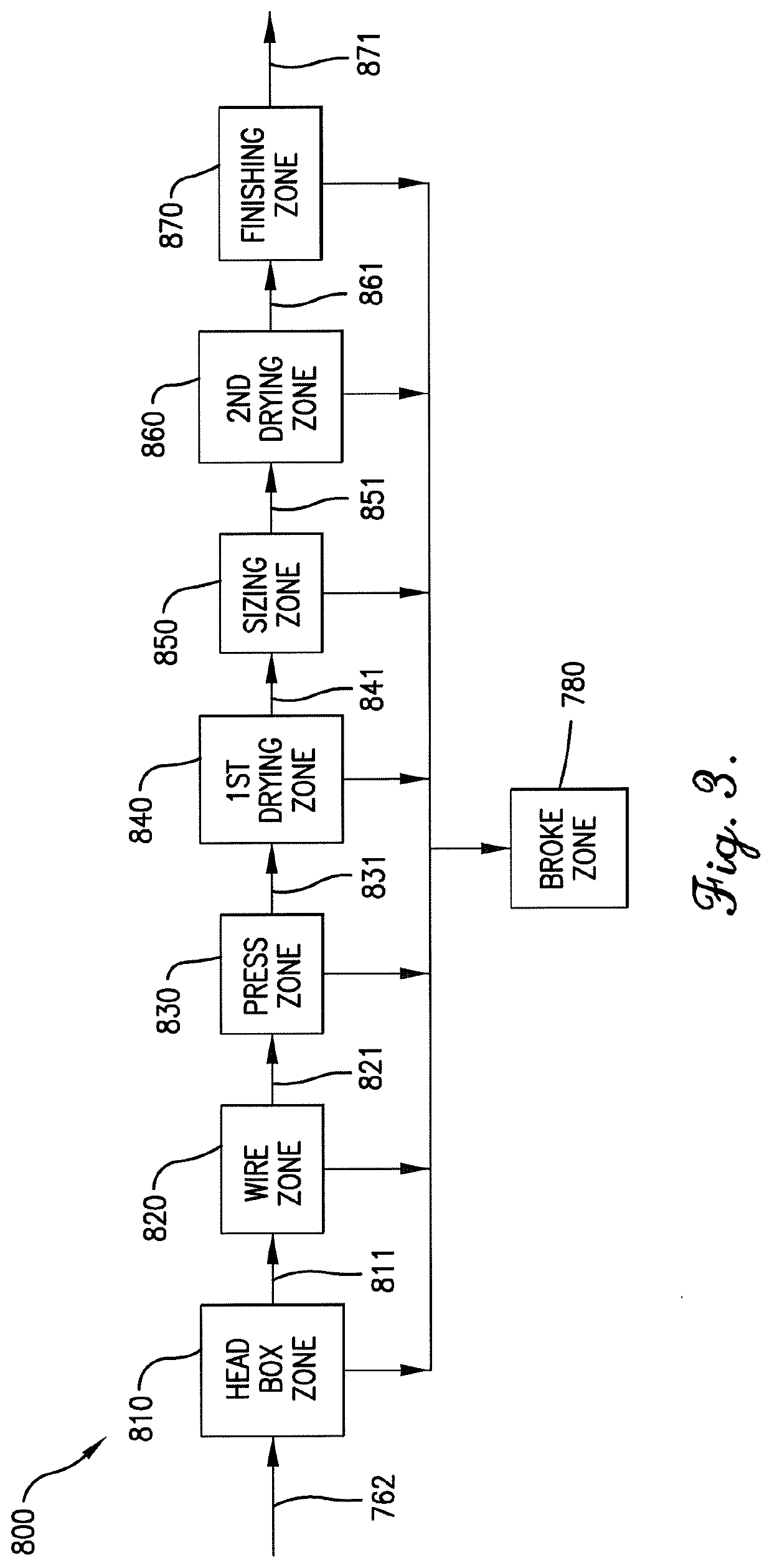

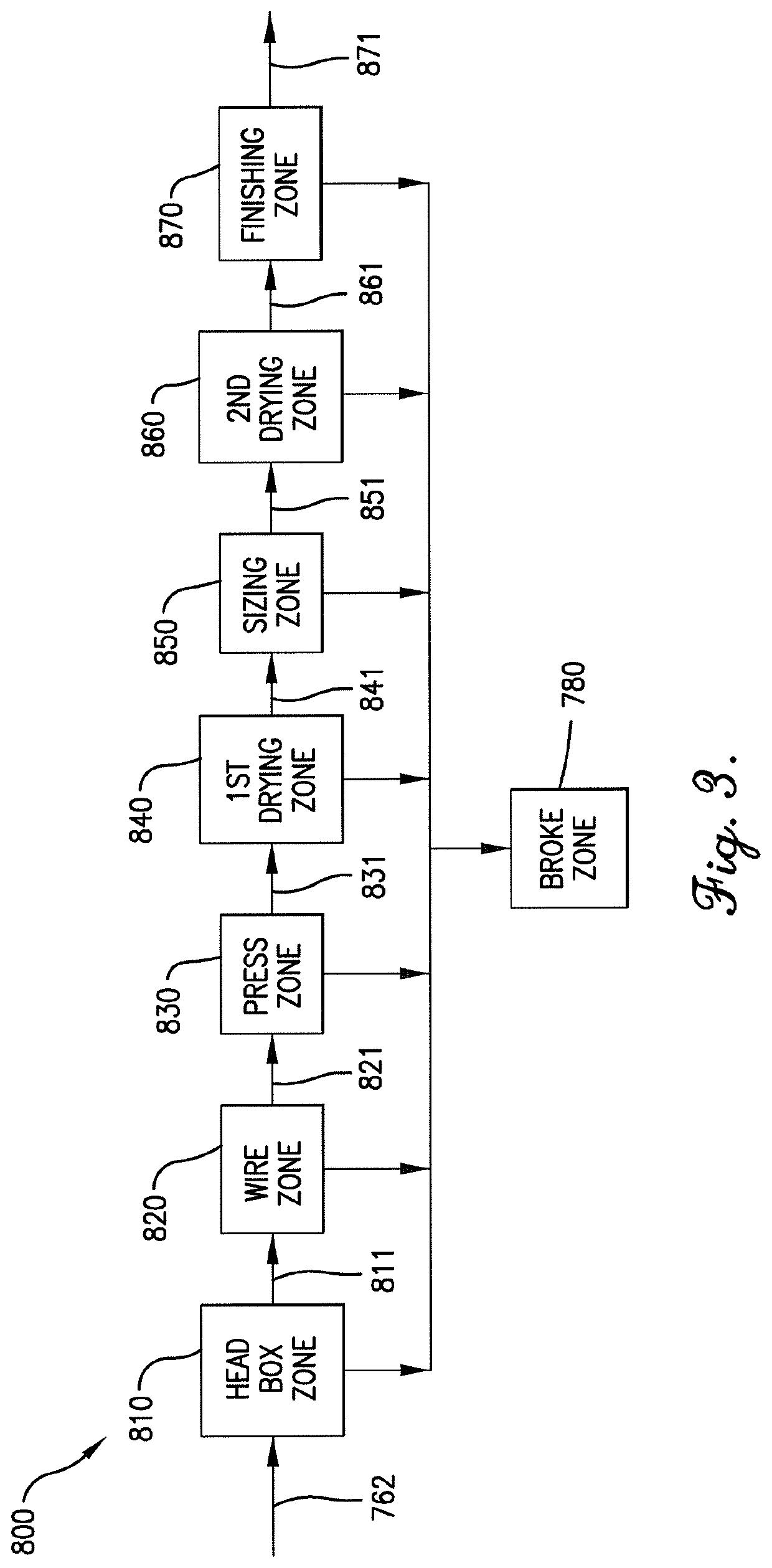

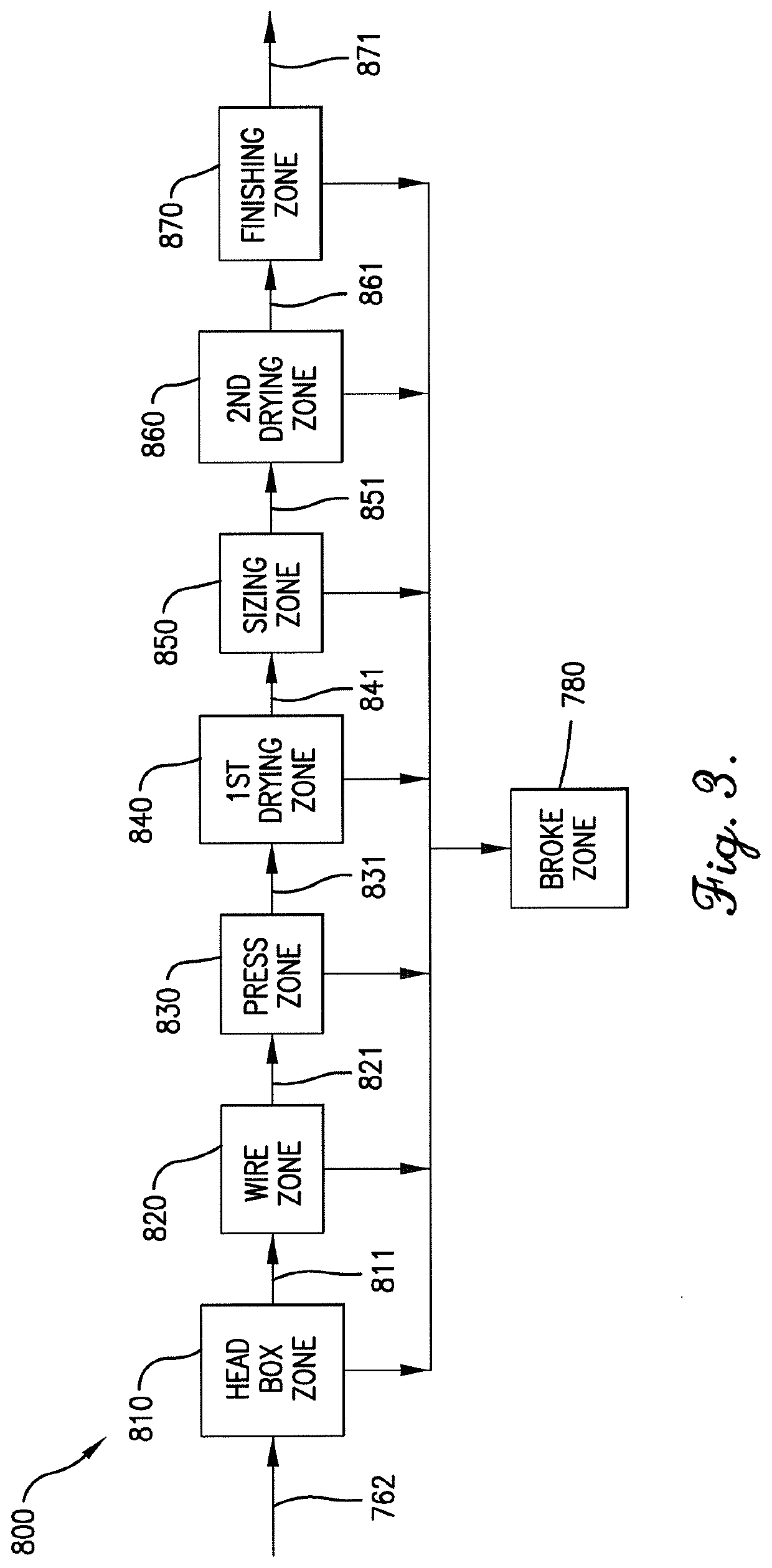

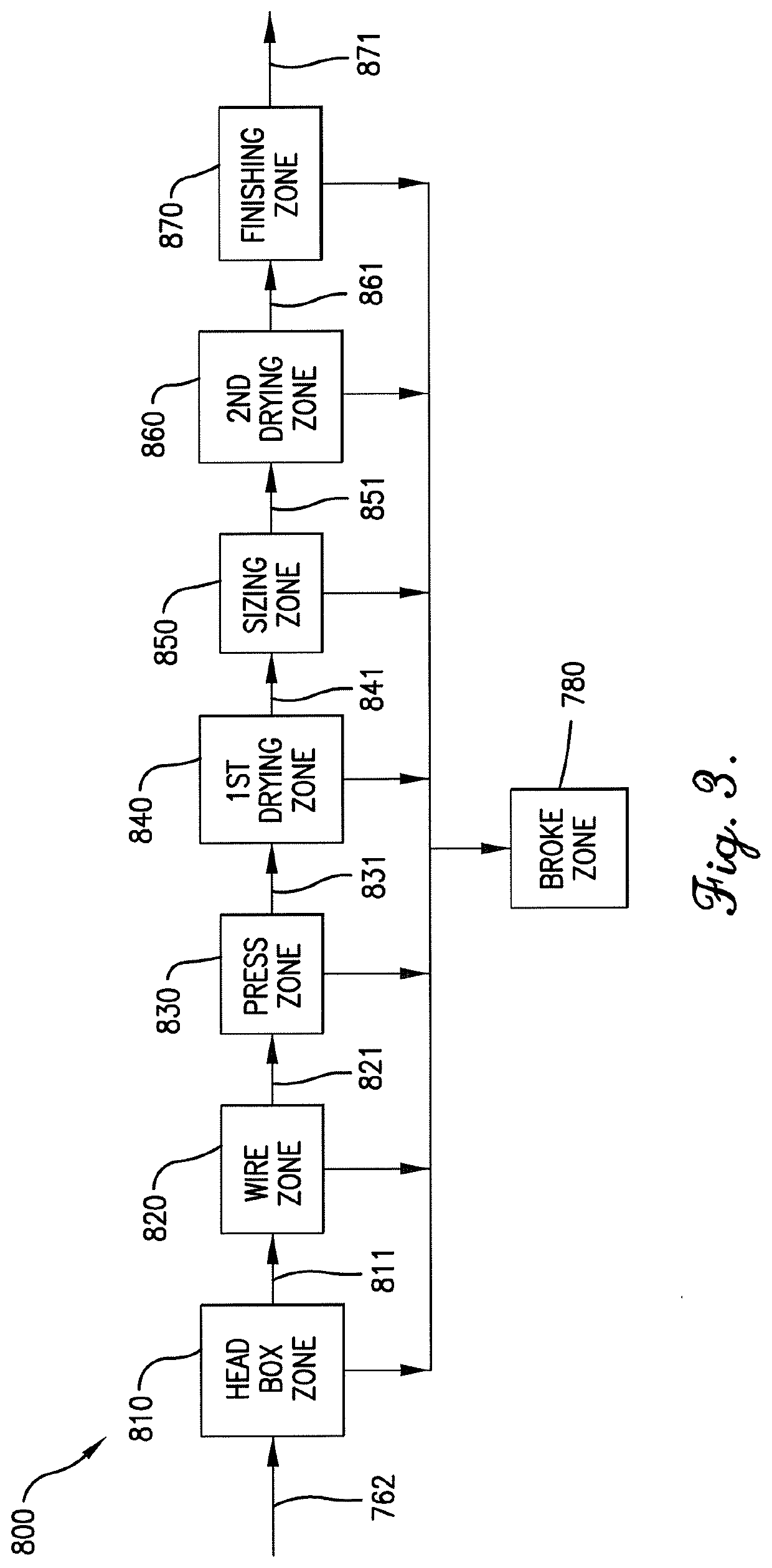

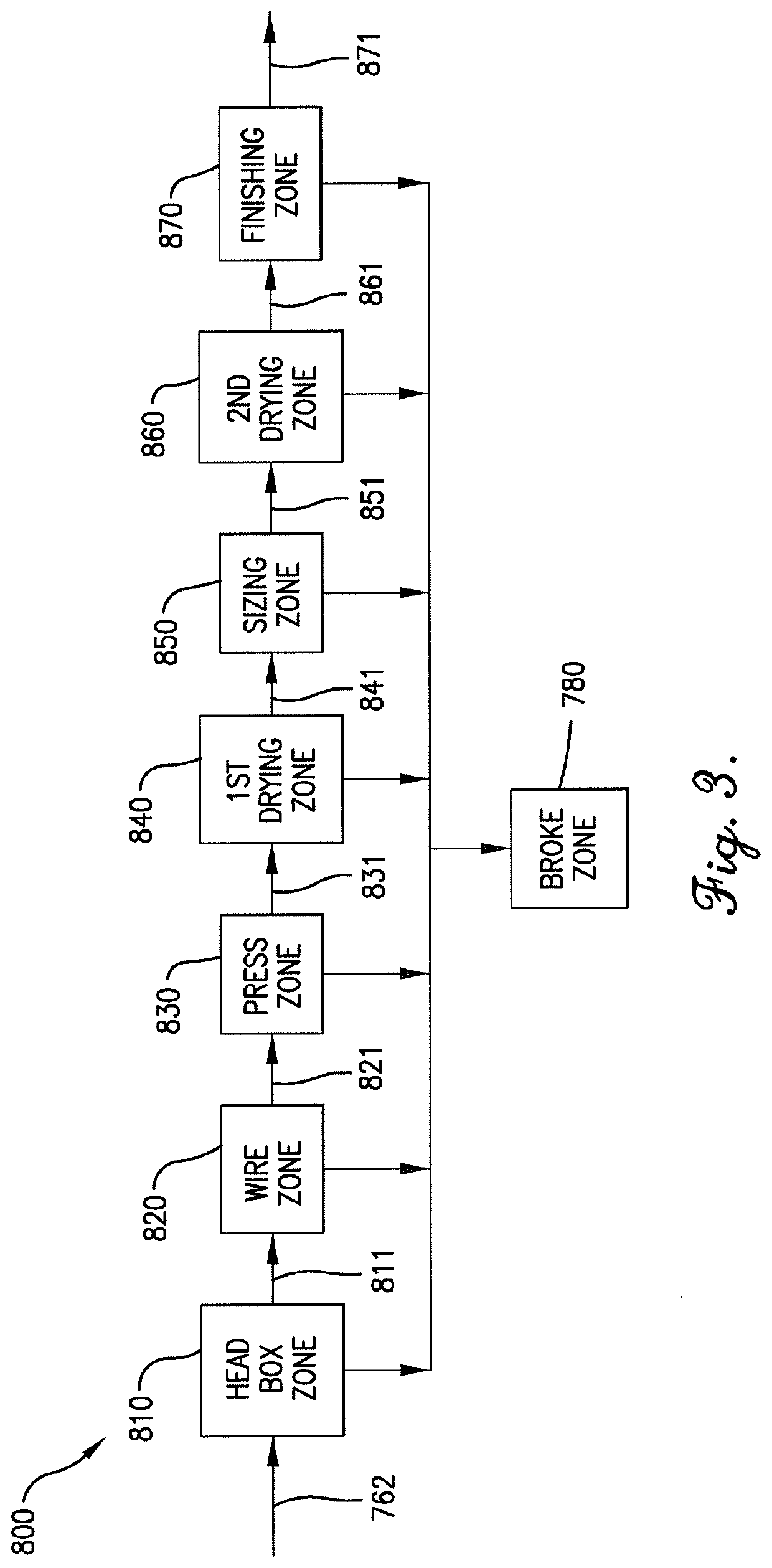

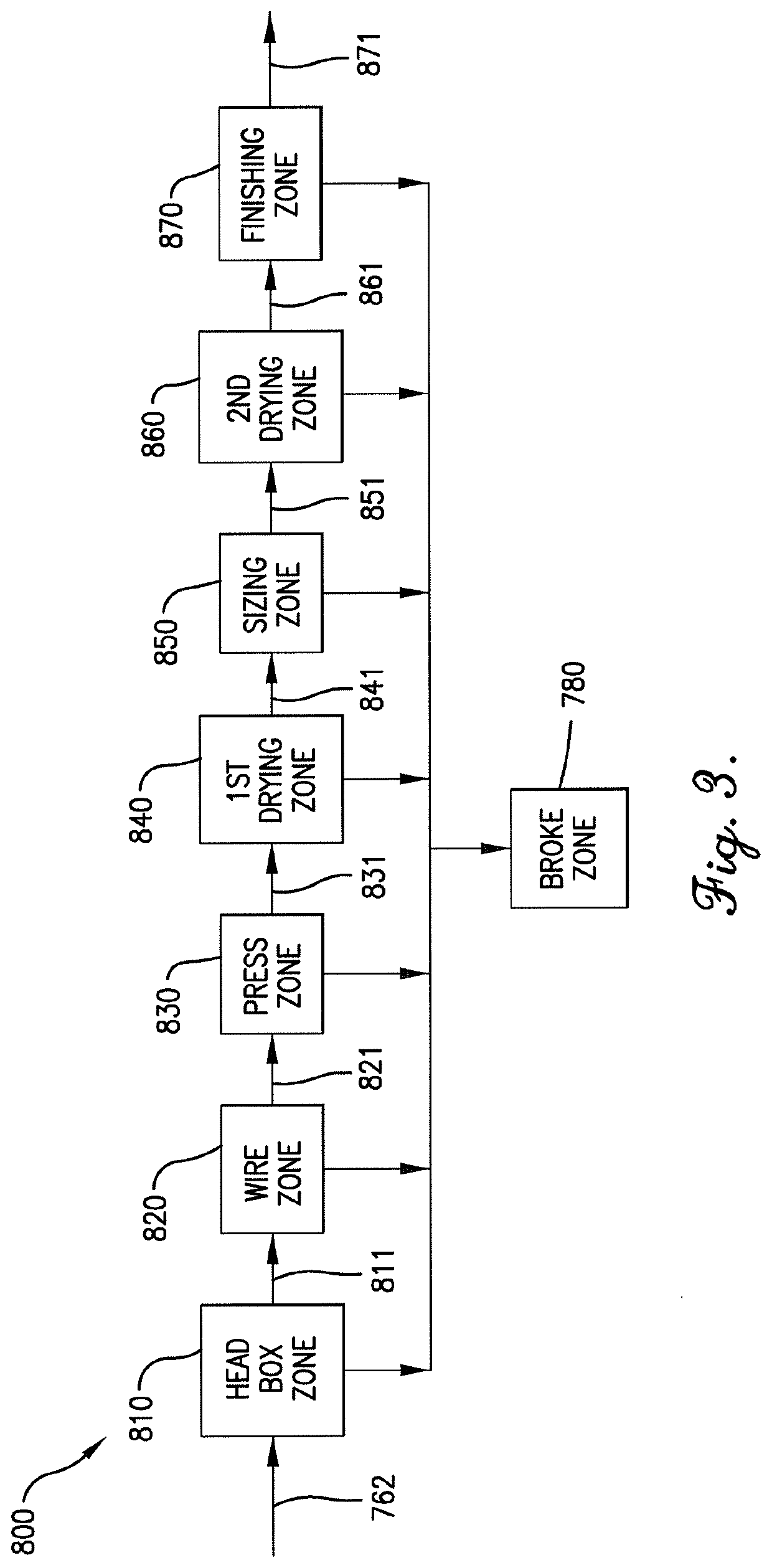

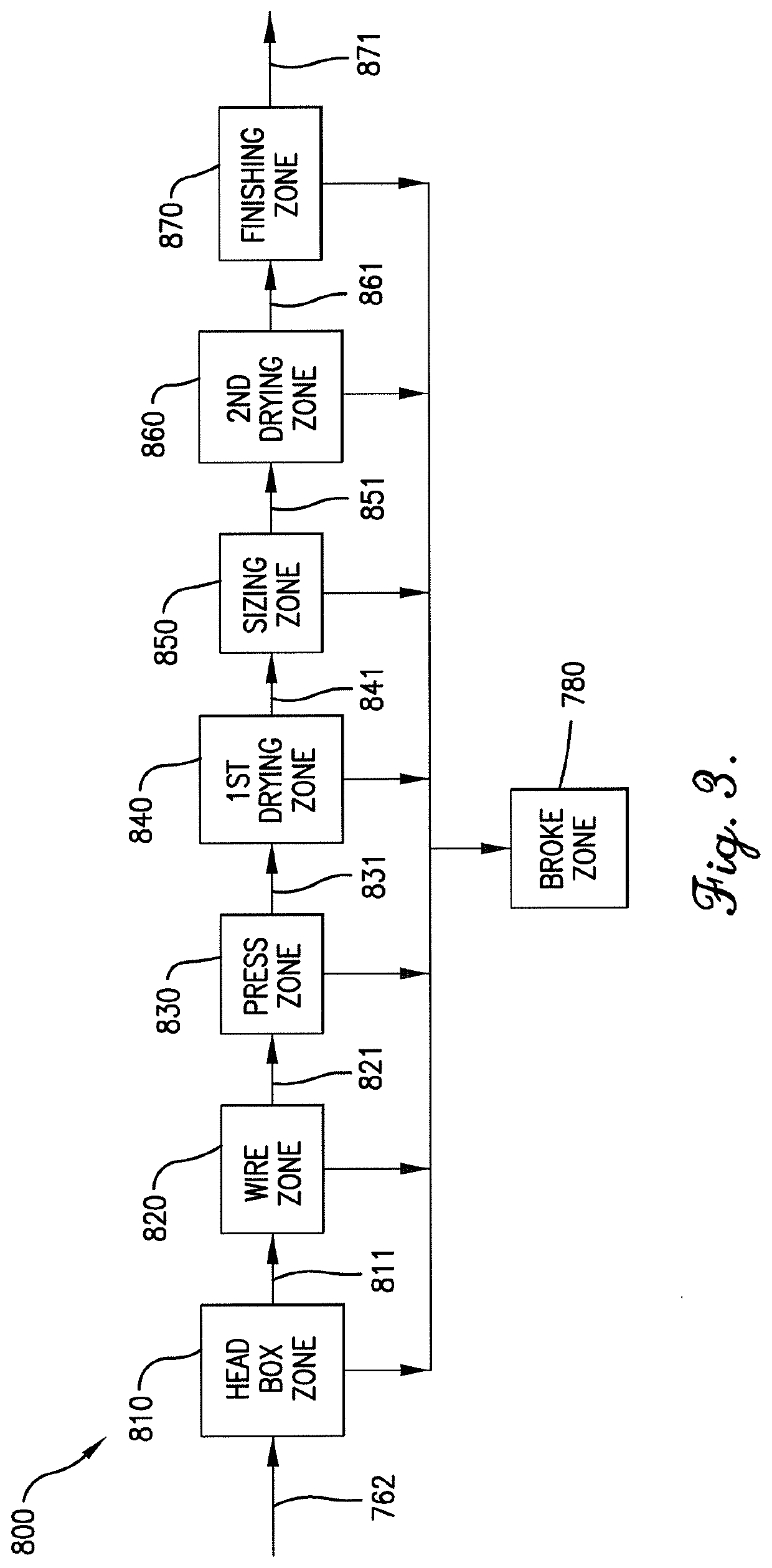

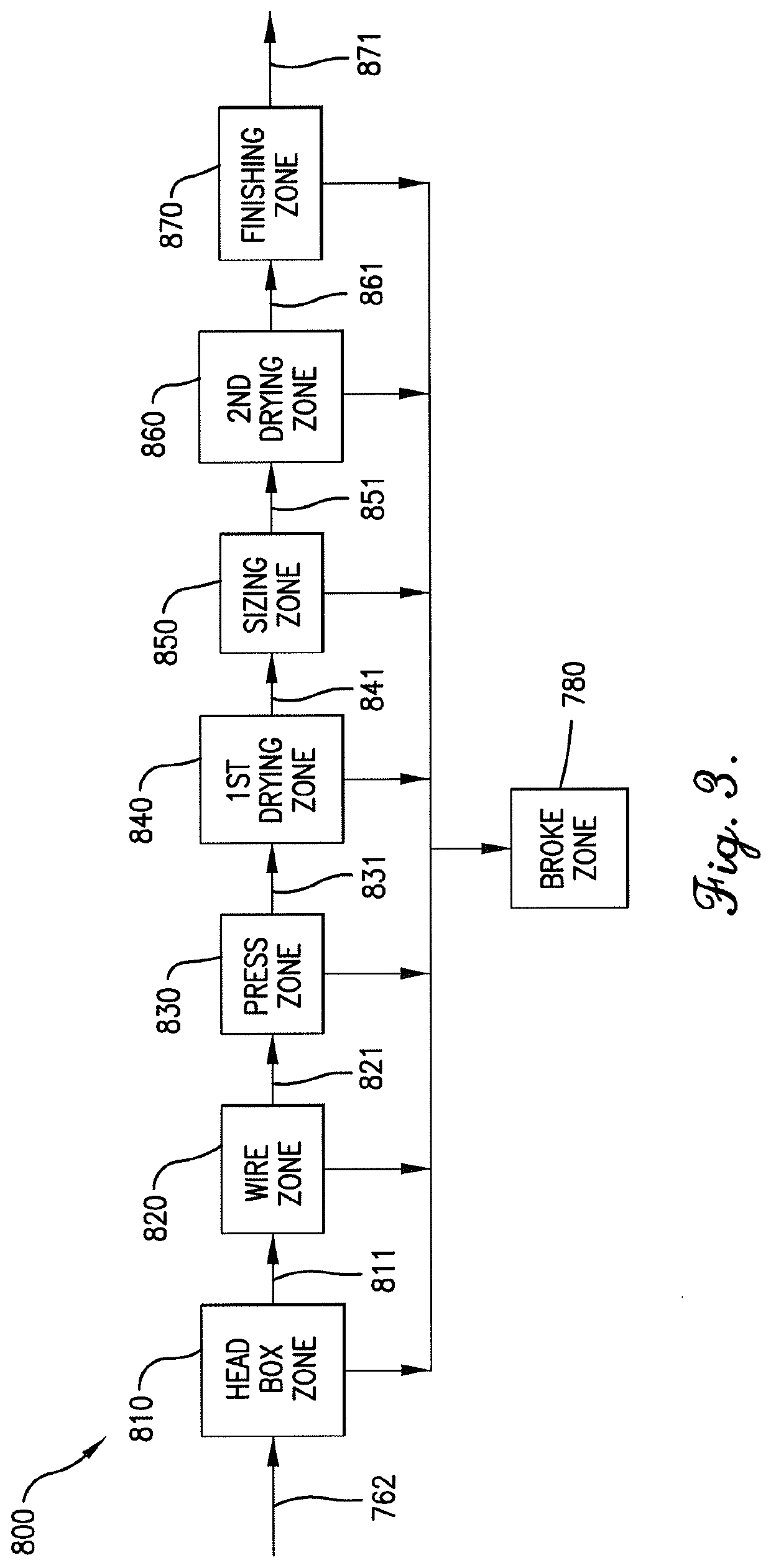

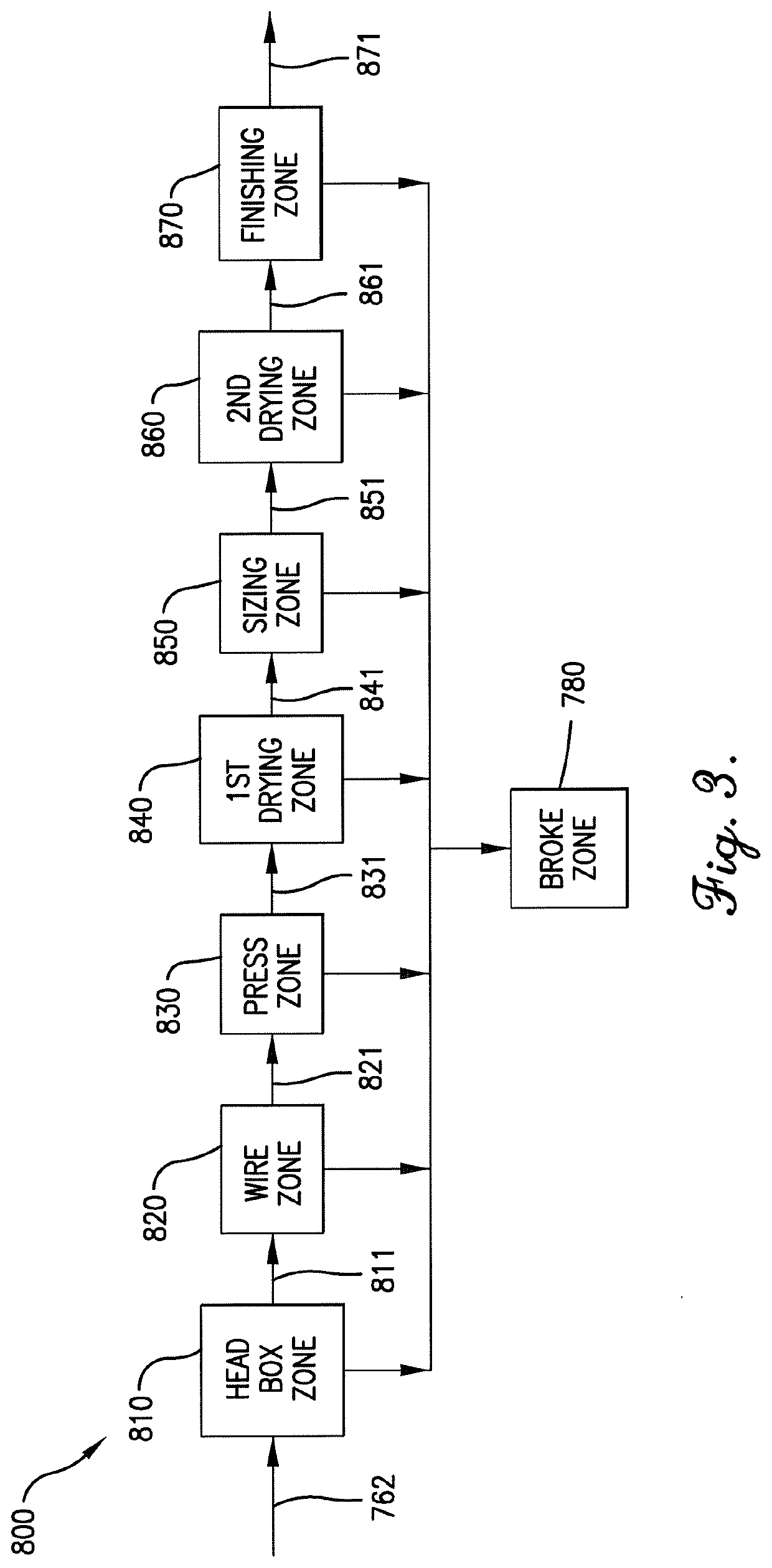

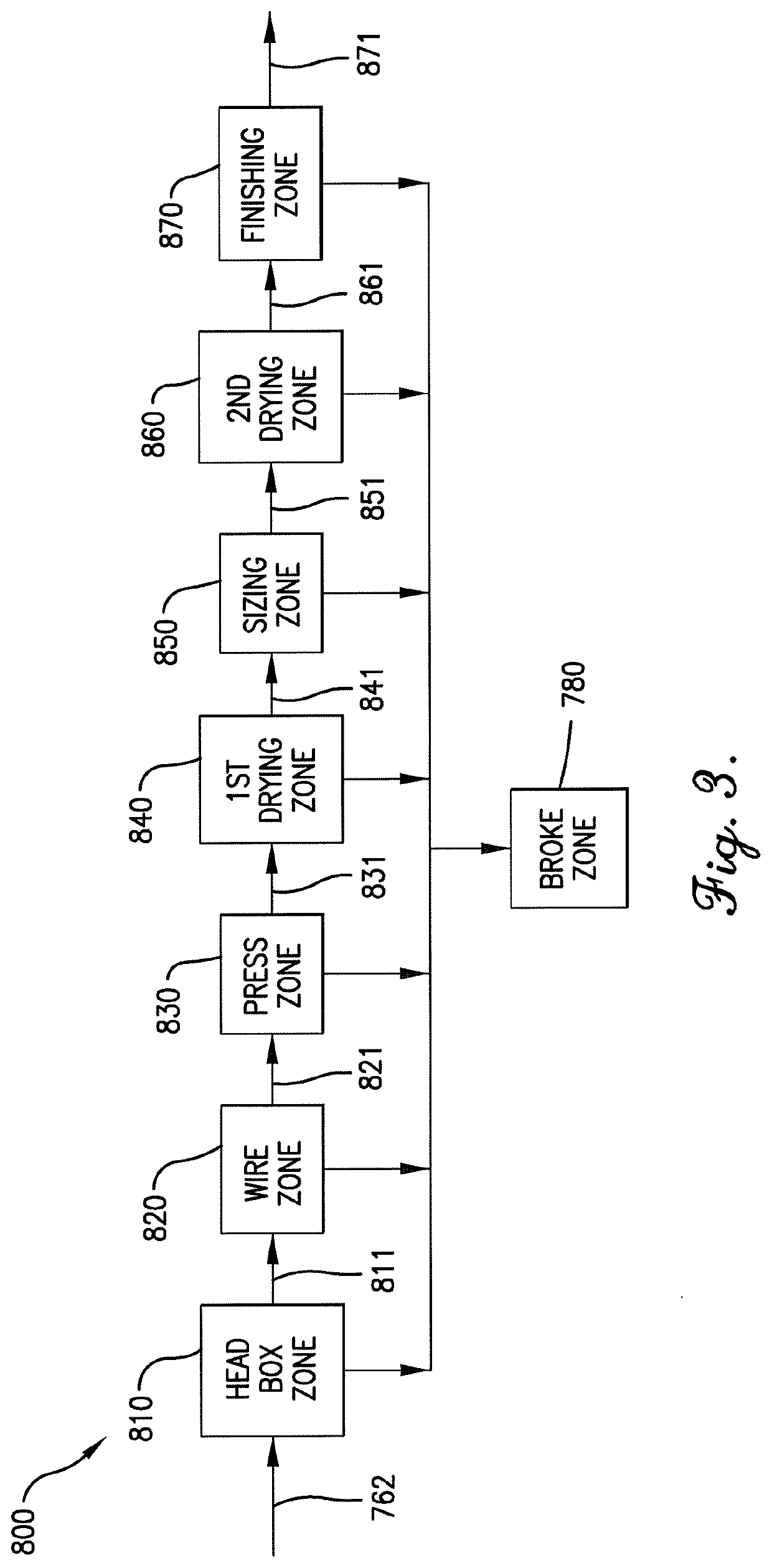

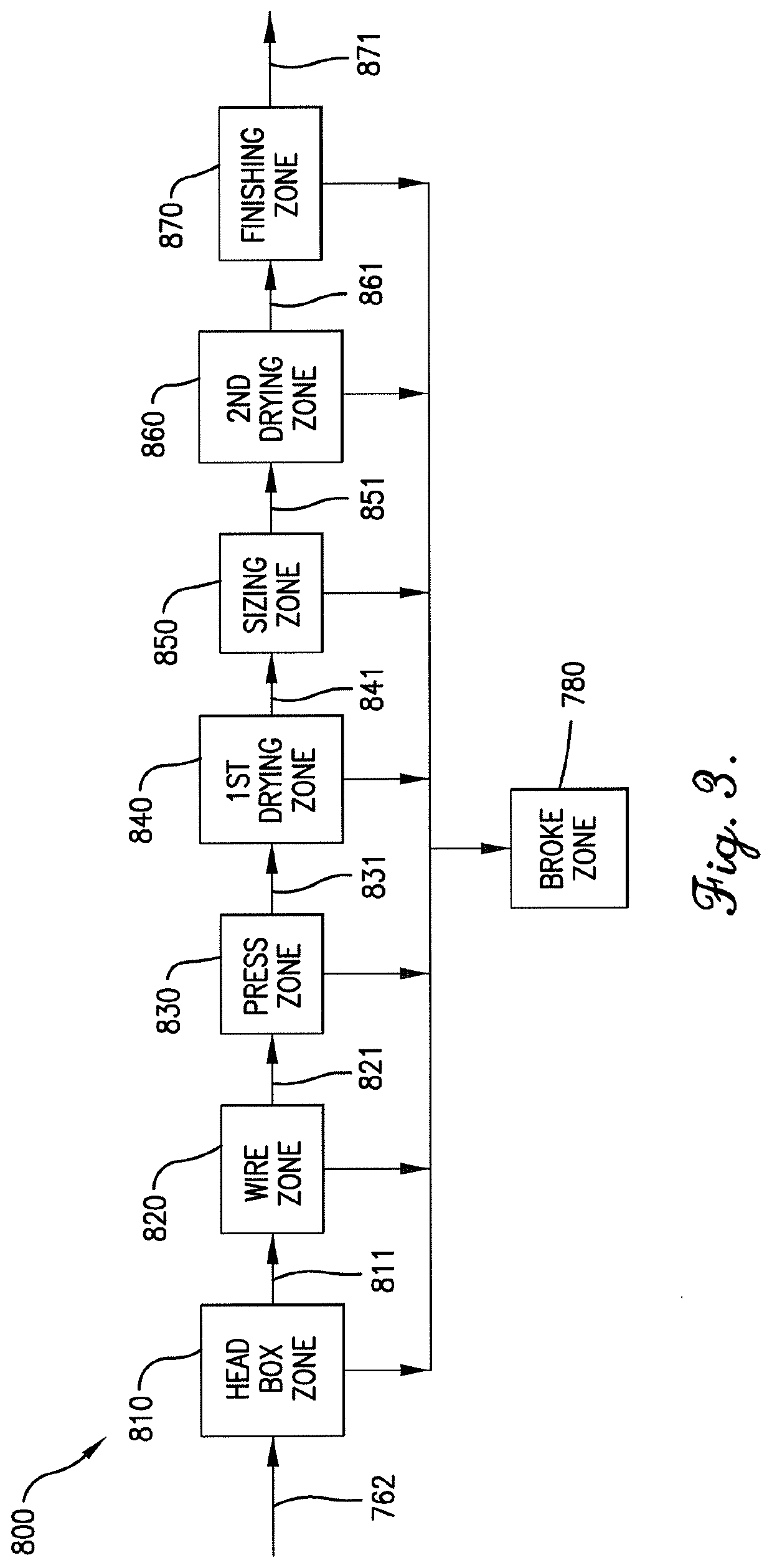

Composition of matter feed to a head box

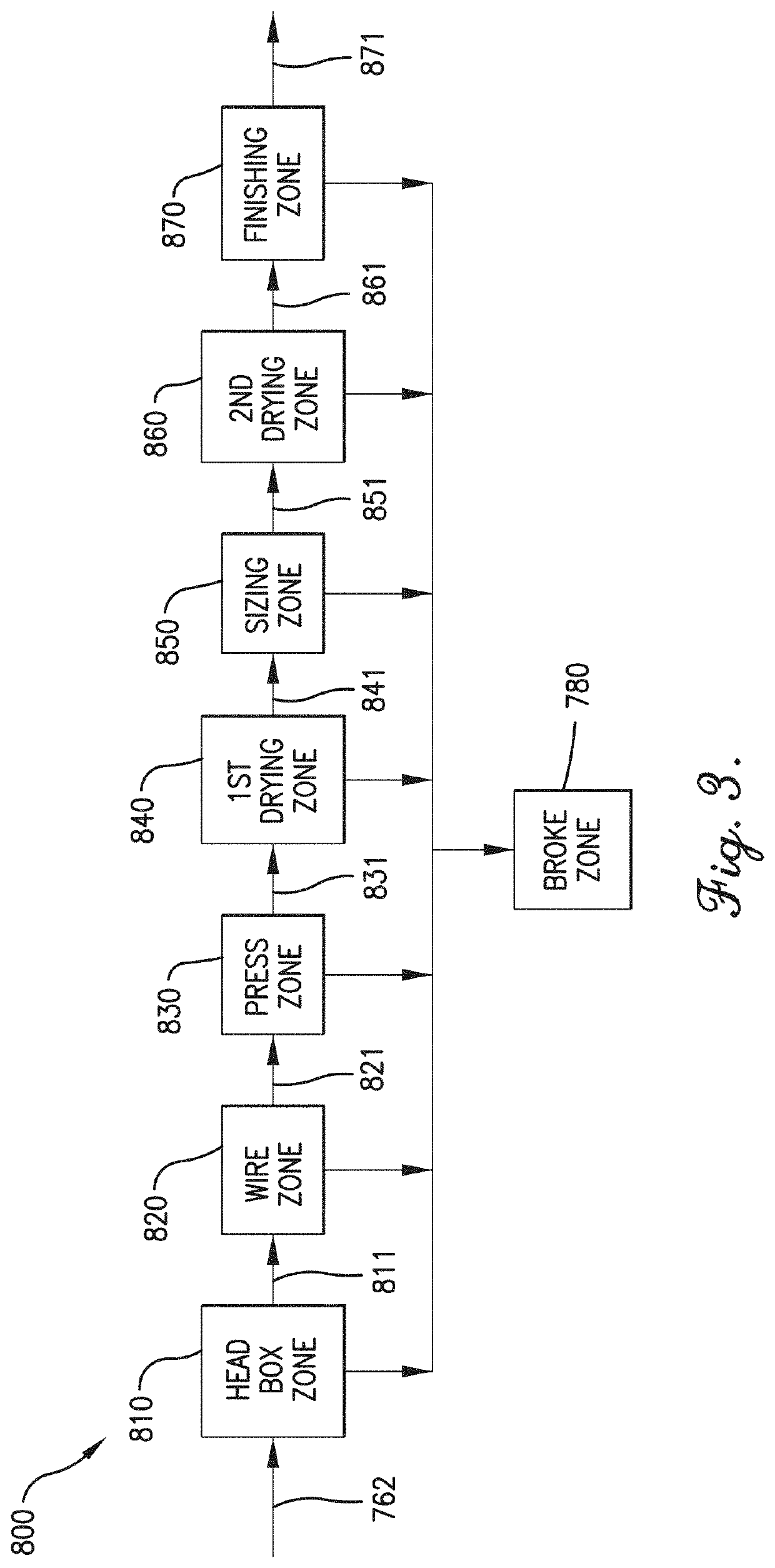

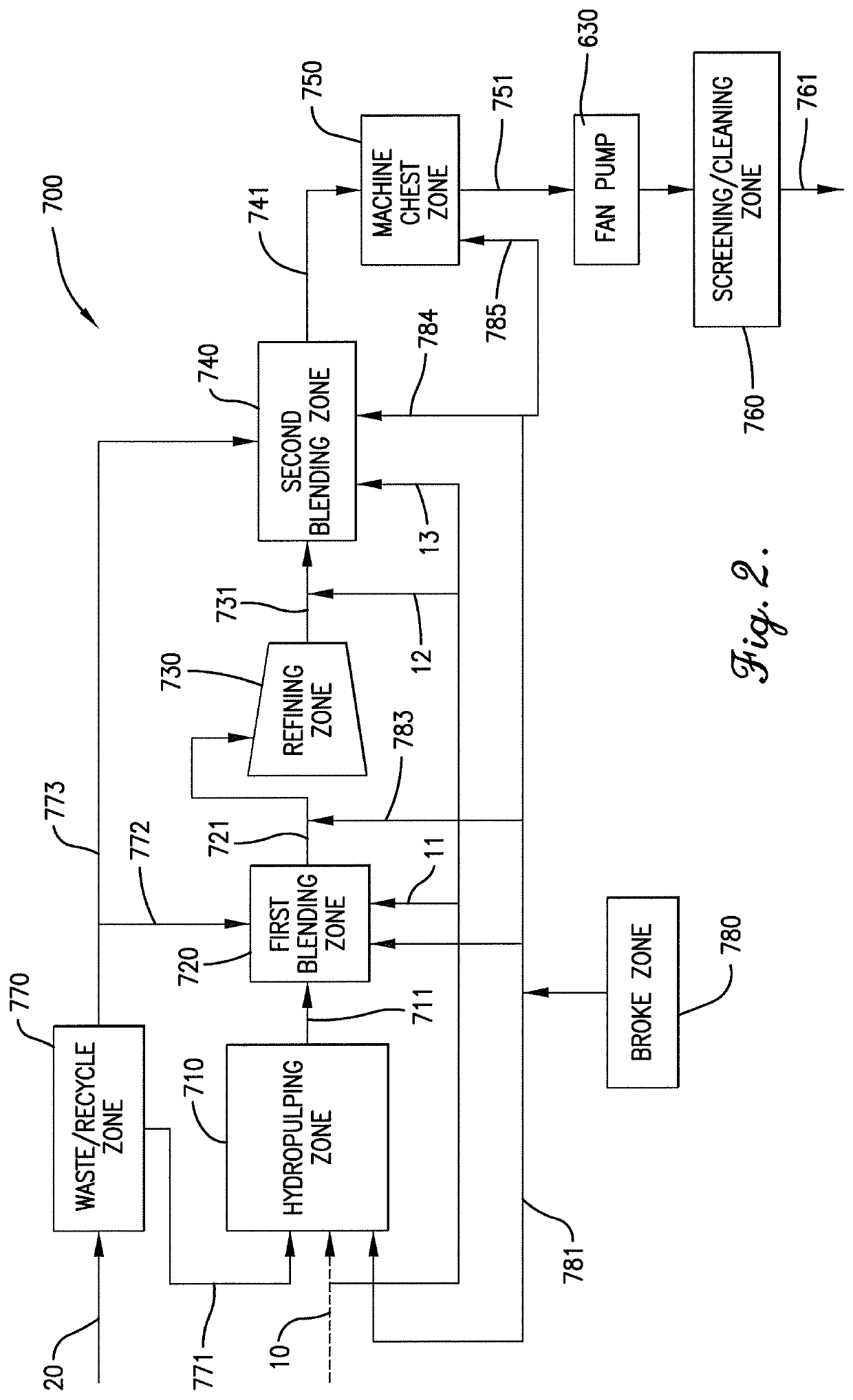

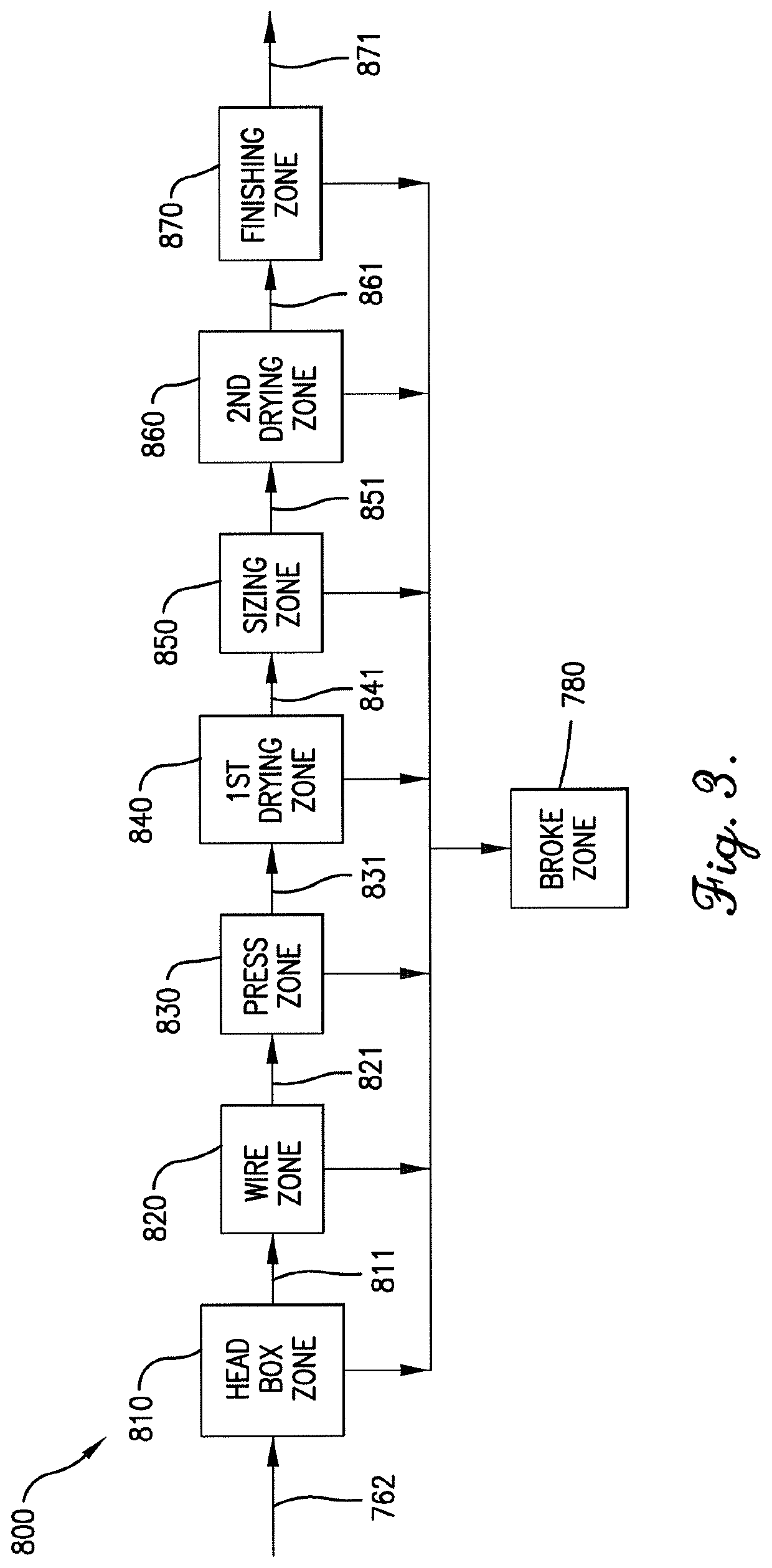

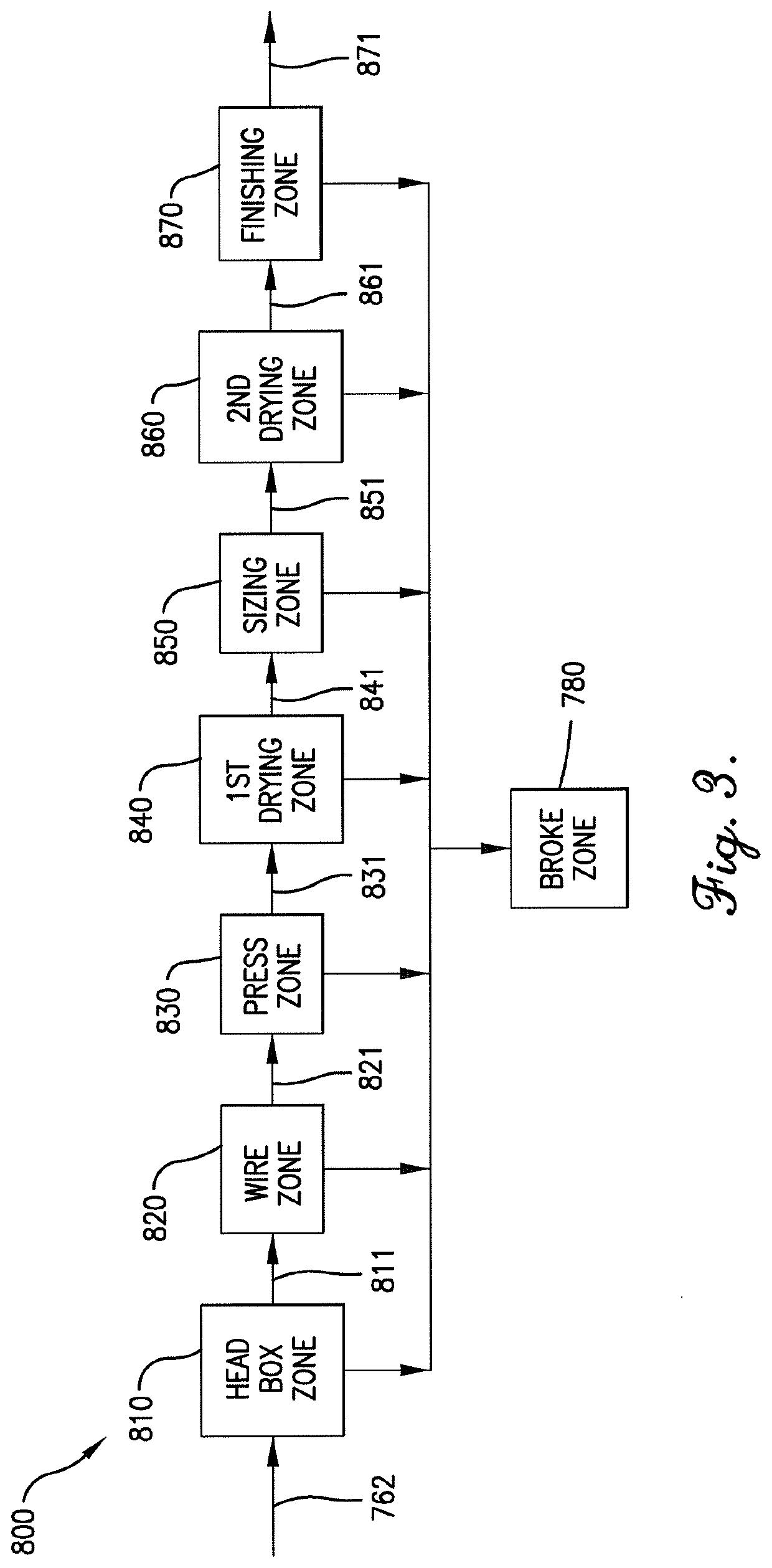

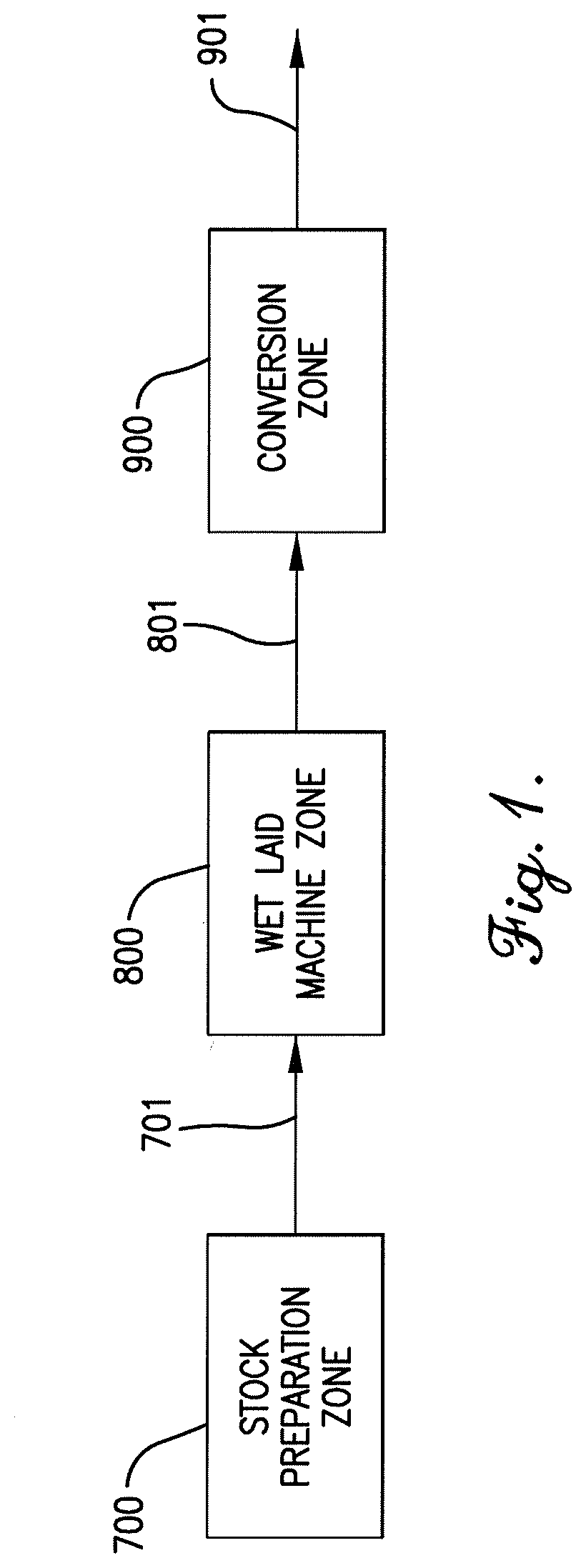

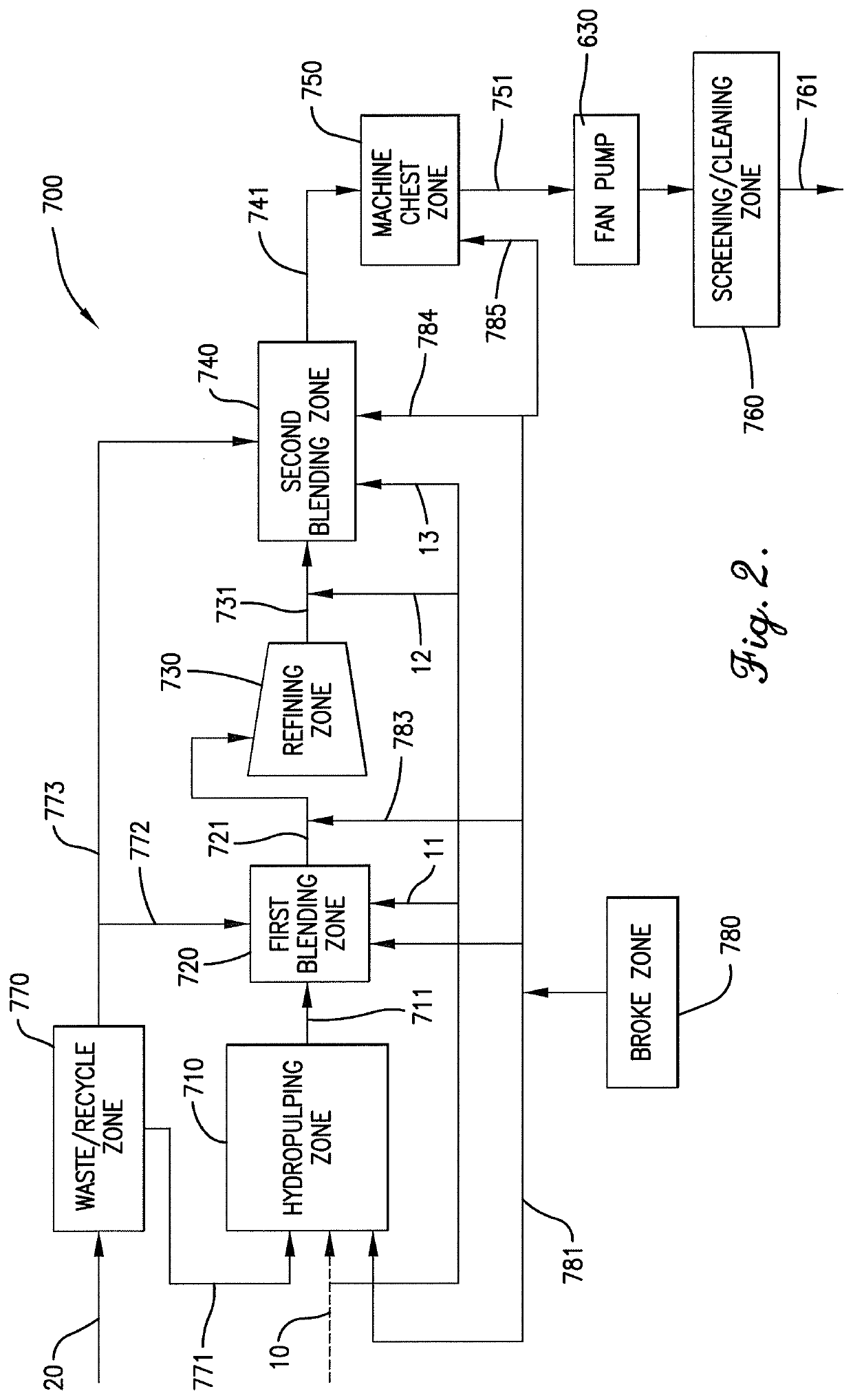

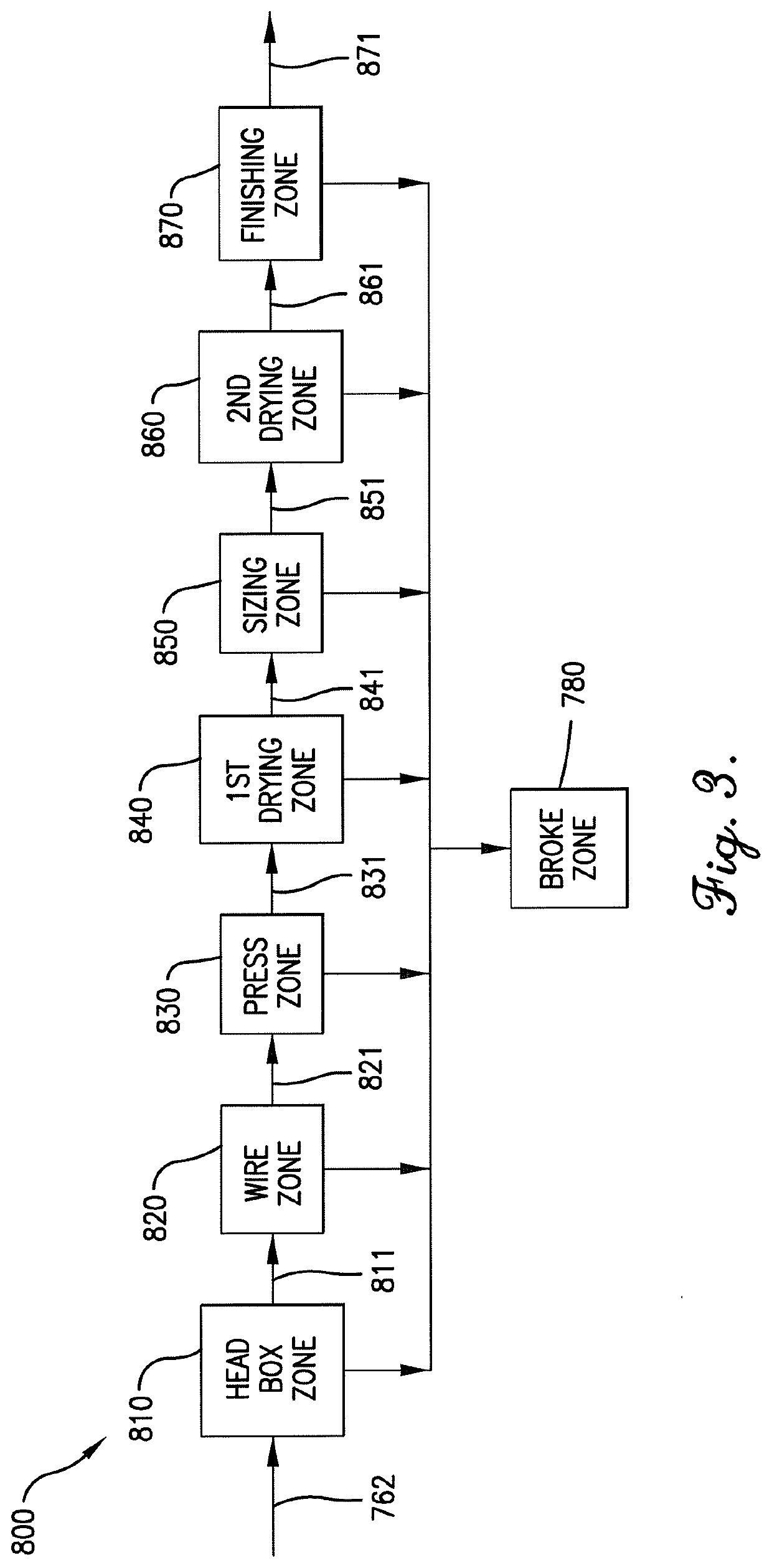

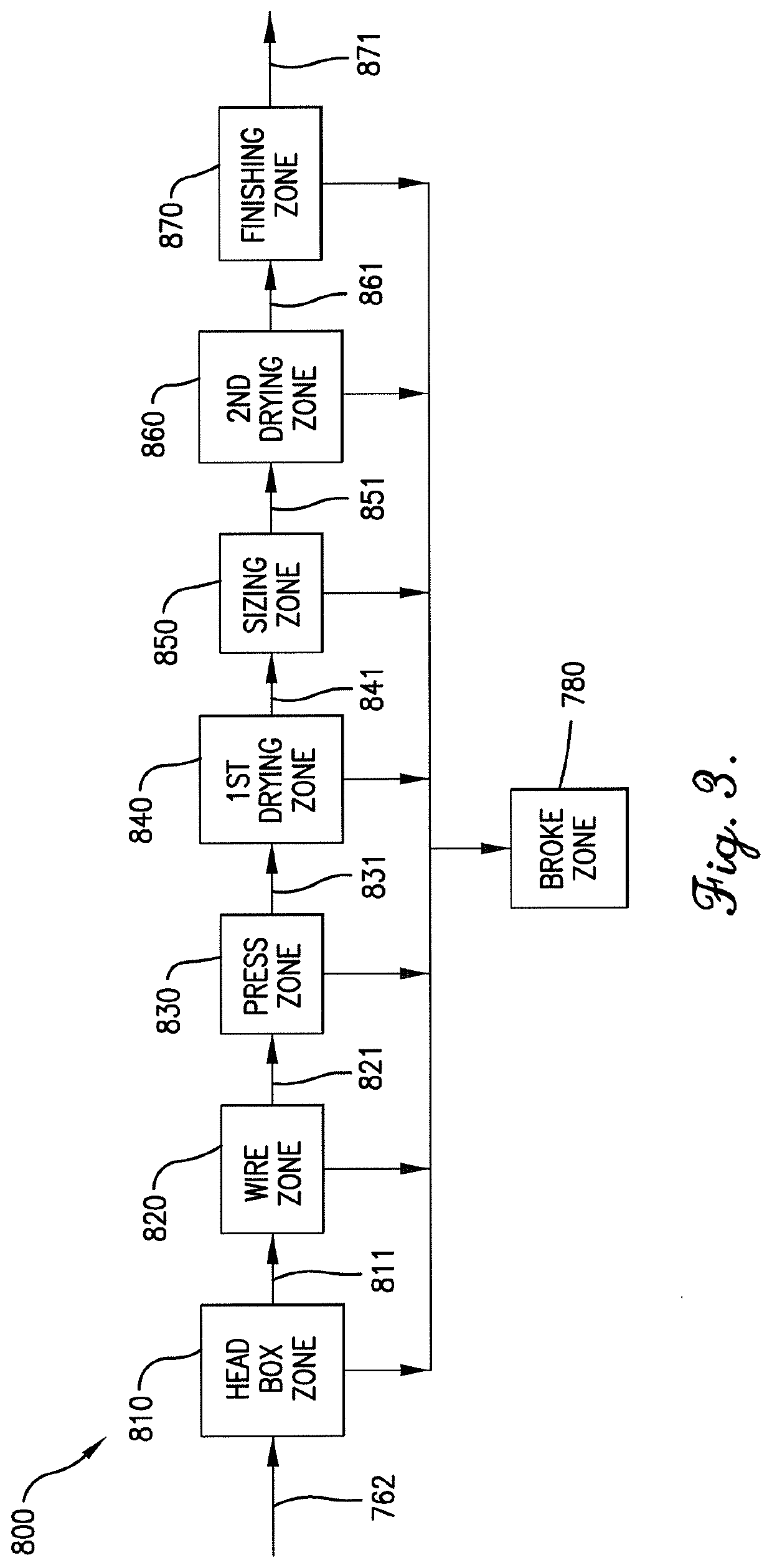

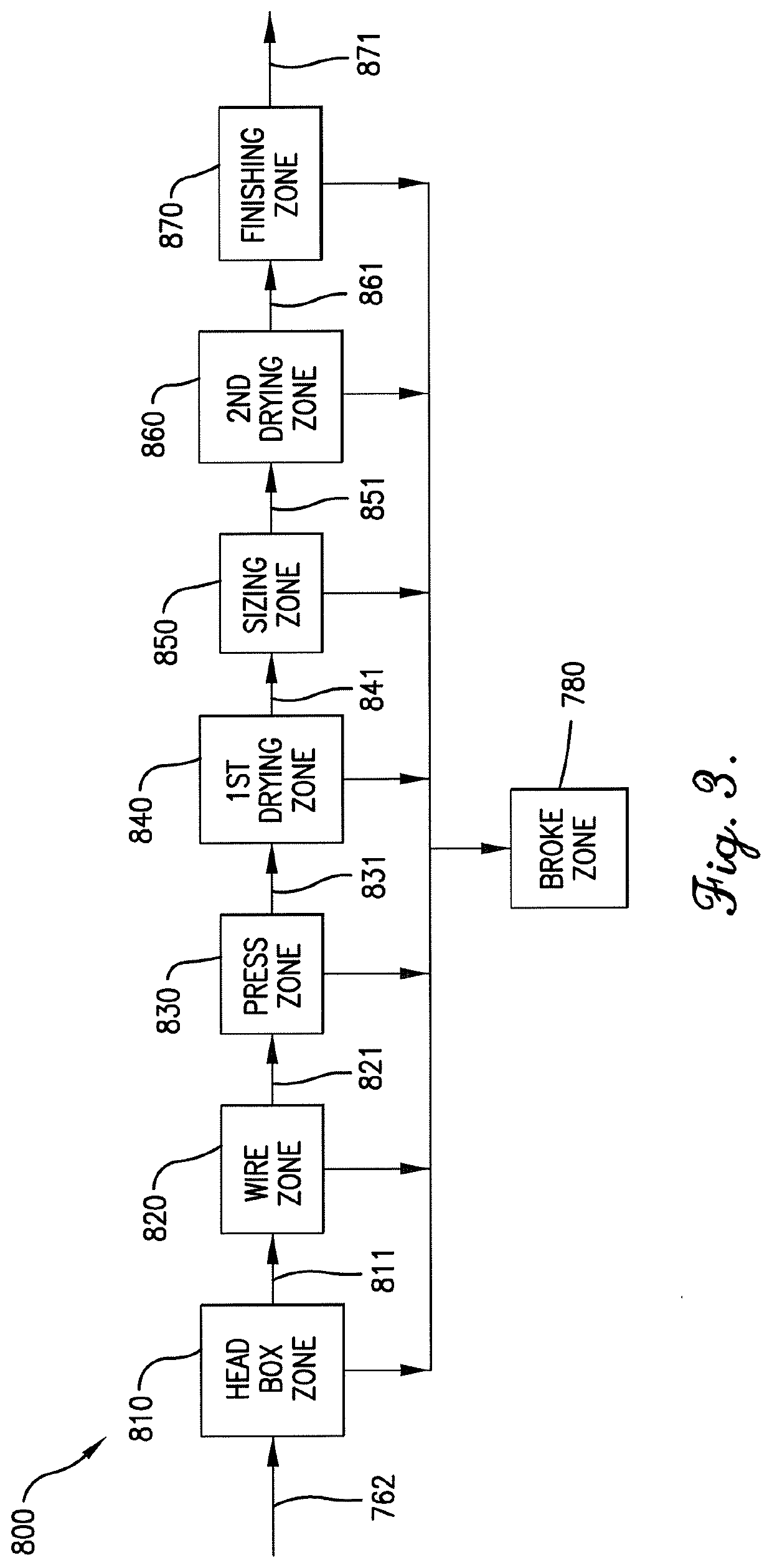

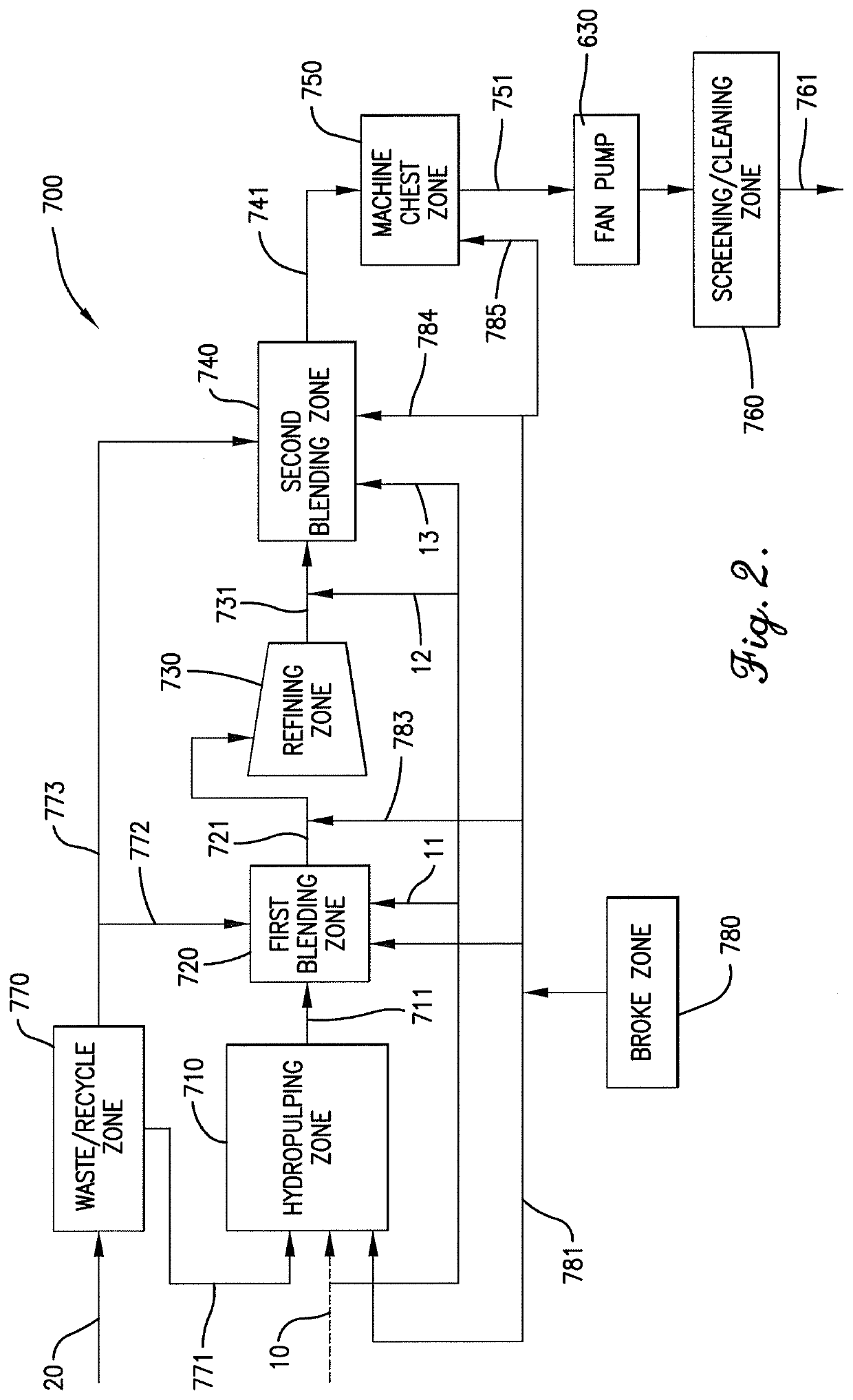

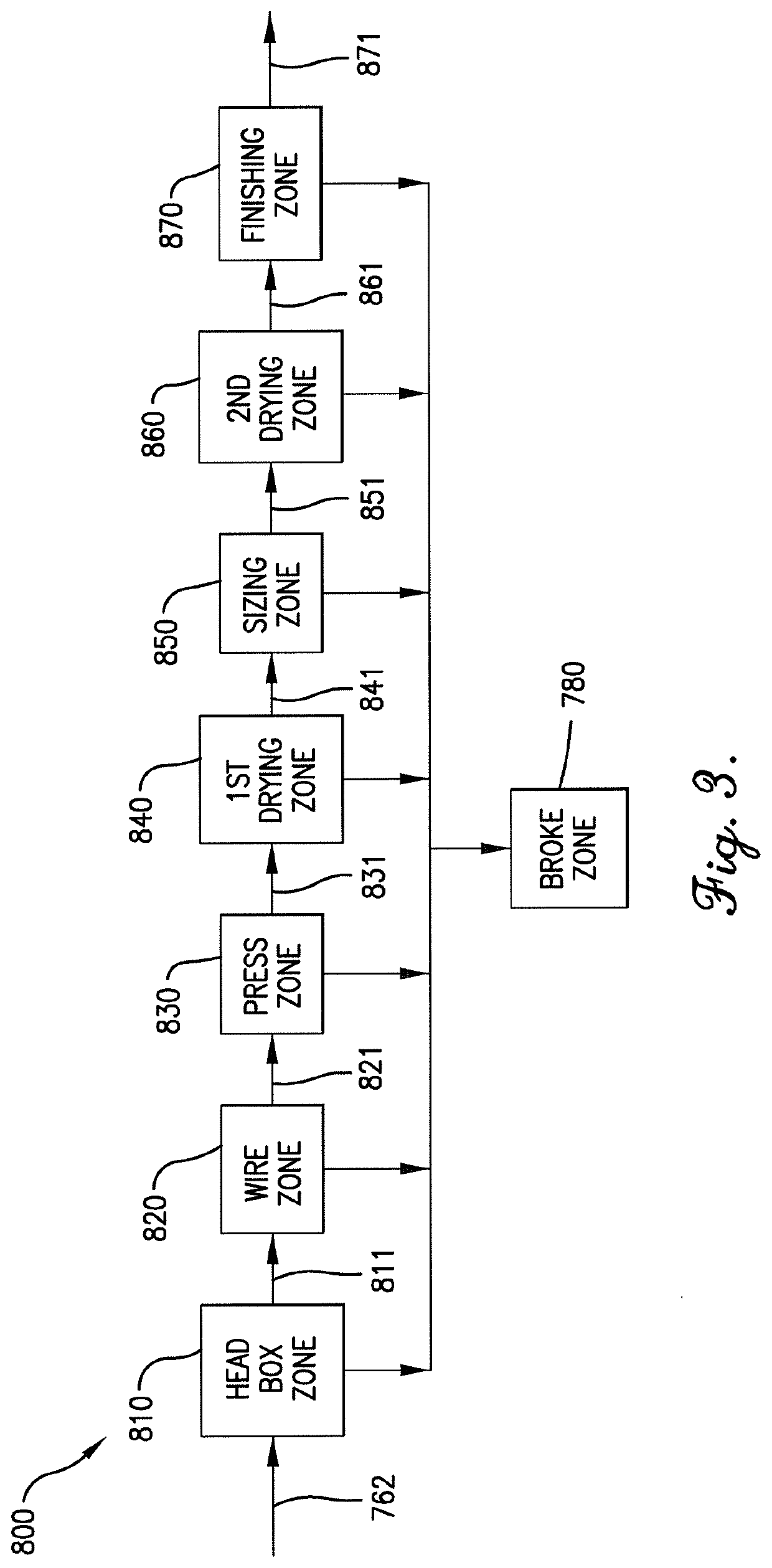

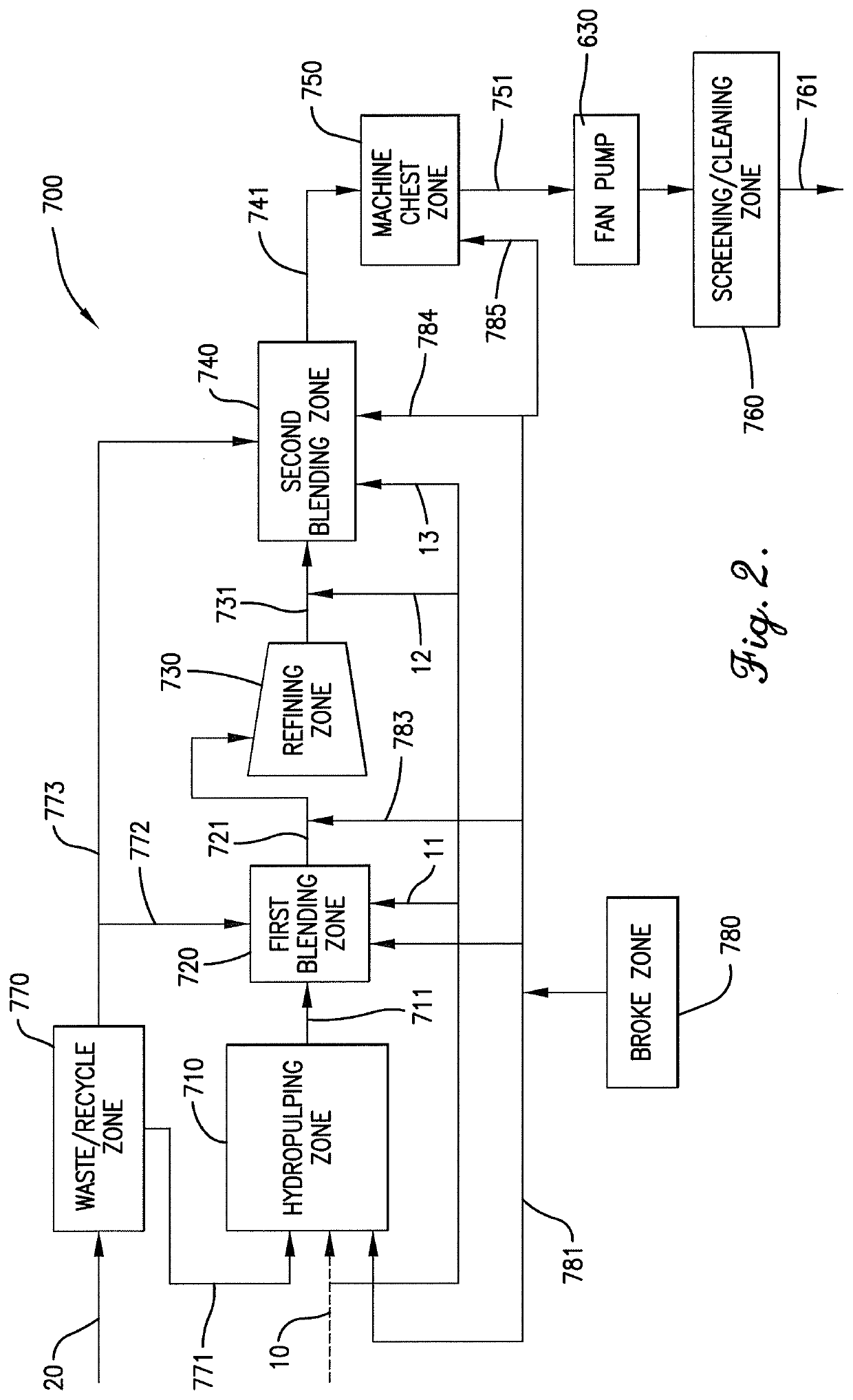

ActiveUS20200063359A1Reduce consistencyLow variabilityWater-repelling agents additionWashing/displacing pulp-treating liquorsProcess engineeringCellulose fiber

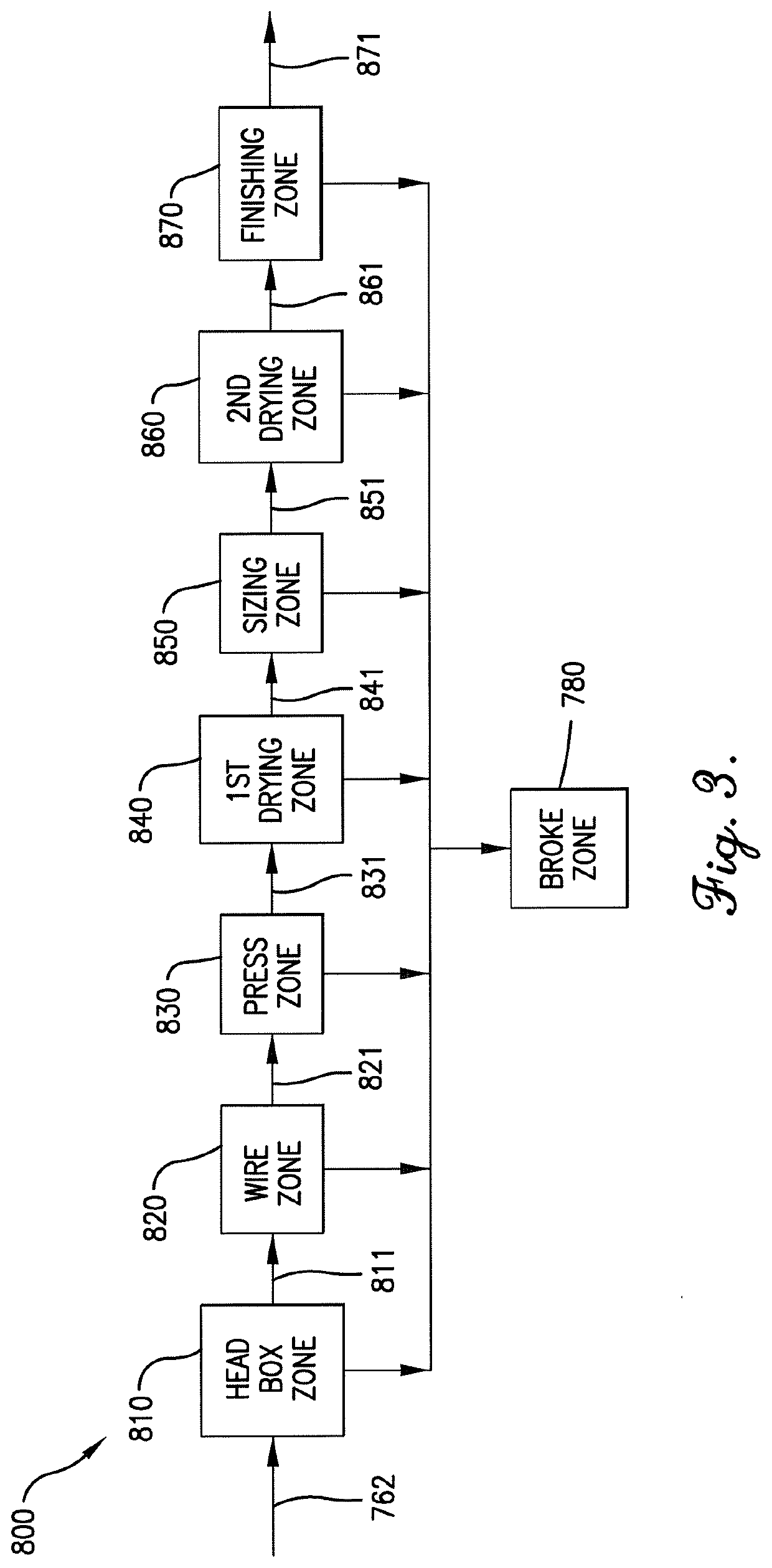

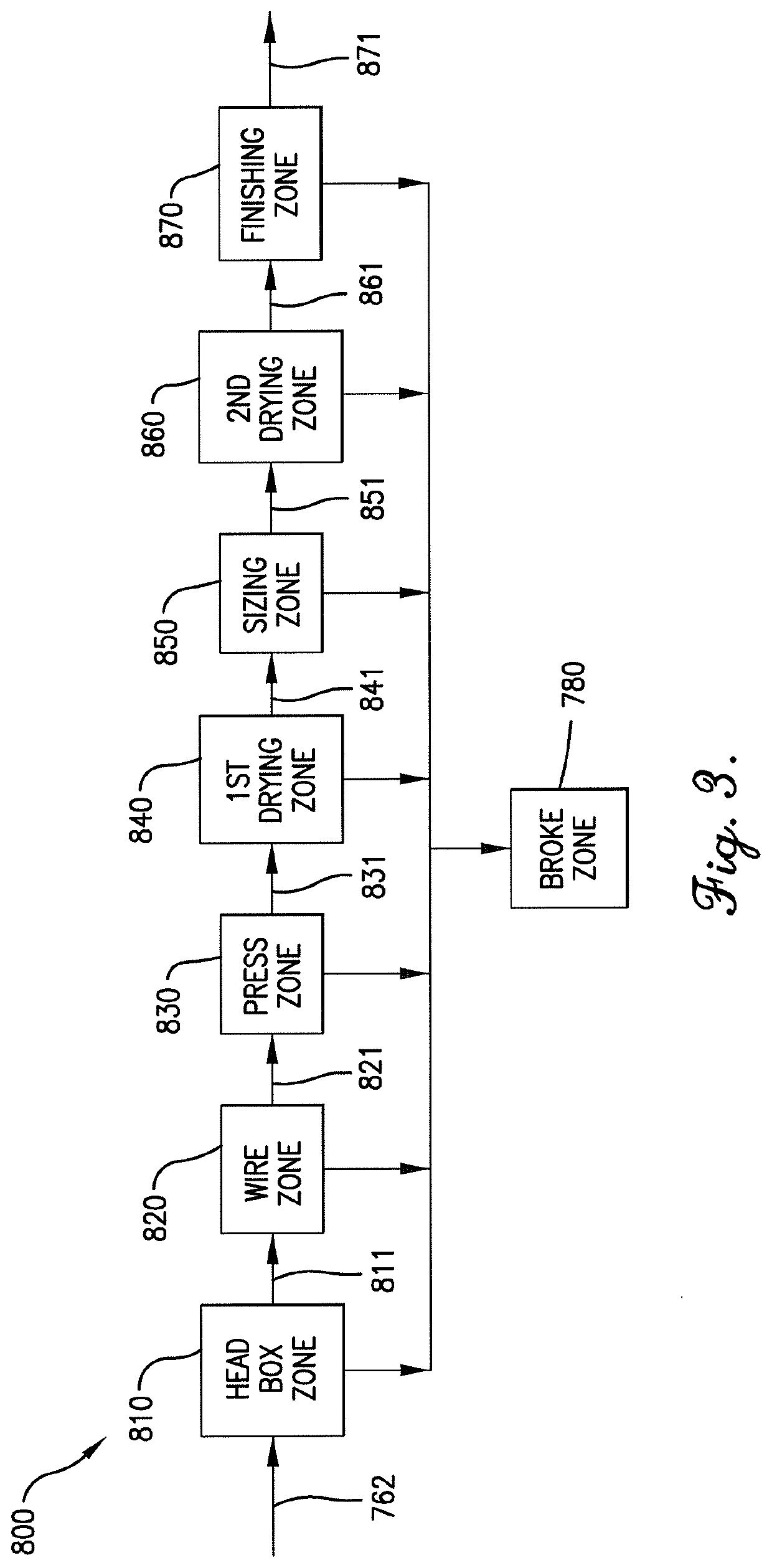

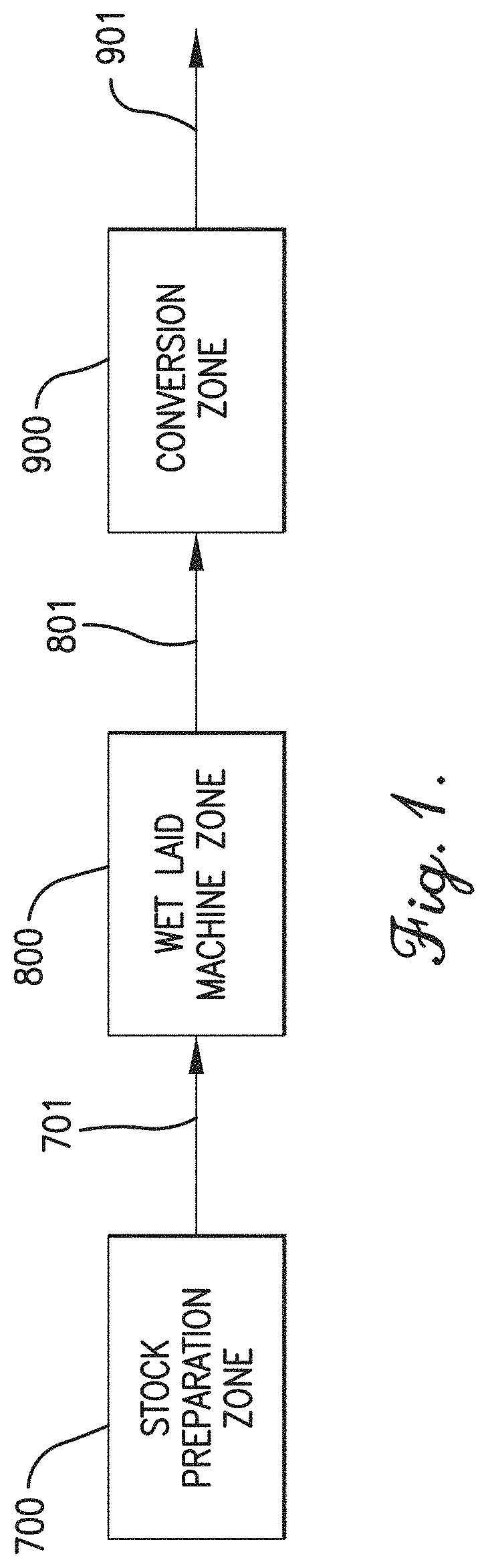

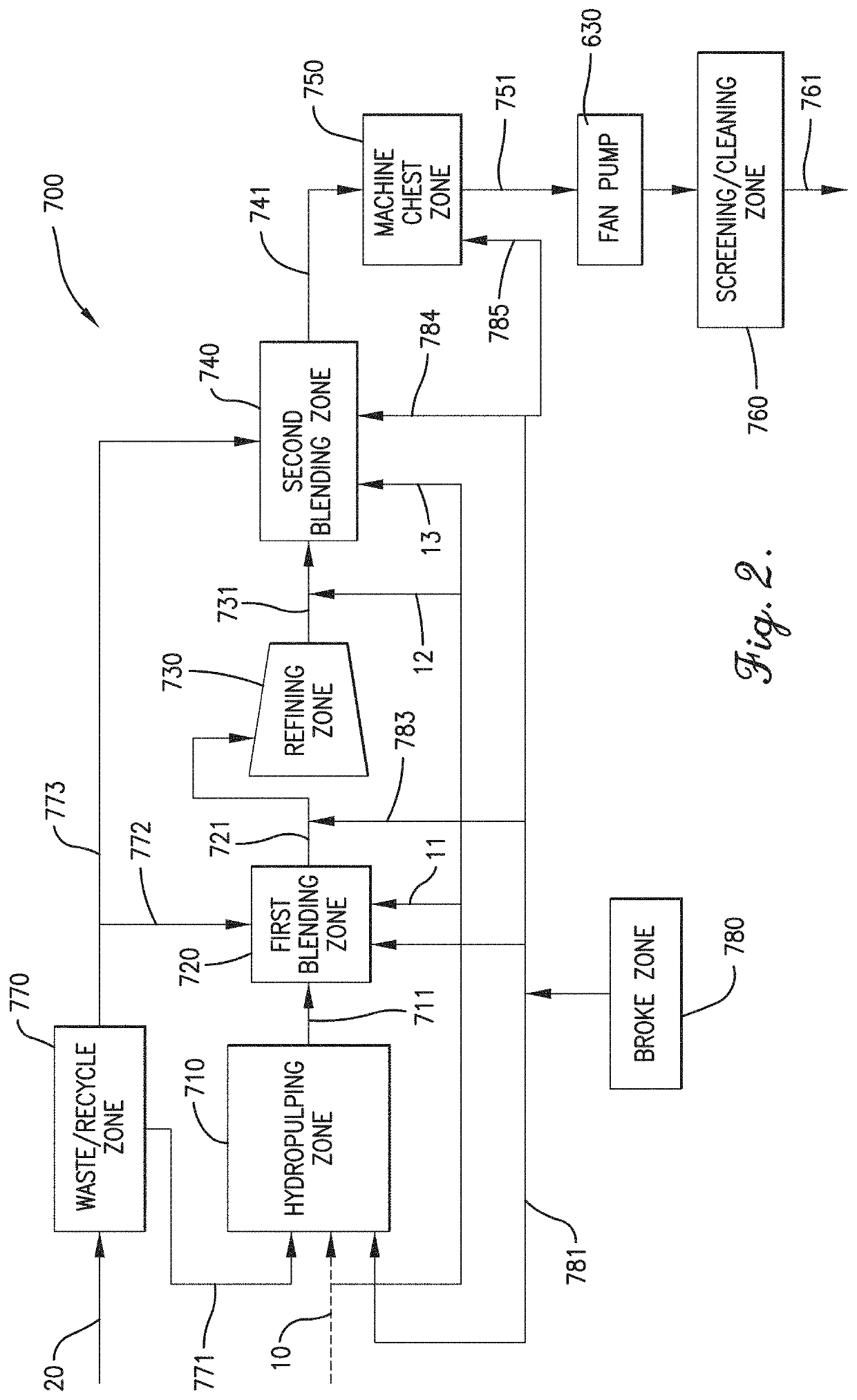

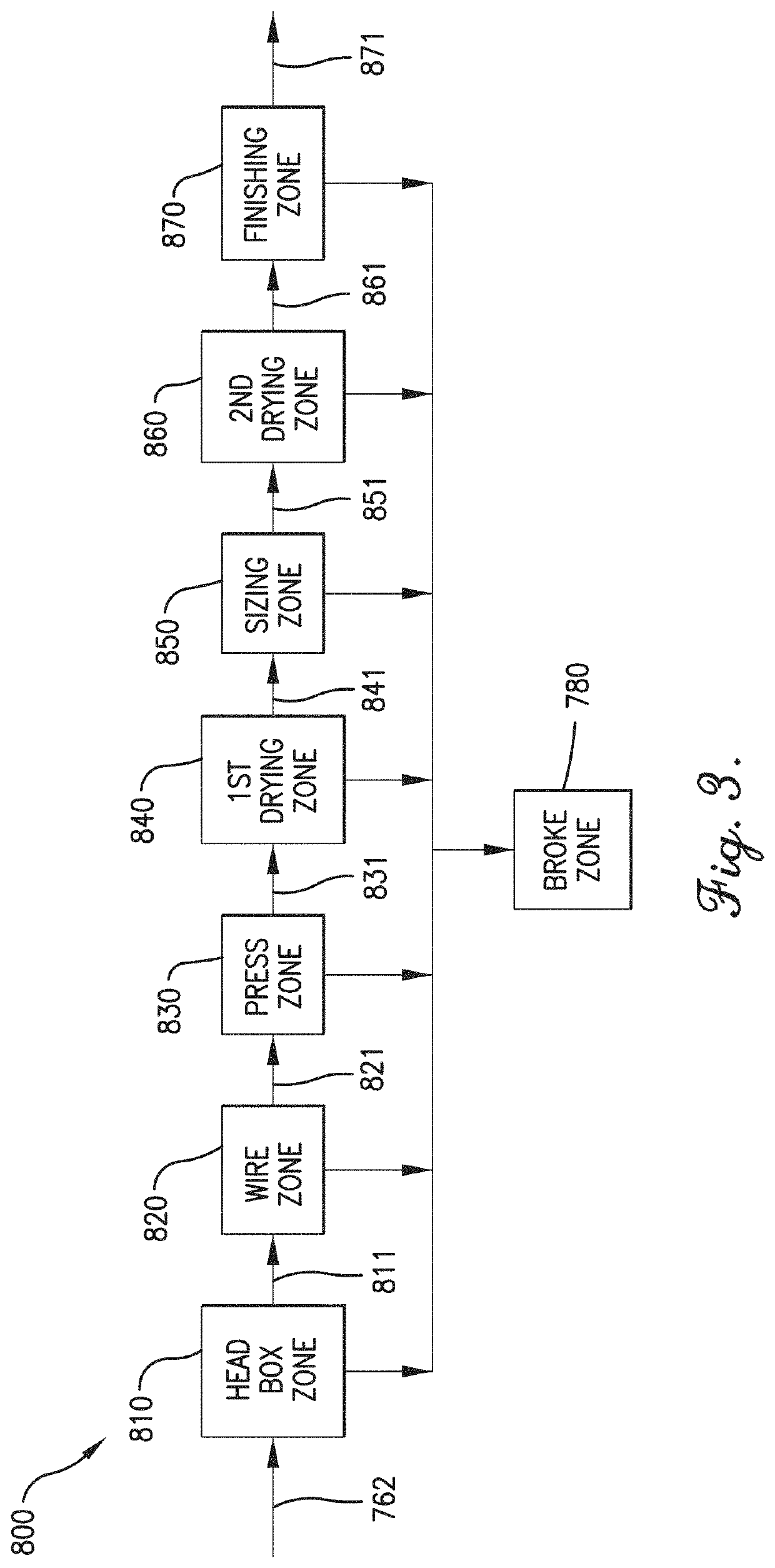

A wet laid process includes a method for making paper in which a composition containing co-refined cellulose fibers and cellulose ester fibers made into a thick stock composition in a machine chest, the thick stock is fed to a cleaning / screening zone through a device that regulates the flow rate of thick stock, the consistency of the thick stock fed to the screening / cleaning zone is reduced to form a thin stock composition; the thin stock composition is subjected to a process for cleaning the thin stock and feeding the cleaned thin stock through screens to form a cleaned and screened thin stock composition, and the cleaned and screened thin stock composition is fed to a headbox.

Owner:EASTMAN CHEM CO

Paper press process with high hydrolic pressure

ActiveUS20200063352A1Reduce consistencyLow variabilityPress sectionSynthetic cellulose fibresPolymer scienceCellulose acetate

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many desired benefits. Specifically, a wet laid process comprising a process that allows the quantity of water removed from a web passed through press rolls is increased relative to a web made from a 100% cellulose comparative composition or any composition without cellulose ester staple fibers co-refined with cellulose at the same press loading

Owner:EASTMAN CHEM CO

Lightweight cardboard and paper articles

InactiveUS20200063361A1Reduction in Gurley stiffnessLow densityFlexible coversWrappersPaperboardProcess engineering

Wet laid products such as cardboard, paperboard, and packaging and container board can be light-weighted or made thicker, while retaining Gurley stiffness. The wet laid products contain co-refined CE staple fibers that have:i. a denier per filament (DPF) of less than 3, orii. a cut length of less than 6 mm, oriii. crimping, oriv. a combination of any two or more of (i)-(iv).

Owner:EASTMAN CHEM CO

Molded articles from a fiber slurry

ActiveUS20200063373A1Reduce consistencyLow variabilityFibreboardLayered productsPolymer scienceCutlery

Contoured articles formed in a mold from a fiber slurry are provided. The articles comprise a blend of cellulose fibers and cellulose ester, such as cellulose ester staple fibers. The articles are suitable in a wide array of end uses, including as cups, lids, boxes or pouches, storage containers, trays, plates, food trays, cutlery, coffee cups, coffee cup lid, packaging, bowls, clam shells, bottle caps, straws, covers, and packaging inserts.

Owner:EASTMAN CHEM CO

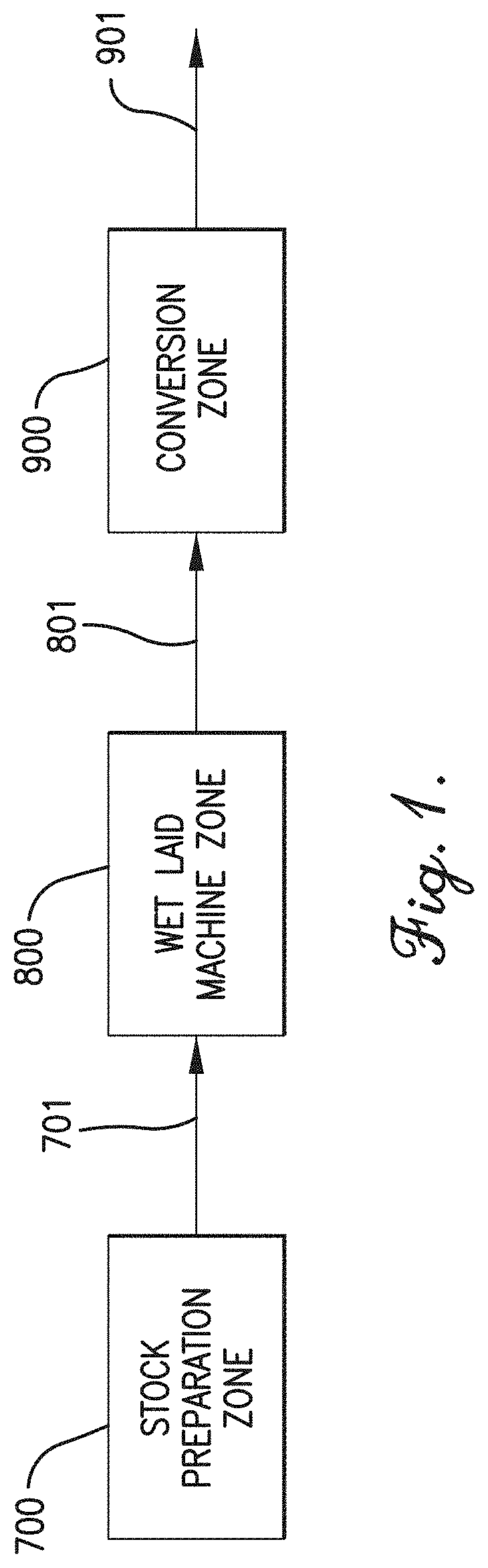

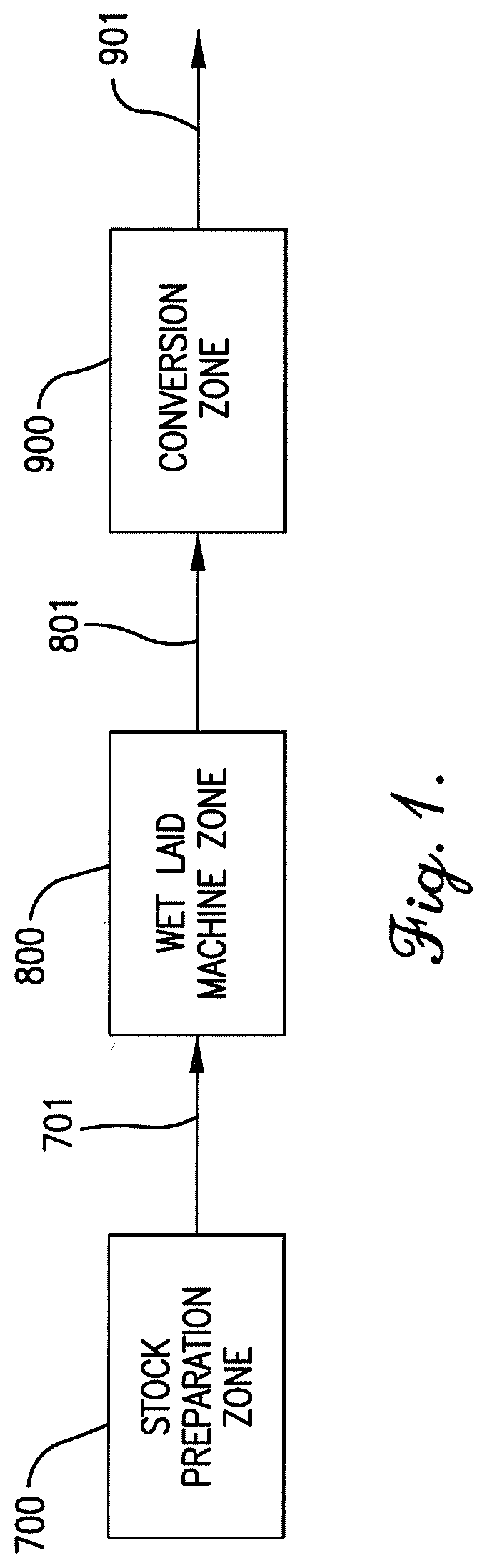

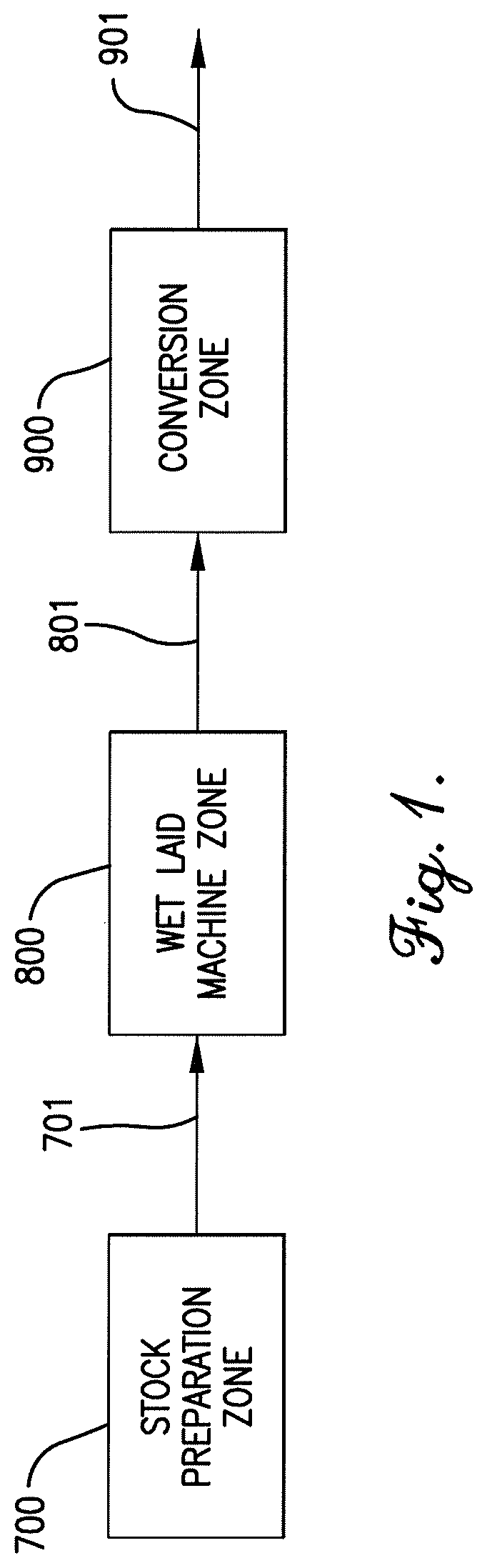

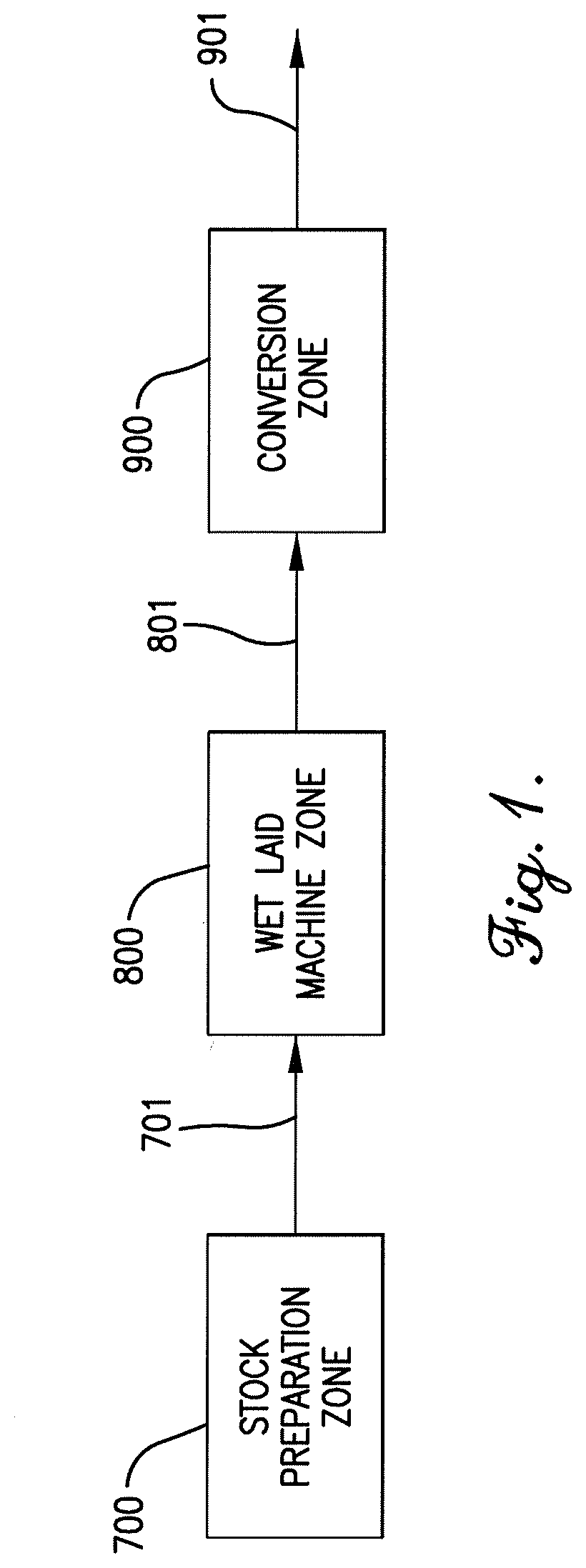

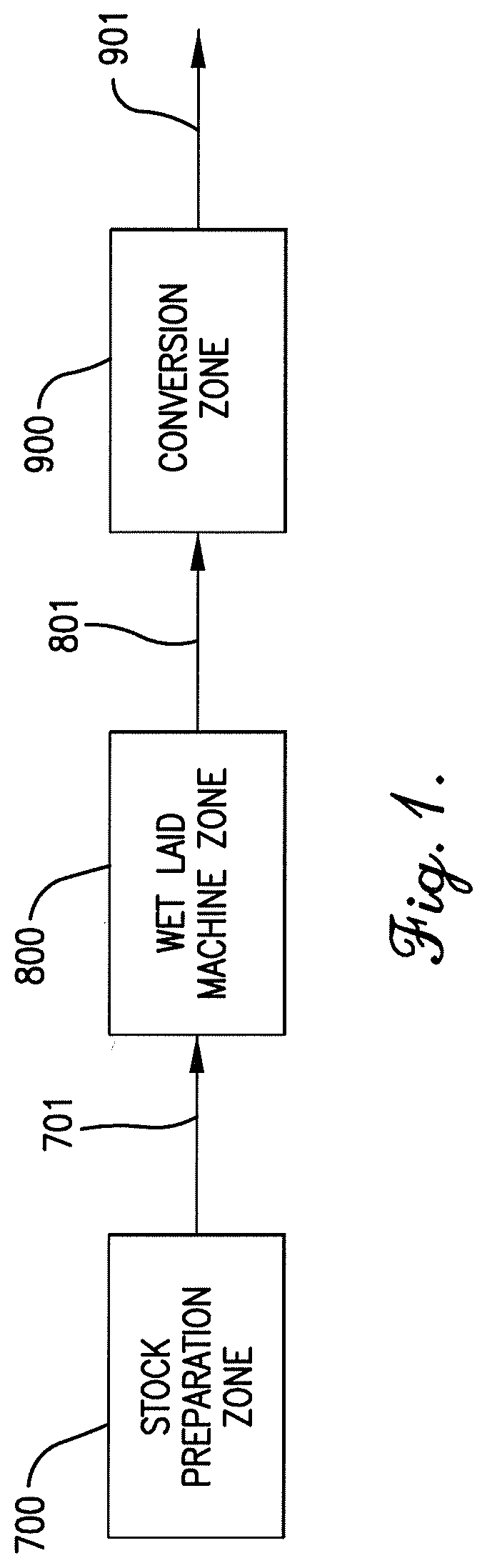

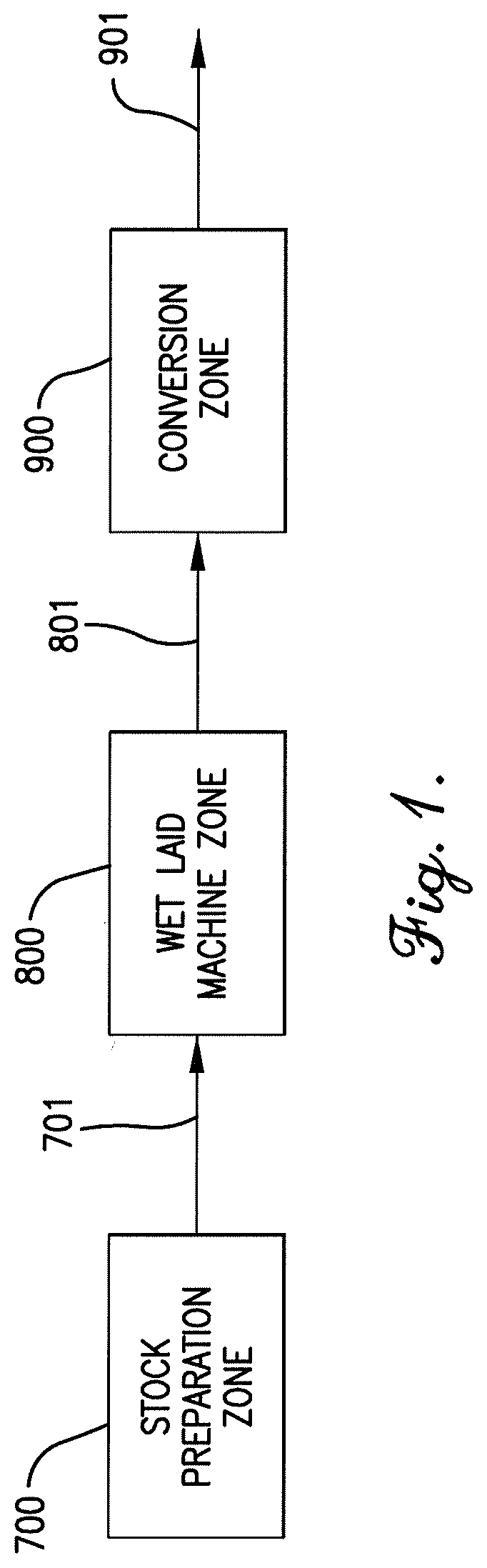

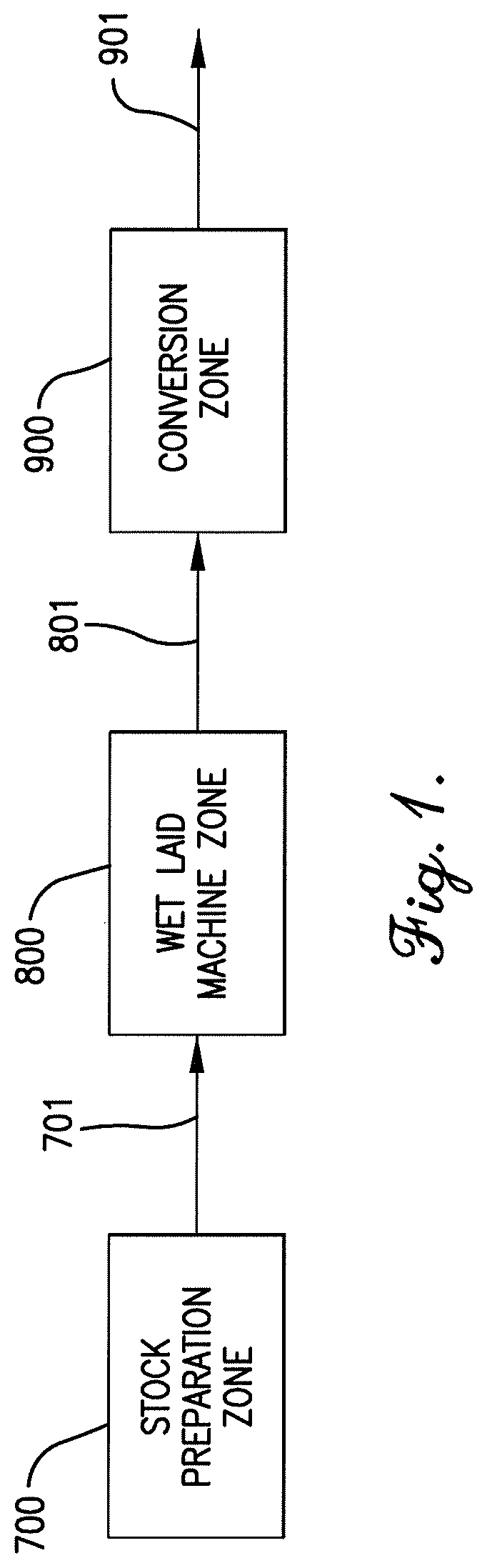

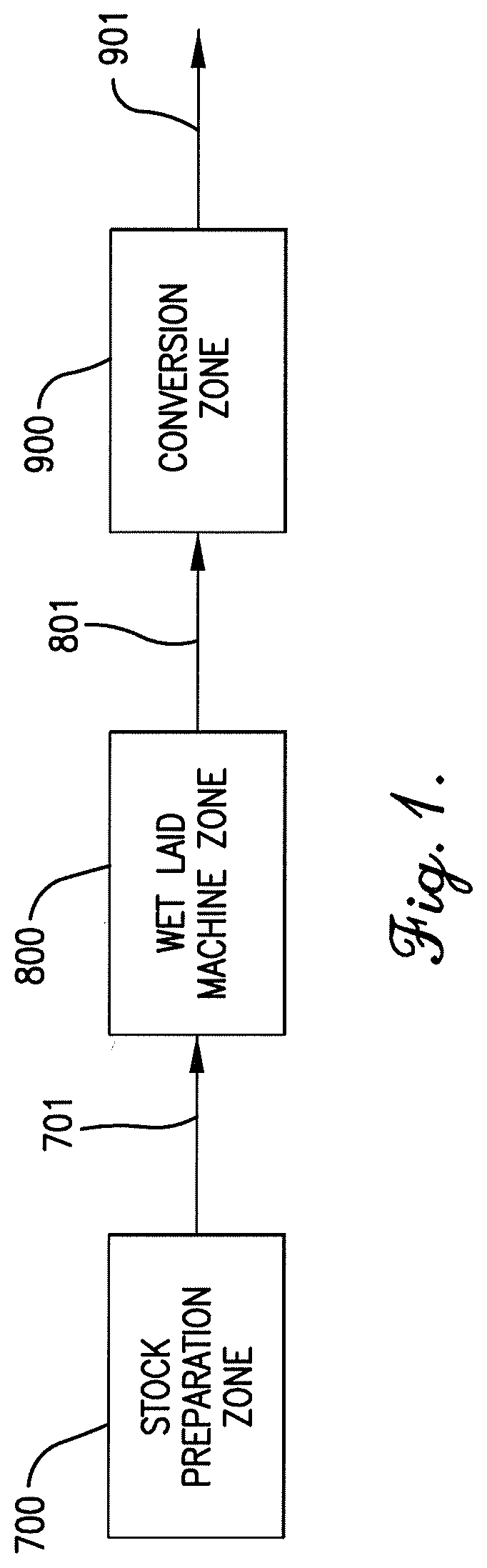

Process to produce a paper article comprising cellulose fibers and a staple fiber

ActiveUS20200063346A1Reduce consistencyLow variabilityReinforcing agents additionPaper/cardboardPolymer scienceCellulose acetate

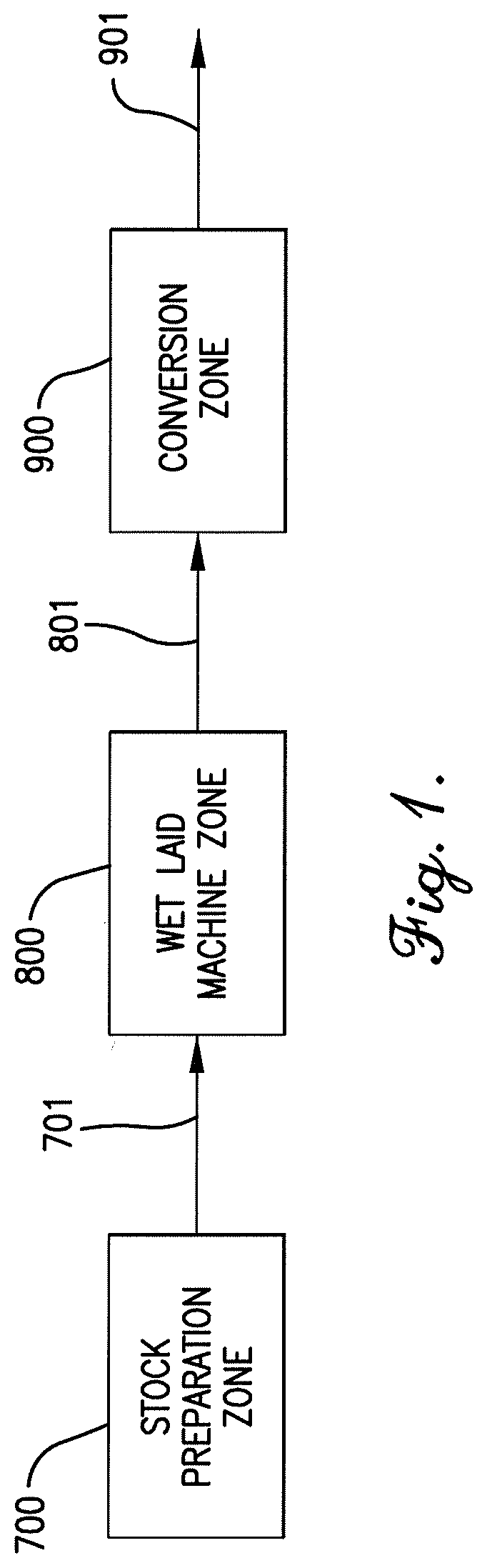

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many desired benefits.

Owner:EASTMAN CHEM CO

Paper composition cellulose and cellulose ester for improved texturing

ActiveUS20200063368A1Reduce consistencyLow variabilityPaper/cardboardTissue/absorbent paperPaper sheetPolymer chemistry

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to composition, process, wet laid product, or articles exhibiting any one of many desired benefits. The invention also relates to a composition comprising cellulose fiber and a staple fiber exhibiting improved texturing.

Owner:EASTMAN CHEM CO

Paper product articles

ActiveUS20200063351A1High air permeabilityHigh permeabilityPaper/cardboardMembrane filtersCellulose acetatePolymer science

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many the desired benefits. The Present invention also relates to a wet laid product having higher air permeability the same or lower pore size relative to a 100% cellulose comparative composition

Owner:EASTMAN CHEM CO

Soft wipe comprising cellulose acetate

ActiveUS20200063348A1Low densityIncreasing the thicknessTissue/absorbent paperNon-woven fabricsPolymer scienceCellulose acetate

A soft wipe article is provided comprising a wet-laid sheet which comprises cellulosic fibers and cellulose ester staple fibers, wherein the cellulose ester staple fibers are present in an amount sufficient to provide the wet laid-sheet with a lower density and higher thickness at a given basis weight compared to a 100% Cellulose Comparative composition, when processed under similar conditions. The cellulose ester staple fibers can also provide the wet laid-sheet with a higher softness, while maintaining or increasing tear strength, compared to a 100% Cellulose Comparative composition, when processed under similar conditions.

Owner:EASTMAN CHEM CO

Air filtration articles

ActiveUS20200063354A1Improve breathabilityReduce consistencyPaper/cardboardMembrane filtersAir filtrationPolymer science

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many the desired benefits. The present invention also relates to a filter media for air filtration comprising cellulose fiber and a staple fiber; wherein said staple filter comprises cellulose ester; wherein said air permeability is higher for a given mean pore size as compared to a filtration that comprises 100% cellulose.

Owner:EASTMAN CHEM CO

Highly absorbent articles

ActiveUS20200063372A1Excellent characteristicsImprove propertiesReinforcing agents additionPaper/cardboardBursting strengthPolymer science

Absorbent wet laid products are made containing cellulose fibers and cellulose ester staple fibers that are co-refined to obtain products and articles that have improved water absorbency and tensile strength or burst strength or both. The absorbent wet laid products can now be made with a synthetic fiber in the wet laid operation since cellulose ester can be subjected to a refining operation.

Owner:EASTMAN CHEM CO

Beverage filtration article

ActiveUS20200063350A1Reduce consistencyLow variabilityPaper/cardboardBeverage vesselsPolymer scienceBeverage filtration

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many desired benefits. The present invention relates a filtration article comprising a wet-laid composition comprising cellulose fibers and staple fibers.

Owner:EASTMAN CHEM CO

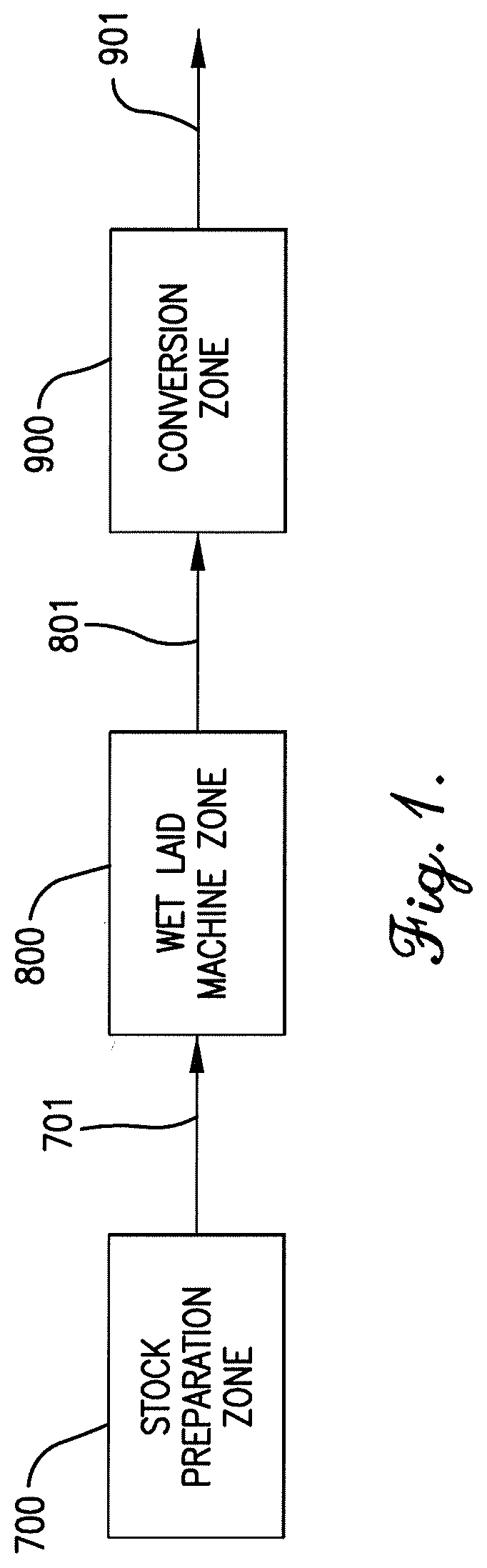

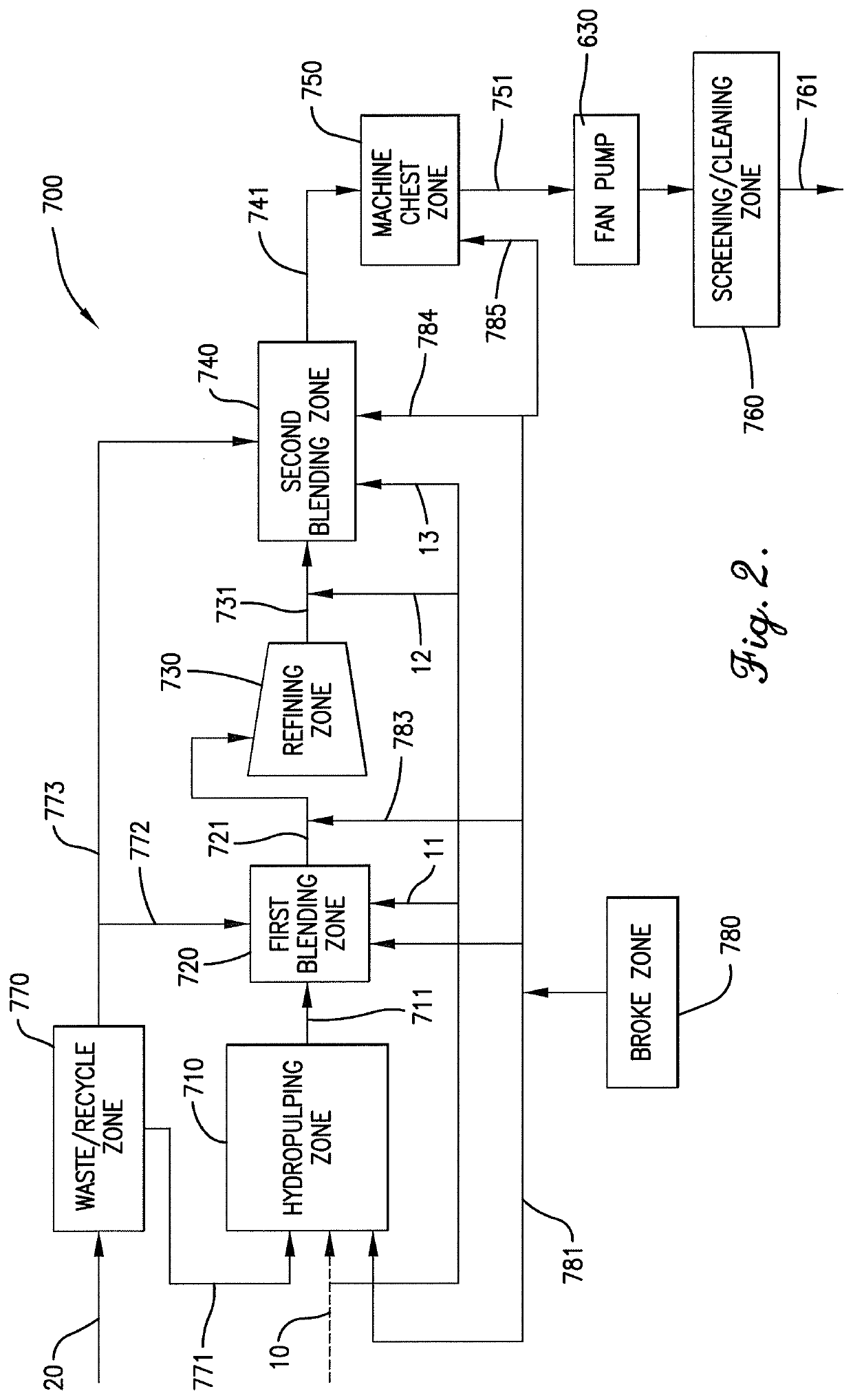

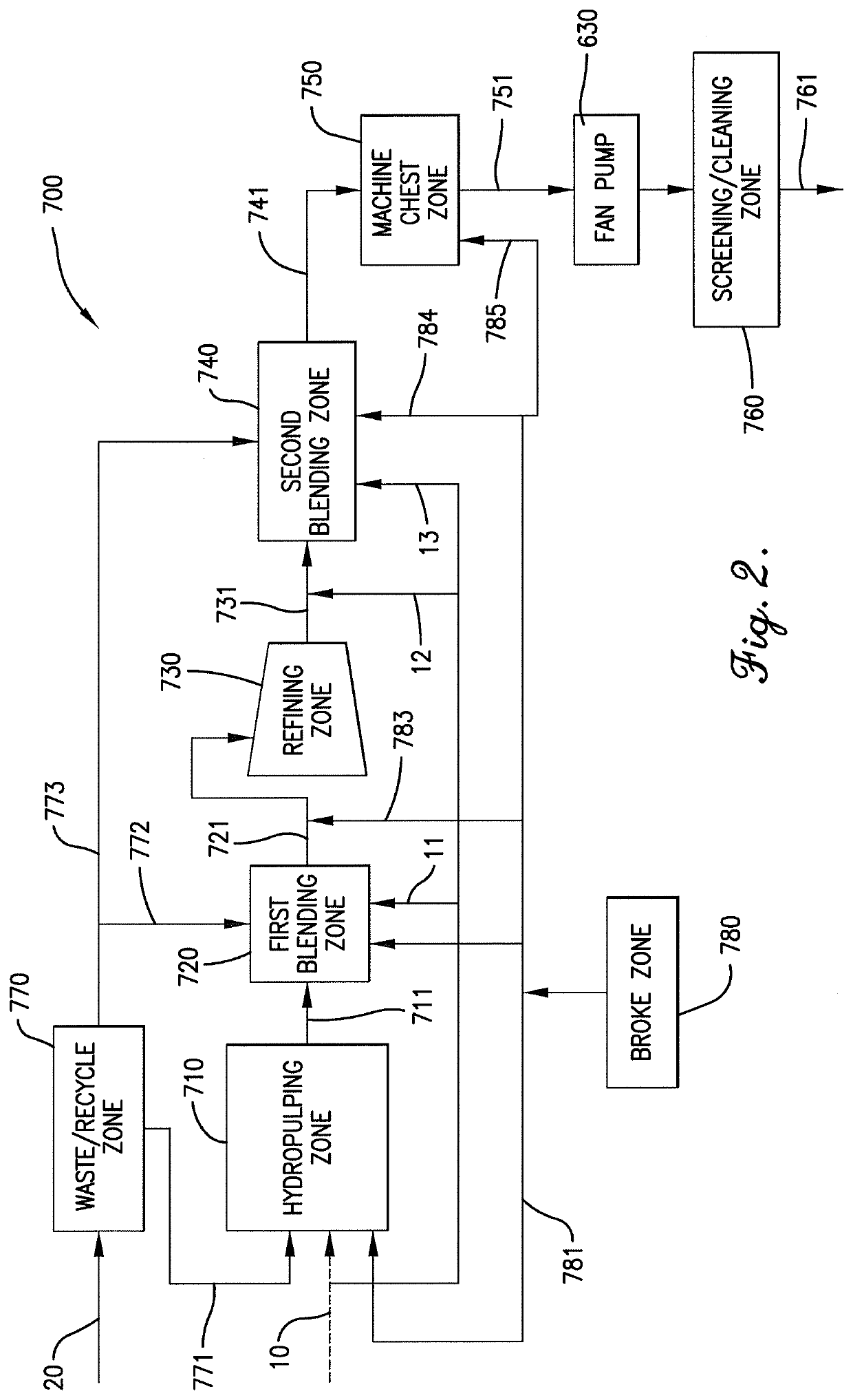

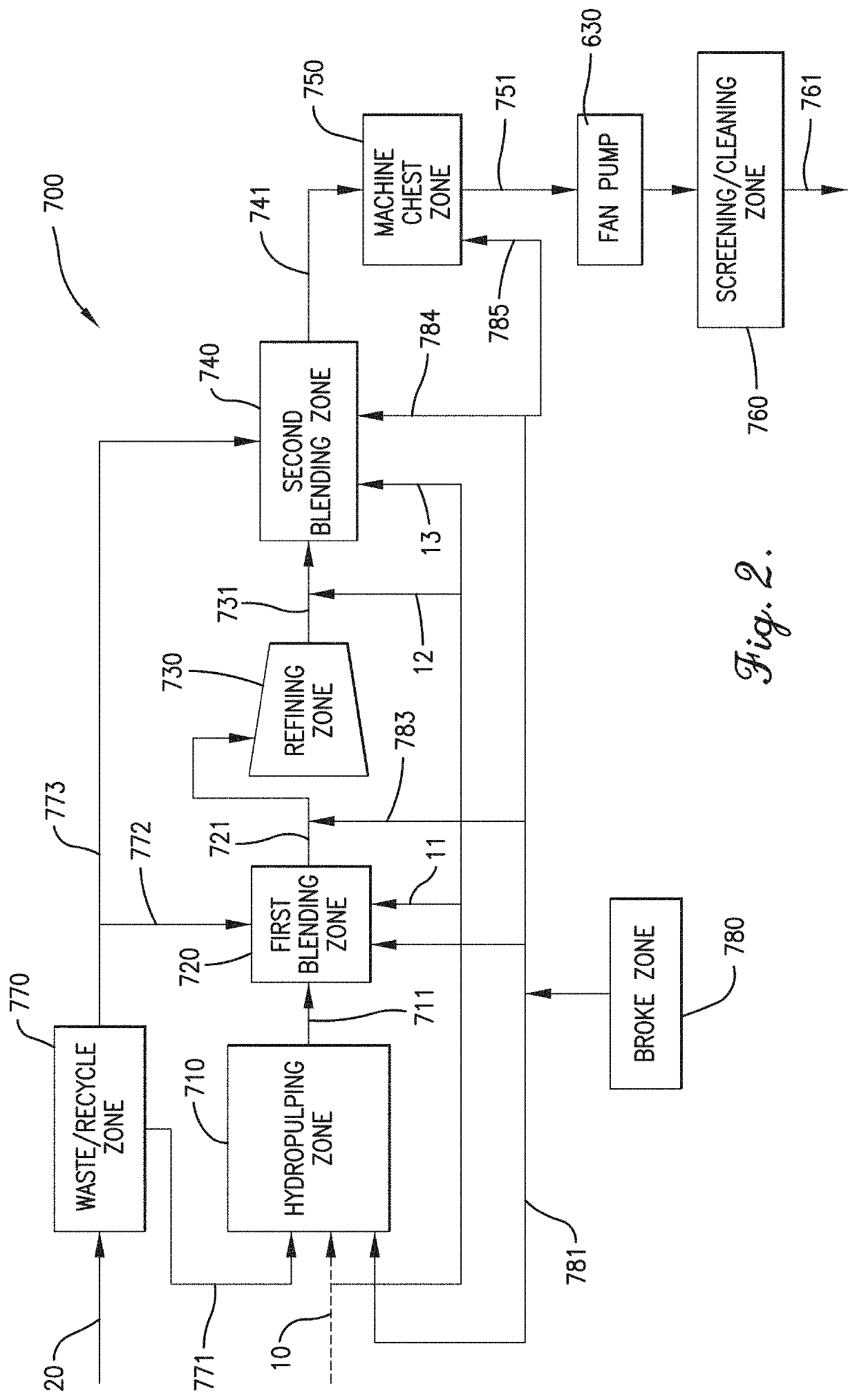

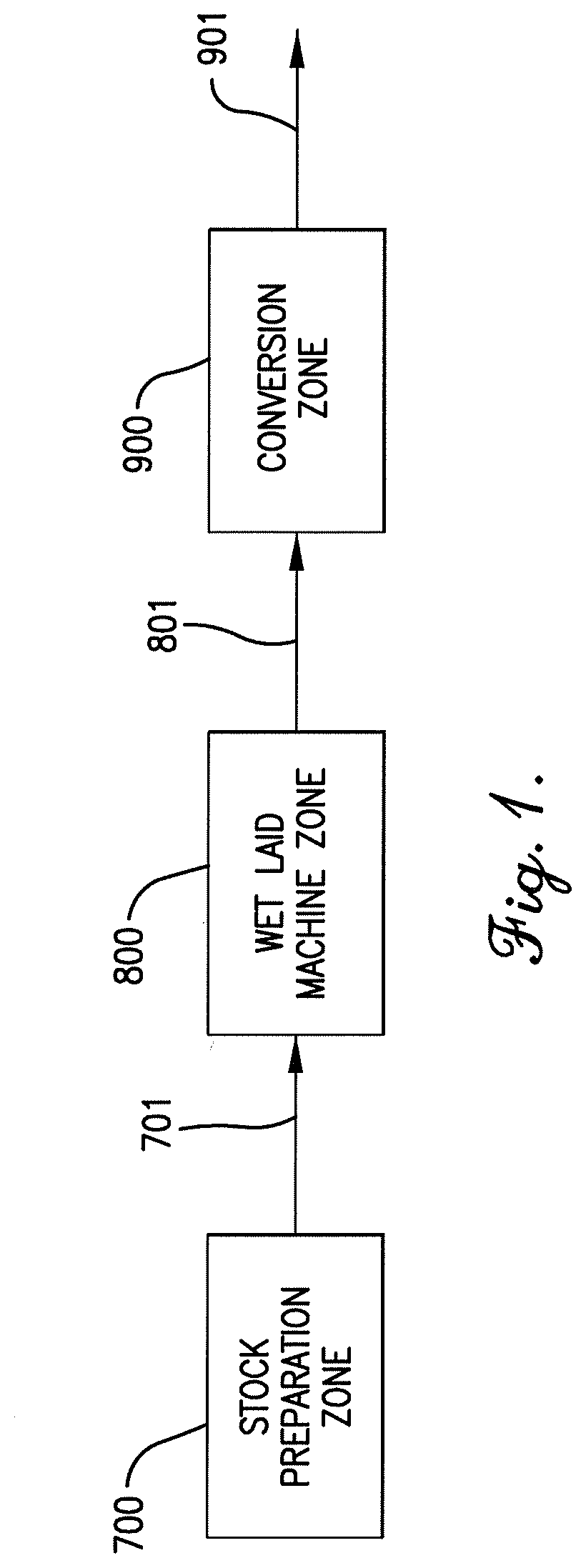

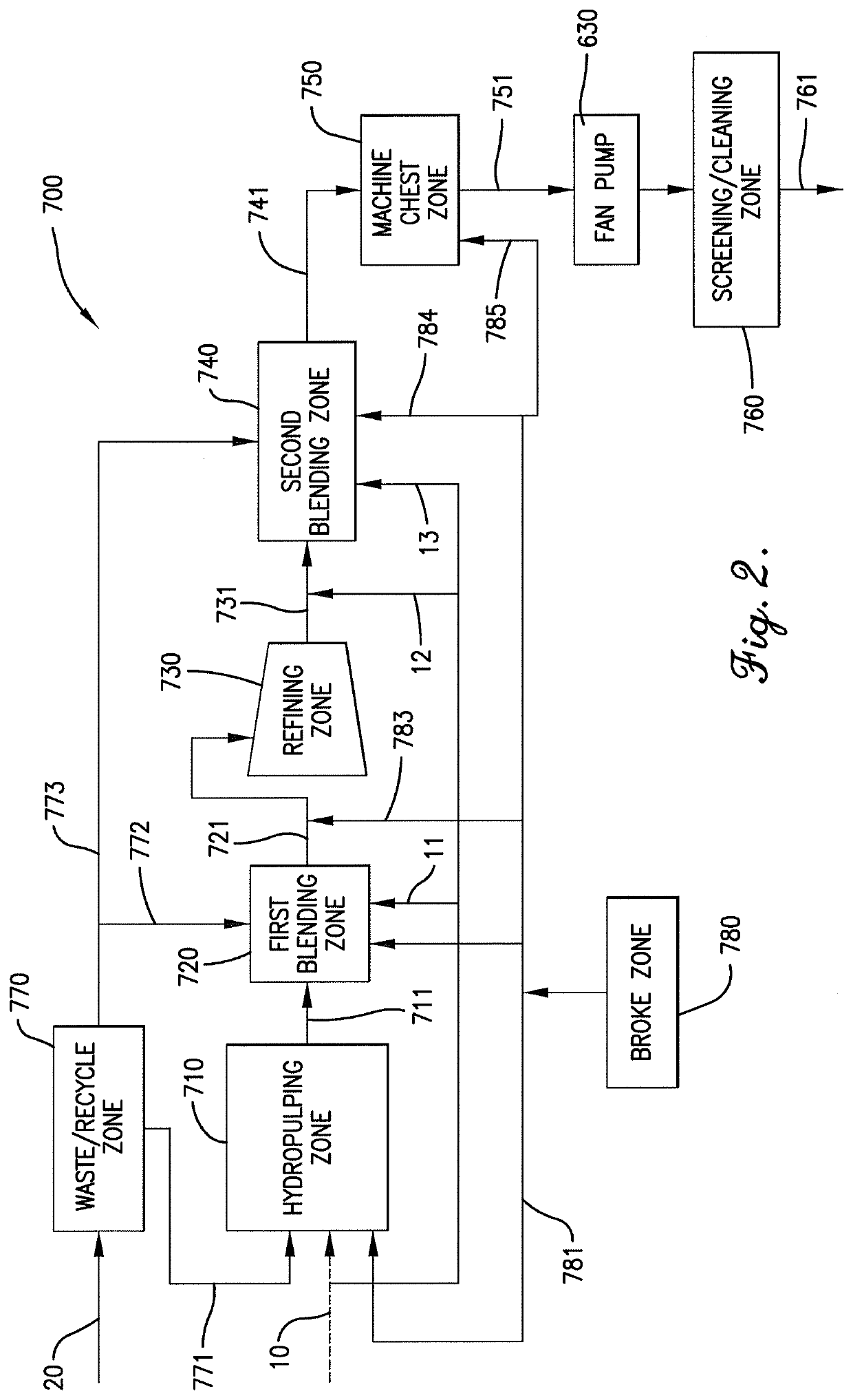

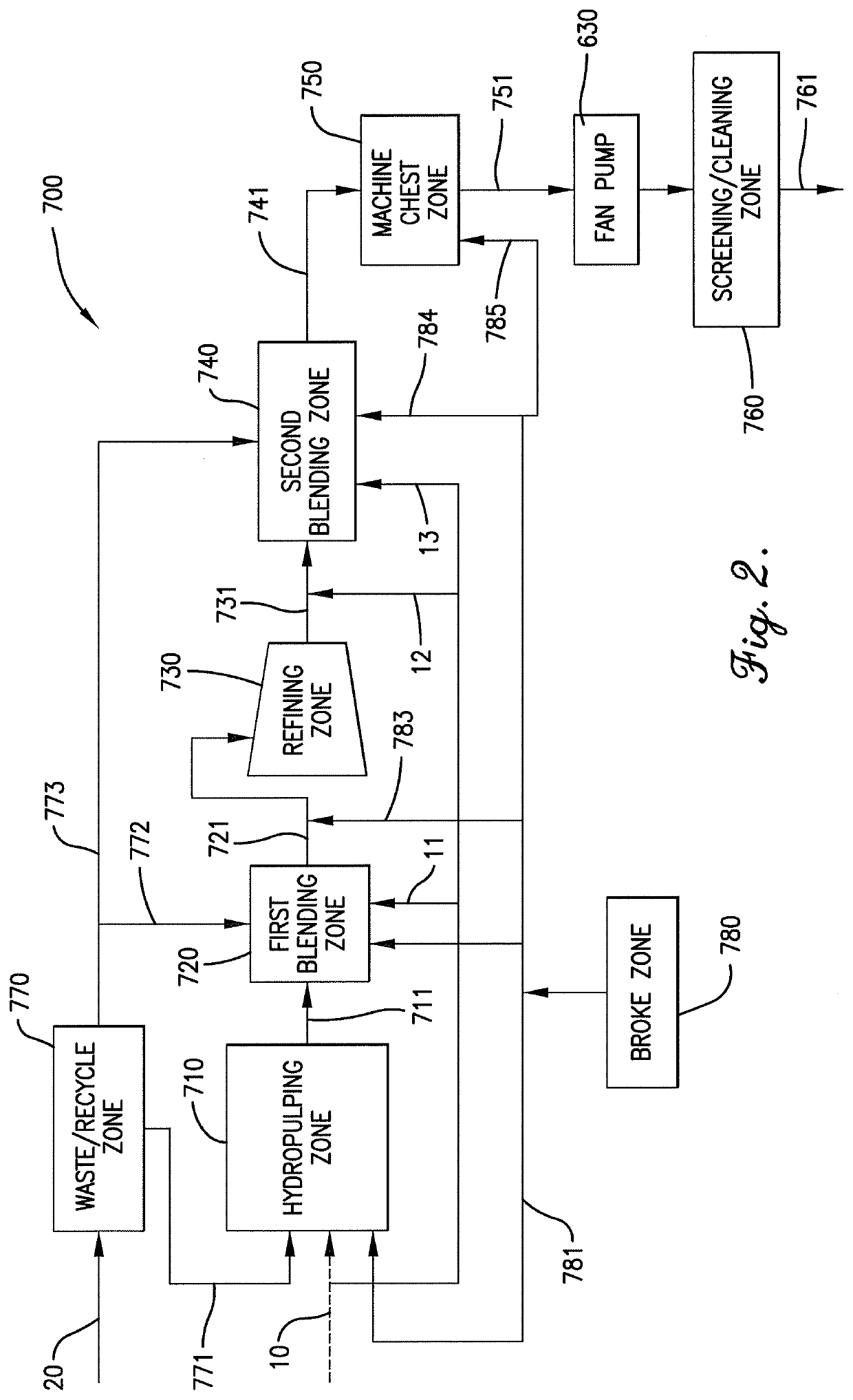

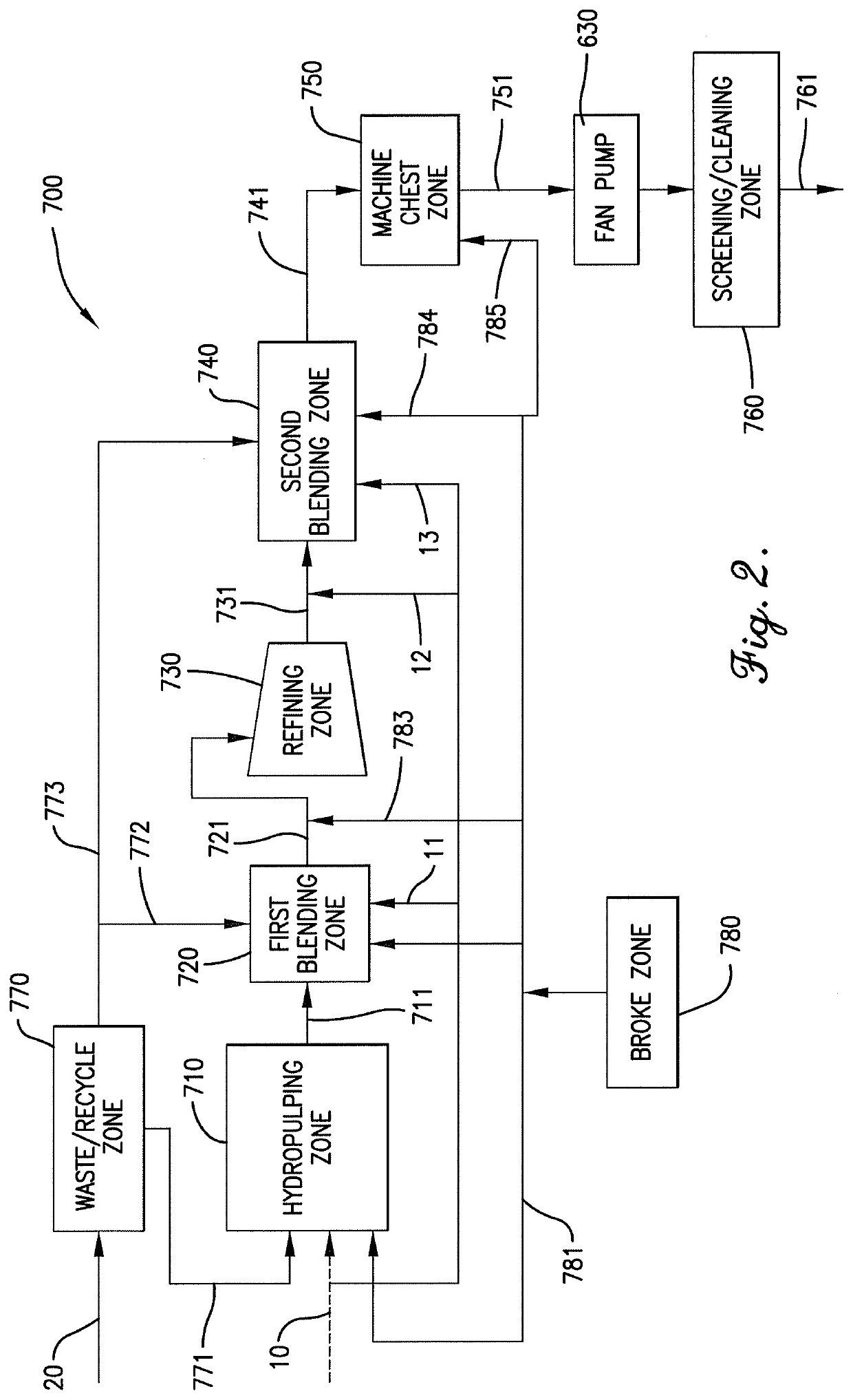

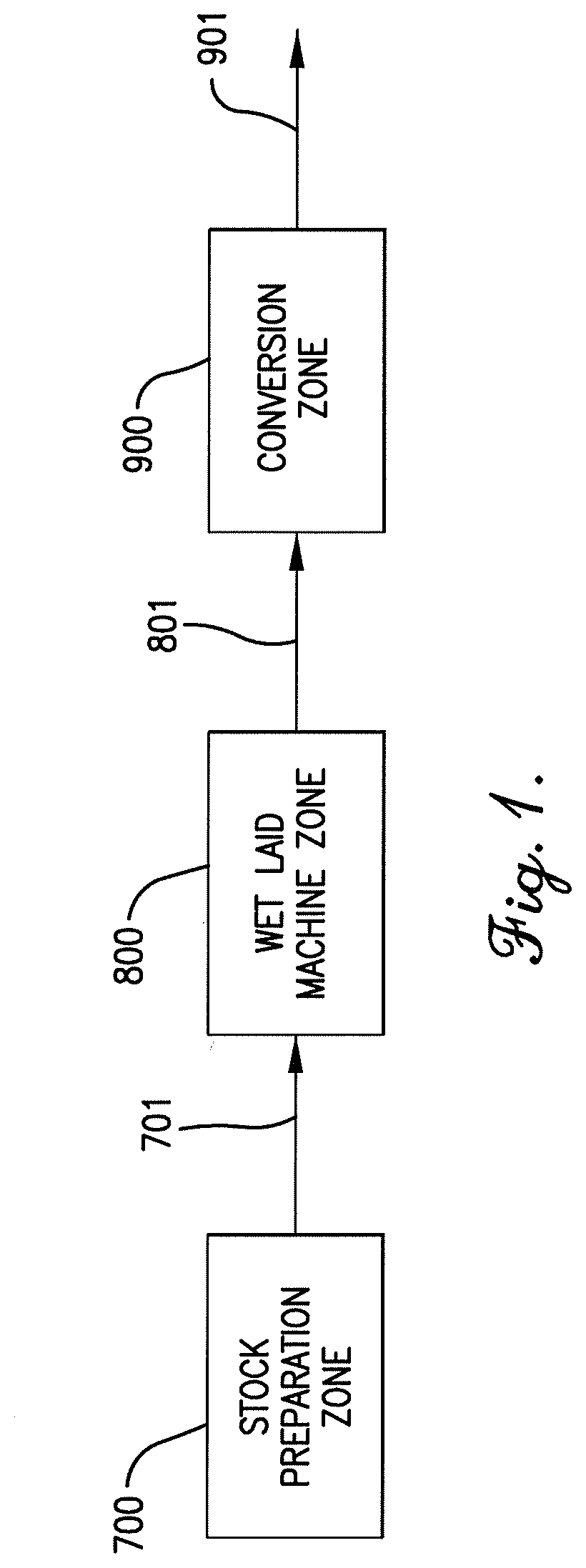

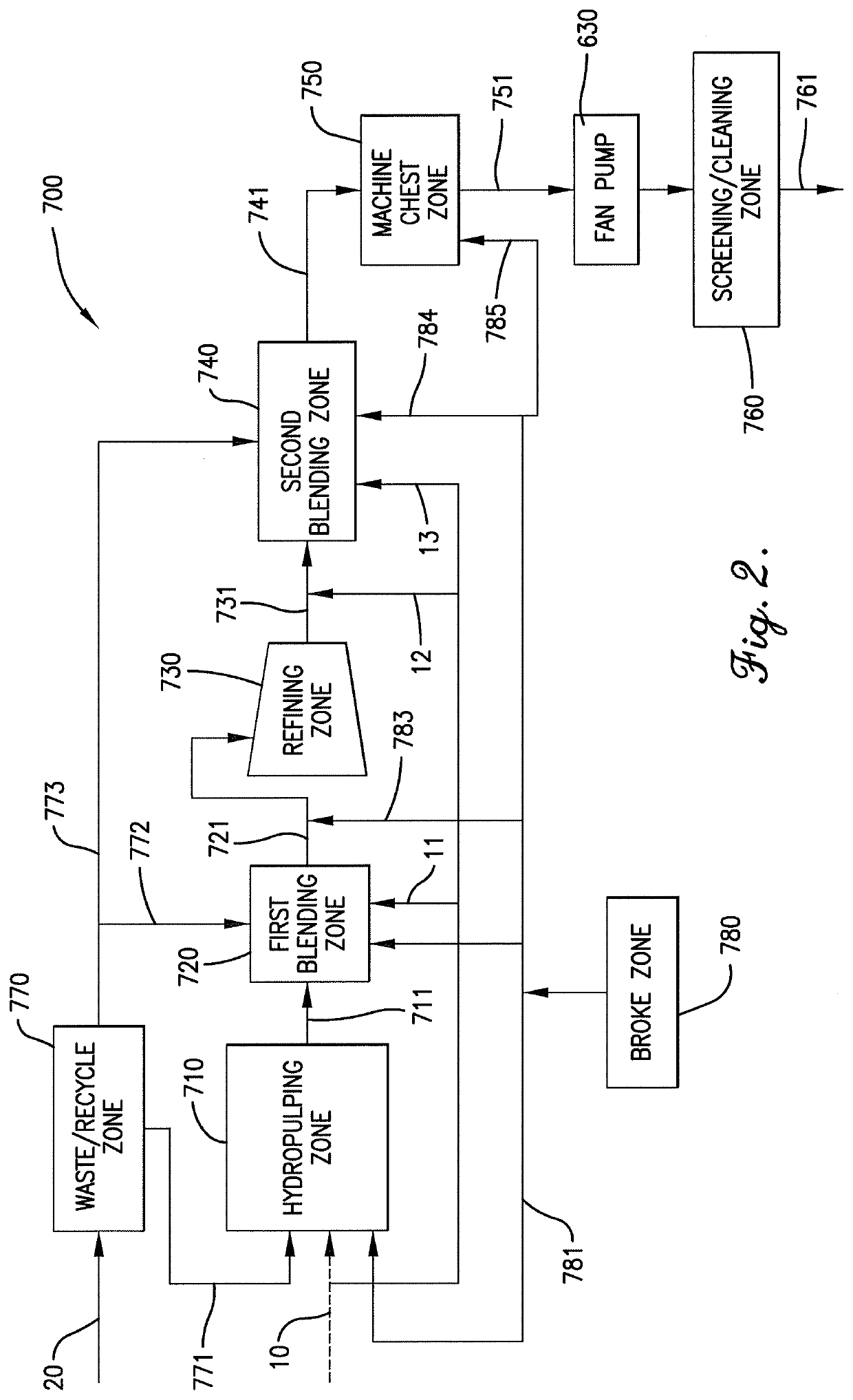

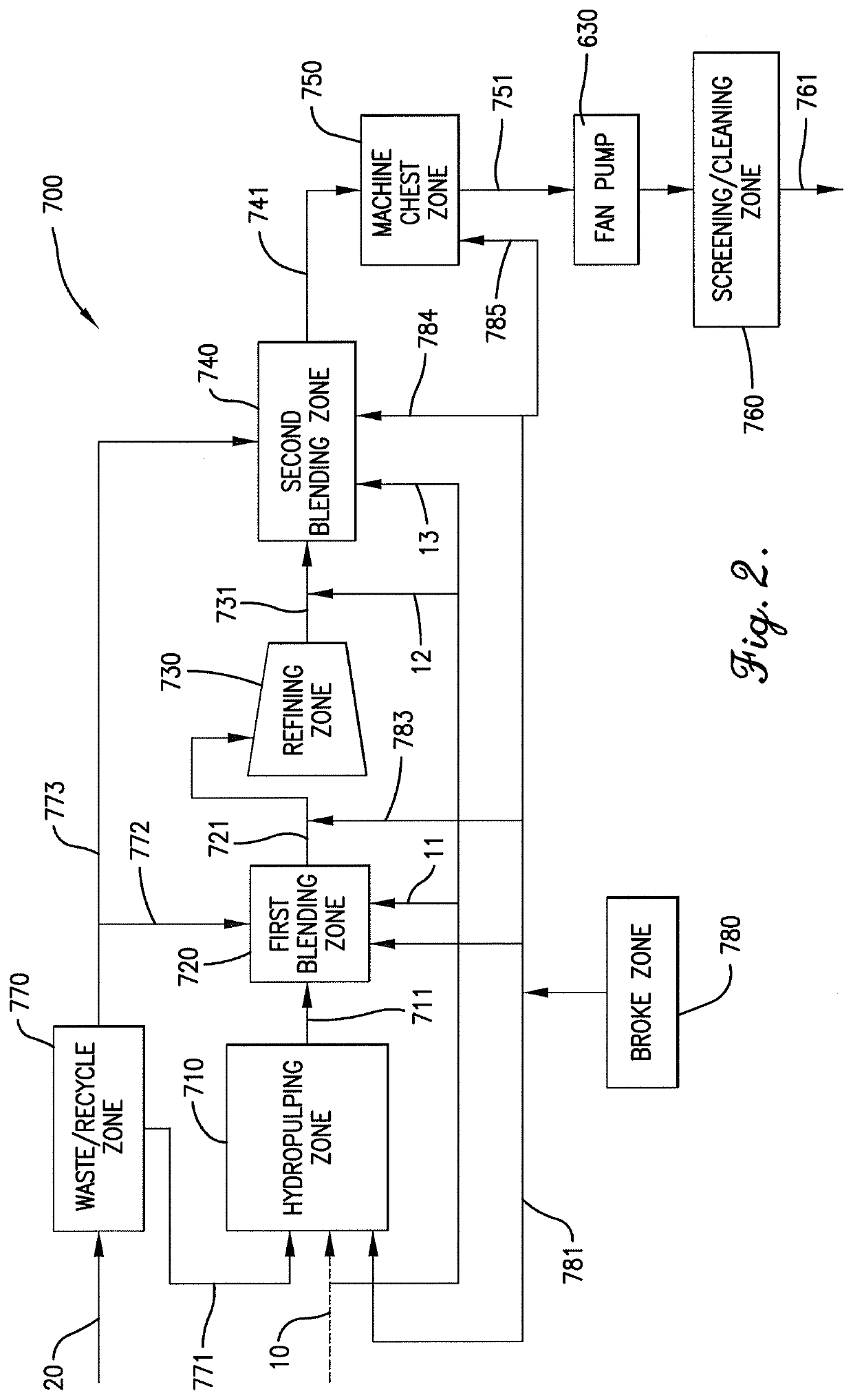

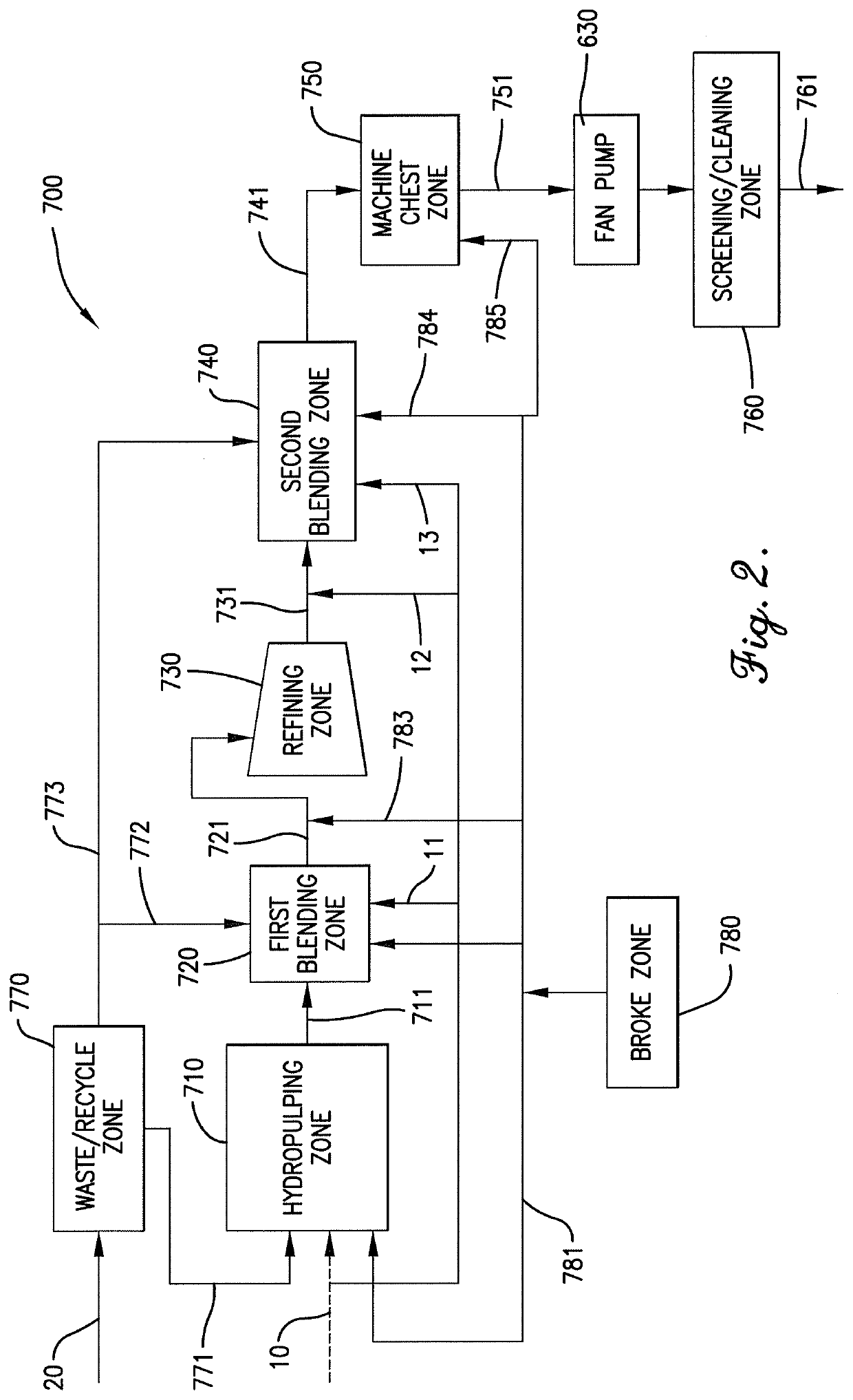

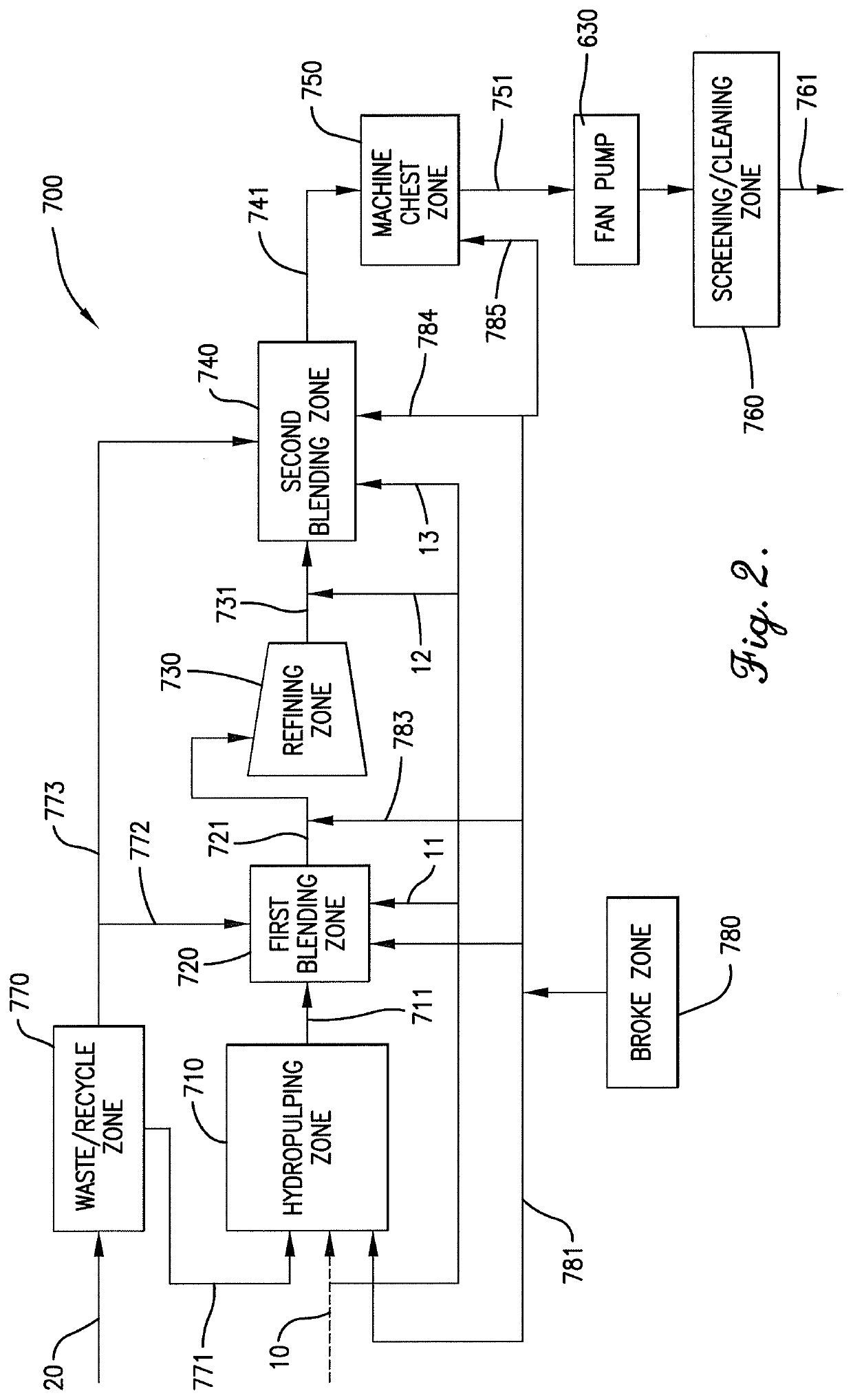

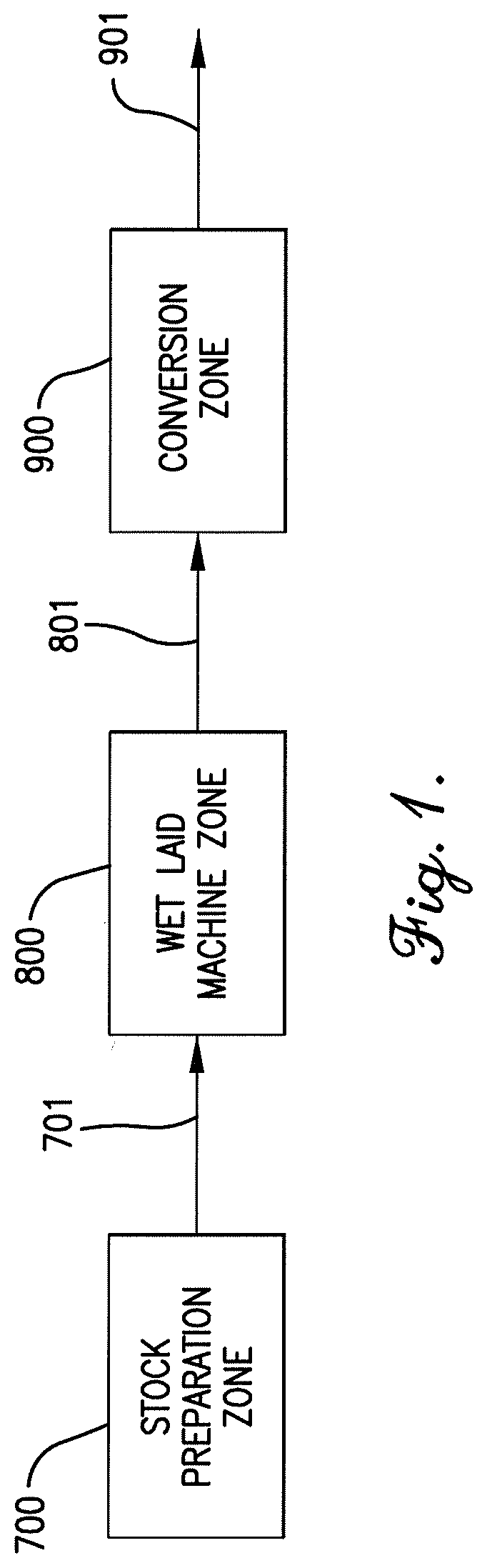

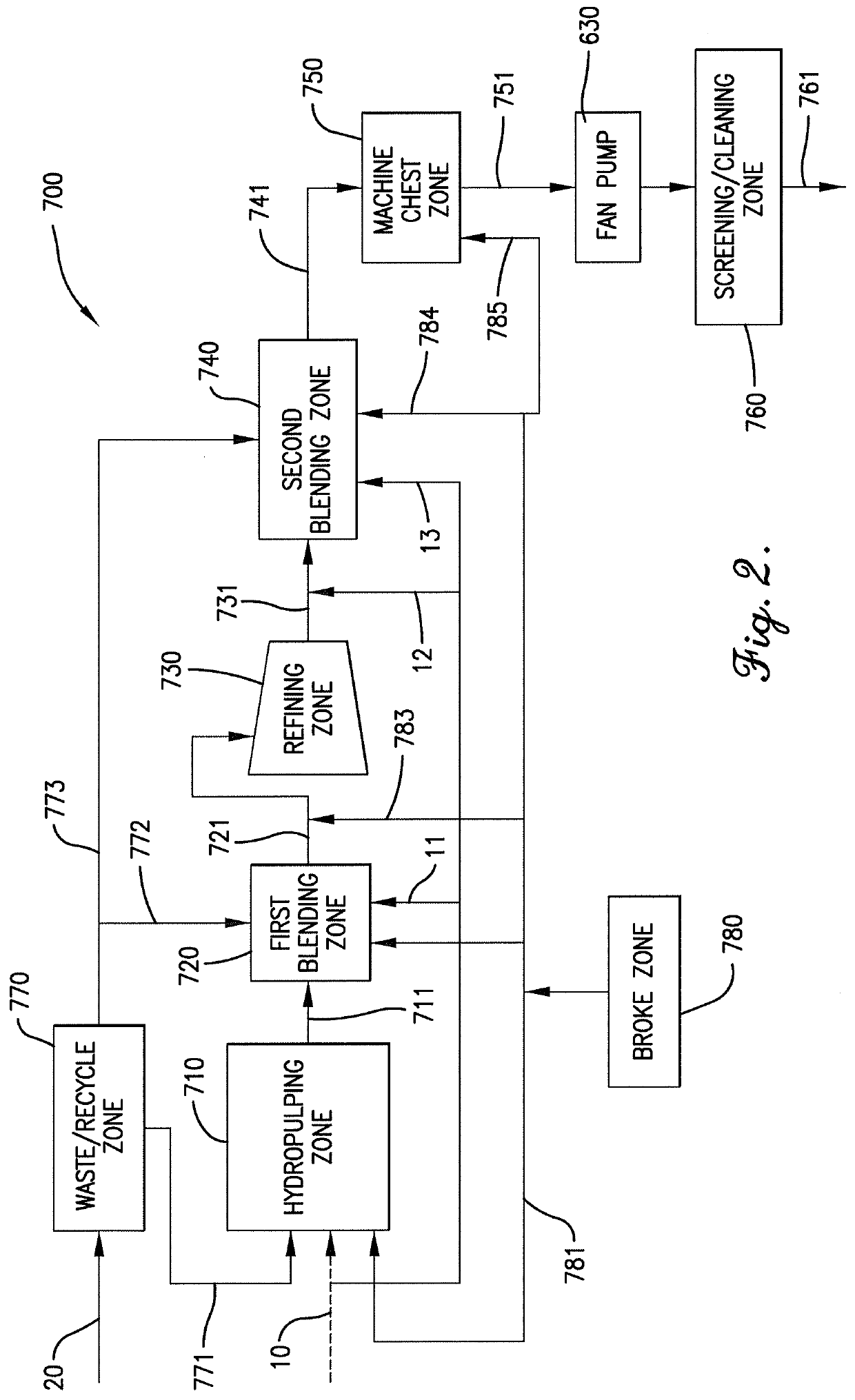

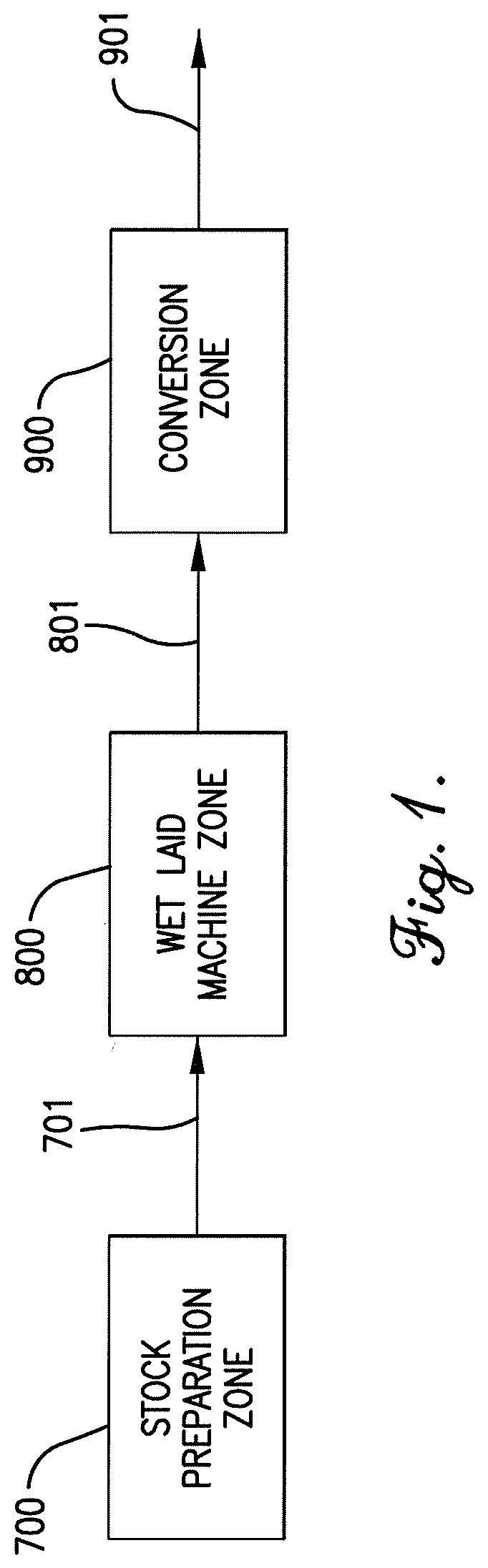

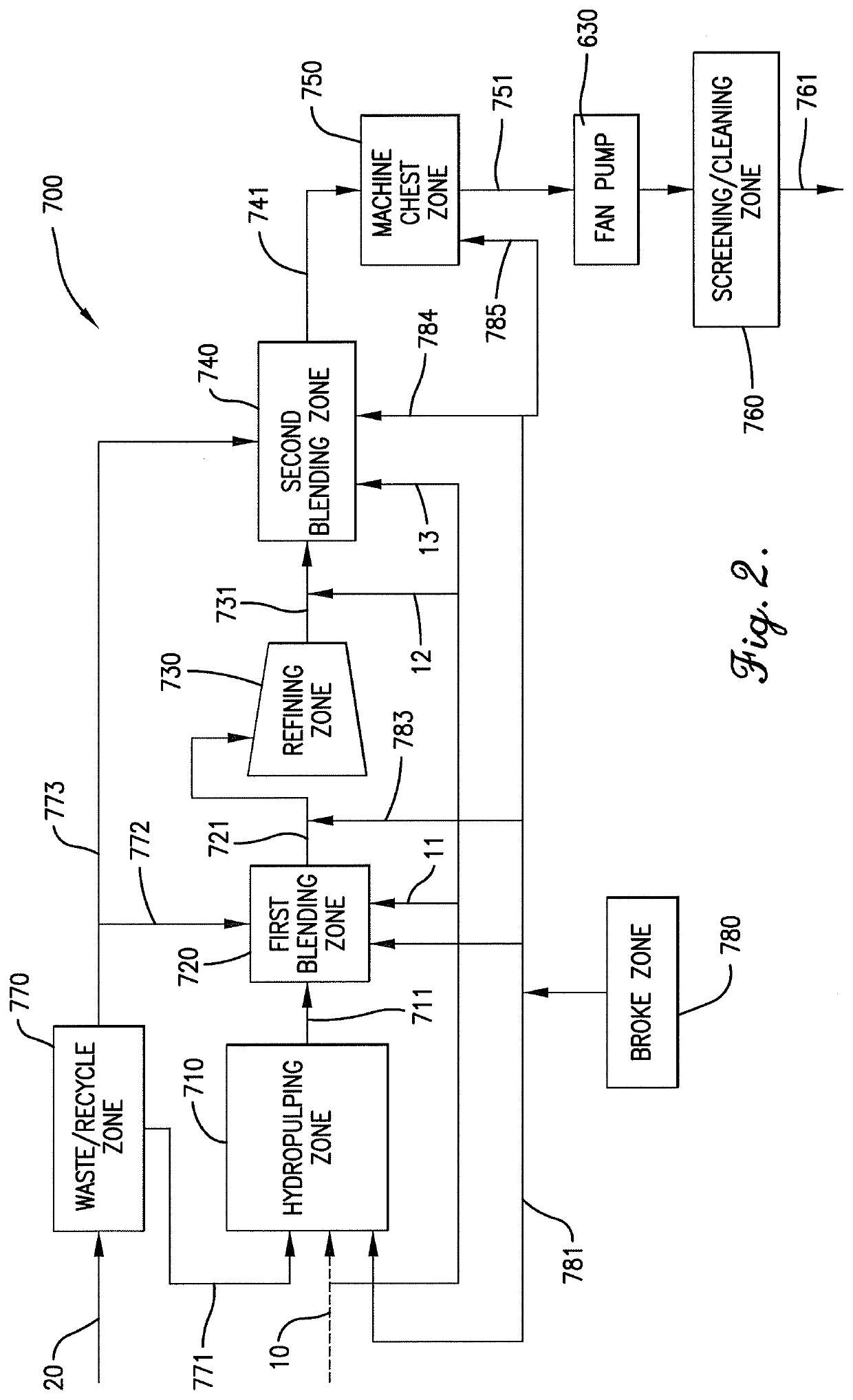

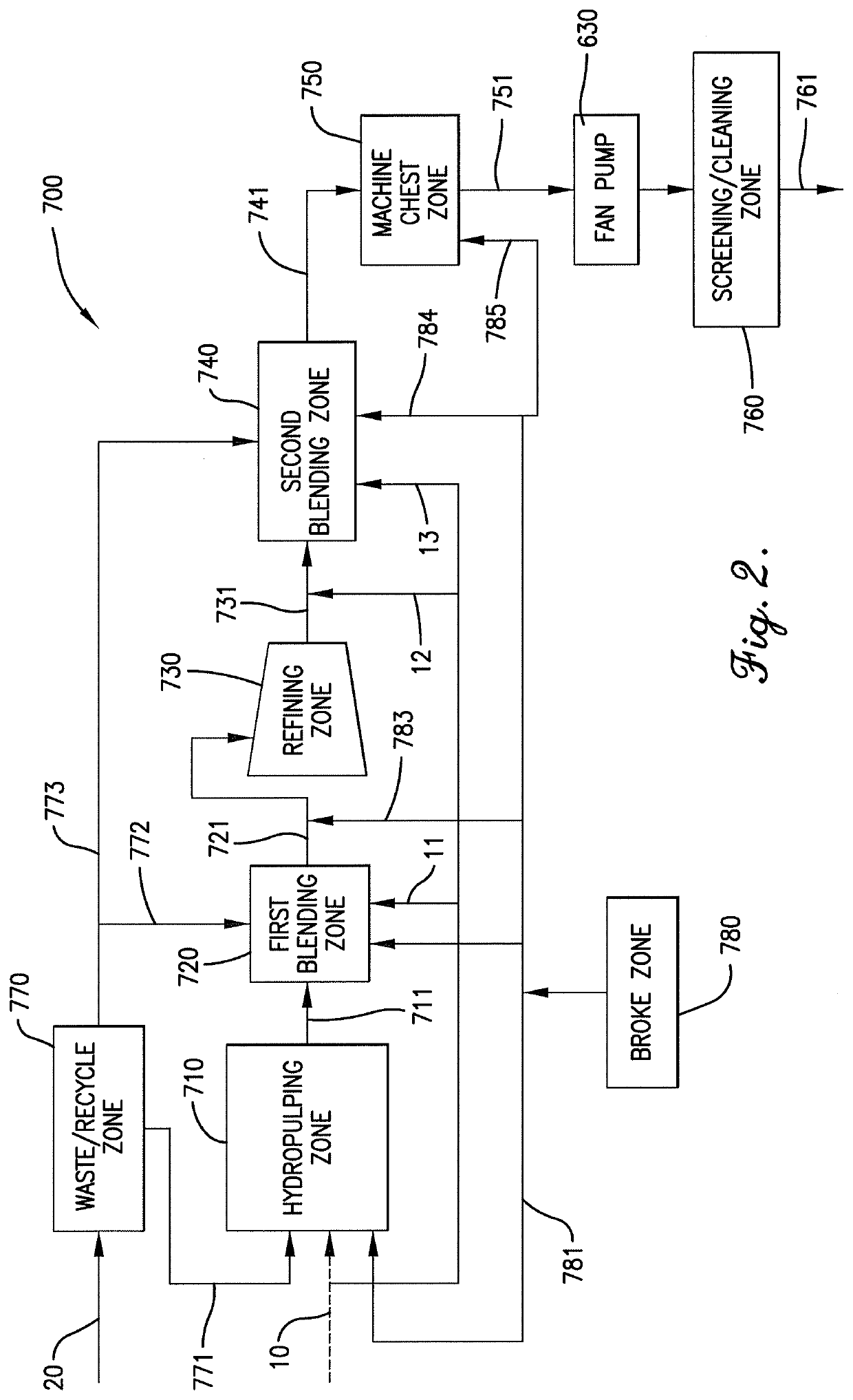

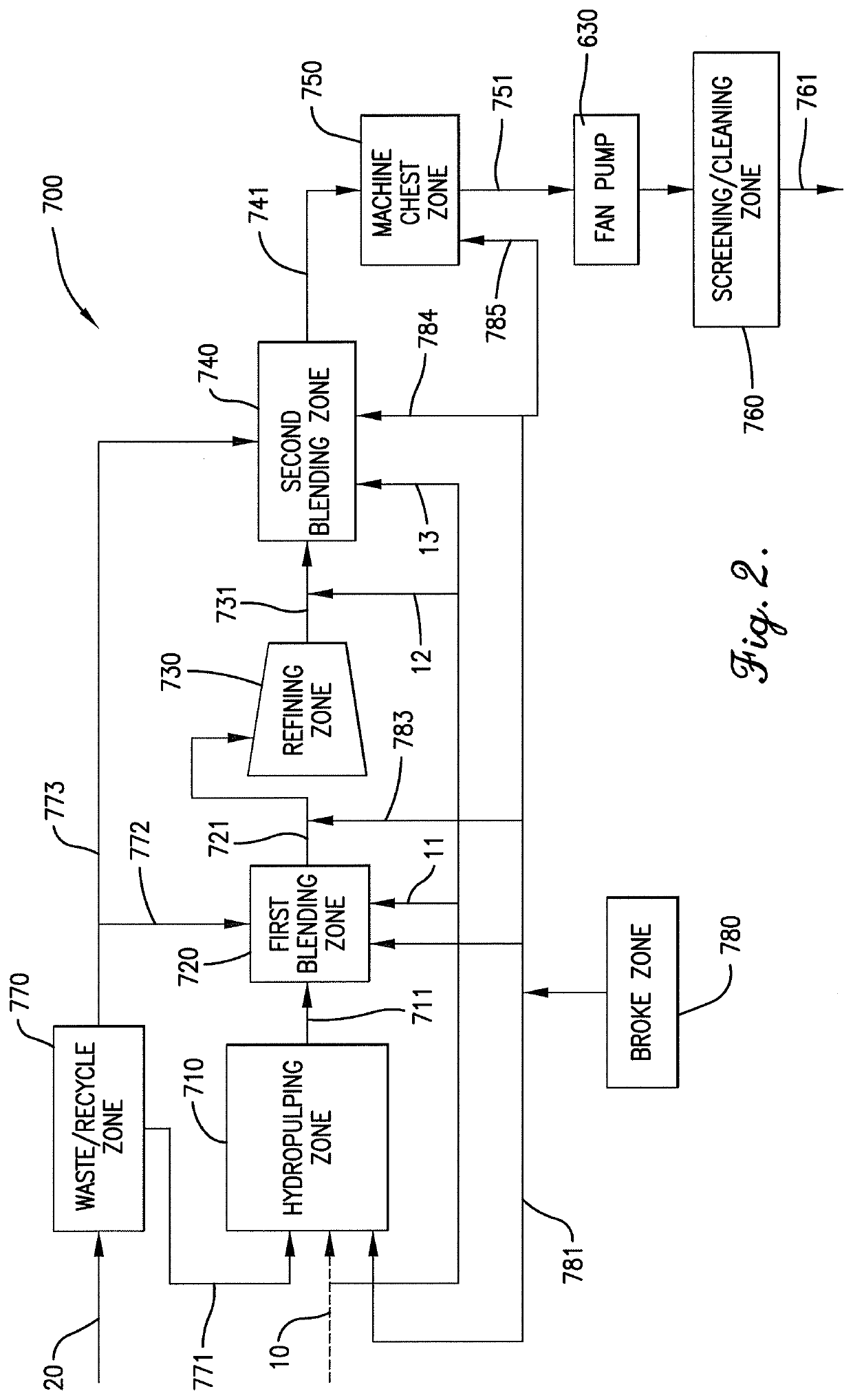

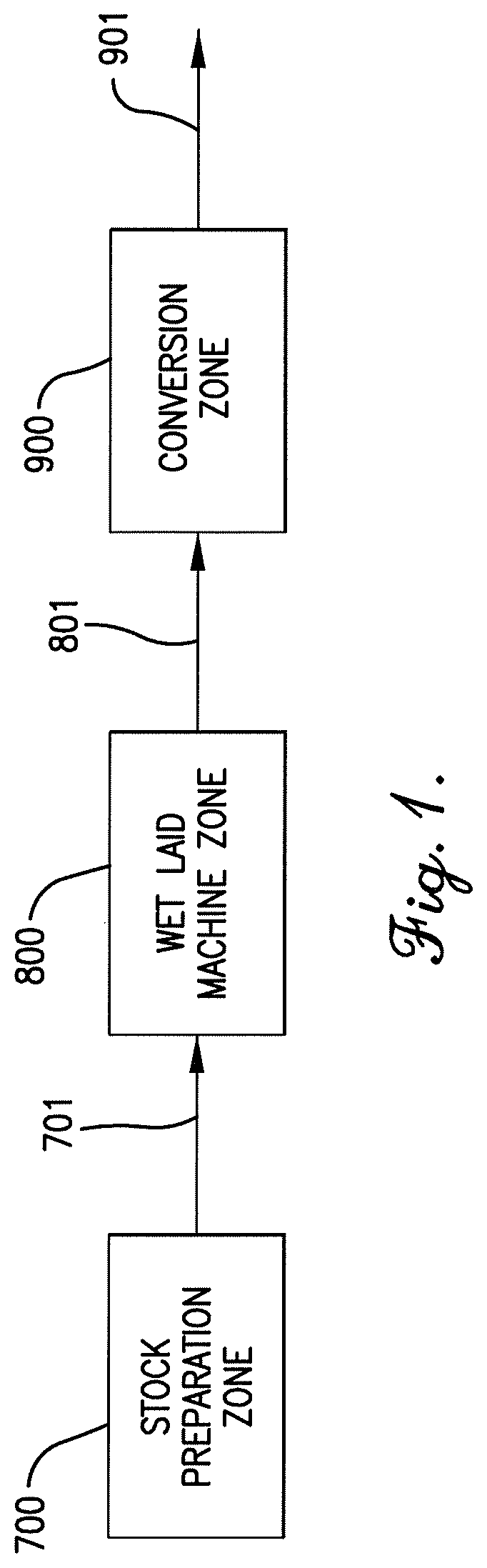

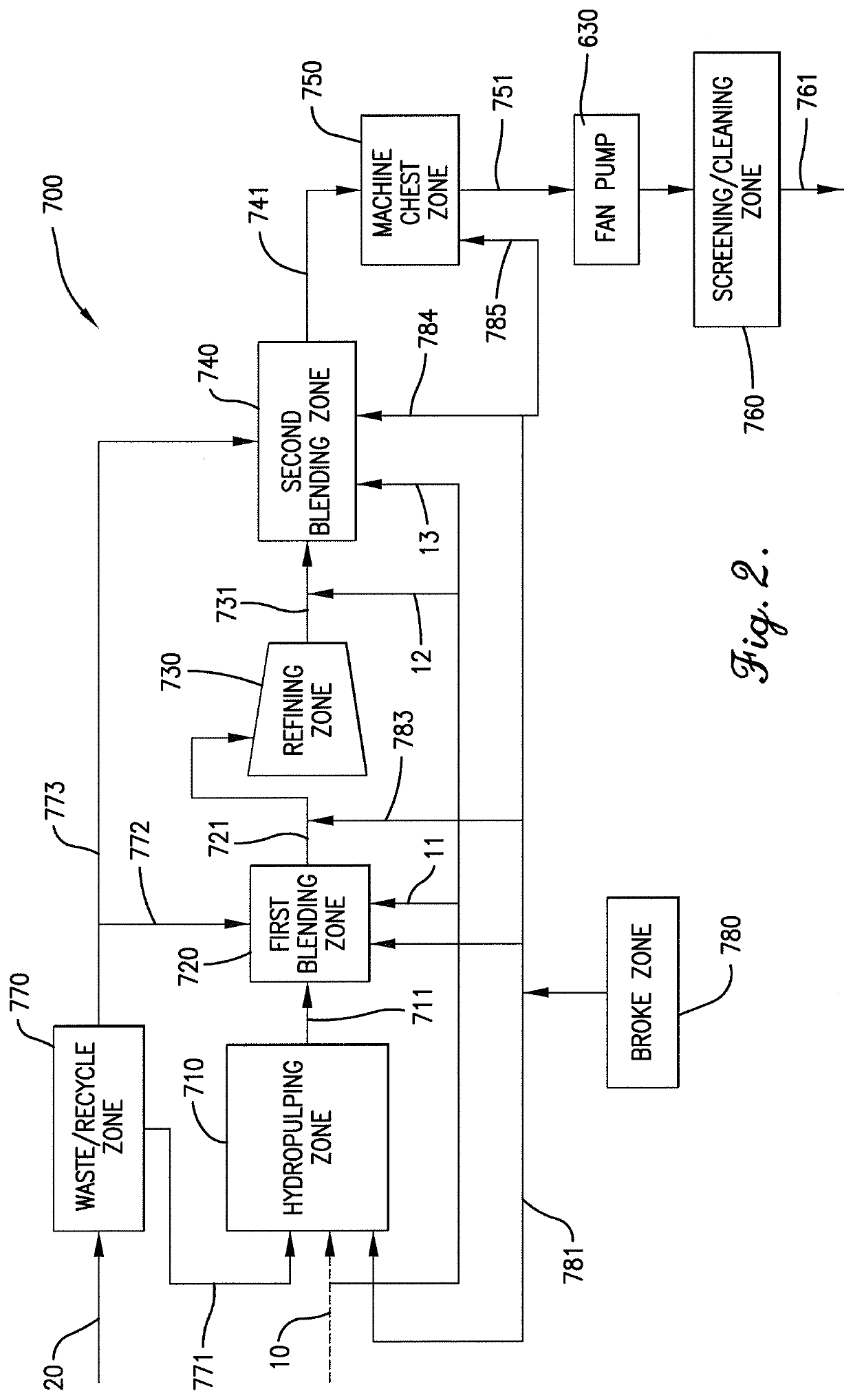

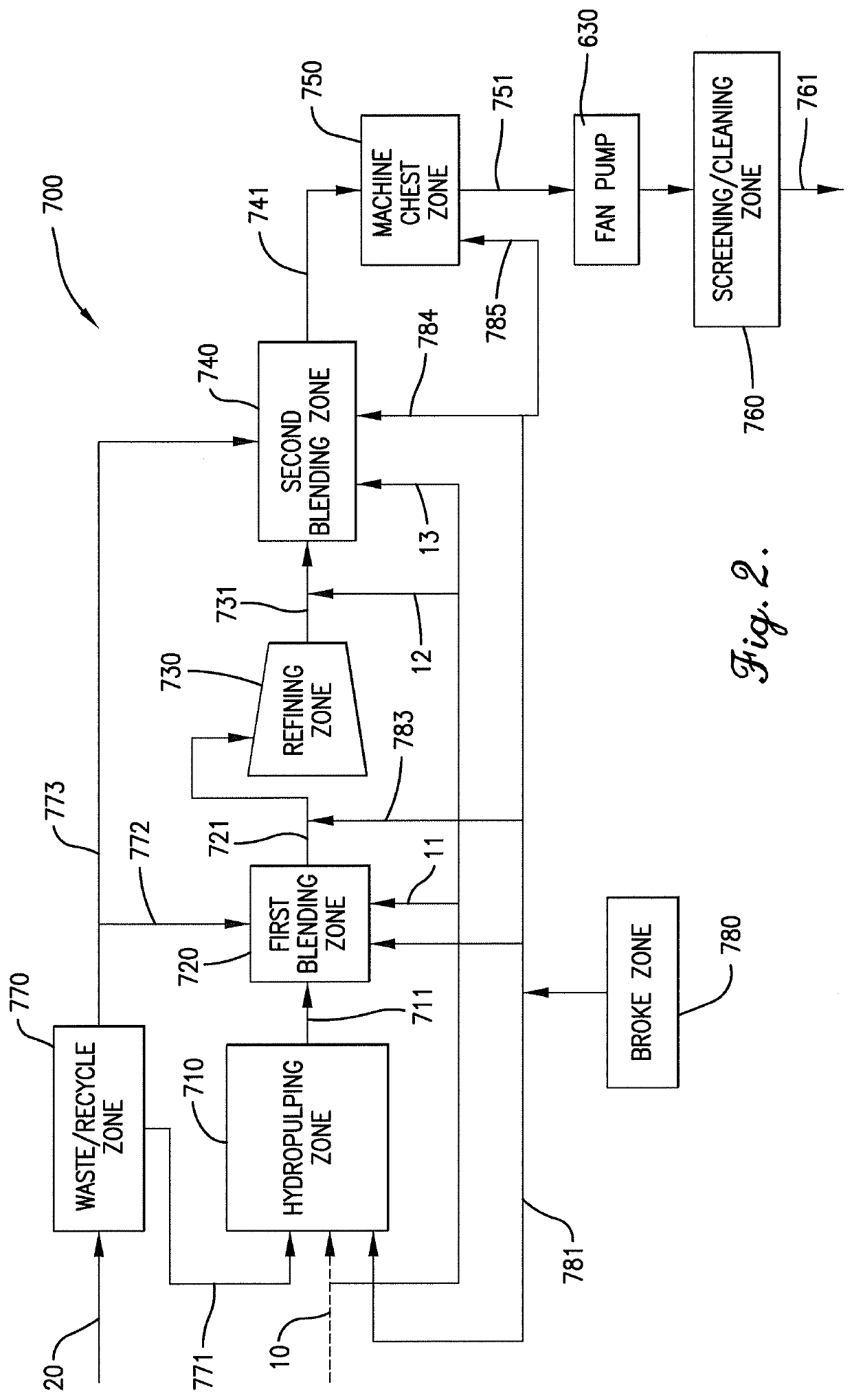

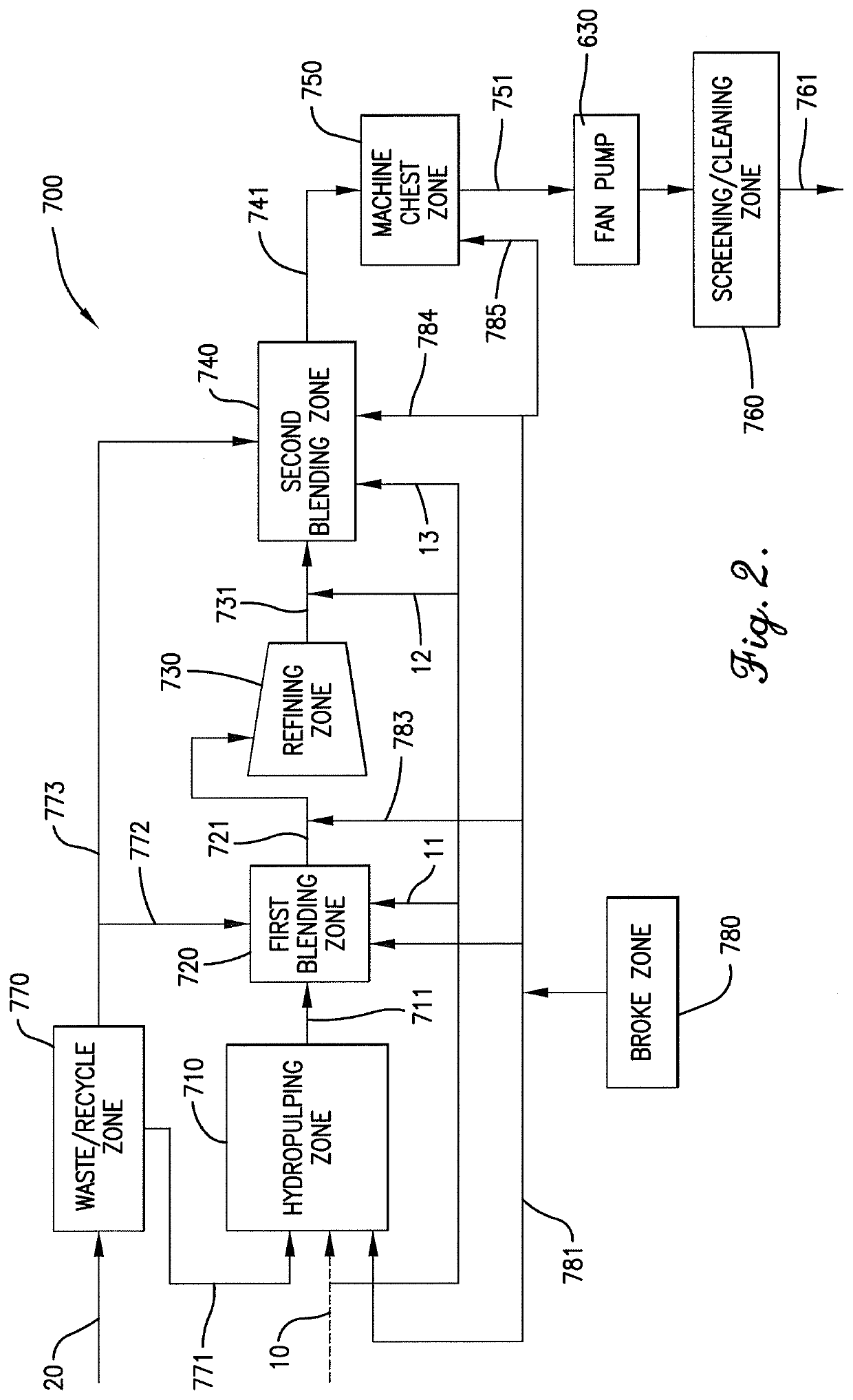

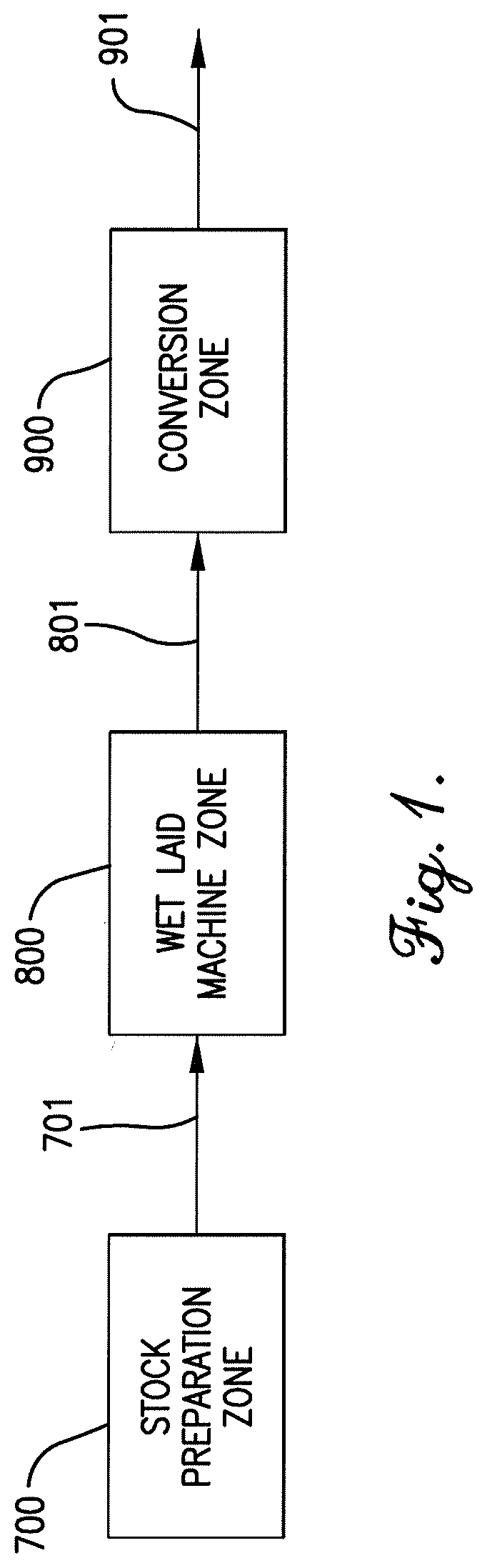

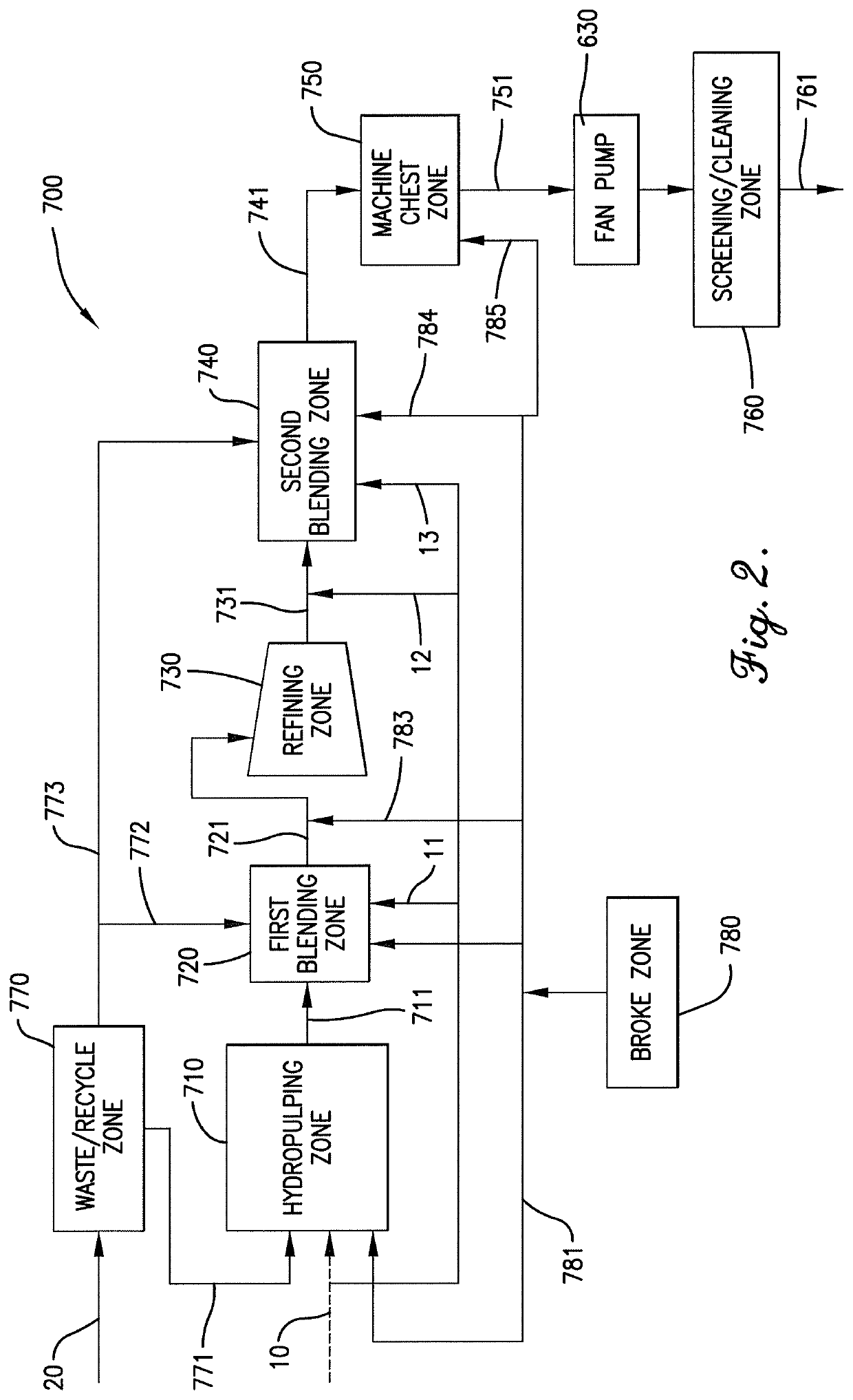

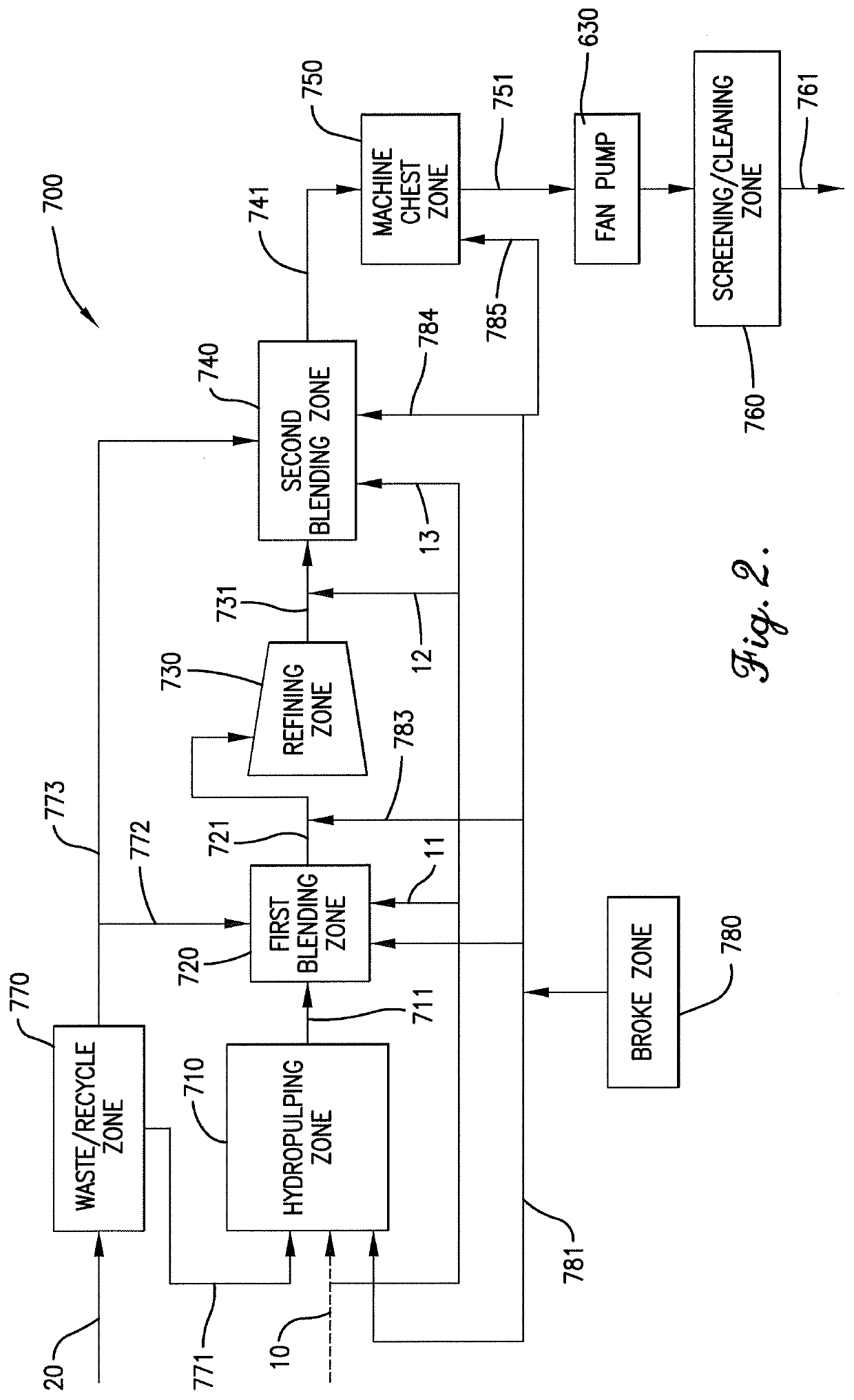

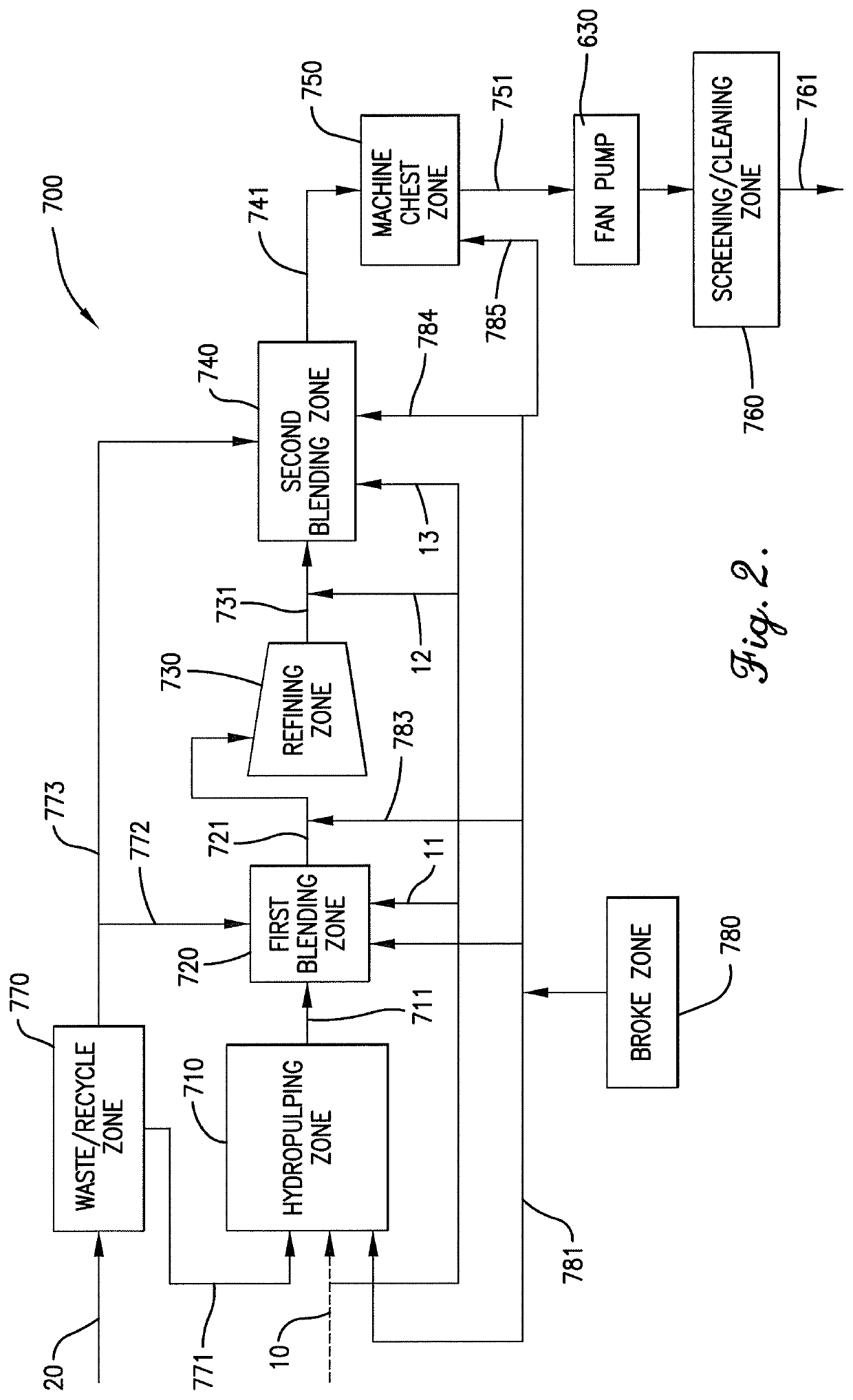

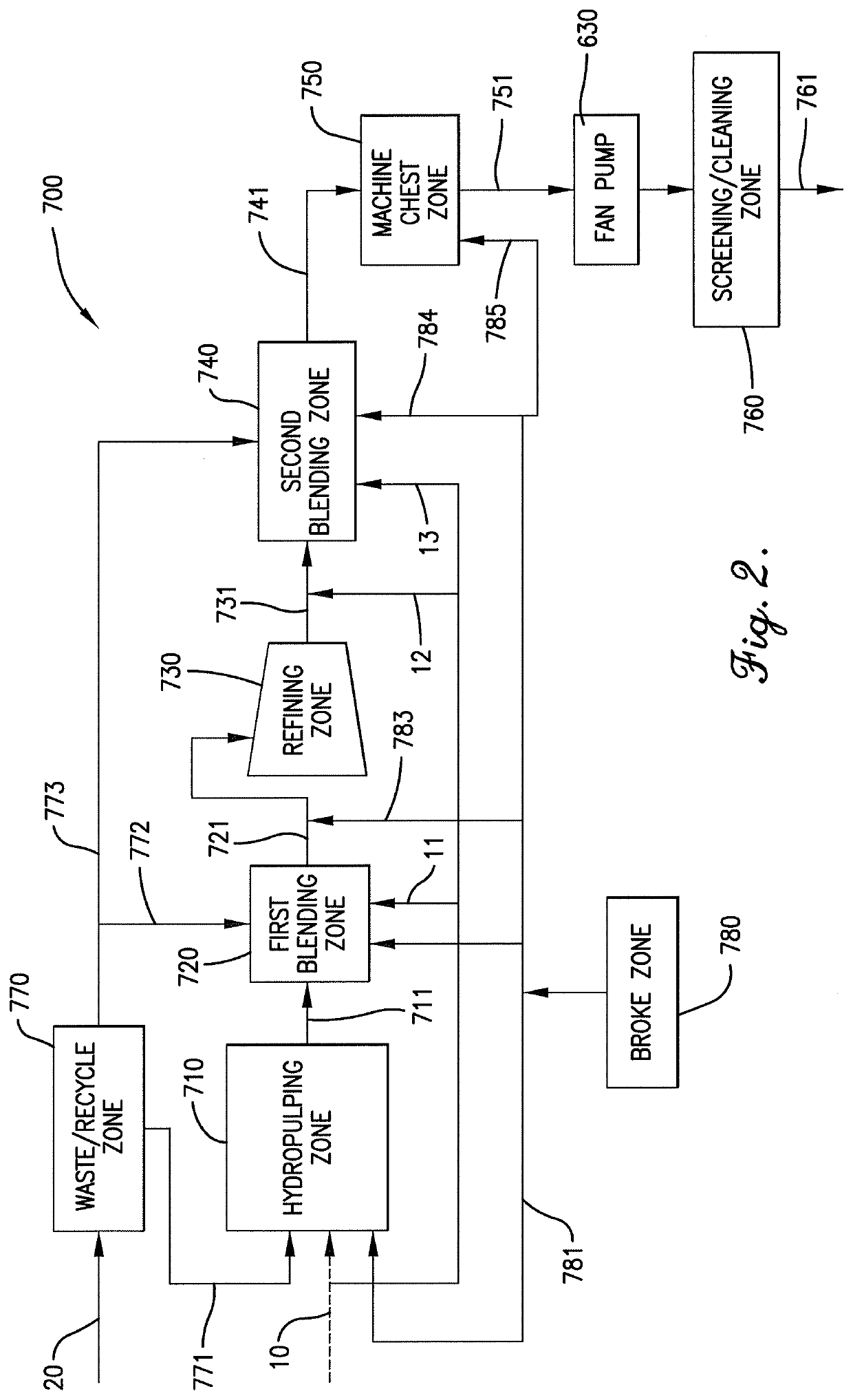

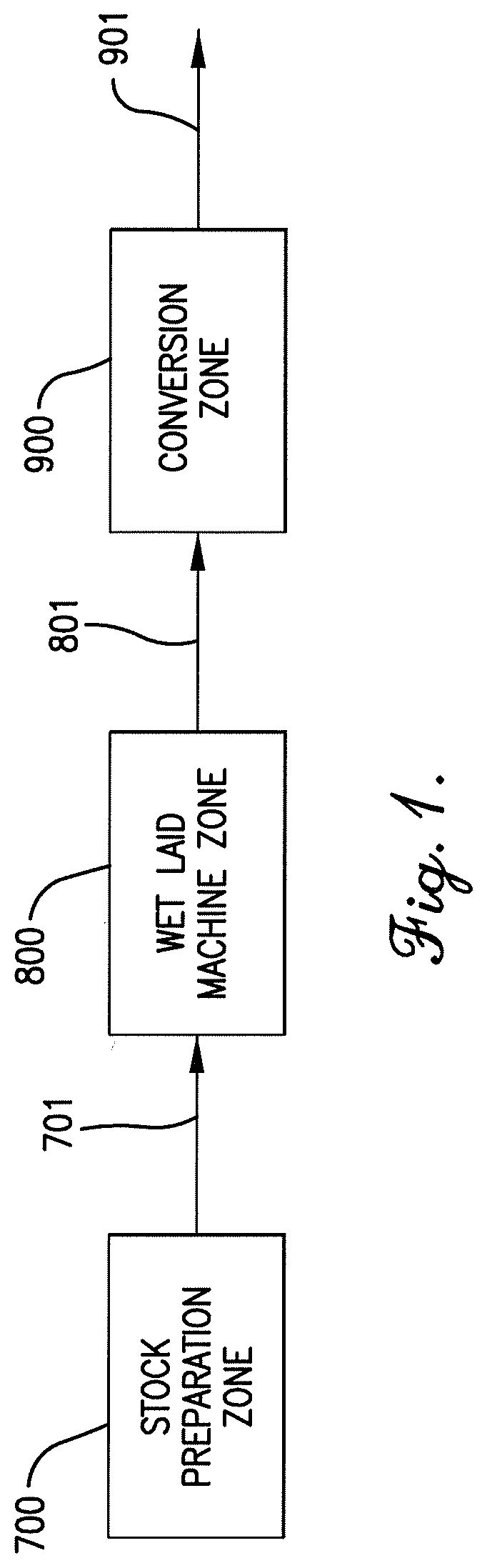

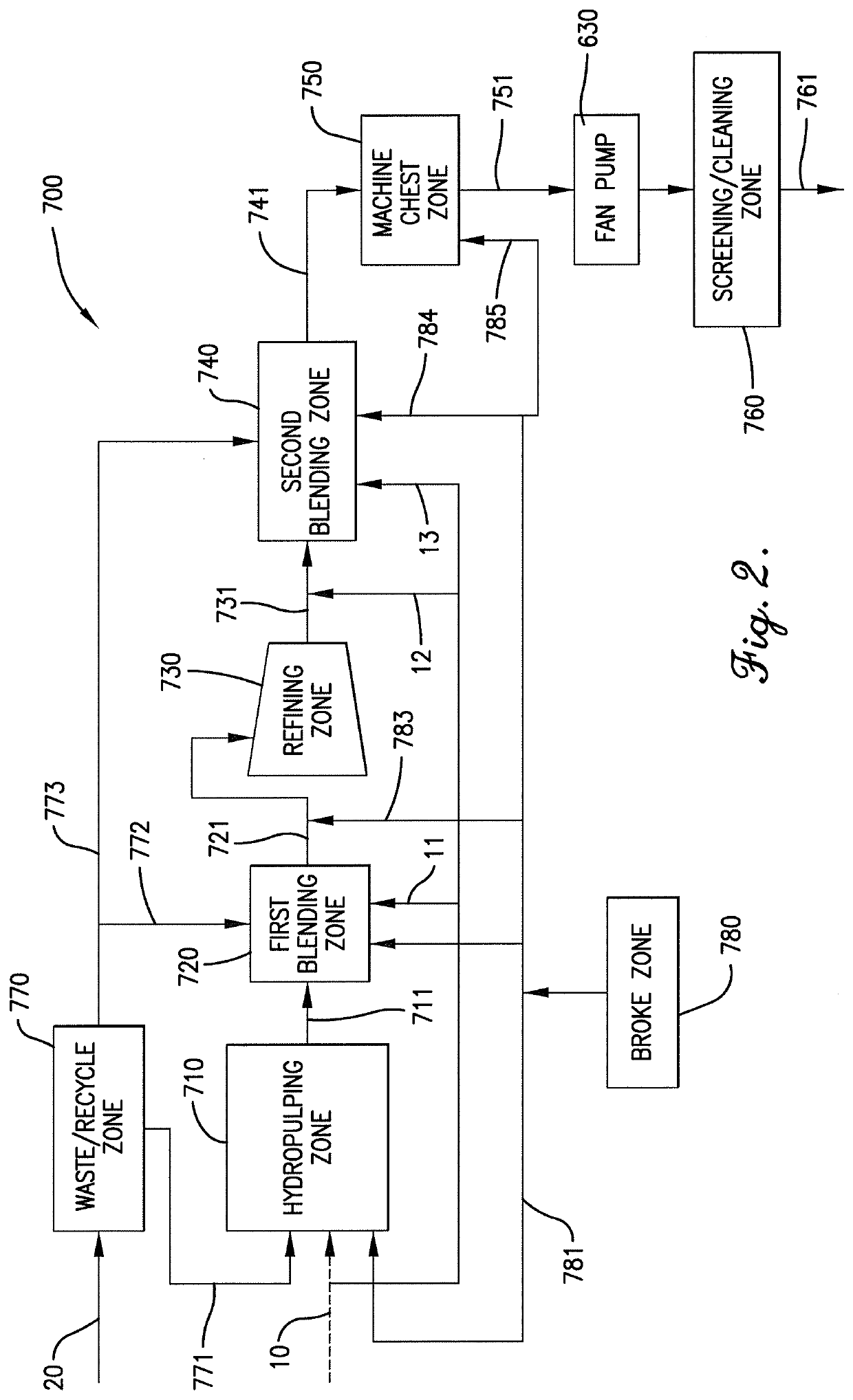

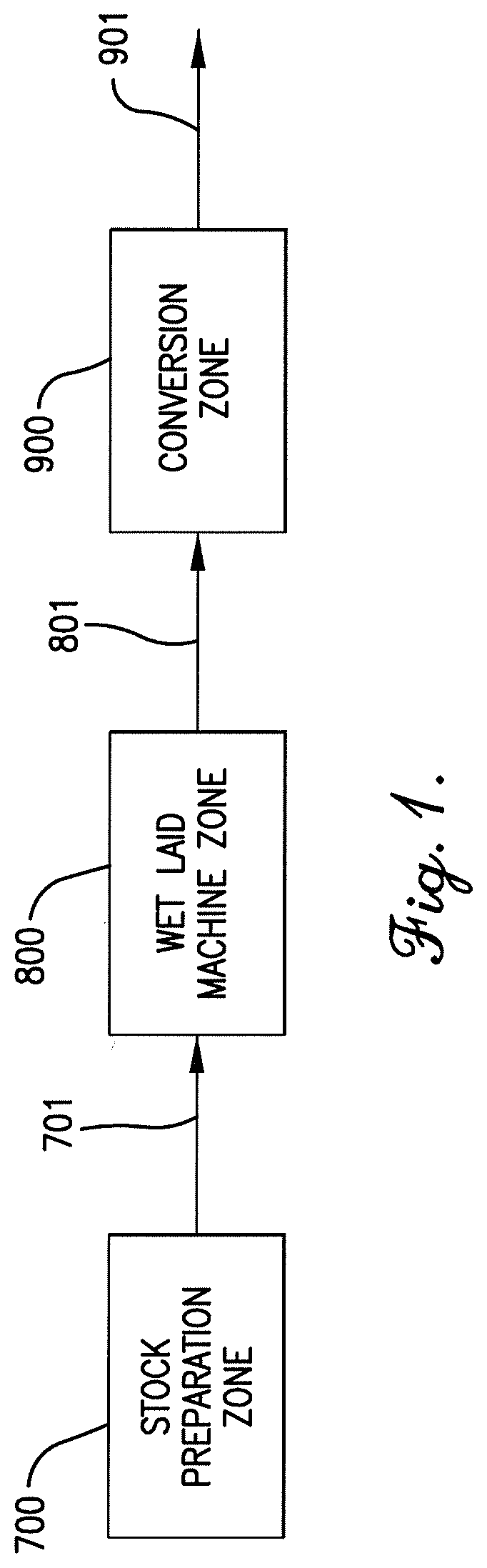

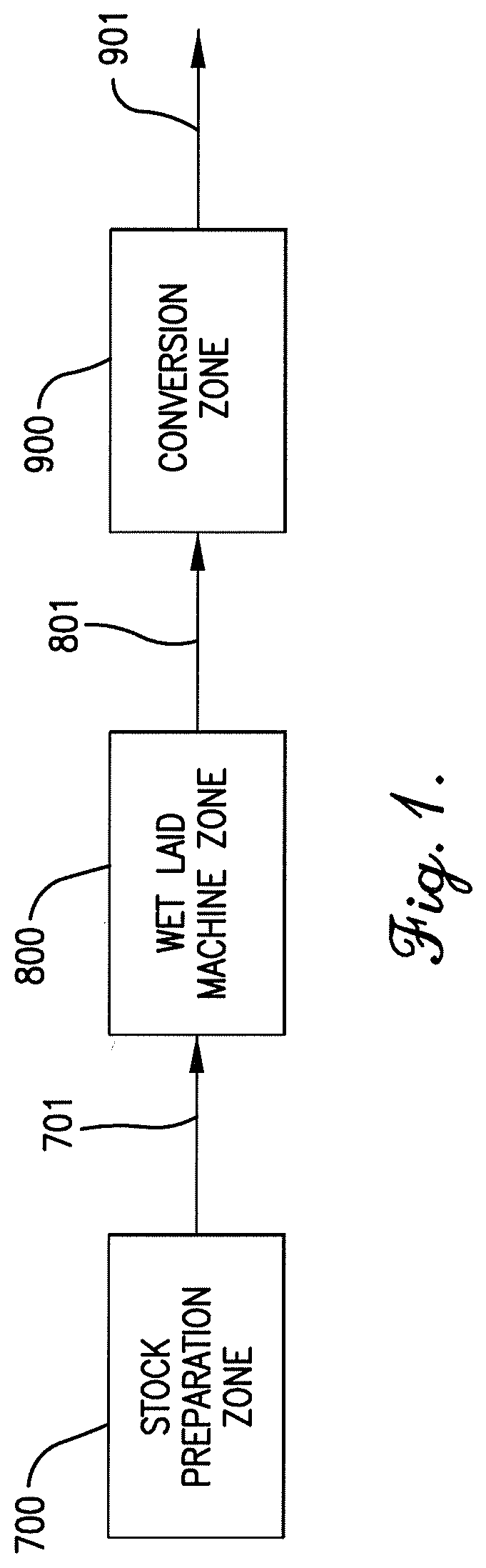

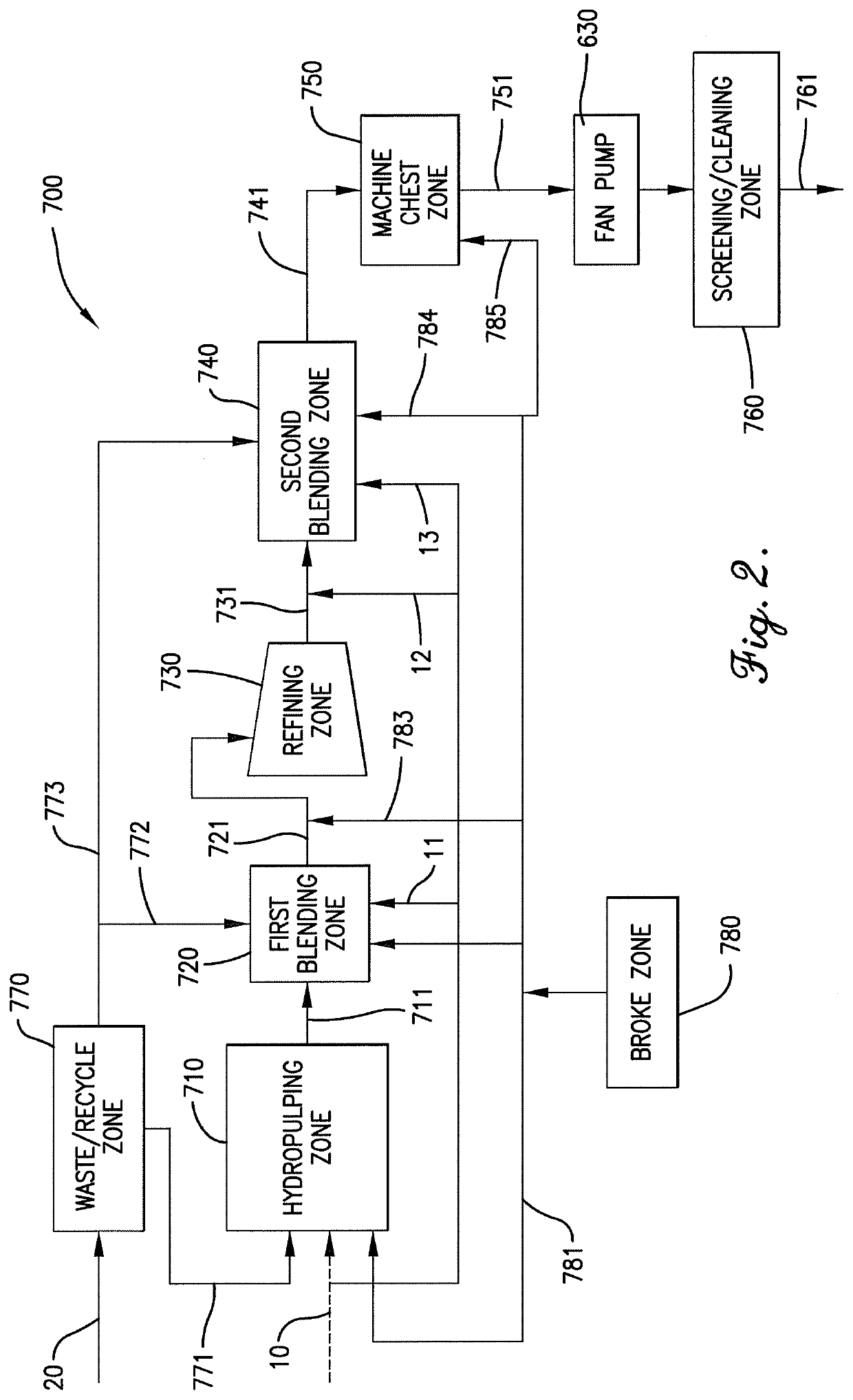

Composition of matter in stock preparation zone of wet laid process

ActiveUS20200063356A1Reduce consistencyLow variabilityPaper/cardboardNon-woven fabricsBursting strengthCardboard

A composition obtained by combining virgin cellulose fibers, cellulose ester (CE) staple fibers having a denier per filament (DPF) of less than 3, and water, and water. The CE staple fibers can also have a short cut length of less than 6 mm and can be crimped. The compositions, when co-refined, are useful to make wet laid products such as paper, cardboard, and filters that have improved water drainage, air permeability, tensile strength, bulk, burst strength, or stiffness, or a combination of these properties.

Owner:EASTMAN CHEM CO

Waste recycle composition

ActiveUS20200063347A1Reduce consistencyLow variabilityPaper recyclingNon-woven fabricsPolymer scienceCellulose fiber

A recycled cellulose pulp composition is provided which comprises recycled cellulosic fibers and cellulose ester staple fibers. The recycled cellulose pulp containing co-refined re-cycled cellulose fibers and cellulose ester staple fibers can be added to a hydropulper and fed back through a refiner to make wet laid products.

Owner:EASTMAN CHEM CO

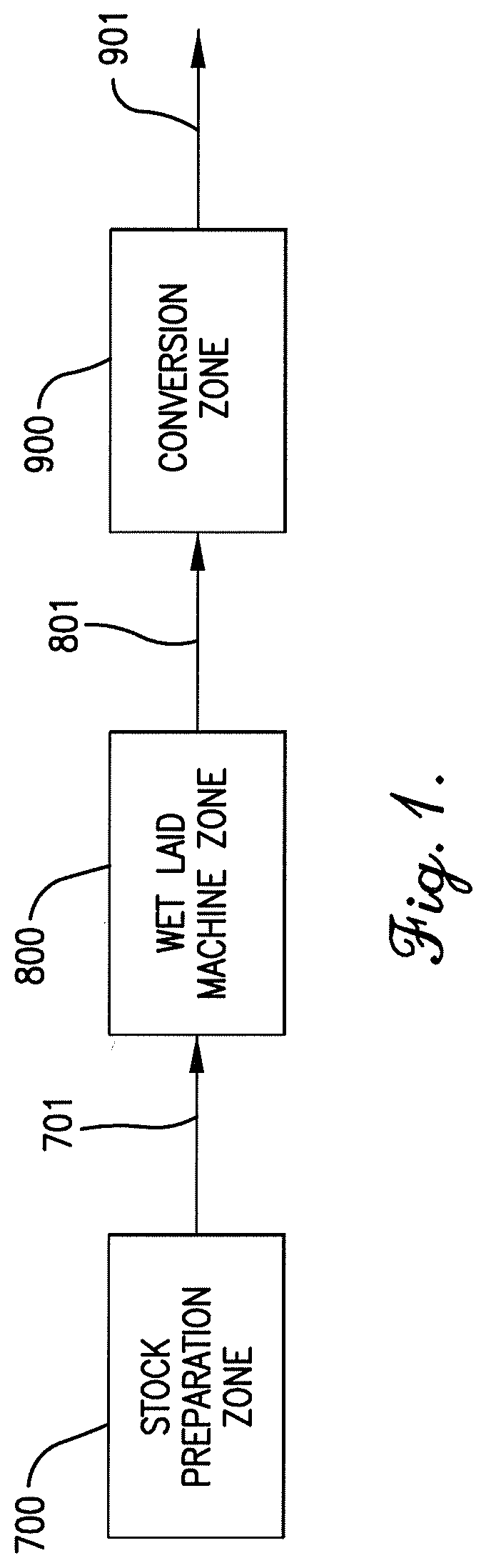

Addition of cellulose esters to a paper mill without substantial modifications

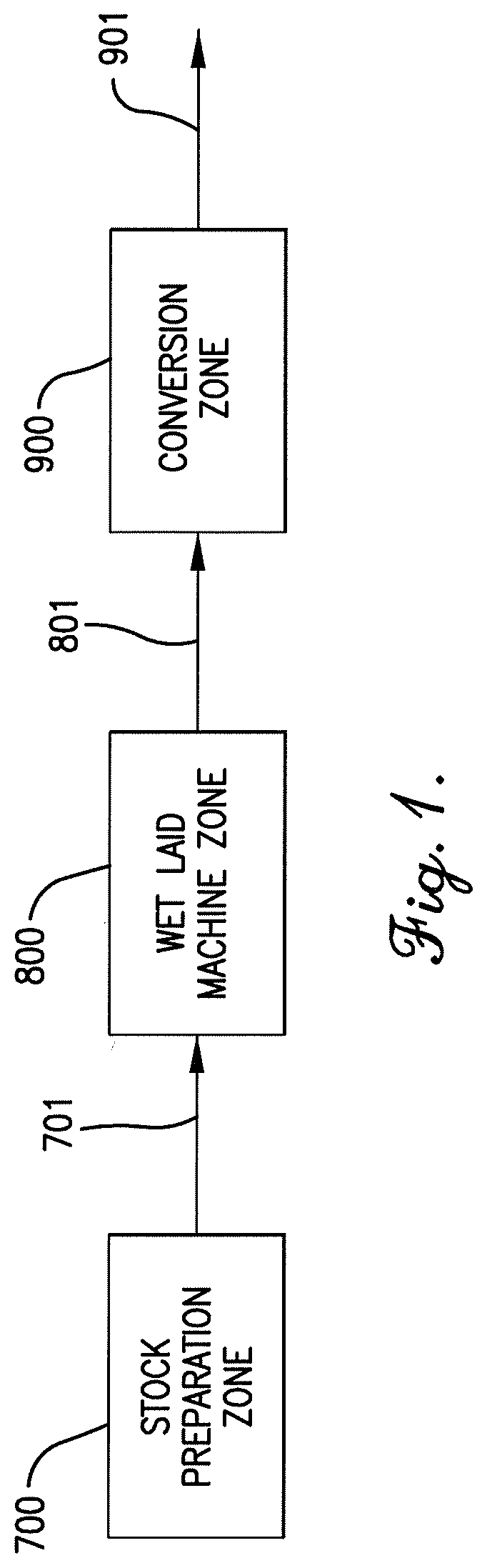

ActiveUS20200063342A1Reduce consistencyLow variabilityMachine wet endPaper/cardboardPolymer scienceCellulose acetate

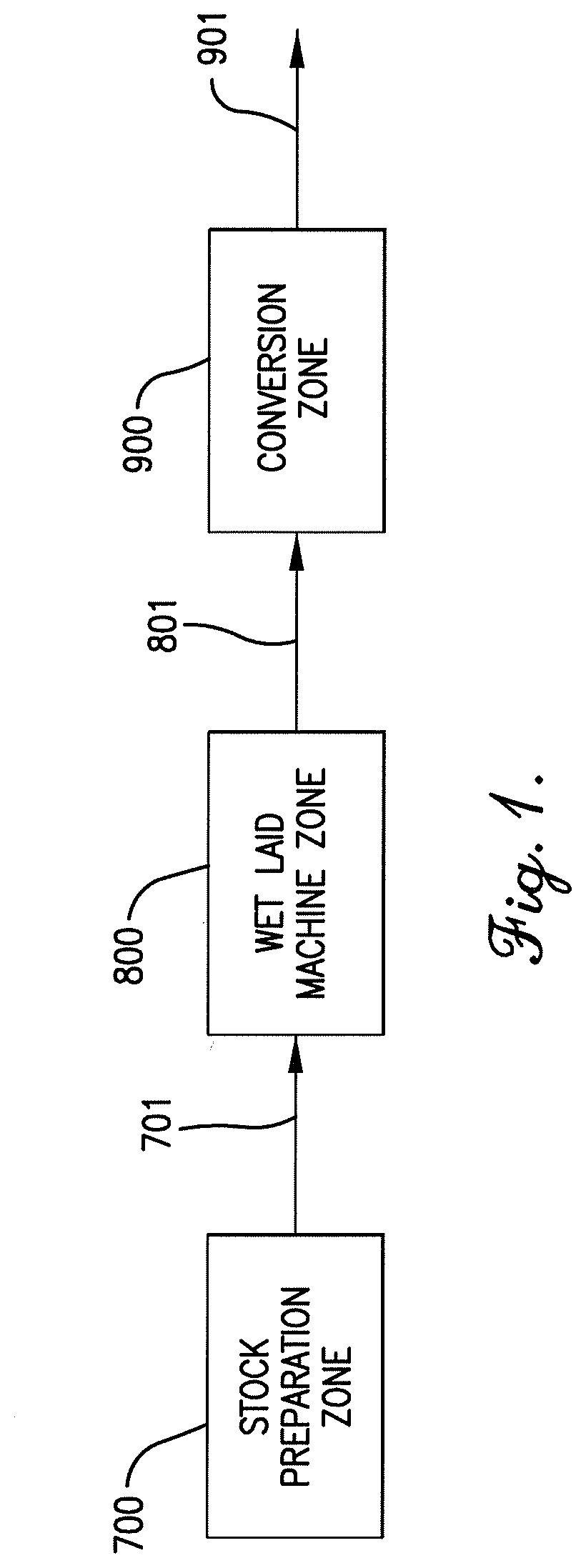

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many the desired benefits. This invention also relates to a process to produce a wet laid article in a paper mill, said process comprising adding cellulose ester staple fiber to a hydropulper zone, and / or to a refining zone, and / or after the refining zone wherein said paper mill process is not substantially modified to allow for said adding of said cellulose ester

Owner:EASTMAN CHEM CO

Water removal between wire and wet press of a paper mill process

ActiveUS20200063345A1High removal rateReduce consistencyPulp de-wateringPaper/cardboardPolymer scienceCellulose acetate

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many desired benefits.

Owner:EASTMAN CHEM CO

Composition of matter in a pre-refiner blend zone

ActiveUS20200063357A1Reduce consistencyLow variabilityWater-repelling agents additionPaper/cardboardAntifoam agentPolymer chemistry

A composition is contained a blend zone prior to refining containing non-fibrillated virgin cellulose fibers, waste / recycle cellulose fibers or both; cellulose ester fibers, water, and one or more additives comprising fillers, internal sizing agents, biocides, process anti-foaming agents, colorants, optical modifiers, or a combination thereof. An in-line mixer can be used for adding the additives, and the consistency of the composition is lowered relative to a feed of material from a hydropulper.

Owner:EASTMAN CHEM CO

Broke composition of matter

ActiveUS20200063360A1Reduce consistencyLow variabilityMachine wet endPaper/cardboardCellulose fiberSingle filament

Broke pulp in a paper making process is obtained by pulping broke, and the broke pulp is made of fibrillated cellulose fibers and cellulose ester (CE) staple fibers having a denier per filament (DPF) of less than 3, or a cut length of less than 6 mm, or crimped, or non-round with a DPF of less than 3. The broke pulp can be added to the stock preparation zone of a wet laid manufacturing facility and fed through a refiner.

Owner:EASTMAN CHEM CO

Composition of matter effluent from refiner of a wet laid process

ActiveUS20200063339A1Reduce consistencyLow variabilityFats/resins/pitch/waxes removal in pulpChemical/chemomechanical pulpPolymer scienceCellulose fiber

A composition and process for making the composition by co-refining: fibrillated virgin cellulose fibers, waste / recycle cellulose fibers, or both; co-refined cellulose ester (CE) staple fibers having a denier per filament (DPF) of less than 3 and the weight percent of CE staple fibers is less than 30 wt. %, based on the weight of CE staple fibers and said cellulose fibers; and water. The composition can be co-refined to obtain lower Canadian standard freeness yet improved drainage and wet laid products having good tensile strength, air permeability, stiffness, burst strength, and bulk.

Owner:EASTMAN CHEM CO

Bale of virgin cellulose and cellulose ester

ActiveUS20200063363A1Reduce consistencyLow variabilityDigestersPaper/cardboardPolymer scienceEngineering

A bale of sheets made of virgin cellulose fibers and cellulose ester (CE) staple fibers can be fed to a hydropulper. The CE staple fibers have:i. a denier per filament (DPF) of less than 3, orii. a cut length of less than 6 mm, oriii. crimping, oriv. a combination of any two or more of (i)-(iii).The bales can be fed and dropped in as entire bales to a hydropulper, or a blend tank directly or indirectly in fluid communication with a hydropulper, using the same feed system employed for feeding cellulose to the hydopulper and avoiding having to defiberize by pulling or drawing fibers from a box container into a hydropulper.

Owner:EASTMAN CHEM CO

Recycle bale comprising cellulose ester

ActiveUS20200063362A1Reduce consistencyLow variabilityPaper recyclingPaper/cardboardPolymer scienceEngineering

A bale of sheets made of waste / recycle cellulose fibers and cellulose ester (CE) staple fibers can be fed to a hydropulper. The CE staple fibers have:i. a denier per filament (DPF) of less than 3, orii. a cut length of less than 6 mm, oriii. crimping, oriv. a combination of any two or more of (i)-(iii).The bales can be fed and dropped in as entire bales to a hydropulper, or a blend tank directly or indirectly in fluid communication with a hydropulper, using the same feed system employed for feeding cellulose to the hydopulper and avoiding having to defiberize by pulling or drawing fibers from a box container into a hydropulper. The waste / recycle cellulose fibers and CE staple fibers can be co-refined prior to making the bale of sheets.

Owner:EASTMAN CHEM CO

Ultrasonic welding of wet laid nonwoven compositions

ActiveUS11118313B2Reduce consistencyLow variabilitySpecial paperPaper/cardboardPolymer scienceUltrasonic welding

Owner:EASTMAN CHEM CO

Dewatering in paper making process

ActiveUS20200063364A1Reduce consistencyLow variabilityPaper-making machinesSynthetic cellulose fibresPolymer scienceCellulose acetate

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many desired benefits.

Owner:EASTMAN CHEM CO

Refining to a desirable freeness

ActiveUS20200063343A1Maintaining and increasing Canadian freenessDecreasing Williams slownessPaper/cardboardPulp beating/refining methodsPolymer scienceCellulose acetate

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many desired benefits.

Owner:EASTMAN CHEM CO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com