Deep scarification cultivator adopting automatic sowing and hole entering device and using method

A seeding device and cultivator technology, applied to planting methods, single-seed seeders, seeder parts, etc., can solve the problems of fields that cannot adapt to different seeding conditions, uneven seed distribution, low seeding efficiency, etc., to achieve Avoid artificial secondary burial, reduce manual workload, and improve the effect of germination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

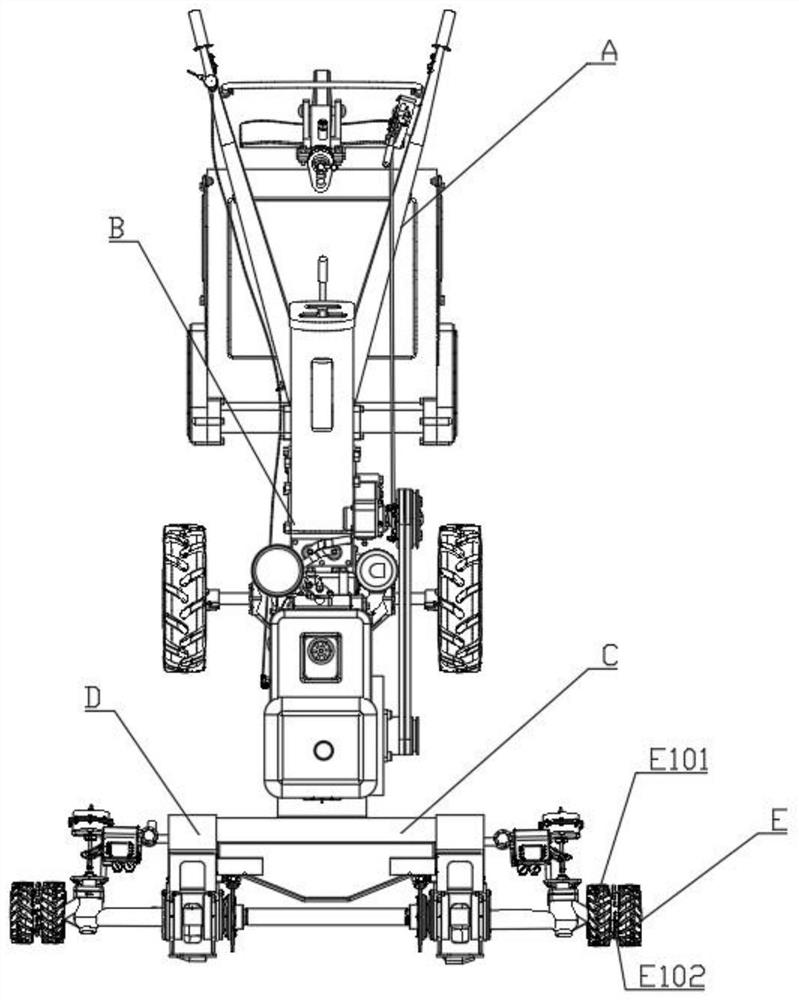

[0061] like Figures 1 to 9 As shown, the subsoiling cultivator adopting the automatic seeding and hole-entry device is characterized in that it includes a frame assembly A, a drive assembly B, a material distribution device C, a feeding device D and a seeding device E, and the frame assembly The front part of A is fixedly connected with the rear part of the drive assembly B, the front part of the drive assembly B is connected with the distribution device C, the two sides of the connection of the distribution device C are fixedly connected with the feeding device D, and the two sides of the feeding device D are equipped with sowing device E;

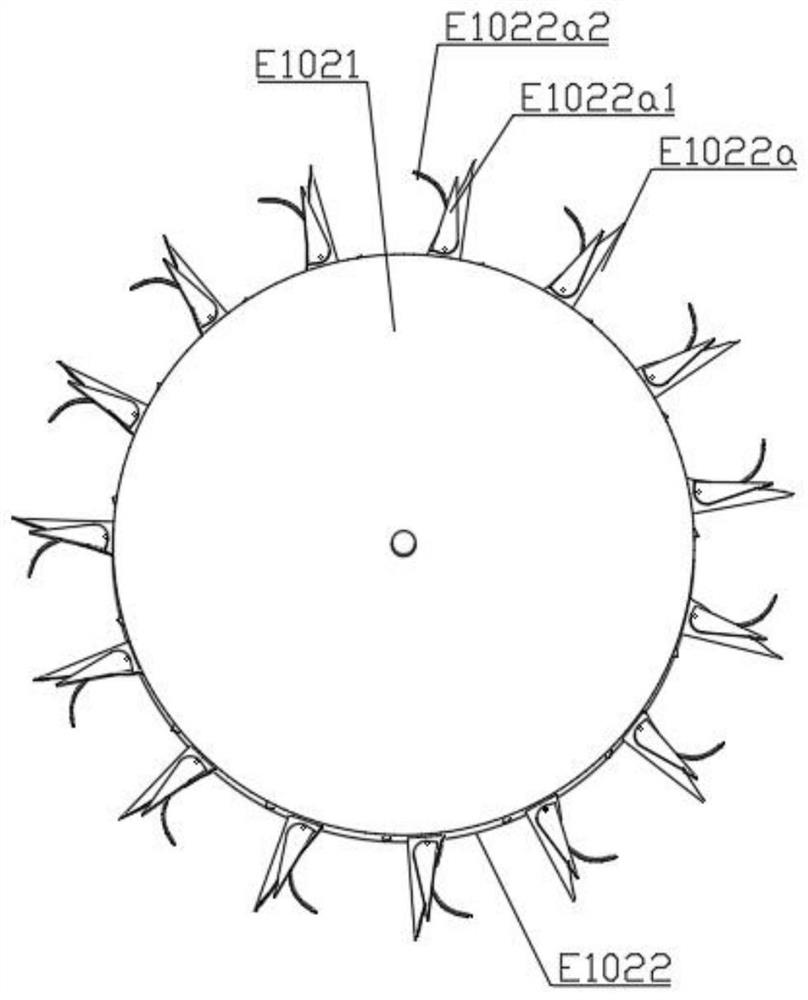

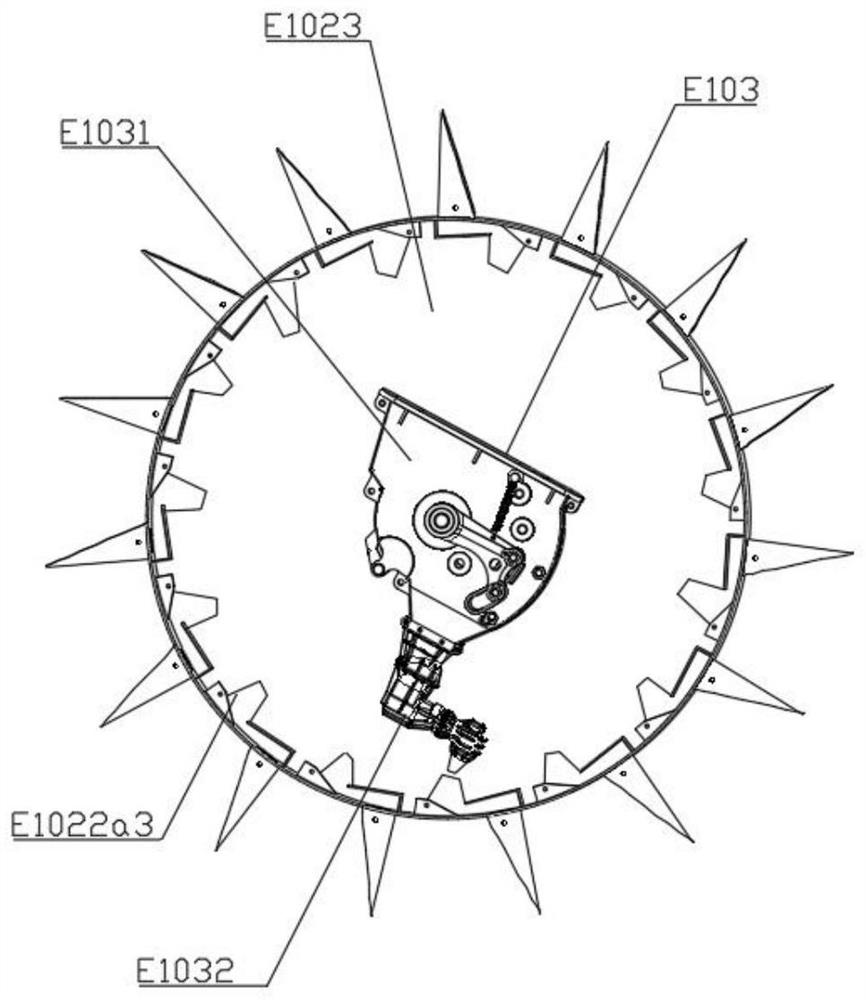

[0062] The sowing device E includes a sowing outer wheel E101, a hole-entry inner wheel E102, and a seeding mechanism E103. There are two sowing outer wheels E101, and the hole-entry inner wheel E102 is fixed between the two sowing outer wheels E101. The seed arrangement E103 is installed inside the hole-entry inner wheel E102.

[0063]...

Embodiment 2

[0074] This embodiment is carried out on the basis of the foregoing embodiment 1, and mainly introduces the structure of the power mechanism of the subsoiling cultivator adopting the automatic seeding device of the present invention.

[0075] like Figures 1 to 9 As shown, the subsoiling cultivator adopting the automatic seeding and hole-entry device is characterized in that it includes a frame assembly A, a drive assembly B, a material distribution device C, a feeding device D and a seeding device E, and the frame assembly The front part of A is fixedly connected with the rear part of the drive assembly B, the front part of the drive assembly B is connected with the distribution device C, the two sides of the connection of the distribution device C are fixedly connected with the feeding device D, and the two sides of the feeding device D are equipped with sowing device E;

[0076] The sowing device E includes a sowing outer wheel E101, a hole-entry inner wheel E102, and a se...

Embodiment 3

[0098] The advantage of the third embodiment compared to the second embodiment is that the direction and speed of the seeder is controlled by the frame to improve the seeding efficiency, and the lower part of the handrail is equipped with a brake, which can effectively reduce the speed of the seeder and prevent the seeder from bumping into foreign objects. The brake switch can quickly stop the seeding mechanism, and when an unexpected situation occurs, it can stop the seeder urgently to ensure the safety of users.

[0099] The method of using the subsoiling cultivator adopting the above-mentioned automatic seeding and hole-entry device, the specific steps are as follows:

[0100] S1, device assembly, frame assembly A, drive assembly B, material distribution device C, and feeding device D and seeding device E, fixedly connect the front of the frame assembly A to the rear of the drive assembly B, drive The front part of the assembly B is connected to the distribution device C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com