Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Precision seeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Movable bin single-seed precision hill seeder

InactiveCN102090186ACompact structureReduce volumeFertiliser distributersSeed depositing seeder partsSeederWhole body

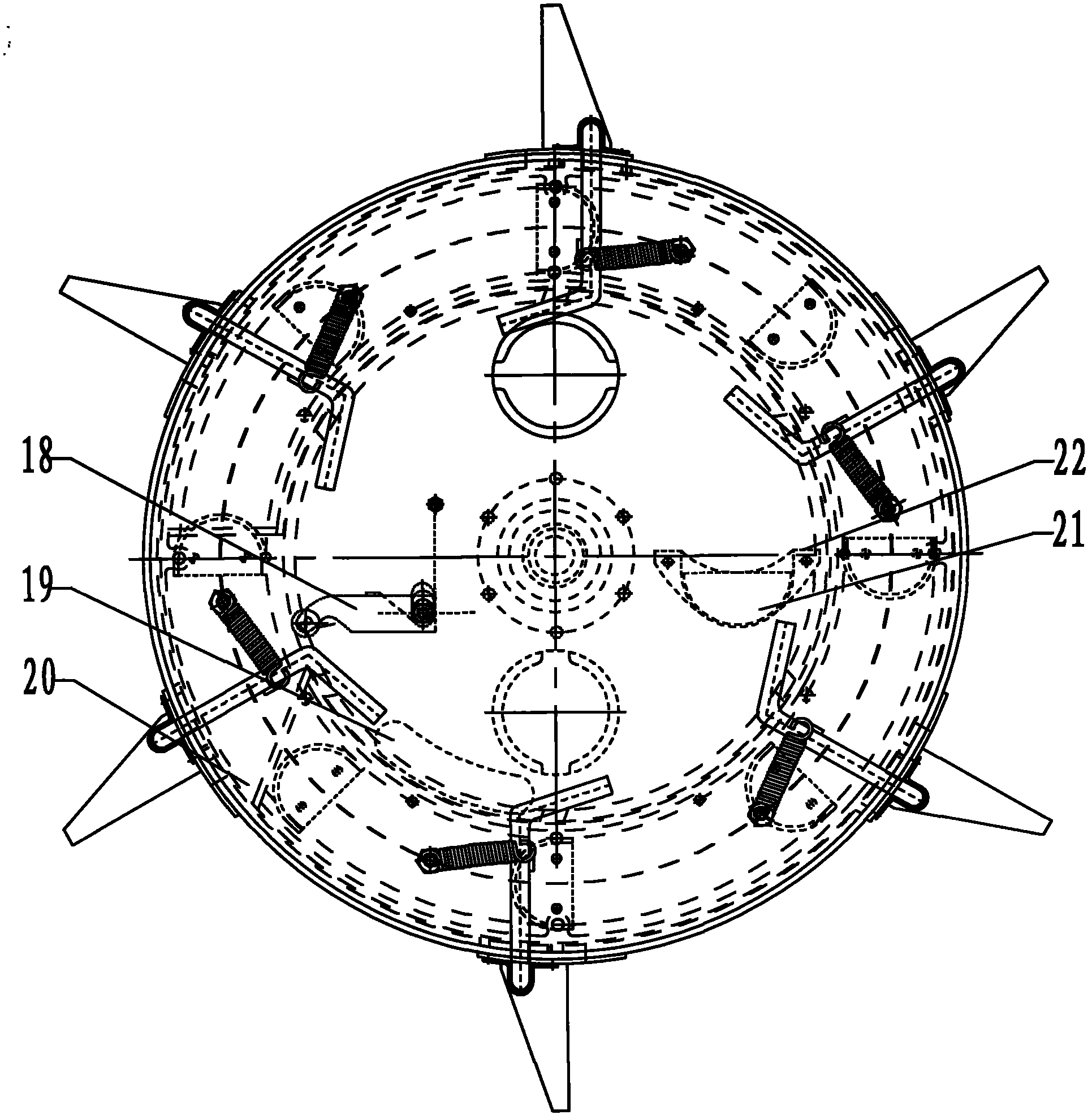

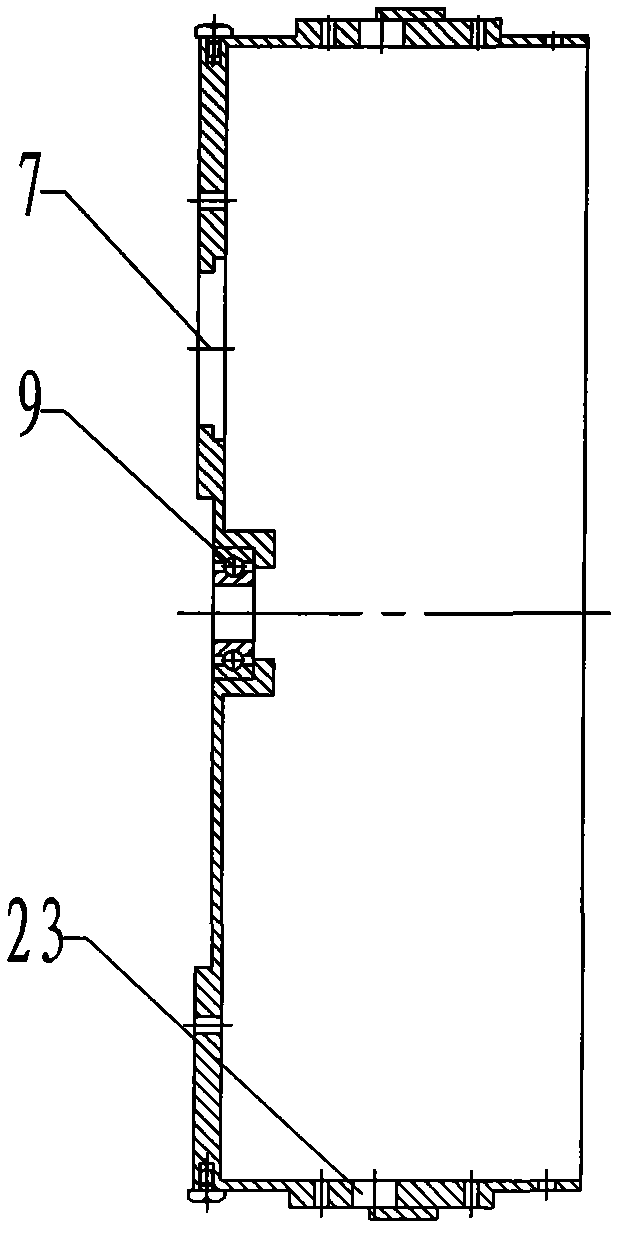

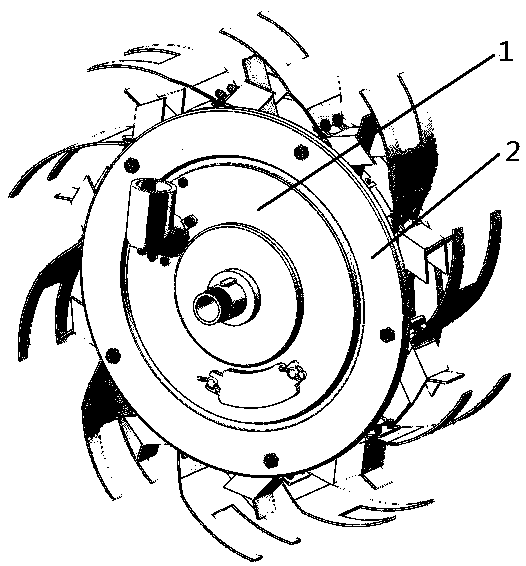

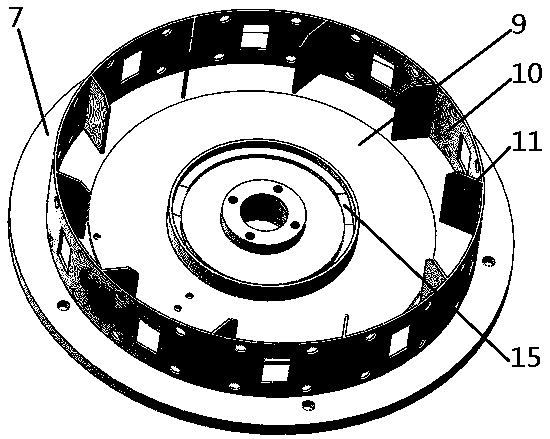

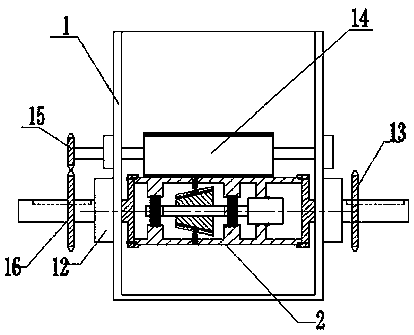

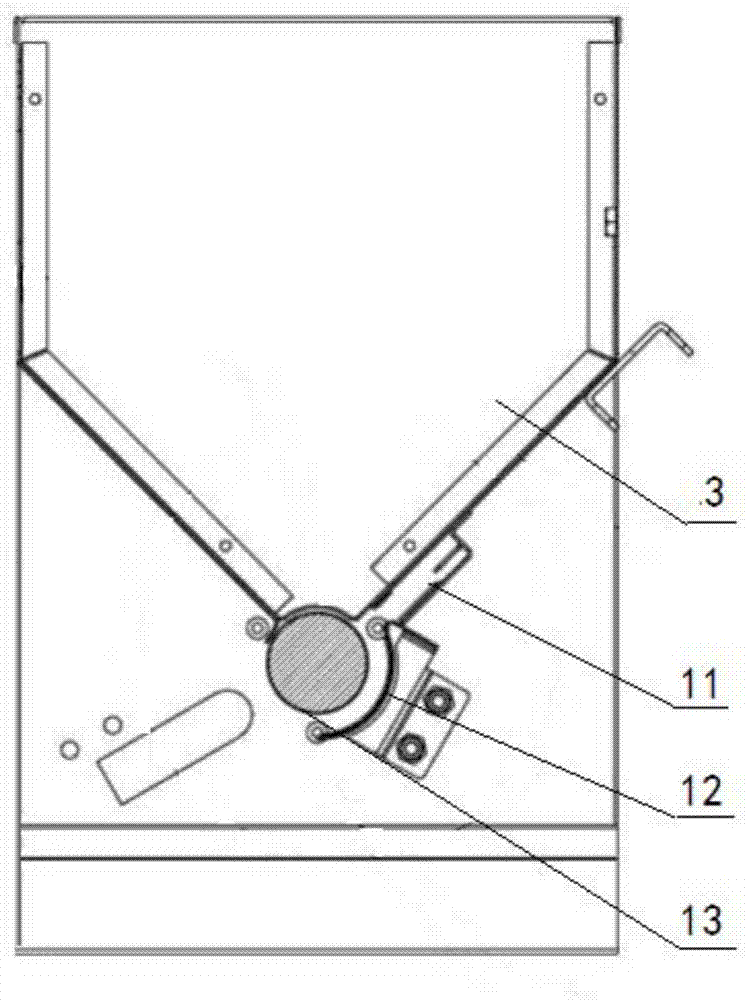

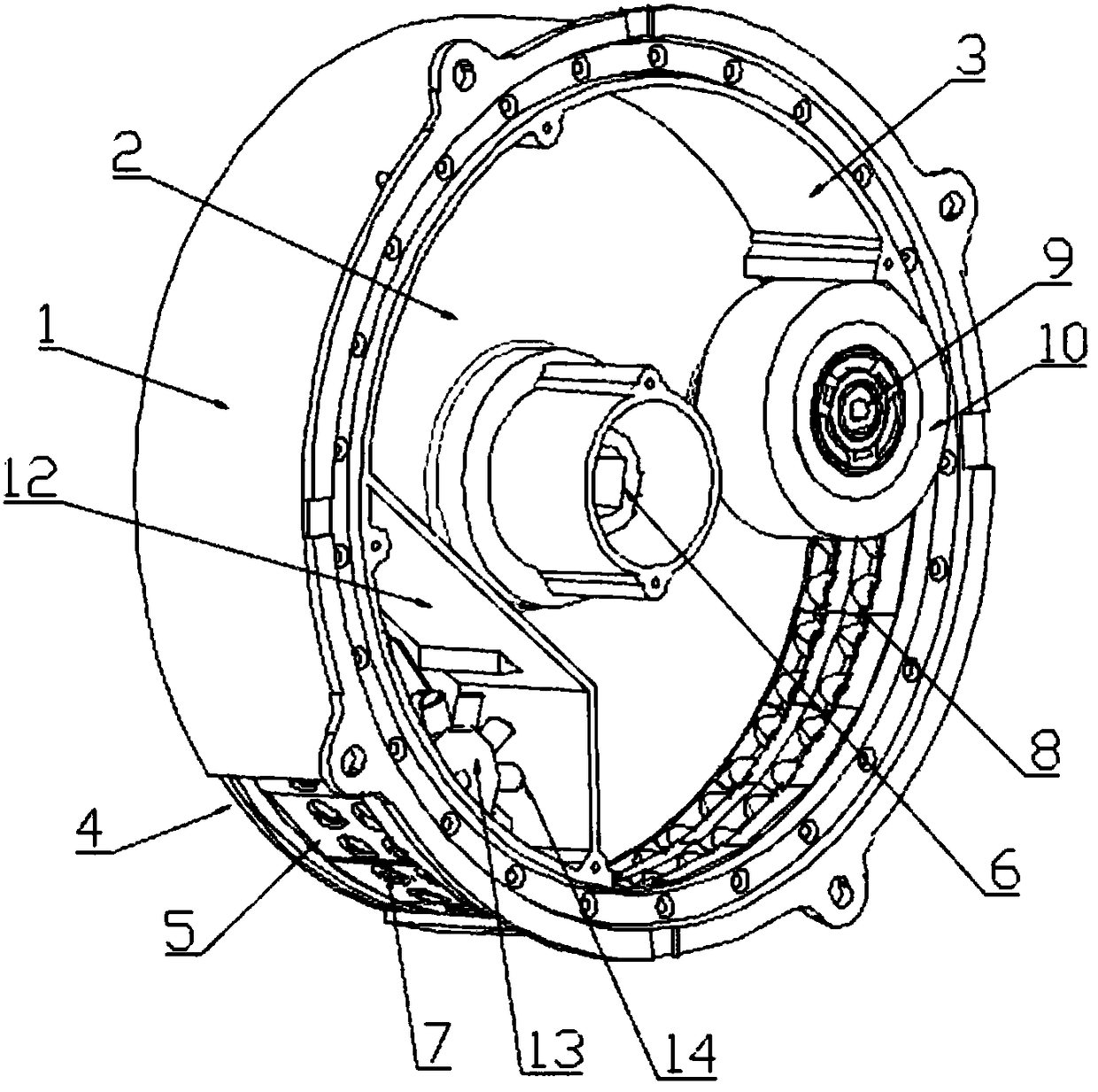

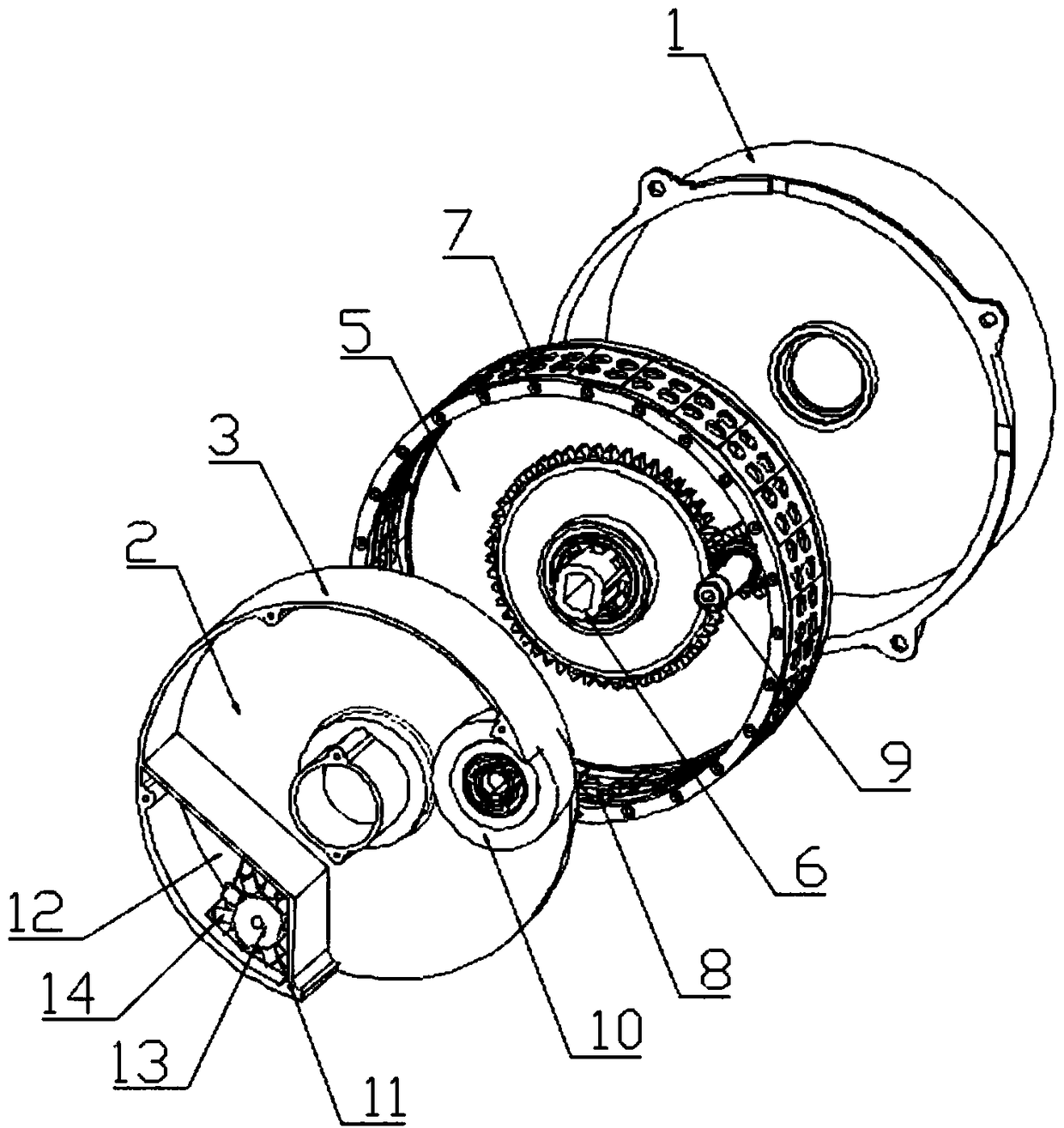

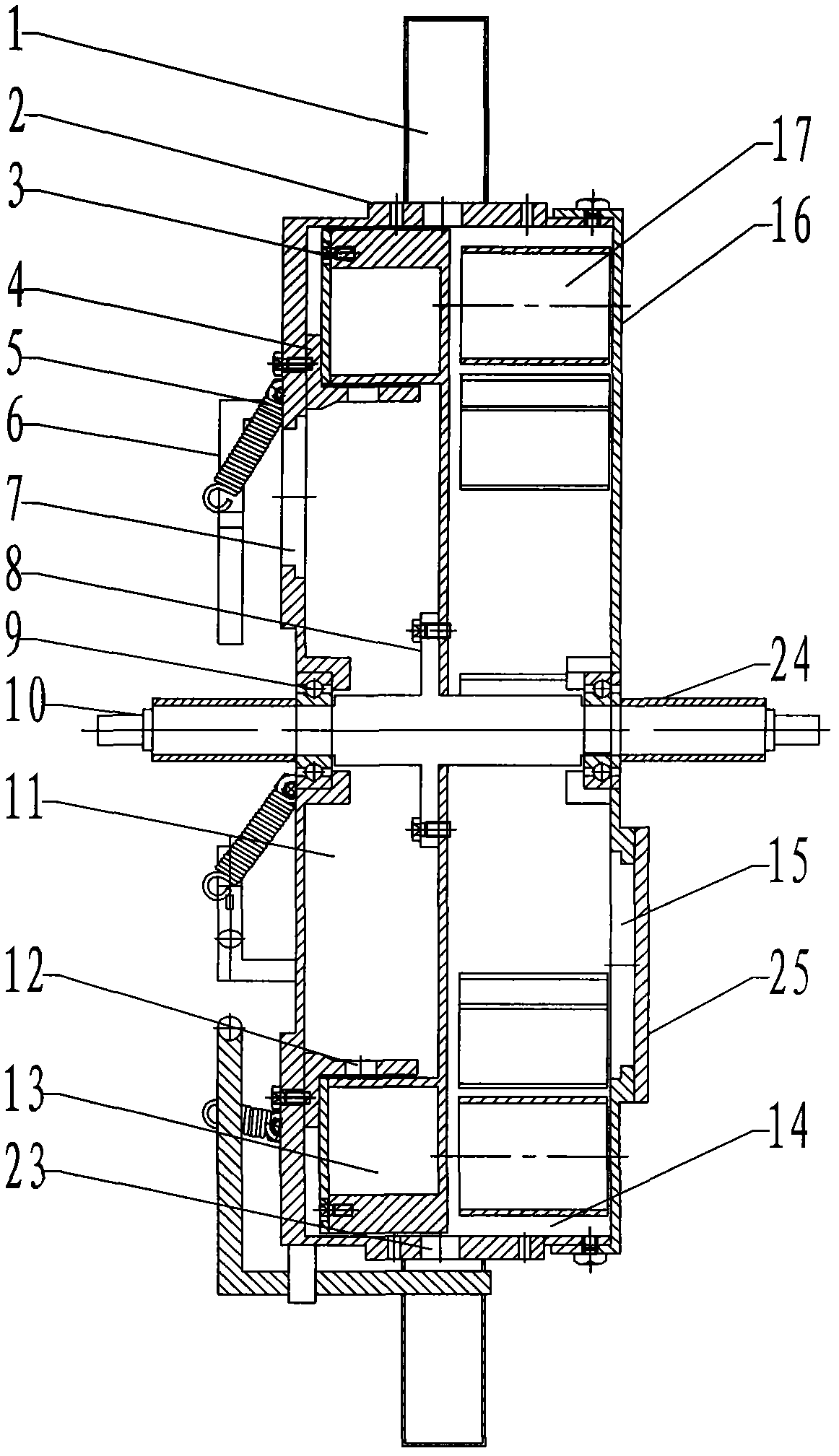

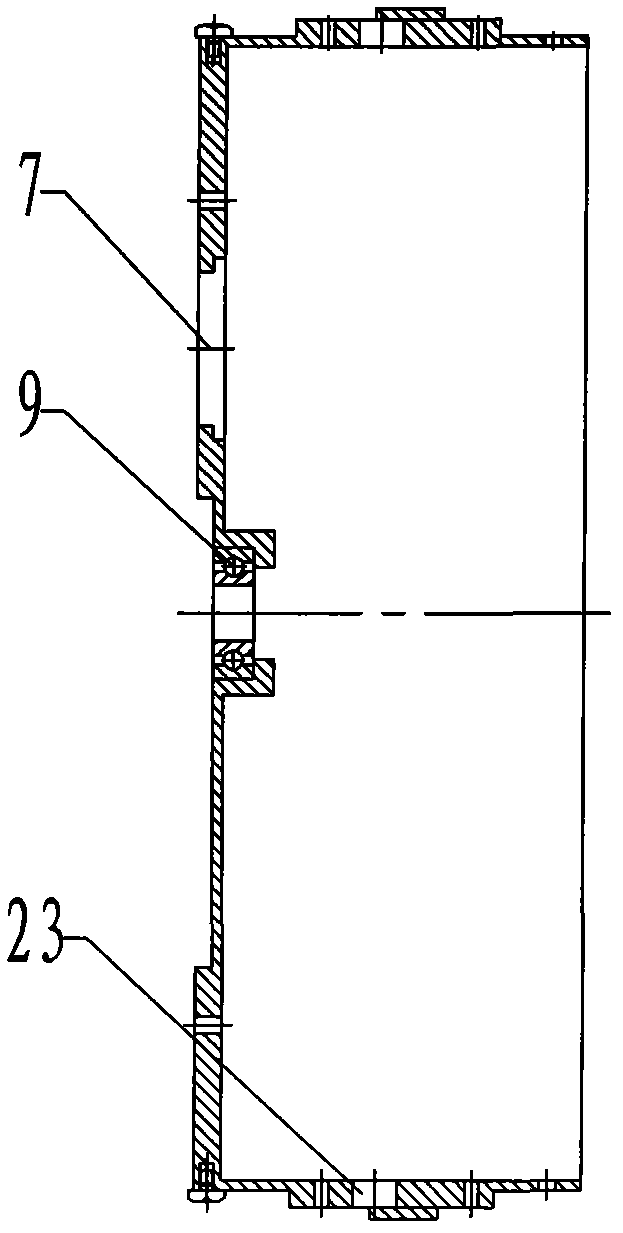

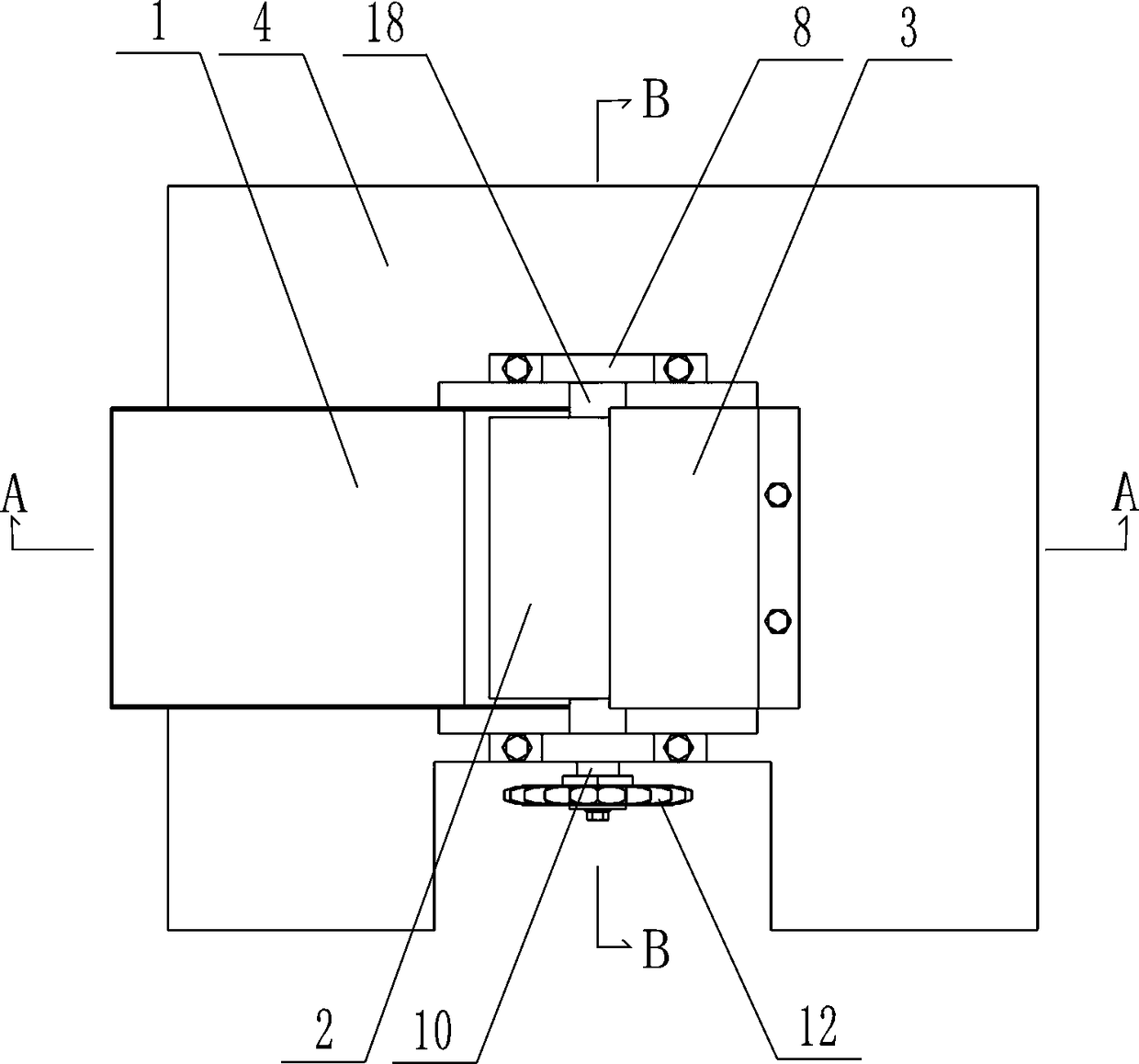

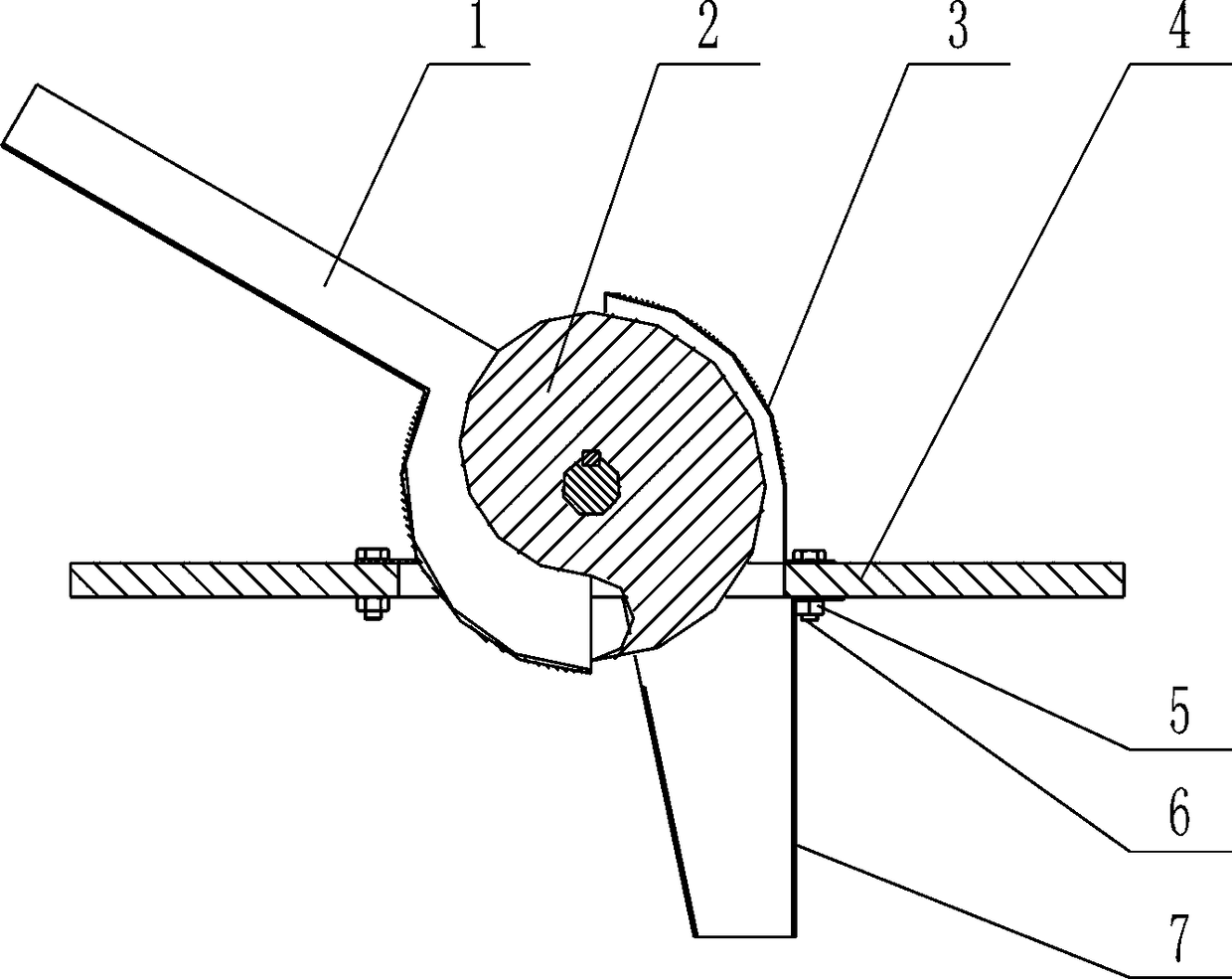

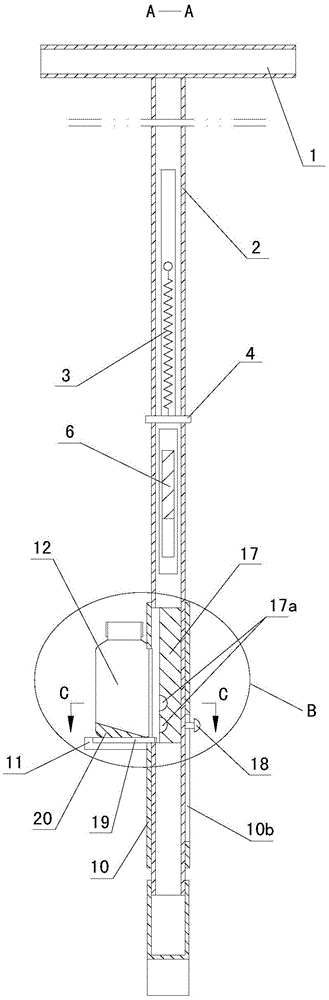

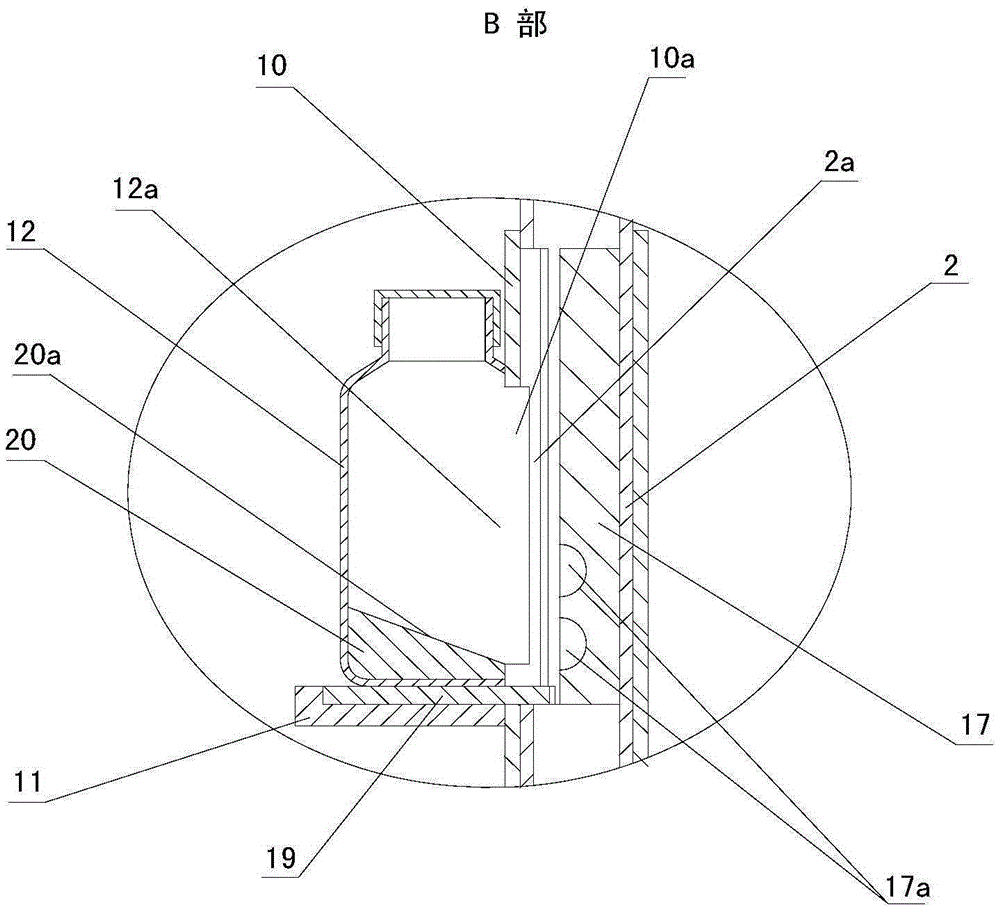

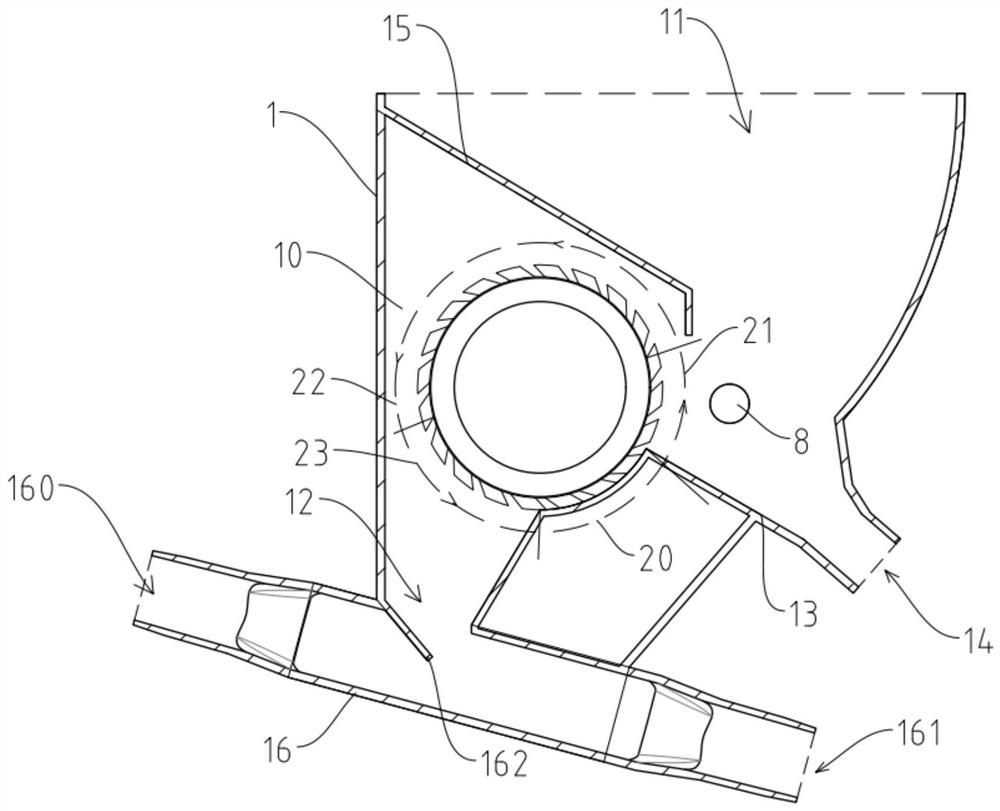

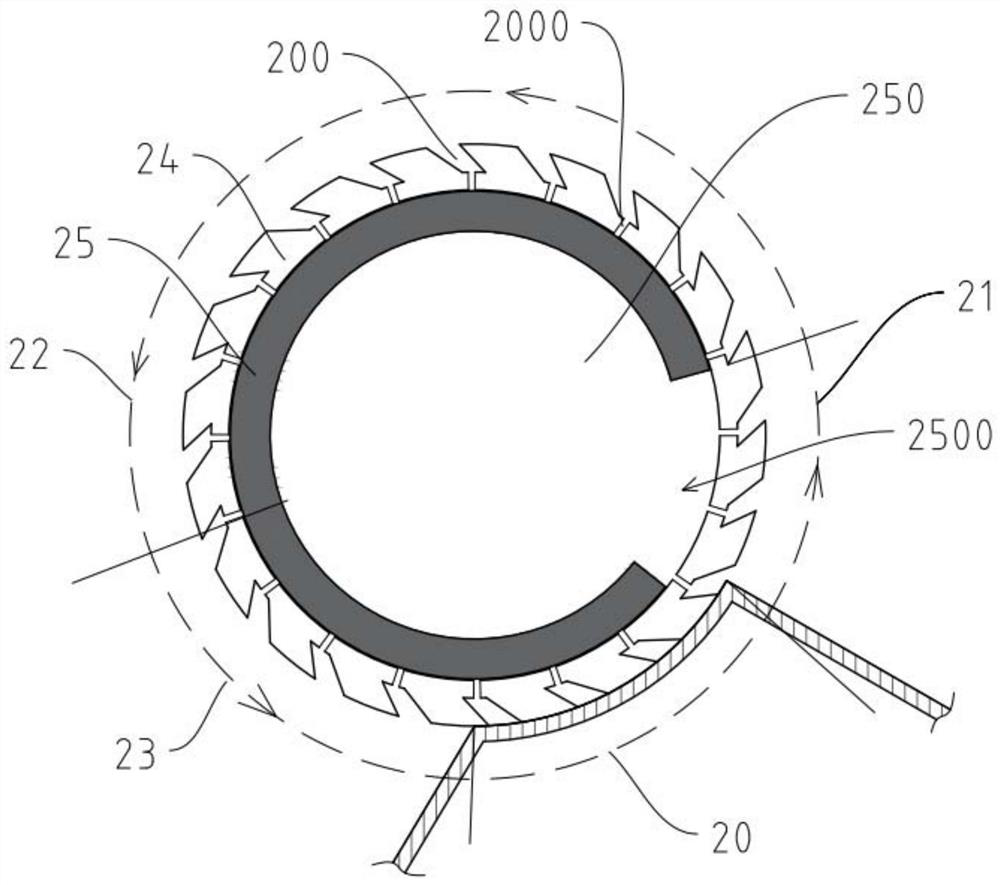

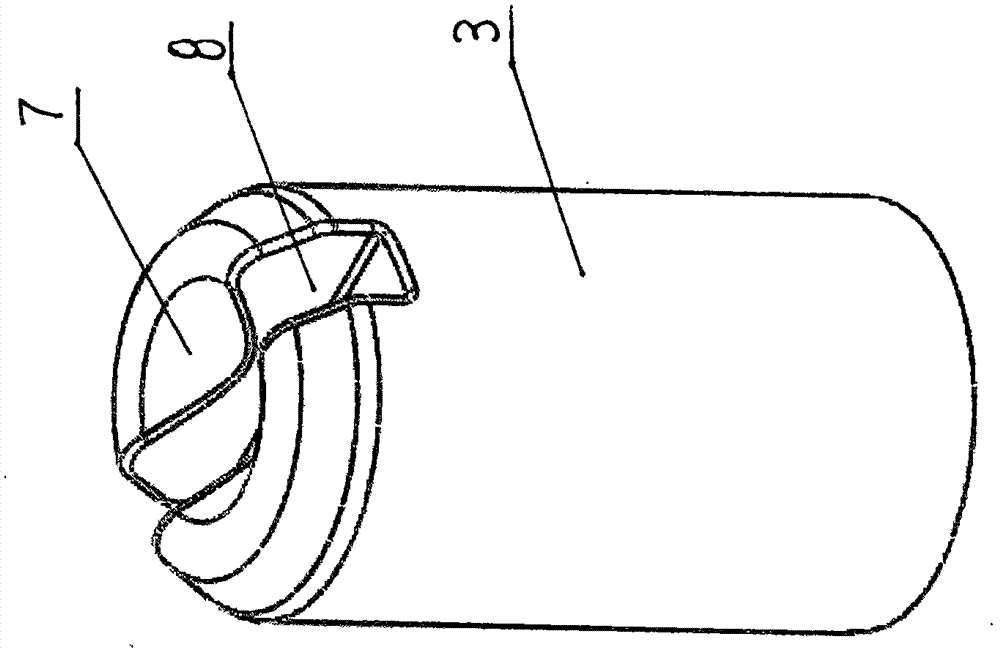

The invention relates to a movable bin single-seed precision hill seeder and belongs to the technical field of a movable bin hill seeder. A plurality of seed falling ports (23) are uniformly distributed on the outer periphery of a roller (2). The roller (2) and an end cover (16) are buckled into one whole body and are arranged on a plate shaft (10) through a bearing (9). One end face of the roller (2) is provided with a switching device for a nozzle (1). A plurality of seed supplementing spoons (17) are uniformly distributed on the inner wall of the end cover (16) in a ring-shaped shape. A discharge plate (3) is arranged in the roller (2). A seed plate (4) is buckled inside the discharge plate (3). A cavity between the discharge plate (3) and the seed plate (4) is a seed charging bin (11). A cavity between the discharge plate (3) and the end cover (16) is a seed storage bin (14). The end face of the discharge plate (3), which is close to the seed storage bin (14), is provided with a seed inlet (21) and a seed overflowing port (19). A seed charging mechanism (18) is arranged in the seed charging bin (11). The movable bin single-seed precision hill seeder has the advantages of functions of automatically feeding, overflowing and cleaning seeds, accurate seeding capacity, no cavity, strong practicality and the like.

Owner:SHANDONG UNIV OF TECH

Precision seed metering device of seeds with middle and large grain diameters

PendingCN110089240APrevent disengagementFix stability issuesSeed depositing seeder partsSingle grain seedersEngineeringCam

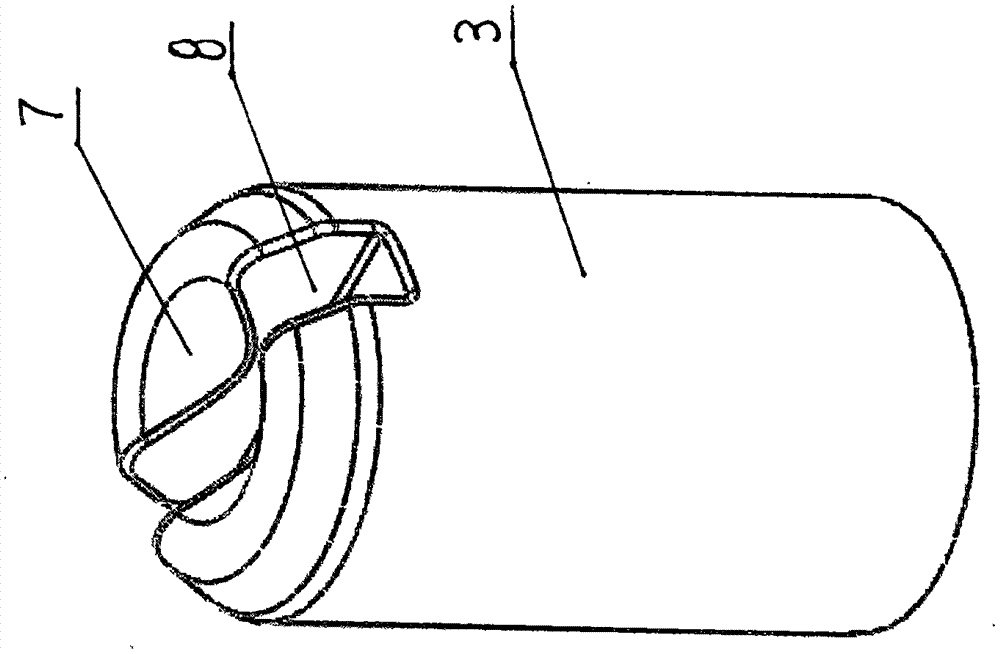

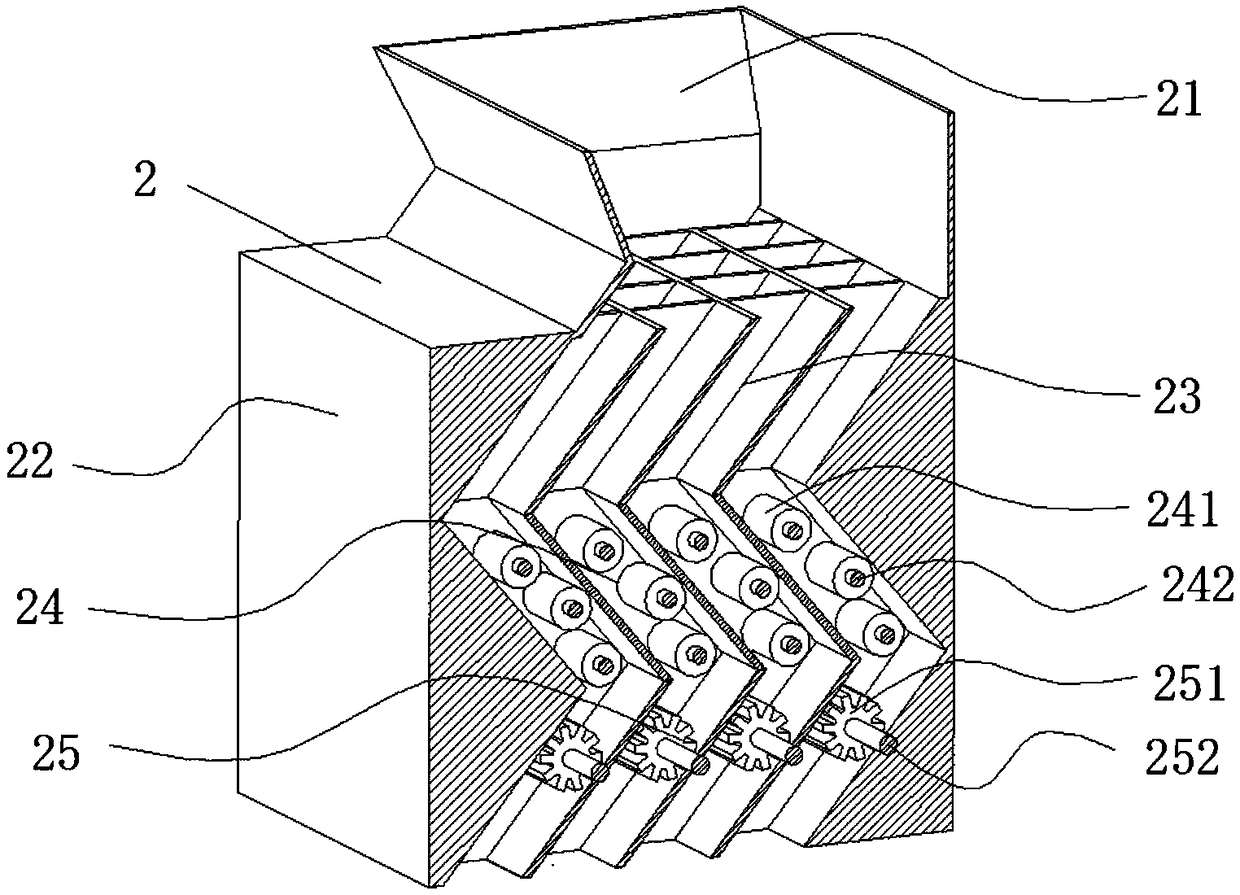

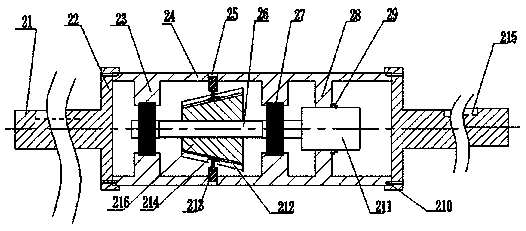

The invention discloses a precision seed metering device of seeds with middle and large grain diameters. Seed taking principles of pneumatic seed metering devices and mechanical seed metering devicesare combined, and a seed carrying component and a seed metering component are designed, wherein negative pressure and indent holes are combined to conduct seed taking. The precision seed metering device includes a seed metering device shell, a seed removing device, a seed storage device and a shaft; the seed metering device shell includes an end cover, a cover plate, a belt and an external fixingplate; the shaft is mounted on the external fixing plate; the seed removing device is located at the inner side of the end cover of the seed metering device, and the seed storage device is composed ofa seed metering disc, an indent hole sliding block mechanism and a cam-like mechanism. The precision seed metering device can adapt to the appearance requirements of the seeds; in a seed taking stage, the seeds enter the indent holes through negative pressure and self-gravity, then, superfluous seeds are brushed back to a seed chamber through the seed removing device and enter a seed carrying area, the seeds are still subjected to an adsorption effect, indent hole sliding blocks are closed so that the seeds can be more stable in a seed carrying process, a dual seed protection effect is achieved, and finally, the seeds pass through a secondary seed putting area to be put into seed holes. Overall, by adopting the precision seed metering device, power consumption can be reduced, the seed carrying rate is increased, the seed damage rate is reduced, and the sowing qualification rate of the precision seed metering device is increased.

Owner:SHIHEZI UNIVERSITY

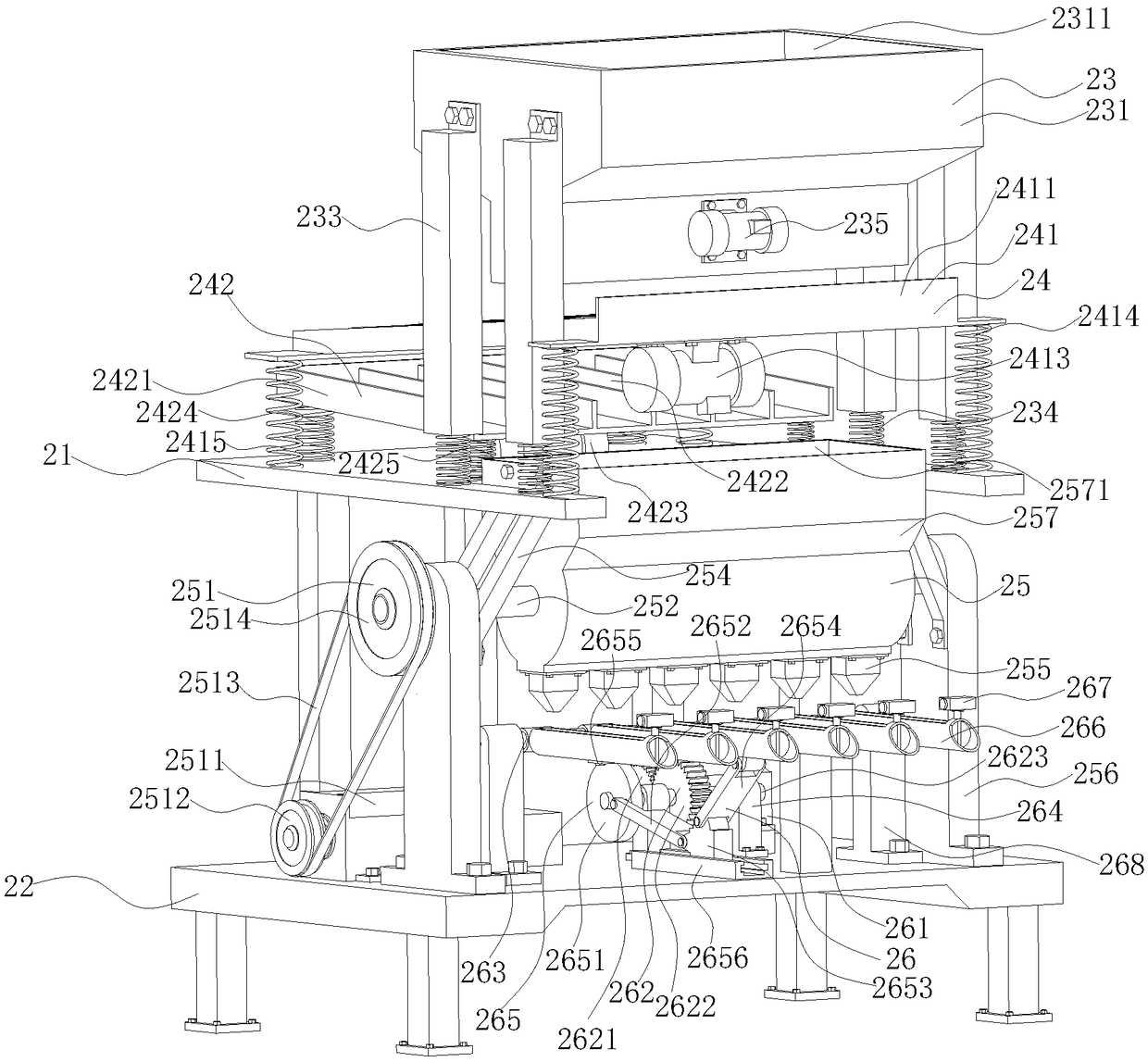

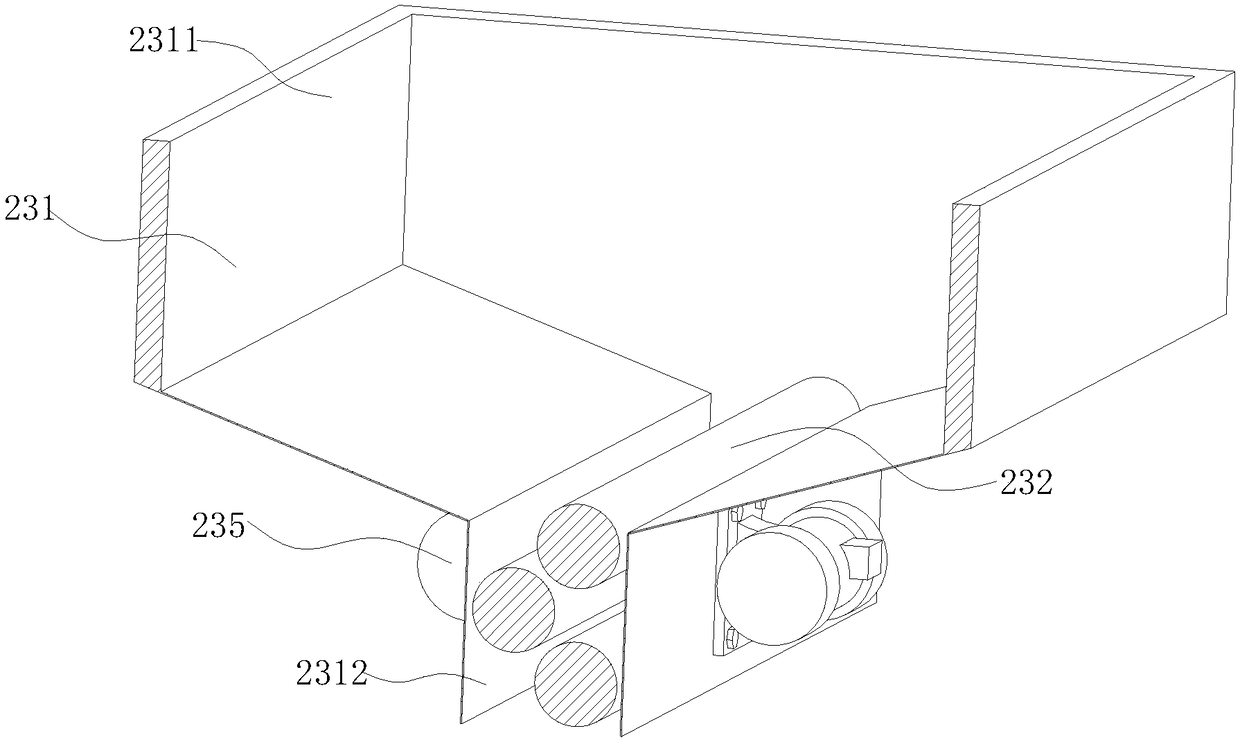

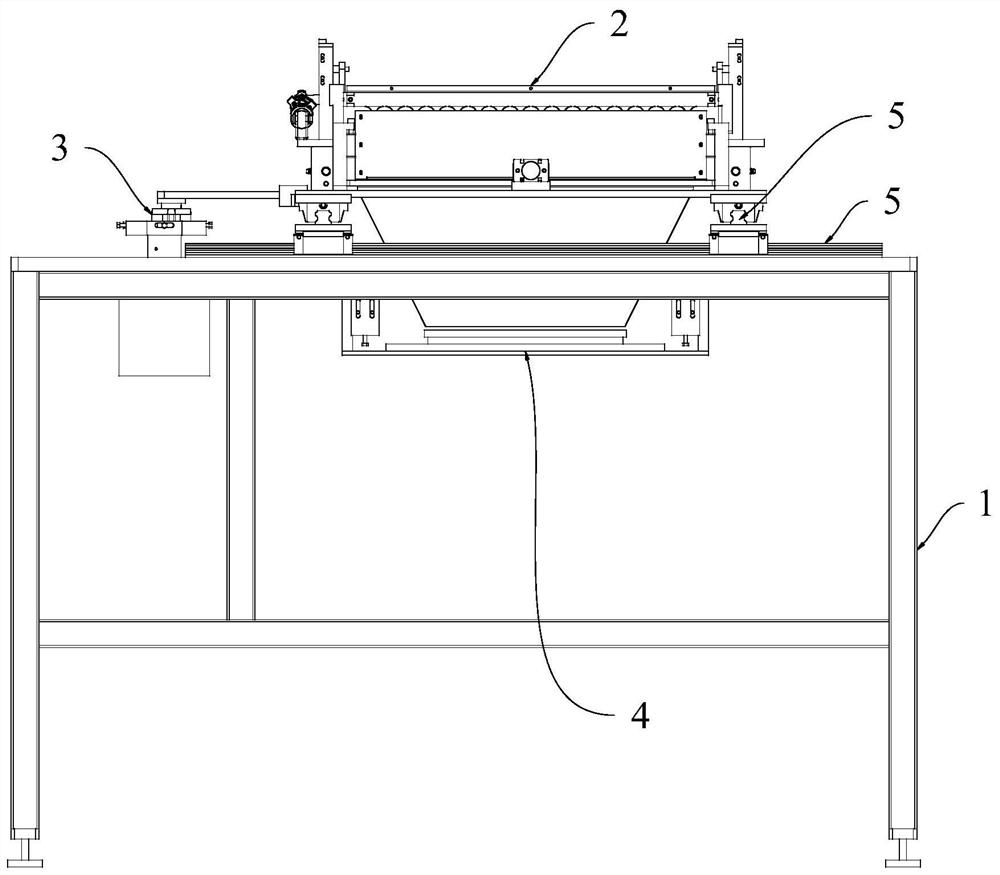

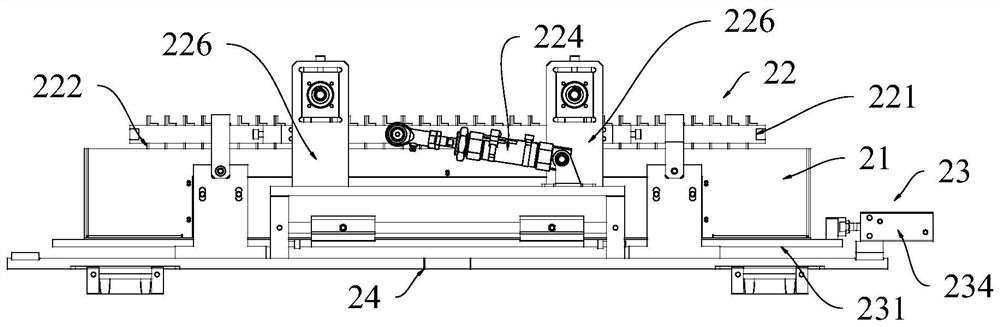

Two-degree-of-freedom adjustment vibrating sucker type precision sowing device

InactiveCN108432415AOvercoming the Technical Defects of Sowing MachineryOvercoming technical deficienciesSeed depositing seeder partsRegular seed deposition machinesEngineeringTwo degrees of freedom

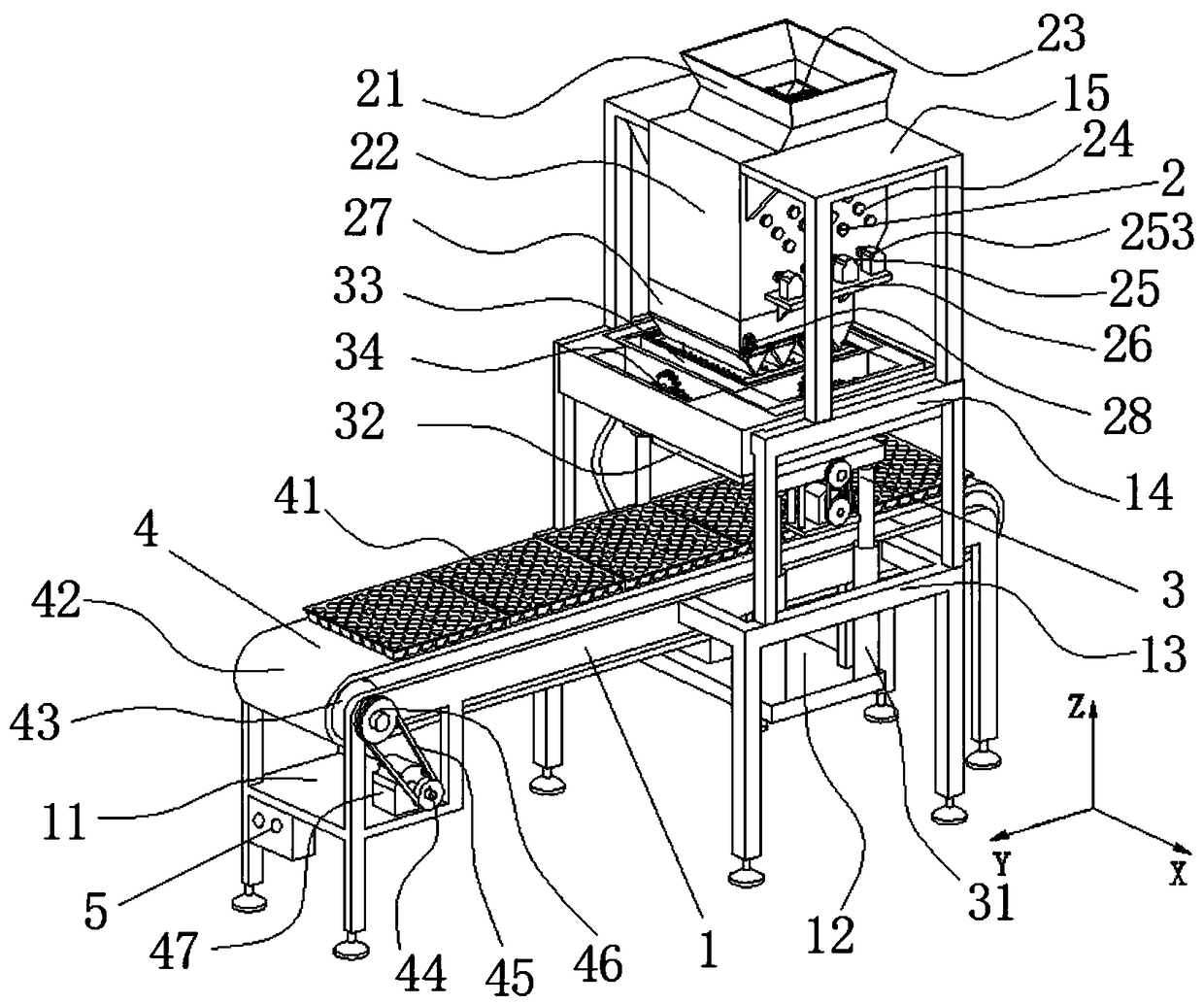

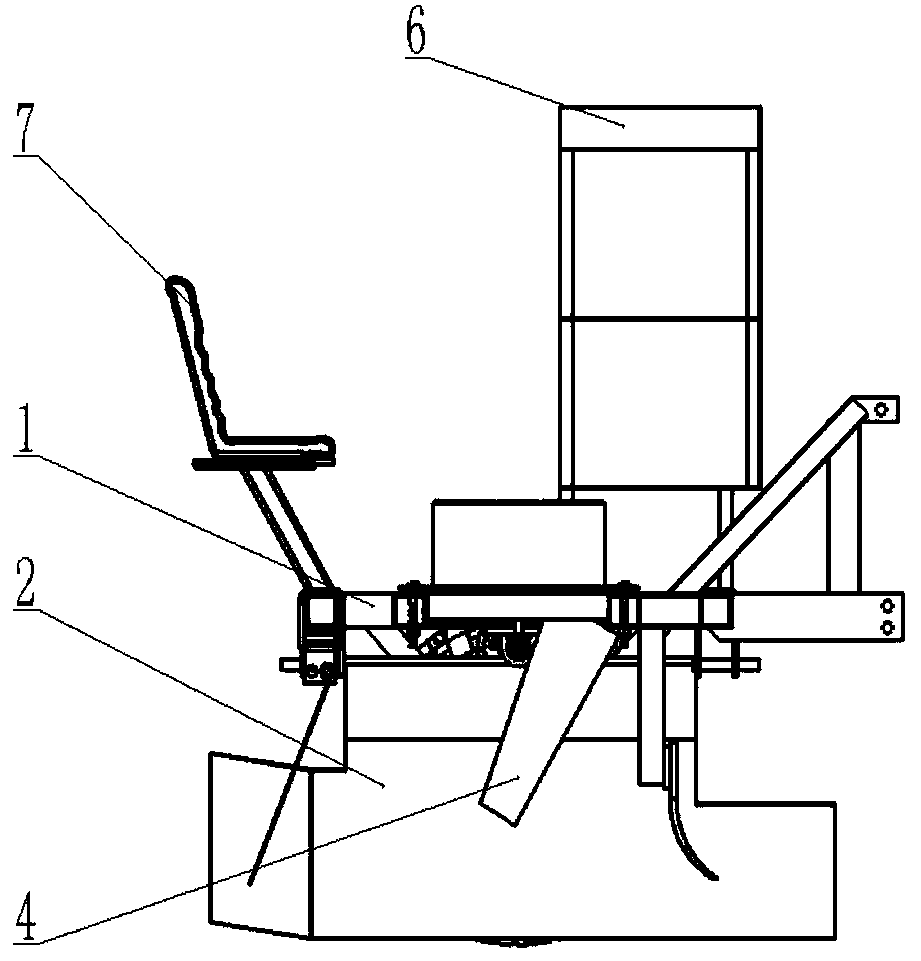

The invention discloses a two-degree-of-freedom adjustment vibrating sucker type precision sowing device. The two-degree-of-freedom adjustment vibrating sucker type precision sowing device comprises astand, a seed adding device, a controller, a seed tray device, a seed sucking device and a seedling tray driving device, wherein by use of the seed adding device, seeds can be uniformly, continuouslyand precisely added into the seed tray device; the seed tray device adopts two-degree-of-freedom adjustment; the angle of a seed tray can be adjusted by using a driving mode of lead screw and screw nut and gear and rack; the seed tray device is suitable for different sowing environments; the seeds are violently shaken by adopting vibration, and further a frictional force among the seeds can be reduced; the seed sucking device provides power for sucking the seeds by adopting an air pump; a sensor can be used for sensing whether the seeds are sucked to single suction nozzle of the seeds or not;if the seed suction rate does not reach the requirements, the seed sucking tray stays for a longer time and the missing sowing rate is reduced; after seed suction is finished, the seed sucking tray moves to the seedling tray driving device for sowing. The two-degree-of-freedom adjustment vibrating sucker type precision sowing device disclosed by the invention has the advantages of reliable work,diversified functions, convenience in maintenance, high sowing efficiency, no damage to the seeds, low missing sowing rate, high degree of automation and the like.

Owner:CHAOHU UNIV

Single-deck double-row seed sowing device

InactiveCN108156900ASolve missed broadcastAccurate seedingSeed depositing seeder partsSingle grain seedersDouble rowSowing

The invention discloses a single-deck double-row seed sowing device, and aims to provide the single-deck double-row seed sowing device which is more accurate in sowing seeds and more stable in seed sowing performance. A seed separating box is arranged on the bottom part of a shell; an upper opening of a seed separating box body is downwards inclined relative to a direction of a seed sowing plate;two seed separating pipes are connected with a lower opening of the seed separating box in parallel; the seed separating box is provided with a seed separating tongue plate on a perpendicular center surface in a length direction of a rectangular body; the seed separating tongue plate upwards extend to a horizontal center line of the seed sowing plate; a seed baffling plate is arranged on a short side of the seed separating box body and is parallel to the seed separating tongue plate; the seed baffling plate upwards extend to penetrate through an inner ring seed absorbing hole circumference line; a side of the seed baffling plate is attached to a seed absorbing surface of the seed sowing plate; a seed cleaner is arranged above the horizontal center line of the seed sowing plate, and is located on one side of an upward rotating direction of the seed sowing plate. The single-deck double-row seed sowing device provided by the invention is applicable to being matched with a double-row seeder on a ridge for use.

Owner:哈尔滨市百鑫成机械制造有限公司

Seeder with seedling strip cleaner

InactiveCN102415234APrevent weedFront and rear dimensions shortenedSpadesPlantingSeederAgricultural engineering

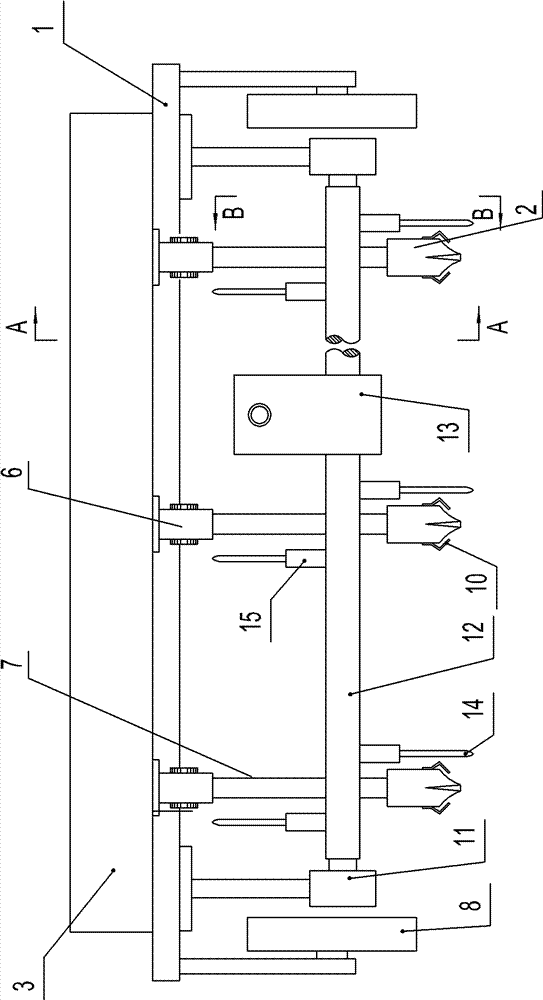

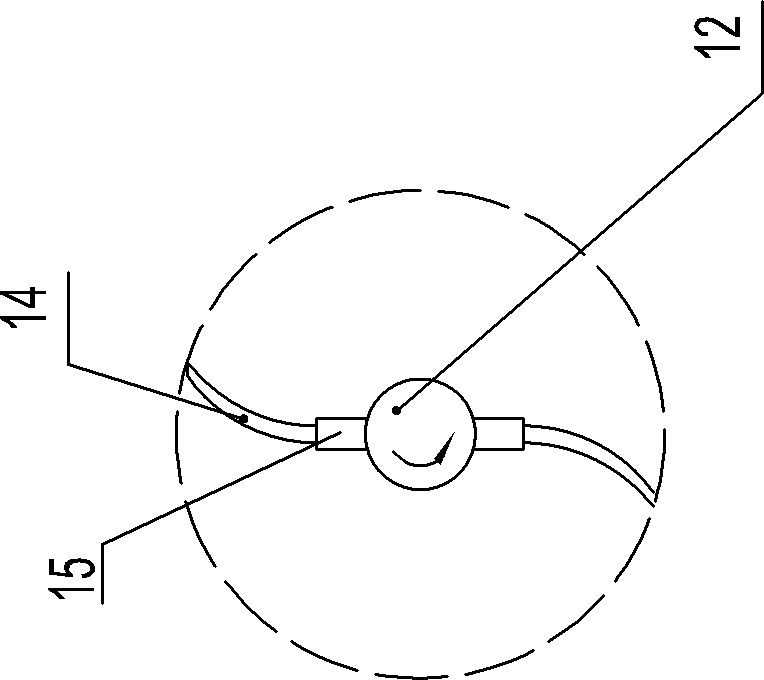

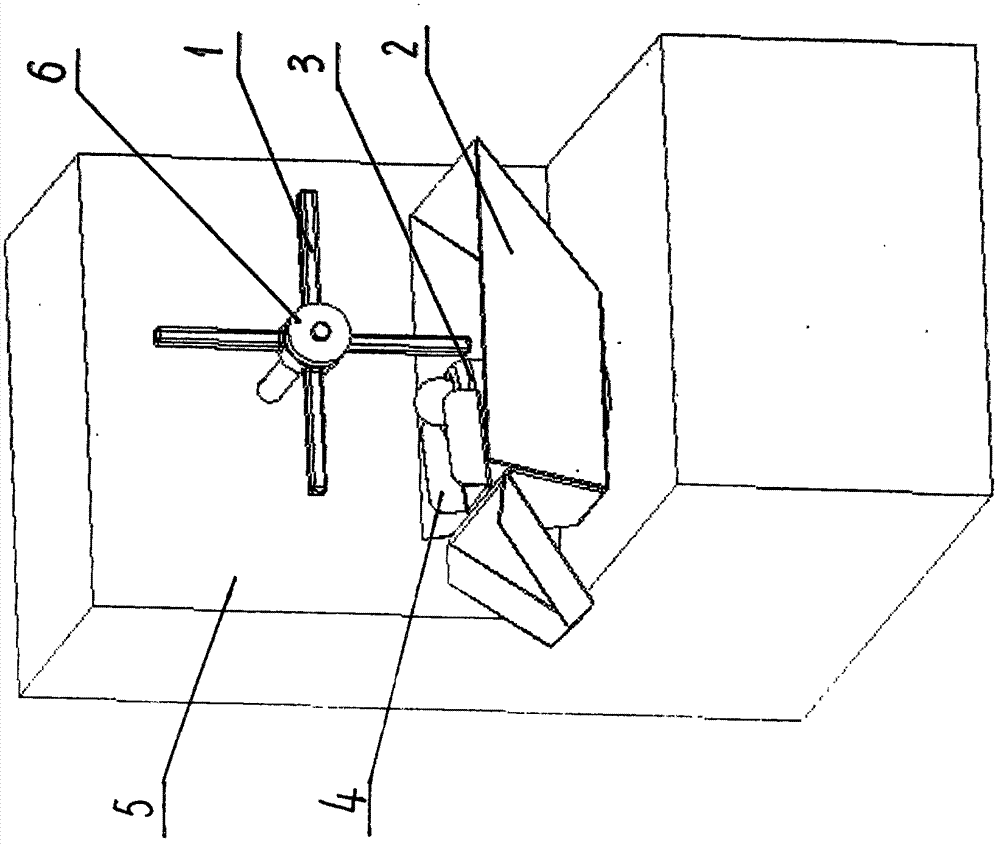

The invention provides a seeder with a seedling strip cleaner. The seeder comprises a frame, furrow openers as well as a seedling box, a fertilizer box, seed-metering devices, fertilizer apparatuses, plow poles, ground wheels and roller sealers which are arranged on the frame, wherein the plow poles are all hollow; each furrow opener is fixed at the bottom of the frame by the plow pole; the plow poles extend into the lower ends in the furrow openers so as to serve as fertilizer discharge outlets; the upper ends of the plow poles are communicated with the fertilizer box by the fertilizer apparatuses; and the seed-metering devices which are communicated with the seed box are positioned above the rear ends of the furrow openers. The seeder is characterized in that: the bottom surfaces of thefurrow openers are raised in a ladder shape from front to back along the travelling direction; both sides, which are positioned between the fertilizer discharge outlets and the seed-metering devices,of the furrow openers are provided with scrapers; the seedling strip cleaner is arranged at the front ends of the furrow openers; the seeder comprises two axle bases which are suspended on the frame,a rotary knife shaft of which a horizontal bearing is arranged between the two axle bases, a power transmission mechanism and pairs of rotary knives which are arranged on the rotary knife shaft; eachpair of rotary knives are symmetrically arranged at an angle of 180 degrees; and one furrow opener is arranged right behind each pair of rotary knives. The seeder has a simple structure and excellentworking performance.

Owner:山东颐和农机制造有限公司

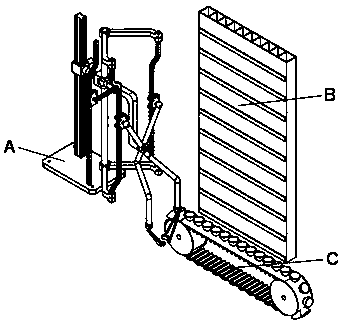

Factory needle-like suction pseudo-ginseng seeder

PendingCN108174658APrecision seedingSowing speedSeed depositing seeder partsBroadcast seedersSeederAgricultural engineering

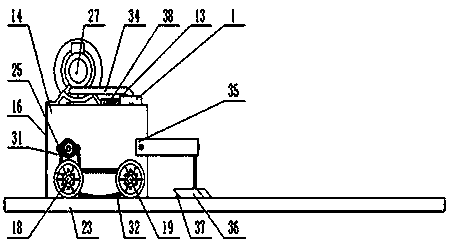

The invention relates to a factory needle-like suction pseudo-ginseng seeder, which belongs to the field of an agricultural machine. The needle-like suction pseudo-ginseng seeder comprises a seed metering device, a swing cylinder I, a swing cylinder seat I, a slide block seat, a slide block, a limited pillar I, a limited pillar II, a rocking bar I, a rocking bar II, a rotating shaft, a pedestal I,a pedestal II, a seed case, a protective cover I, a protective cover II, a cover plate I, a cover plate II, a walking wheel I, a walking wheel II, a walking wheel III, a walking wheel IV, a walking wheel connection shaft, a track I, a track II, a mounted bearing I, a mounted bearing II, a negative pressure machine, a motor, a gas insulation board, a sprocket wheel, a chain I, a chain II, a chainIII, an inhalation pipeline, a trench digging rack, an opening share, a seed-induction pipe, an angle iron, a slide block rod, a seed-discharging needle, a guide rail II, a swing cylinder II, and a swing cylinder seat II. The seeder realizes accurate sowing during factory pseudo-ginseng sowing work, increases sowing speed, reduces labor intensity, increases the pseudo-ginseng quality, reduces cost, has the advantages of reasonable structure and high efficiency, and can satisfy the agronomic requirement for a factory pseudo-ginseng plantation industry.

Owner:KUNMING UNIV OF SCI & TECH

Small seed potato shifting wheel type seed metering device

InactiveCN105432194ACreate novel structuresCreate a reasonable structurePotato plantersEngineeringSpherical form

The invention discloses a small seed potato shifting wheel type seed metering device, and belongs to agricultural machinery; a vertical inner side face and a horizontal upper end face of an L-shaped power driving box assembly are respectively provided with a seed shifting wheel in a rotating manner and a seed filling and supply column in an up and down telescopic moving manner; seed shifting rods are evenly distributed and arranged on the seed shifting wheel; a small seed potato box is arranged on the horizontal upper end face of the L-shaped power driving box assembly, and is located at the outer side part of the seed filling and supply column; the outer part of the upper end of the seed filling and supply column is in a cone shape; a hemispherical pit and a horizontal groove are formed in the upper end face of the seed filling and supply column; a seed metering conveying frame is arranged on the small seed potato box; the hemispherical pit has the diameter of 20 mm. The device has the advantages of novel and reasonable structure, accurate seed metering, low sowing leakage rate, low re-sowing rate, reliable operation and less failure, and meets the requirements of precise sowing.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Planting method of tulips

InactiveCN105284336AOvercome the miss rateOvercome the disadvantage of high replay rateHorticultureUltimate tensile strengthTractor

The invention discloses a planting method of tulips, pertaining to the technical field of agriculture. The planting method of tulips comprises following five steps: selecting soil, selecting and disinfecting bulbs, mechanically sowing, applying fertilizers to soil and performing post-harvest treatment. A planting and sowing machine for tulips is utilized in the manner of matching a tractor so that operation such as trench digging, sowing, earthing and ridging is finished at one time. The planting method of tulips has following beneficial effects: the above-mentioned operation is advantaged by protecting and picking, labor-saving, seed-saving, fertilizer-saving and is uniform in depth; by utilizing mechanical sowing, sowing quality is increased and labor intensity is decreased; seeds are discharged accurately and rapidly; leakage sowing rate is considerably decreased; sowing precision and efficiency are enhanced; defects of a scoop-type sower such as high leakage sowing rate and re-seeding rate are solved; and the percentage of damaged seeds is low during work.

Owner:XINJIANG TULIP BIOTECH LTD

Seeding rate-adjustable corn planter

InactiveCN109005785AAdjust line spacingPrecision seedingPlantingDibble seedersCouplingAgricultural engineering

The invention discloses a seeding rate-adjustable corn planter. The seeding rate-adjustable corn planter comprises a frame, a seed box and supporting wheels, the bottom of the seed box is connected with a plurality of seed-metering devices, all the seed-metering devices are connected by a shaft coupling, the seed-metering devices are also connected with a transmission mechanism, every seed-metering device comprises a seed-metering device shell, a feeding port is arranged at the upper part of every seed-metering device shell, a discharging port is arranged at the lower part of every seed-metering device shell, a feeding baffle plate, a seeding wheel, a hairbrush and a seed protector are also arranged in every seed-metering device shell, every seeding wheel comprises a seeding wheel shell, every seeding wheel shell is a hollow cylindrical structure, every seeding wheel shell is provided with uniformly-distributed through holes, a lead screw, a motor and a guiding wheel are arranged in every seeding wheel shell, every guiding wheel is a cone structure, every guiding wheel is provided with a sliding slot, a sliding block is arranged in every sliding slot, every sliding block is connected with a blocking block, and the blocking blocks are arranged in the through holes of the seeding wheel shells. The seeding rate-adjustable corn planter can realize the adjustment of the depths of seeding holes in order to adjust the seeding rate, and also can adjust a line spacing of hole sowing.

Owner:陈卫

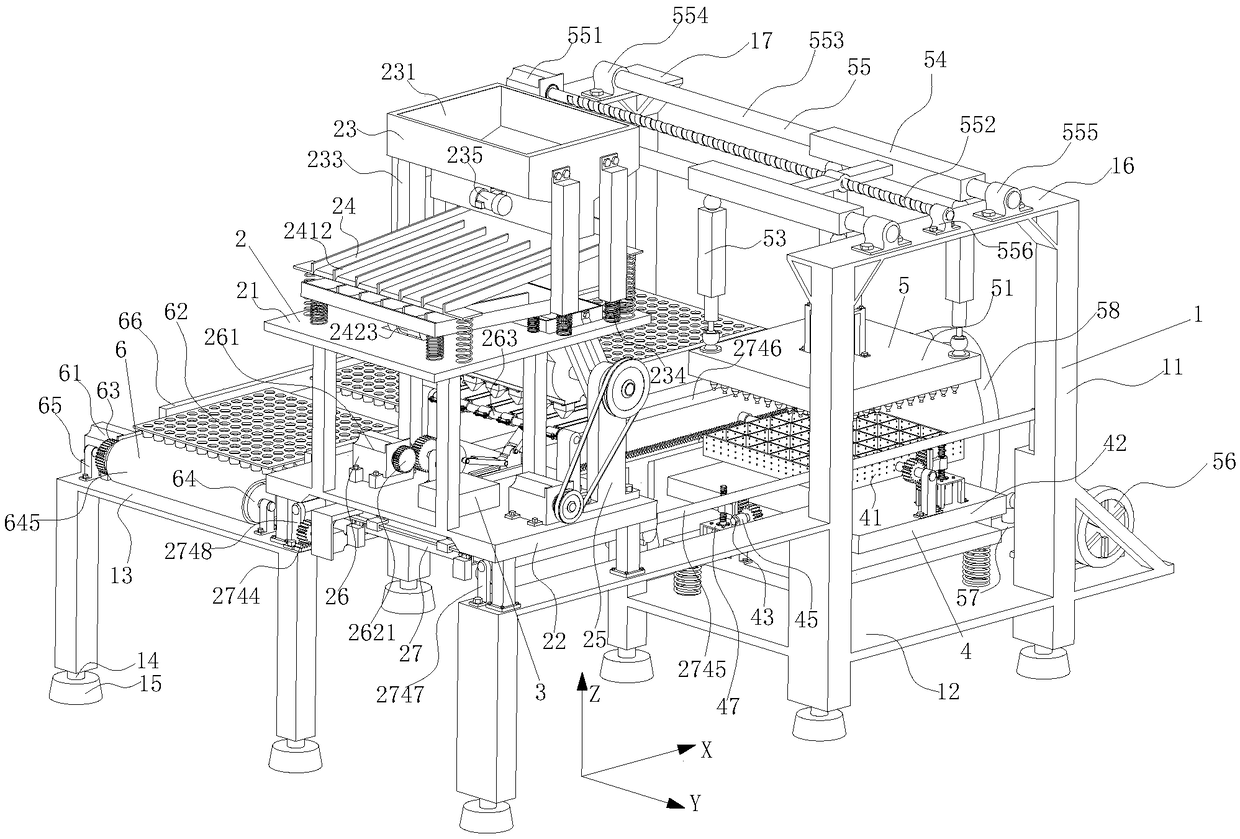

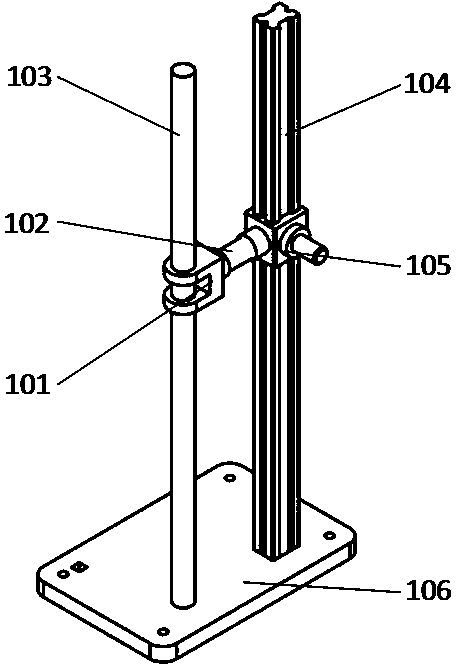

Level adjustable embedded vacuum-vibration precision seeding apparatus

InactiveCN108283038AFully automatedSuction process is smooth and simpleSeed depositing seeder partsSingle grain seedersCurrent limitingAgricultural engineering

The invention discloses level adjustable embedded vacuum-vibration precision seeding apparatus, and particularly relates to the technical field of precision seeding machinery. The apparatus consists of a rack, a seed adding device, a seed suction device, a conveying device and a controller; the seed adding device is mounted on a fifth bracket; a lifting and turning device and a level adjusting device in the seed suction device are respectively arranged on a second bracket and a fourth bracket; and the conveying device is mounted on a first bracket. The lifting and turning device is adopted toadvance a seed suction disc to a seed disc, so that the upward suction of seeds can be realized, and a seed suction process is simplified; a seed shaking mechanism can enable the seeds to be in a ''boiling'' state; the seed suction rate is improved; the level adjusting device can adapt the apparatus to different sites; a current limiting mechanism, a shutoff mechanism and a seed discharging mechanism are arranged, so that precision seeding can be realized and the seeding precision can be improved. The apparatus provided by the invention can be used for raising plug seedlings of cereal crops, and has the characteristics of high automation degree, high seeding rate, small leakage rate and small damage to seeds.

Owner:CHAOHU UNIV

High-speed seeder

InactiveCN107018715AReduce the effects of formation lagPrecision seedingPlantingSeed depositing seeder partsCircular discSeeder

The present invention discloses a high-speed seeder, which comprises a rack assembly, a seeding box, a seeding monomer rack, a round disc ditching device, a sliding cutter ditching device, a soil covering device and a pressing depth limiting wheel, wherein the seeding monomer rack is connected to the rack assembly, the seeding box is arranged on the seeding monomer rack, the round disc ditching device, the sliding cutter ditching device, the soil covering device and the pressing depth limiting wheel are sequentially arranged on the seeding monomer rack from front to rear, a seeding mechanism is arranged in the seeding box, and comprises a diversion plate, seeding wheels and a seeding shaft, the seeding shaft penetrates through a pair of the side walls of the seeding box, the diversion plate is arranged between the two side walls of the seeding box, and is positioned below the side of the seeding shaft, a seeding flow channel is reserved between the diversion plate and the seeding shaft, both ends of the seeding shaft are provided with the seeding wheels, and the seeding wheels are connected to the round disc ditching device through a chain. According to the present invention, the seeding is performed with the seeding mechanism, such that the seeding effect is good, the ditching depth is stable, the seeding quality is high, and the high-speed seeder is suitable for the basic situation of the vast rural areas of our country.

Owner:GUANGXI GAONONG MACHINERY

Deep scarification cultivator adopting automatic sowing and hole entering device and using method

InactiveCN112243644AReduce travel speedAvoid hittingPlantingDibble seedersSeederAgricultural science

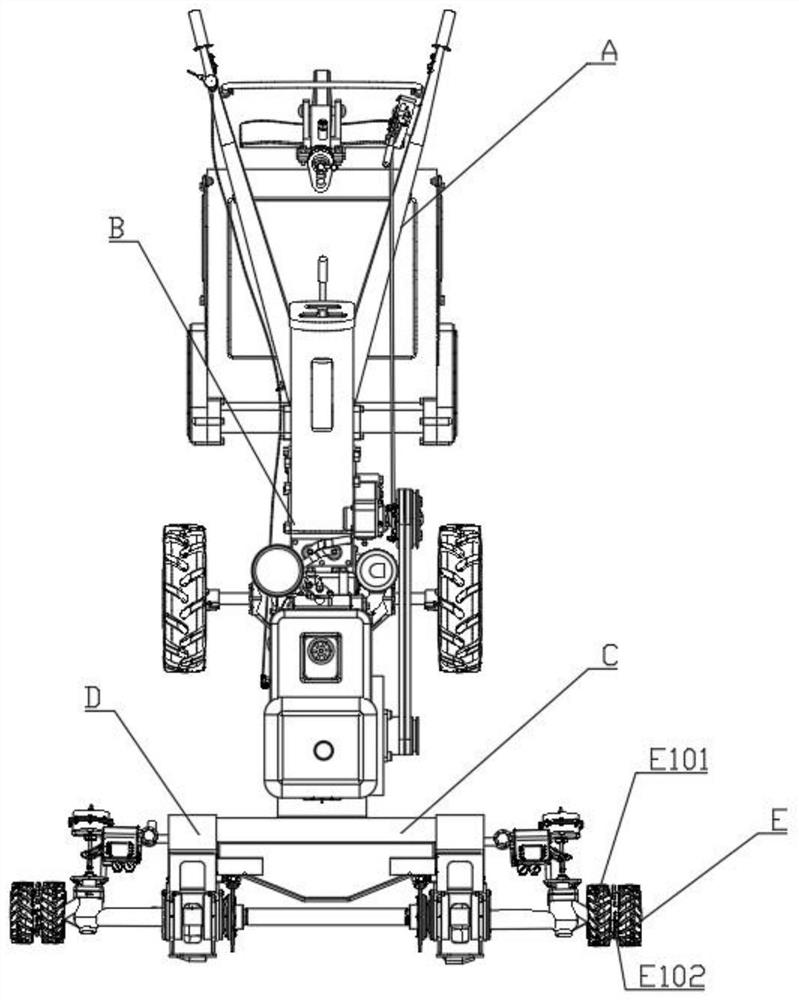

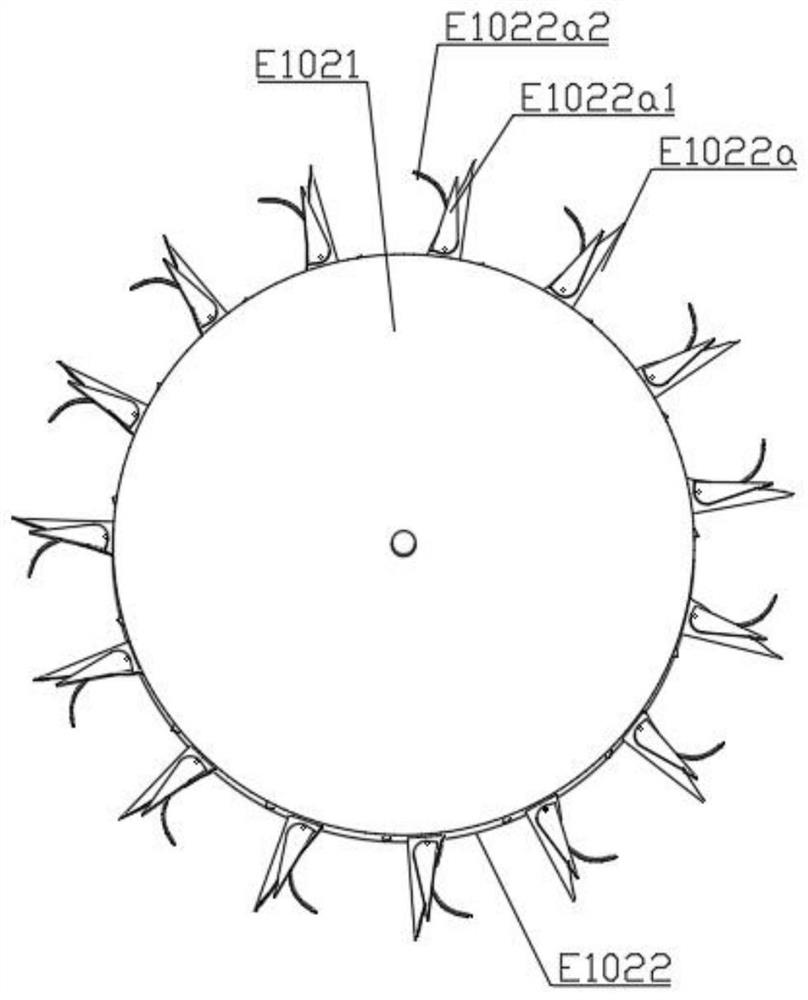

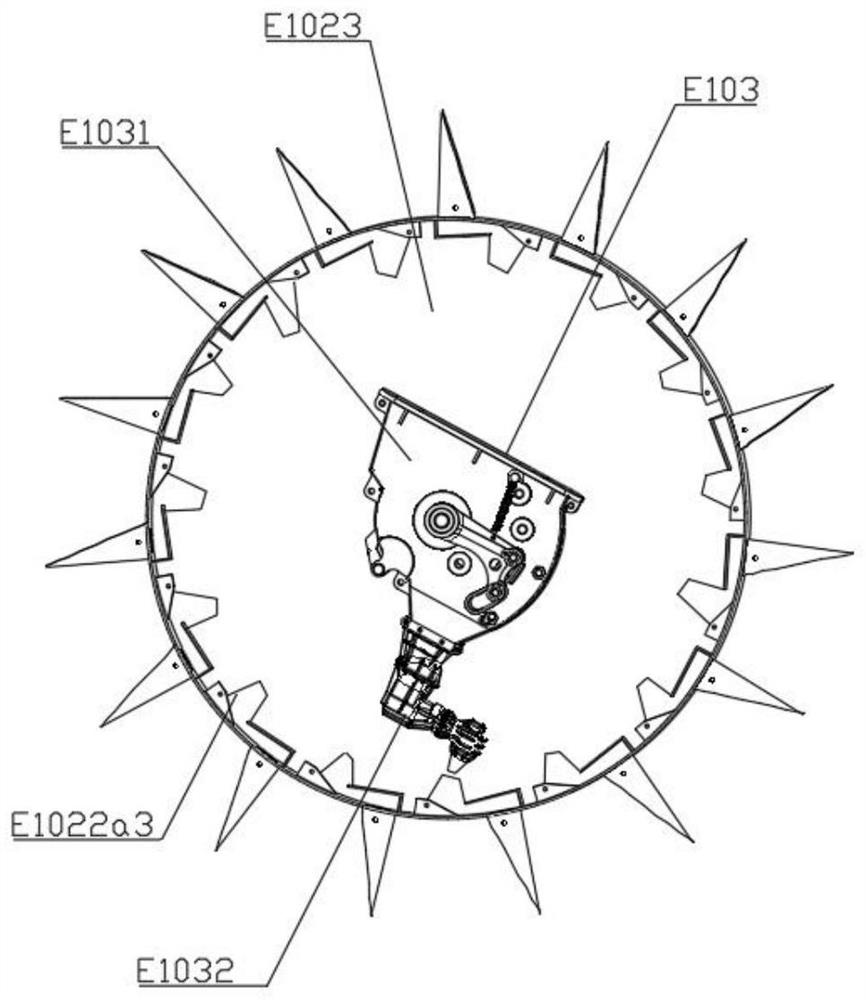

The invention belongs to the field of agricultural machinery, and particularly relates to a deep scarification cultivator adopting an automatic seeding and hole entering device. The device comprises arack assembly, a driving assembly, a material distributing device, a feeding device and seeding devices, the front part of the rack assembly is fixedly connected with the rear part of the driving assembly, the front part of the driving assembly is connected with the material distributing device, the two sides of the material distributing device are fixedly connected with the feeding device, and the seeding devices are arranged at the two sides of the feeding device; and each seeding device comprises two seeding outer wheels, a hole entering inner wheel and a seed metering mechanism, the holeentering inner wheel is fixed between the two seeding outer wheels, and the seed metering mechanism is mounted in the hole entering inner wheel. The cultivator solves the problems of low efficiency, seed leakage, high reseeding rate, non-uniform seed distribution and incapability of adapting to fields with different seed metering conditions in a conventional seeder. The invention further providesa using method of the deep scarification cultivator adopting the automatic sowing and hole entering device.

Owner:重庆贻晨兴工业设计有限责任公司

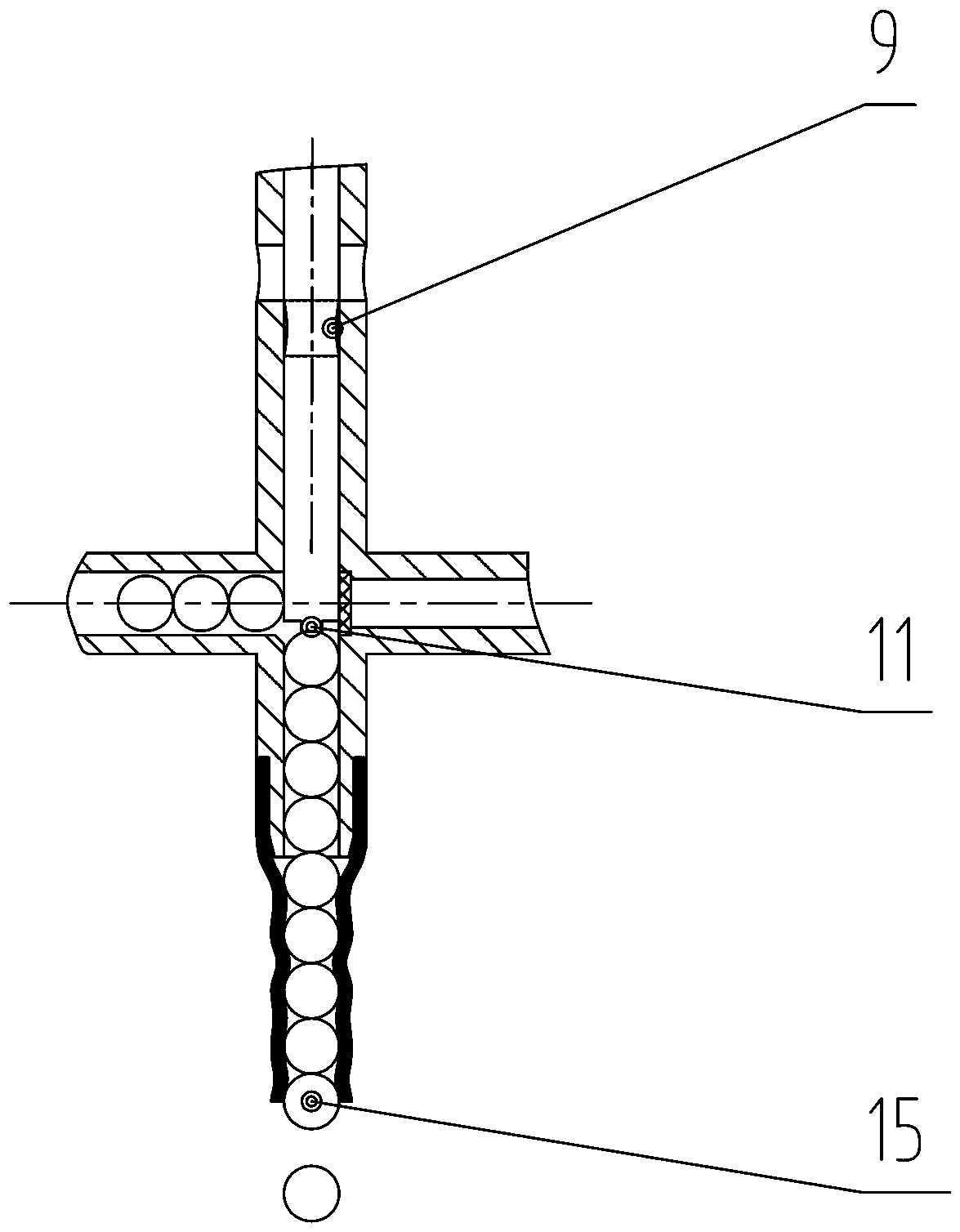

Shaft pinhole type American ginseng pneumatic precision seeder

PendingCN110192458ASolve uneven distributionIntegrity guaranteedSpadesPlantingSeederAgricultural engineering

The invention discloses a shaft pinhole type American ginseng pneumatic precision seeder, and relates to the technical field of agricultural machinery. The seeder comprises a rack, an arc surface shaping plate is arranged at the lower front part of the rack, and an upwards turned arc plate is arranged at the front end of the arc surface shaping plate; a seed metering disc is arranged on the rack and is located behind the arc surface shaping plate, and an upwards turned arc plate is arranged at the front end of the seed metering disc; the bottom end of the seed metering disc is an arc surface;a furrow opener is arranged below the seed metering disc. The seeder has the advantages that continuous secondary shaping and sowing-depth-consistent precision seeding of the high-width arc-shaped ridge surface can be realized, the problems that the ditching depth is not uniform in the seeding process and seed distribution is not uniform are solved, the seeding precision is improved, and precise seeding is realized; uniform seeding on the arc-shaped ridge surface can be realized, and the seeding efficiency is improved; a pneumatic seeding mode is designed, the completeness of seeds is guaranteed to the maximum extent, the seed taking quantity of each shaft needle cylinder not larger than two, and the repeated seeding phenomenon is avoided.

Owner:QINGDAO AGRI UNIV +1

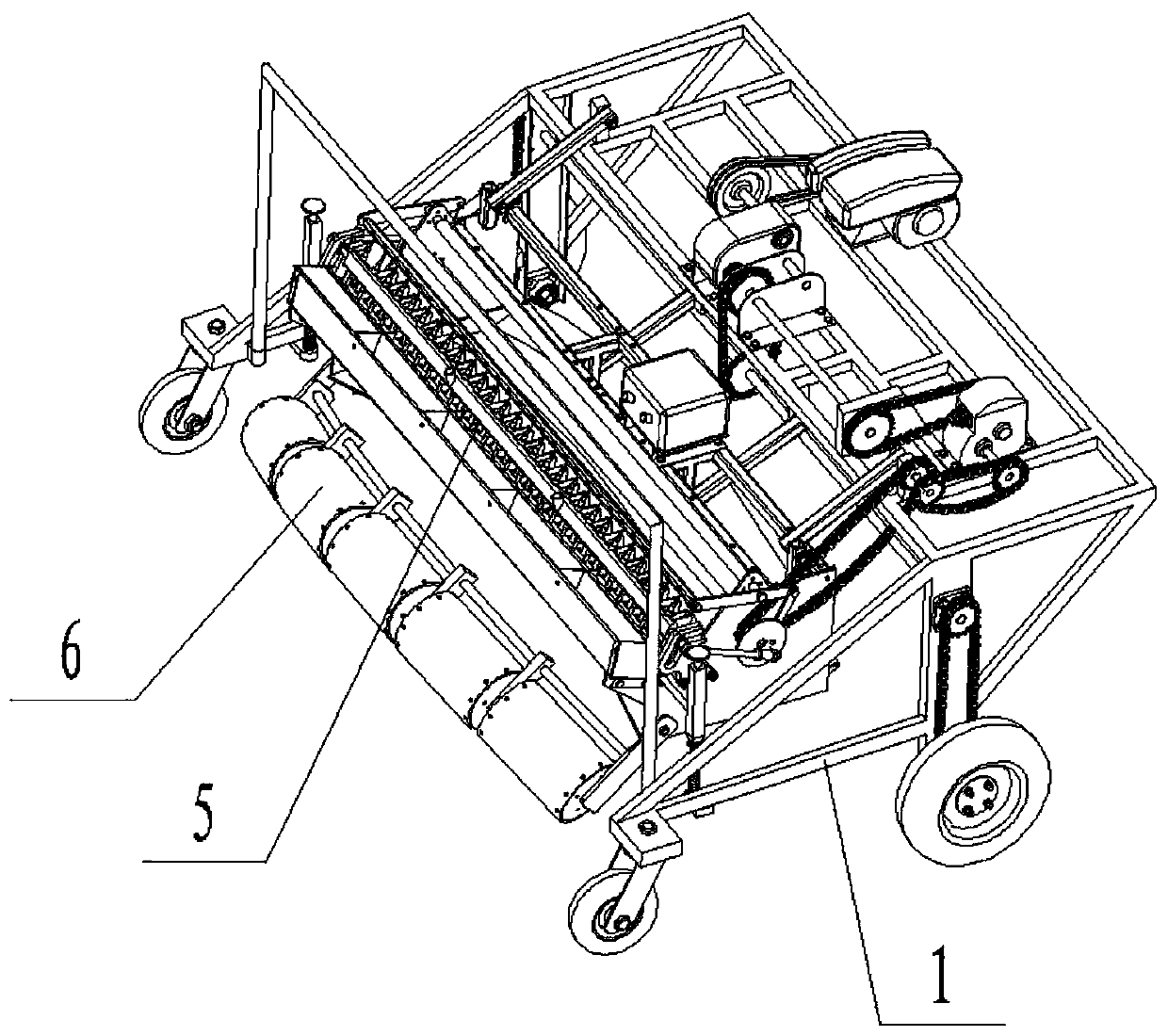

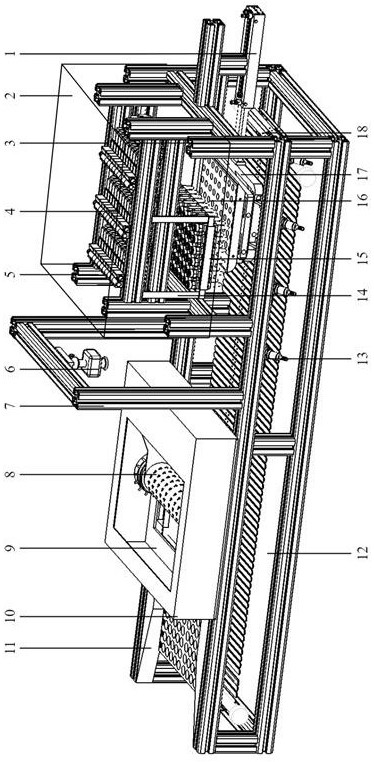

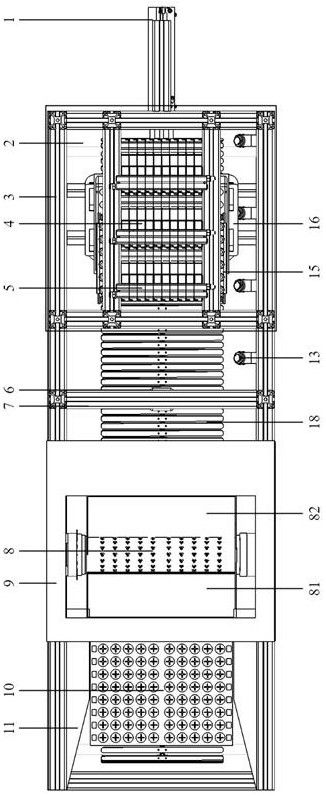

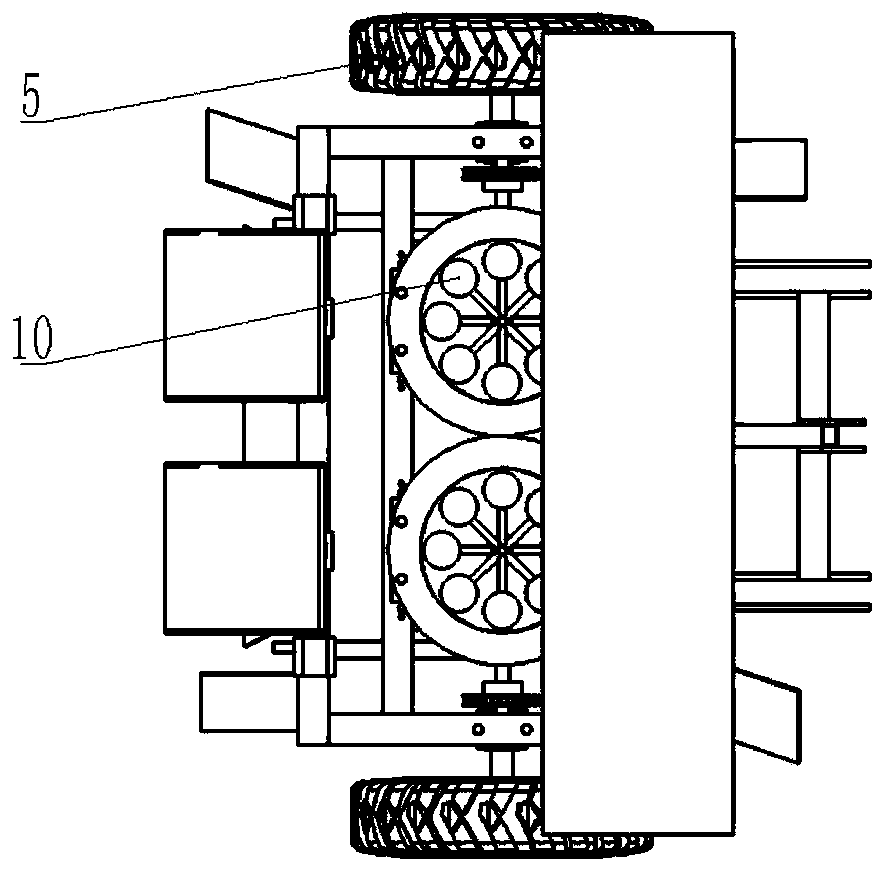

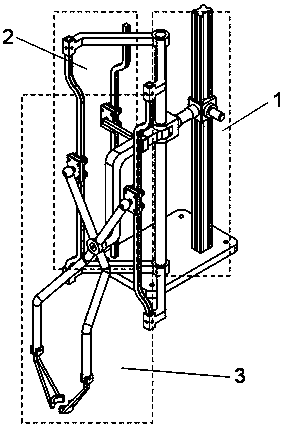

Miss-seeding detection and reseeding device and method for plug seedling machine based on machine vision

PendingCN114793567AMeet the agronomic requirements of full seedingMeet mechanizationTelevision system detailsCharacter and pattern recognitionAgricultural scienceMachine vision

The invention relates to a device and a method for miss-seeding detection and reseeding of a plug-type seedling machine based on machine vision, and the device comprises a loading platform, and a drum-type seed metering device, an information collector and a miss-seeding reseeding mechanism which are sequentially arranged along the moving direction of a plug, a seed outlet of the drum-type seed metering device and a seed outlet of the miss-seeding reseeding mechanism respectively correspond to seed holes of the hole tray, and the information collector is used for collecting position information of the hole tray and miss-seeding information in the seed holes of the hole tray. The miss-seeding information in the hole tray is collected through the information collector, the miss-seeding reseeding mechanism is used for reseeding the miss-seeding seed holes, hole tray conveying, accurate seed metering, miss-seeding identification and accurate reseeding can be completed at a time, the full-seeding planting agronomic requirement of the hole tray type seedling raising machine is met, and the production efficiency is improved. Due to the intensive design, the occupied space and size are greatly reduced, the integrality is high, and mechanical, intelligent and precise reseeding of the plug type seedling raising machine is met.

Owner:SHANDONG AGRICULTURAL UNIVERSITY +1

Inside-filling accurate-quantification seed metering device

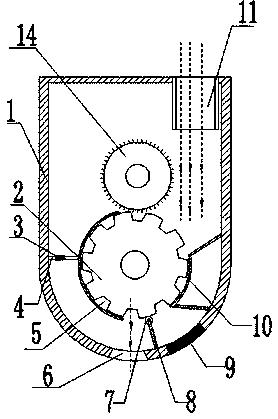

ActiveCN108207207APrecision seedingAvoid wastingAgriculture gas emission reductionSeed depositing seeder partsGear wheelAgricultural engineering

The invention relates to an inside-filling accurate-quantification seed metering device. The inside-filling accurate-quantification seed metering device comprises a housing, a seed-storage plate arranged in the housing, an arc seed-protection plate arranged at the seed-storage plate, a seed-discharge port close to the end of the seed-protection plate is arranged at a sidewall of the housing, a seed-metering plate is arranged between the housing and the seed-storage plate, seed holes are circumferentially arranged at a peripheral plate of the seed-metering plate, a roller passes through an initial end of the seed-storage plate close to the seed-protection plate, a rolling hairbrush is arranged at a front end of the roller, a driven gear is arranged at a rear end of the roller, a driving gear engaged with the driven gear is arranged at center of the front transverse plane of the seed-metering plate, a seed-metering wheel is arranged at the front transverse plane of the seed-storage plateclose to the seed-metering port, cylindrical seed-metering tooth are circumferentially and uniformly arranged at the seed-metering wheel, and external ends of the cylindrical seed-metering tooth passthrough a window and abuts against the corresponding seed holes. The superfluous crop seeds in a same aperture are put back to the seed-storage plate, and waste phenomenon generation due to excessivecrop seeds at a same position of cultivated land can be avoided; the crop seeds rotated to the seed-discharge port can be smoothly discharged, seeds shortage on the cultivated land can be prevented,accurate seed metering is realized, and crop output is guaranteed.

Owner:梁双林

Seed metering device having adjustable seeding wheel

InactiveCN108848802APrecision seedingAccurate spacingSeed depositing seeder partsEngineeringMotor drive

The invention discloses a seed metering device having an adjustable seeding wheel. The device comprises a seed metering device housing. A feeding port is arranged at the upper part of the seed metering device housing, and a discharge port is arranged at the lower part. A feeding baffle, a seeding wheel, a brush, and a seed protector are also arranged in the seed metering device housing. The seeding wheel comprises a seeding wheel housing which is of a hollow cylindrical structure. Uniformly-distributed through holes are arranged at the seeding wheel housing. A screw, a motor, and a guide wheelare also arranged inside the seeding wheel housing. The guide wheel is connected to the screw lever through a central screw hole of the guide wheel; two ends of the screw are respectively connected with a bearing; one end of the screw is also connected with the motor; the motor drives the screw to rotate; the guide wheel is of a conical structure; a sliding slot is arranged on the guiding wheel;a sliding block is arranged on the sliding slot; a blocking blocks are connected to the sliding block; and the blocking block are arranged in the through holes of the seeding wheel housing. Accordingto the invention, the blocking blocks are enabled, by means of the rotation of the motor, to move up and down in the through holes on a seeding wheel housing, so that the depth of a seeding hole can be adjusted, and then the seeding quantity can be adjusted.

Owner:陈卫

Wide-narrow dual-row ridging seed pre-cutting type cassava planting machine

PendingCN111406485AGuaranteed uniformityEvenly seededPotato plantersFurrow making/coveringAgricultural engineeringManihot esculenta

The present invention discloses a wide-narrow dual-row ridging seed pre-cutting type cassava planting machine. The wide-narrow dual-row ridging seed pre-cutting type cassava planting machine comprisesa frame, land wheels, a transmission system and a rotary plate type seeding device, wherein the top side of the frame is provided with the rotary plate type seeding device; the bottom side of the frame is provided with the land wheels; and the land wheels drive the rotary plate type seeding device to rotate through the transmission system. In a manner of pre-cutting cassava seed stalks into seedstems with the lengths of 15-20 cm, a seed-metering mode of a real-time seed cutting type cassava planting machine is changed by the rotary plate type seeding device. The wide-narrow dual-row ridgingseed pre-cutting type cassava planting machine has the characteristics of simple structure, high working stability, uniform and accurate seeding, high efficiency and the like.

Owner:AGRI MACHINERY INST CHINESE TROPICAL ACAD OF SCI

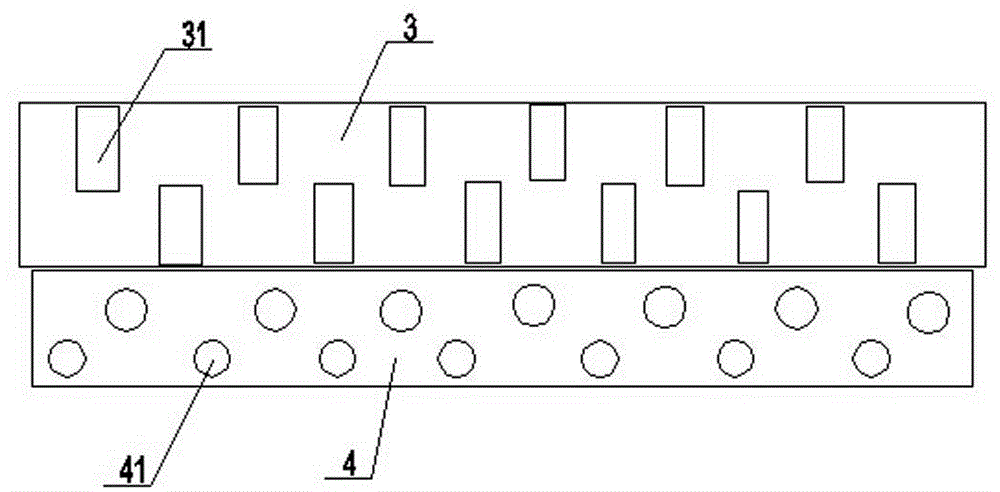

Horizontal circular motion type hybrid rice low-sowing-amount precise seed metering device

ActiveCN112449809APrecision seedingGuarantee sufficiencyDibble seedersSeed depositing seeder partsAgricultural engineeringMechanical engineering

The invention discloses a horizontal circular motion type hybrid rice low-sowing-amount precise seed metering device. The device comprises a base, a seed metering assembly, a seed box driving mechanism and a seed falling mechanism. The seed metering assembly comprises a seed box, an upper blocking mechanism and a lower blocking mechanism; a plurality of seed metering holes for accommodating seedsare formed in a bottom plate of the seed box; the upper blocking mechanism and the lower blocking mechanism are respectively used for blocking the upper sides and the lower sides of all the seed metering holes; the seed box driving mechanism is used for driving the seed box to translate along a circular track; and the seed falling mechanism is used for receiving the seeds from the seed metering holes, guiding the seeds and putting the seeds into a seedling tray. according to the seed metering device, the seed box, the upper blocking mechanism and the lower blocking mechanism included in the seed metering assembly move cooperatively, so that seed filling and seed metering operation can be realized; the seed box driving mechanism drives the seed box to do horizontal circular motion, so thatthe seeds in the seed box can move to ensure the sufficiency of seed filling; and the seed falling mechanism can guide the seeds from each seed metering hole into various holes in the seedling tray.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Multifunctional accurate-measurement seeding device structure

InactiveCN104137686AMeet sowingEvenly seededSeed depositing seeder partsAgricultural engineeringSowing

The invention discloses a multifunctional accurate-measurement seeding device structure which is even and accurate in seeding and free of seed damage. The multifunctional accurate-measurement seeding device structure comprises a seeding box, a seeding axle and a seed sowing axle, wherein the seeding axle and the seed sowing axle are arranged in the seeding box. A thick-tooth seeding wheel and a fine-tooth seeding wheel are arranged on the seeding axle, a plurality of stripe-shaped teeth are evenly arranged on the thick-tooth seeding wheel, a plurality of cylindrical teeth are evenly arranged on the fine-tooth seeding wheel, the fine-tooth seeding wheel is fixed to the seeding axle through a screw, installation holes are respectively formed in the thick-tooth seeding wheel and the fine-tooth seeding wheel, the thick-tooth seeding wheel and the fine-tooth seeding wheel are connected through connecting pins, a seeding tongue and an adjusting support are arranged on the seed sowing axle, the adjusting support is fixed to the seed sowing axle through a fixing screw, an adjusting screw is arranged at the lower end of the seeding tongue, the end of the adjusting screw abuts against the adjusting support, and a tension spring is arranged between the seeding tongue and the adjusting support.

Owner:光明食品集团上海农场有限公司

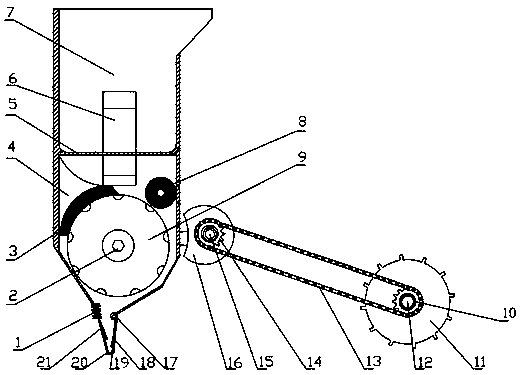

Movable bin single-seed precision hill seeder

InactiveCN102090186BCompact structureReduce volumeFertiliser distributersSeed depositing seeder partsSeederWhole body

The invention relates to a movable bin single-seed precision hill seeder and belongs to the technical field of a movable bin hill seeder. A plurality of seed falling ports (23) are uniformly distributed on the outer periphery of a roller (2). The roller (2) and an end cover (16) are buckled into one whole body and are arranged on a plate shaft (10) through a bearing (9). One end face of the roller (2) is provided with a switching device for a nozzle (1). A plurality of seed supplementing spoons (17) are uniformly distributed on the inner wall of the end cover (16) in a ring-shaped shape. A discharge plate (3) is arranged in the roller (2). A seed plate (4) is buckled inside the discharge plate (3). A cavity between the discharge plate (3) and the seed plate (4) is a seed charging bin (11). A cavity between the discharge plate (3) and the end cover (16) is a seed storage bin (14). The end face of the discharge plate (3), which is close to the seed storage bin (14), is provided with a seed inlet (21) and a seed overflowing port (19). A seed charging mechanism (18) is arranged in the seed charging bin (11). The movable bin single-seed precision hill seeder has the advantages of functions of automatically feeding, overflowing and cleaning seeds, accurate seeding capacity, no cavity, strong practicality and the like.

Owner:SHANDONG UNIV OF TECH

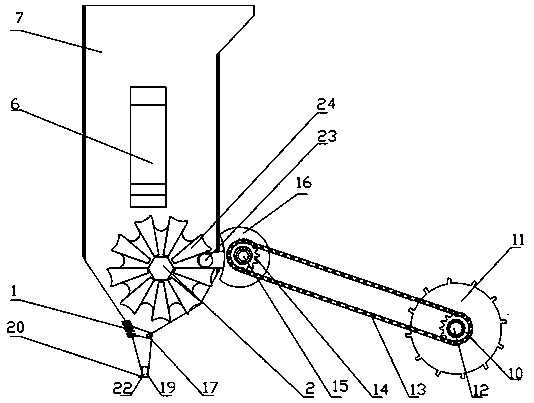

Precut type cassava seed stem seeding device

The invention discloses a precut type cassava seed stem seeding device. The device comprises a base plate, a seed feeding groove, a grooved pulley, a grooved pulley shaft, a seed protective plate anda seed guide groove, wherein the grooved pulley shaft is horizontally arranged on the base plate; the grooved pulley is arranged on the grooved pulley shaft; a cassava seed stem groove is formed in the grooved pulley; the opening direction of the cassava seed stem groove is the tangent direction of the circumference of the grooved pulley; a land wheel is transmitted to a chain wheel in a powered manner through a chain; the chain wheel is used for driving the grooved pulley shaft to rotate; the grooved pulley rotates along with the grooved pulley shaft; cassava seed stems slide along the linearsection of the seed feeding groove, and enter the cassava seed stem groove of the grooved pulley through the arc section of the seed feeding groove; the cassava seed stems outside the cassava seed stem groove are retained in a seed cleaning area by the seed protective plate; when the cassava seed stems in the cassava seed stem groove pass through the seed protective area, the cassava seed stems are prevented from falling off by virtue of the seed protective plate; and when the cassava seed stems are rotated to the seed launching area by the grooved pulley, the cassava seed stems fall into a planting trench through the seed guide groove. The precut type cassava seed stem seeding device has the characteristics of simple structure, good work stability, uniform and accurate seed arrangement and high efficiency.

Owner:AGRI MACHINERY INST CHINESE TROPICAL ACAD OF SCI

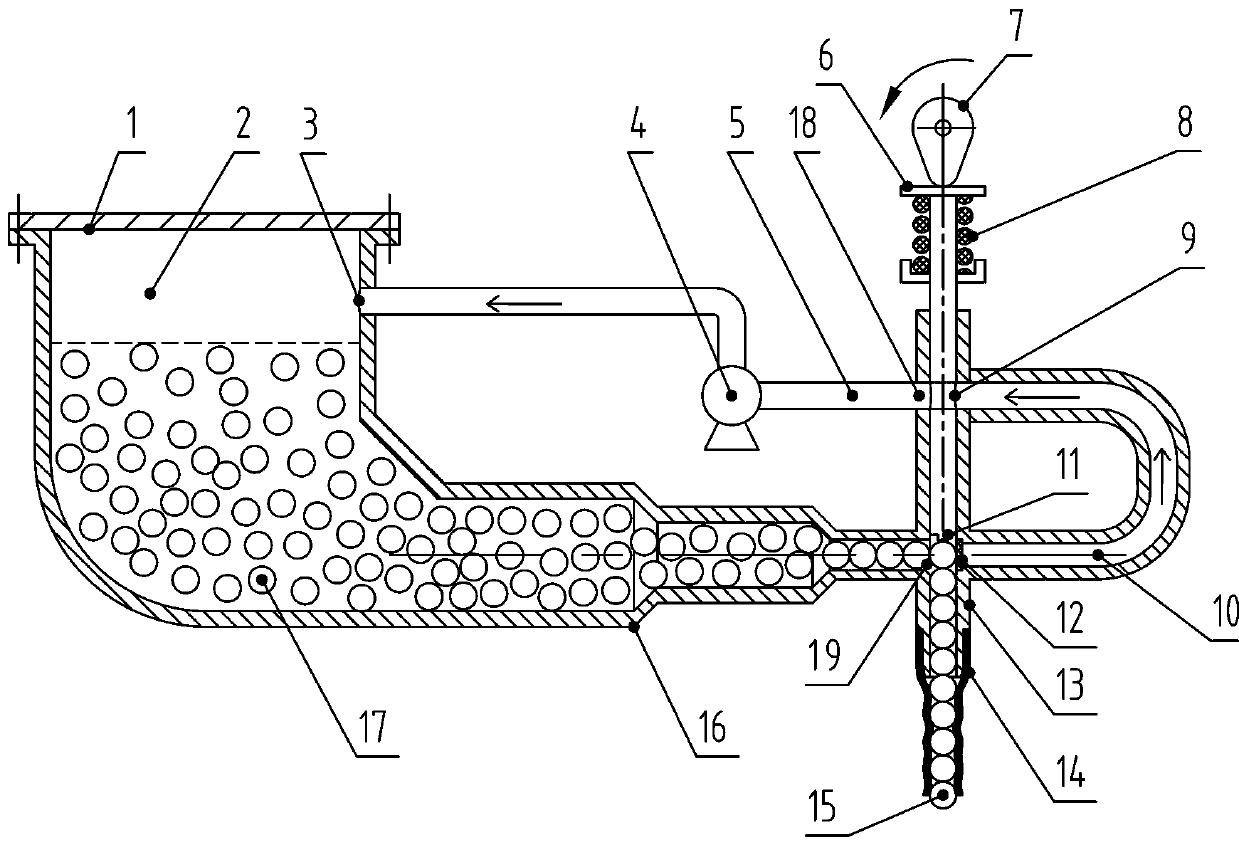

A planter hole sowing device

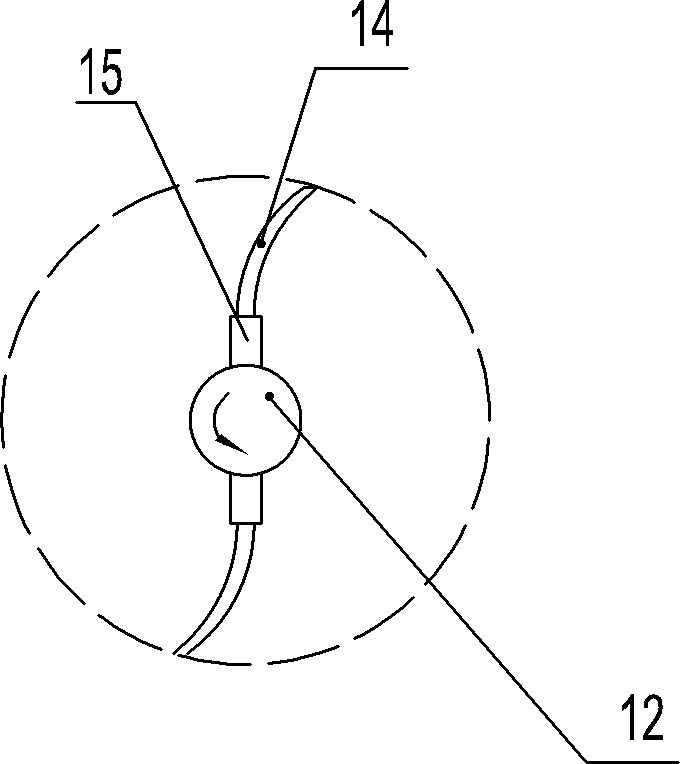

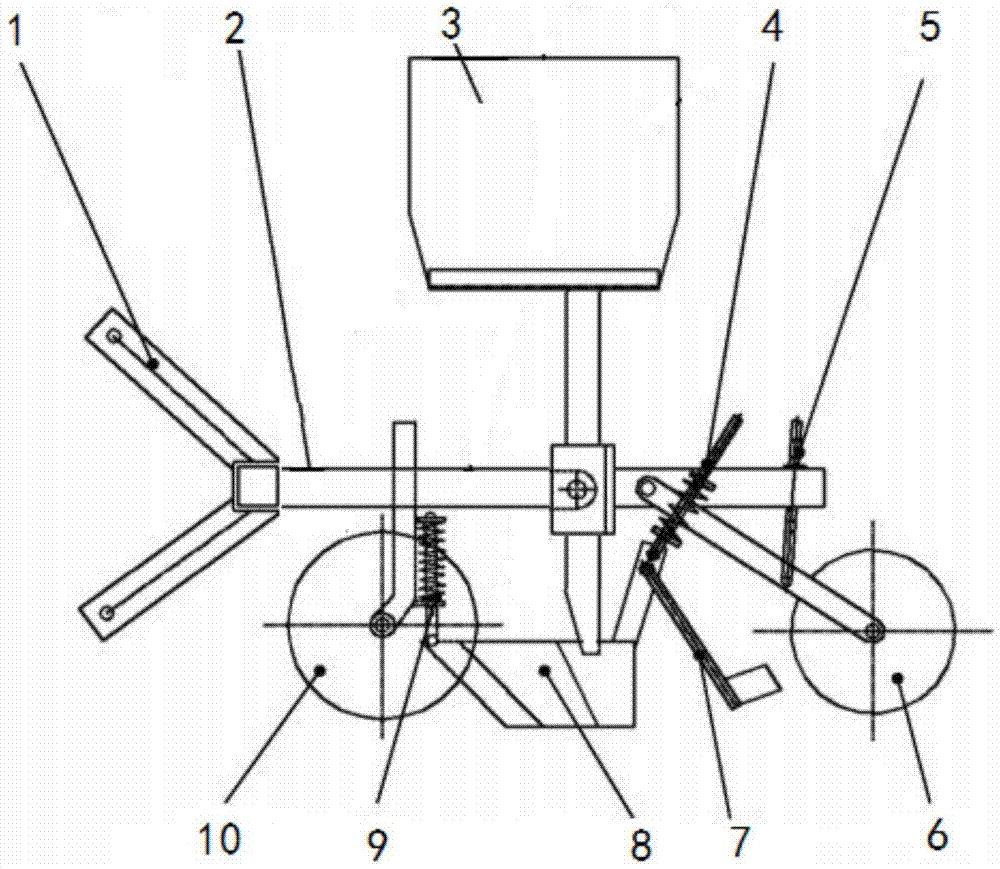

ActiveCN107318310BReasonable structural designSowing precisionSeed depositing seeder partsFertiliser equipmentsSeederField crop

The invention relates to a hole sowing device of a seeder and belongs to the technical field of agricultural machinery. The hole sowing device disclosed by the invention comprises a folded rubber layer, a seeding disk shaft, a separating hairbrush layer, a backfall portion, a seed case partition plate, a seed guide groove, a seed case, a hairbrush roller, a seeding disk, a chain wheel, a land wheel, a land wheel axle, a cylindrical roller chain, a driving plate, a pin shaft, a seed guide plate, a movable stopping plate, a protection plate, a round pin and a geneva wheel. The hole sowing device disclosed by the invention has reasonable structural design; interaction between the geneva wheel mechanism and the land wheel is utilized to achieve interval seeding and achieve accurate seeding; by means of arranging a seed falling device, seeds can fall into holes in a fixed-point short-distance falling mode in a sowing process. When being applied to a hole sowing machine, the hole sowing device disclosed by the invention can achieve accurate seed throwing and reduce missing seeding rate; in a sowing process, a seeding device and the seed falling device cannot be plugged; the hole sowing device has the characteristics of high sowing efficiency, high sowing accuracy and suitability for hole sowing operation of varieties of field crops.

Owner:KUNMING UNIV OF SCI & TECH

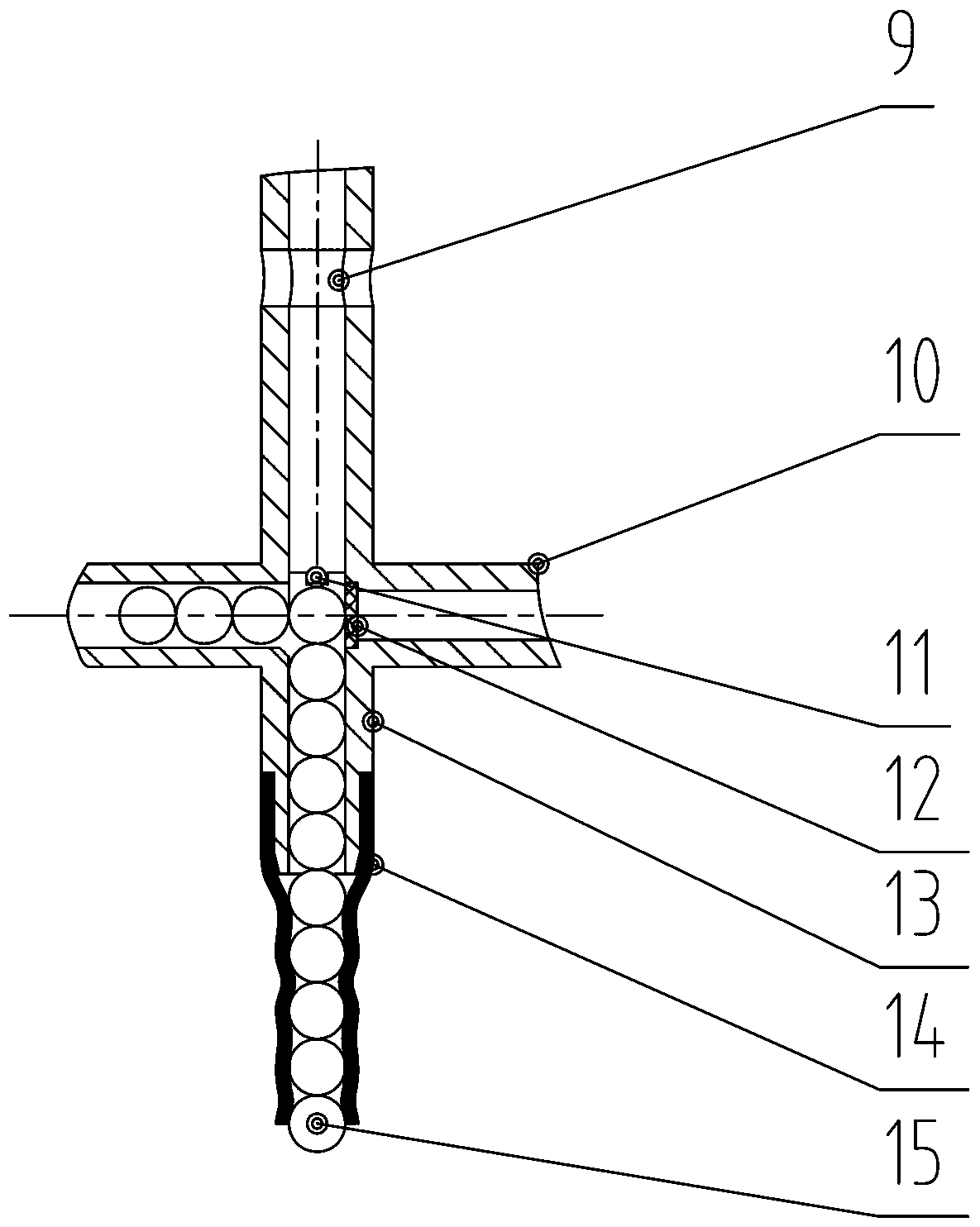

Hydraulic push type precision seeding device

InactiveCN106171195BSolve the situation of single functionSimple structureSeed depositing seeder partsEngineeringCam

The invention provides a hydraulic pushing type precision seed-metering device. The hydraulic pushing type precision seed-metering device comprises a seed box with a sealing cover plate; a water inlet hole (3) is formed in the upper part of the seed box; the bottom of the seed box is communicated with a step diameter-variable pipe (16); the step diameter-variable pipe is communicated with a first water passing hole of a vertical seed-metering pipe (13); a filter screen is arranged at the rear end of the first water passing hole and is connected with a reflowing water pipe (9); a seed push rod (6) sleeved with a spring is inserted into the vertical seed-metering pipe; a cam is arranged on the top of the seed push rod; a second water passing hole (18) is formed in the upper part of the vertical seed-metering pipe; a third water passing hole (9) is formed in the upper part of the seed push rod; the front end of the second water passing hole is connected with the reflowing water pipe and the tail end of the second water passing hole is connected with a water inlet pipe of a water pump; a water outlet pipe of the water pump is communicated with the seed box; when seeds are pushed in sequence, the second water passing hole and the third water passing hole are aligned and water reflows into the seed box; when the seeds are metered, the second water passing hole and the third water passing hole are staggered, and the reflowing water pipe is not communicated with the water inlet pipe of the water pump; and an elastic pipe (14) is arranged at the tail end of the vertical seed-metering pipe, and the inner diameter of the elastic pipe is one half of the diameter of the seeds.

Owner:HUNAN AGRICULTURAL UNIV

Precision seeding machine

InactiveCN107018716AUniform distanceSowing precisionPlantingFurrow making/coveringAgricultural engineeringMonomer

The present invention discloses a precision seeding machine, which comprises a rack assembly, a seeding box, a seeding monomer rack, a round disc ditching device, a sliding cutter ditching device, a soil covering device and a pressing depth limiting wheel, wherein the seeding monomer rack is connected to the rack assembly, the seeding box is arranged on the seeding monomer rack, the round disc ditching device, the sliding cutter ditching device, the soil covering device and the pressing depth limiting wheel are sequentially arranged on the seeding monomer rack from front to rear, a seeding mechanism is arranged in the seeding box, an opening-closing device is arranged between the material discharging port of the bottom portion of the seeding box and the seeding mechanism, the seeding mechanism comprises a seeding pipe, a seeding wheel and a seeding groove, the seeding wheel is arranged in the seeding pipe, the seeing wheel is provided with at least one seeding groove, and the seeding wheel is connected to the round disc ditching device through a drive shaft. According to the present invention, the precision seeding machine has characteristics of simple structure and convenient operation; the seeding is performed with the seeding mechanism, such that the production cost is reduced, the ditching depth is stable, the seed can tightly contact the soil on the bottom of the ditch, and the precision seeding machine is suitable for the basic situation of the vast rural areas of our country, and has advantages of time saving, labor saving, and working efficiency improving.

Owner:GUANGXI GAONONG MACHINERY

A special seed metering device for taro

The invention discloses a seed metering device special for taros and belongs to the field of agricultural machines. The seed metering device is composed of a linear track part, a rotating part and a grabbing part. The seed metering device is characterized in that sliding blocks vertically move, power of the sliding blocks comes from the operation that rotating shafts on the top of a taro sowing machine drive cranks, and the cranks and the sliding blocks are connected through rockers; swing rods connected with the sliding blocks can move vertically, the curve sliding block on the leftmost side moves on a curve track, the swing rods are made to swing left and right, the swing rods are connected with scissor-type long rods, the two topmost ends of each long rod are each connected with another curve track through the corresponding curve sliding block, an upper swing frame and a lower swing frame are adopted to support the curve tracks, supporting frames can synchronously swing along with swing of the swing rods through the connection of the three parts and the restriction of the mutual action force, and the two curve sliding blocks move vertically on the curve tracks. By means of the seed metering device, precision seed metering of the taros can be achieved, damage to main buds of the taros in the sowing process is avoided, it can be ensured that the main buds of the taros in soil are upward, and thus the problem that an existing sowing device cannot effectively sow the taros is solved.

Owner:SHANDONG UNIV OF TECH

Seeder with seedling strip cleaner

InactiveCN102415234BPrevent weedFront and rear dimensions shortenedSpadesPlantingAgricultural engineeringSeedling

Owner:山东颐和农机制造有限公司

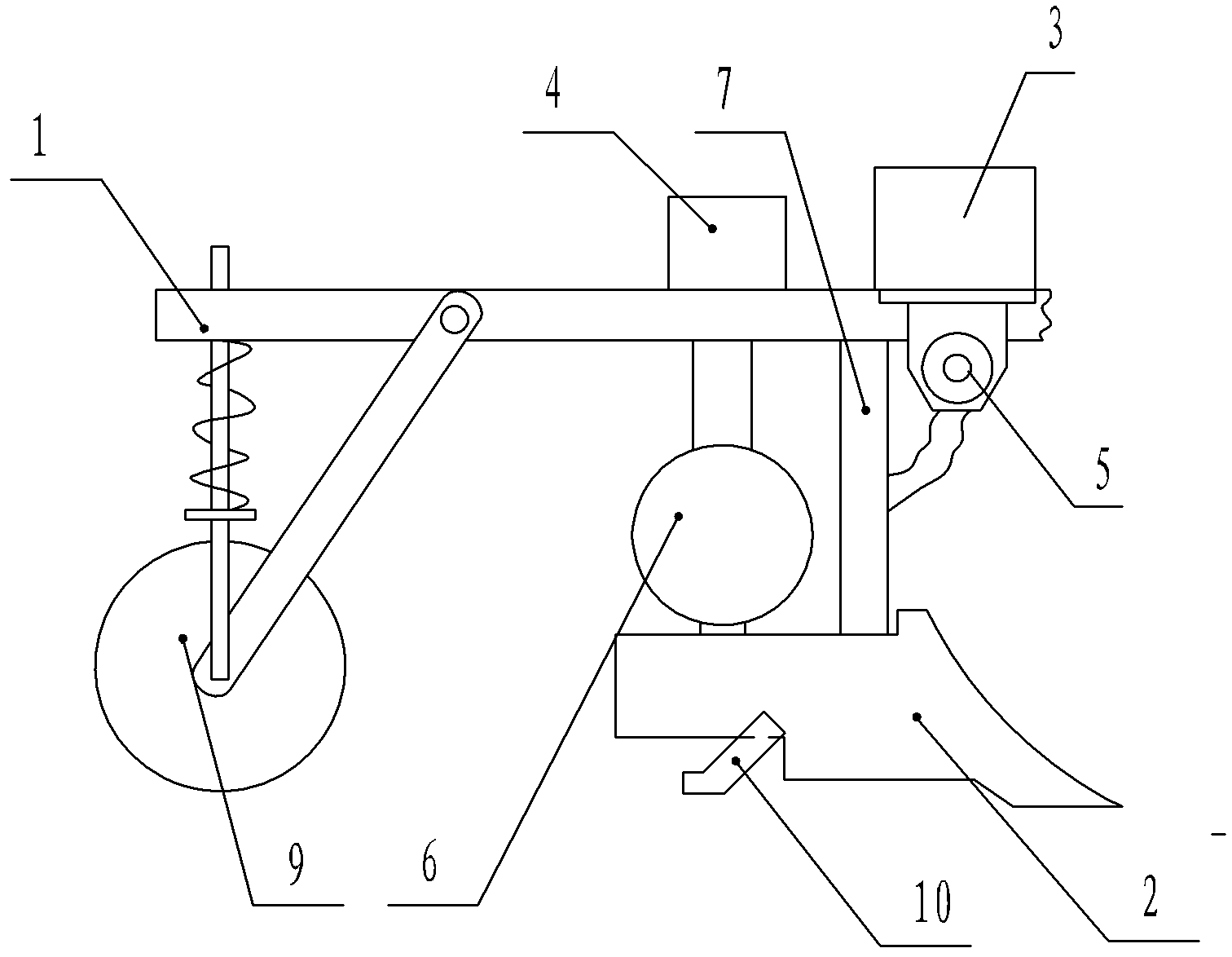

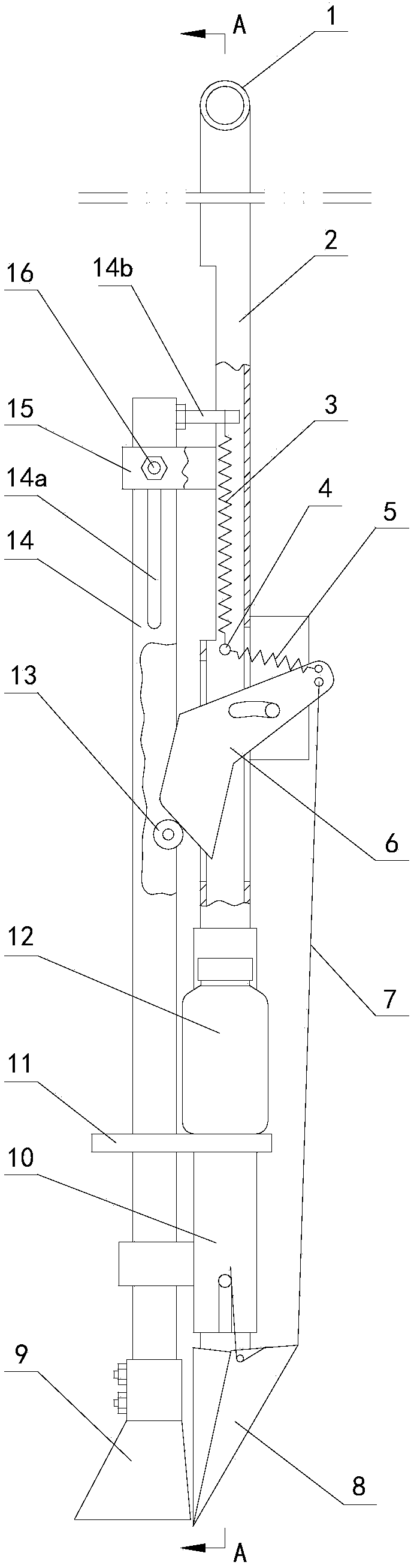

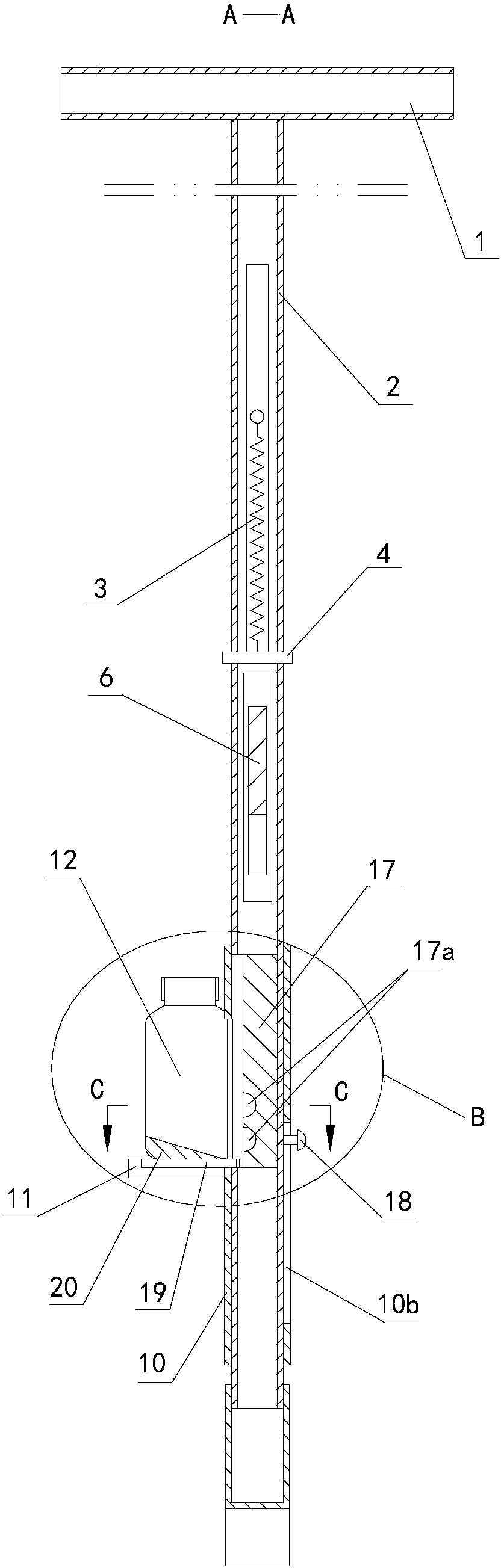

Portable seeder for large-grain crops

Provided is a portable seeder for large-grain crops. A first spring is connected between a supporting rod and a boosting component arranged beside the supporting rod, a duckbilled seed discharging part is arranged at the lower end of the boosting component, a cam is hinged to the boosting component, a second spring is connected between the boosting component and the cam, the cam is matched with a rolling wheel on the supporting rod, a pull rod is connected between the cam and the duckbilled seed discharging part, the boosting component is a tubular push rod, a seed box arranged beside the supporting rod is close to the push rod, a seed discharging opening is formed in the seed box, a notch is formed in the push rod, seed holes are formed in a seed discharging plate arranged in the push rod, and a seed scraping plate arranged at the bottom of the seed box is close to the seed discharging plate. When seeding operation is carried out after seeds are contained in the seed box, the supporting rod is supported on the ground, the push rod is pushed downwards, the duckbilled seed discharging part enters soil, redundant seeds on the seed discharging plate are scraped off by the seed scraping plate in the downward moving process of the seed discharging plate, seeds in the seed holes fall into the duckbilled seed discharging part, external force is removed after movement of the push rod is completed, the push rod returns upwards, the duckbilled seed discharging part is opened, the seeds fall into the soil, and then seeding can be completed.

Owner:ANHUI SCI & TECH UNIV

Seed taking and discharging mechanism, seeder and seed taking and discharging method

PendingCN112166759AAvoid damageReduces snapping into sheavesSeed depositing seeder partsSeederAgricultural science

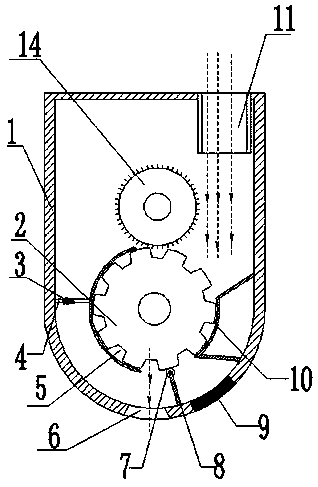

The invention relates to a seed taking and discharging mechanism. The seed taking and discharging mechanism comprises a shell and a grooved wheel, wherein a seed cavity for accommodating seeds is formed in the shell, the grooved wheel is rotationally connected into the shell, an abutting area, a seed taking area, a conveying area and a releasing area which are sequentially arranged in the circumferential direction of the grooved wheel are formed between the outer edge of the grooved wheel and the inner wall of the shell, the part, located in the abutting area, of the grooved wheel abuts against the inner wall of the shell, the seed taking area is lower than the horizontal plane where the top of the grooved wheel is located in the vertical direction, multiple seed grooves are evenly formedin the surface of the grooved wheel, a seed inlet and a seed outlet which communicate with the abutting area and the releasing area are formed in the shell, and the rotating direction of the grooved wheel is the same as the rotating directions of the abutting area, the seed taking area, the conveying area and the releasing area. The invention further provides a seeder comprising the seed taking and discharging mechanism and a seed taking and discharging method. According to the seed taking and discharging mechanism, through low-position seed taking, the risk that seeds are clamped between thegrooved wheel and the shell is reduced, so that the possibility that the seeds are damaged and the later emergence rate is decreased is reduced, the seed taking and discharging mode is novel, and theseed taking and discharging mechanism is suitable for practical application.

Owner:HUBEI YONGXIANG AGRI MACHINERY EQUIP

Potato small seed potato dial seed metering device

InactiveCN105432194BCreate novel structuresCreate a reasonable structurePotato plantersEngineeringSolanum tuberosum

The invention discloses a small seed potato shifting wheel type seed metering device, and belongs to agricultural machinery; a vertical inner side face and a horizontal upper end face of an L-shaped power driving box assembly are respectively provided with a seed shifting wheel in a rotating manner and a seed filling and supply column in an up and down telescopic moving manner; seed shifting rods are evenly distributed and arranged on the seed shifting wheel; a small seed potato box is arranged on the horizontal upper end face of the L-shaped power driving box assembly, and is located at the outer side part of the seed filling and supply column; the outer part of the upper end of the seed filling and supply column is in a cone shape; a hemispherical pit and a horizontal groove are formed in the upper end face of the seed filling and supply column; a seed metering conveying frame is arranged on the small seed potato box; the hemispherical pit has the diameter of 20 mm. The device has the advantages of novel and reasonable structure, accurate seed metering, low sowing leakage rate, low re-sowing rate, reliable operation and less failure, and meets the requirements of precise sowing.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Portable large particle crop seeder

Provided is a portable seeder for large-grain crops. A first spring is connected between a supporting rod and a boosting component arranged beside the supporting rod, a duckbilled seed discharging part is arranged at the lower end of the boosting component, a cam is hinged to the boosting component, a second spring is connected between the boosting component and the cam, the cam is matched with a rolling wheel on the supporting rod, a pull rod is connected between the cam and the duckbilled seed discharging part, the boosting component is a tubular push rod, a seed box arranged beside the supporting rod is close to the push rod, a seed discharging opening is formed in the seed box, a notch is formed in the push rod, seed holes are formed in a seed discharging plate arranged in the push rod, and a seed scraping plate arranged at the bottom of the seed box is close to the seed discharging plate. When seeding operation is carried out after seeds are contained in the seed box, the supporting rod is supported on the ground, the push rod is pushed downwards, the duckbilled seed discharging part enters soil, redundant seeds on the seed discharging plate are scraped off by the seed scraping plate in the downward moving process of the seed discharging plate, seeds in the seed holes fall into the duckbilled seed discharging part, external force is removed after movement of the push rod is completed, the push rod returns upwards, the duckbilled seed discharging part is opened, the seeds fall into the soil, and then seeding can be completed.

Owner:ANHUI SCI & TECH UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com