Sulfur wet forming system

A technology of wet molding and sulfur, which is applied in the direction of sulfur compounds, chemical instruments and methods, preparation/purification of sulfur, etc., can solve the problems of poor molding quality of sulfur particles, and achieve the goal of improving dehydration effect, preventing corrosion, and increasing residence time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

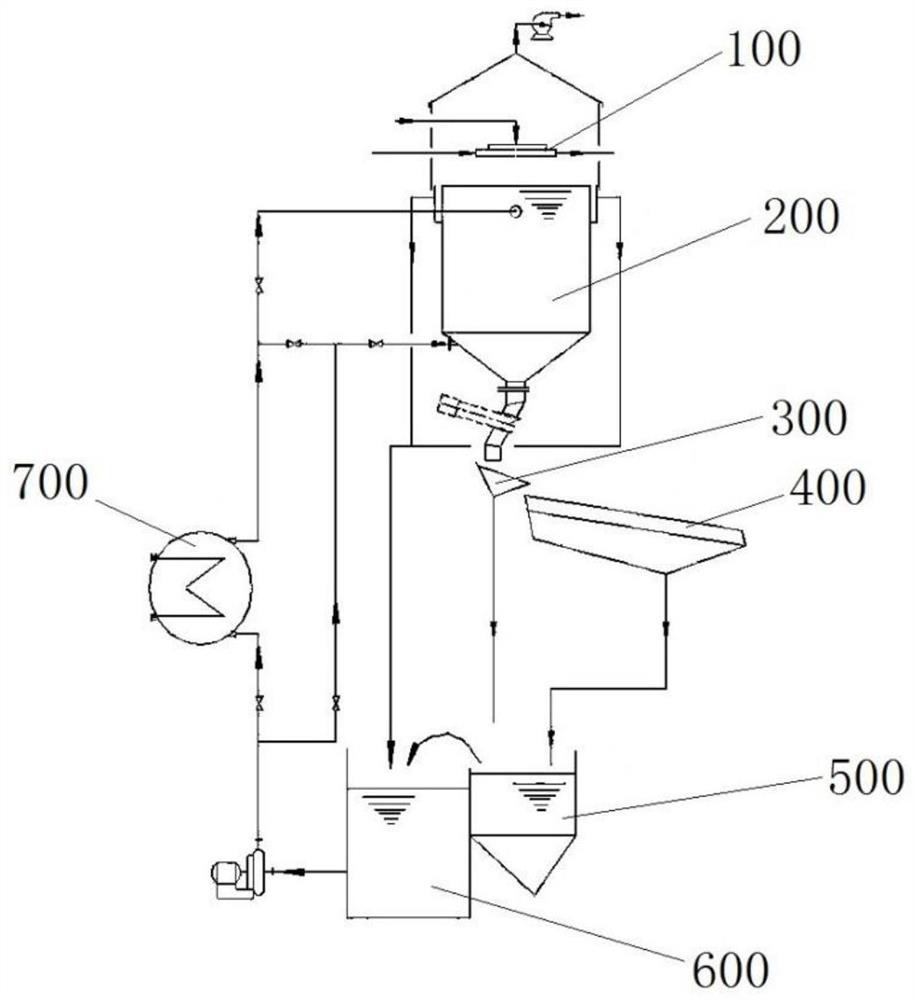

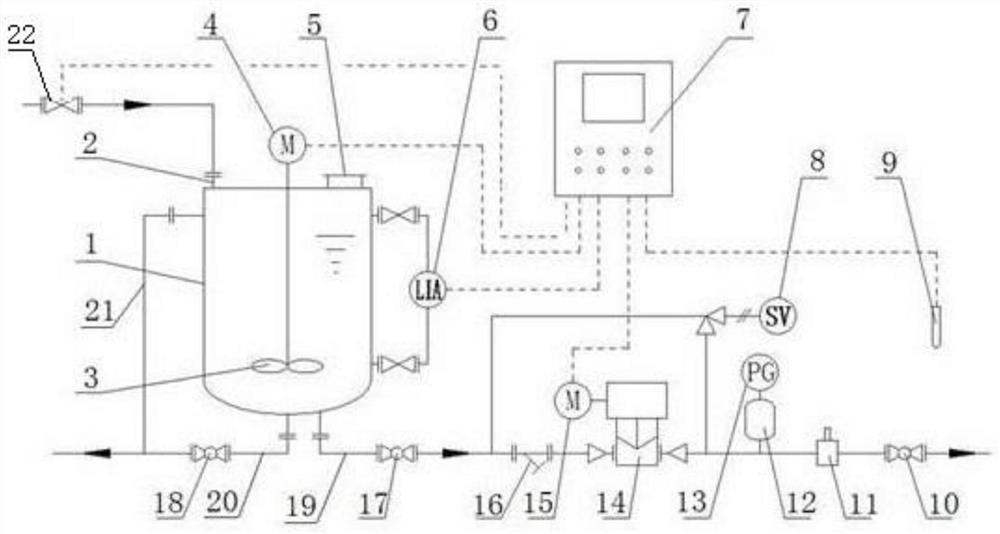

[0071] Such as Figure 2 to Figure 5 As shown, the sulfur wet molding system includes a water tank for holding process water and a process water pH adjustment device. The process water pH adjustment device can detect the pH value of the process water in the water tank in real time, and precisely control the inflow according to the pH value. The amount of lye in the water tank, so that the pH value of the process water is always kept in an appropriate range during the production process, prevents corrosion of equipment and pipelines, prolongs the service life of the sulfur wet molding system, and can improve the overall sulfur wet molding The operation stability of the system improves the molding quality of sulfur granules and ensures production.

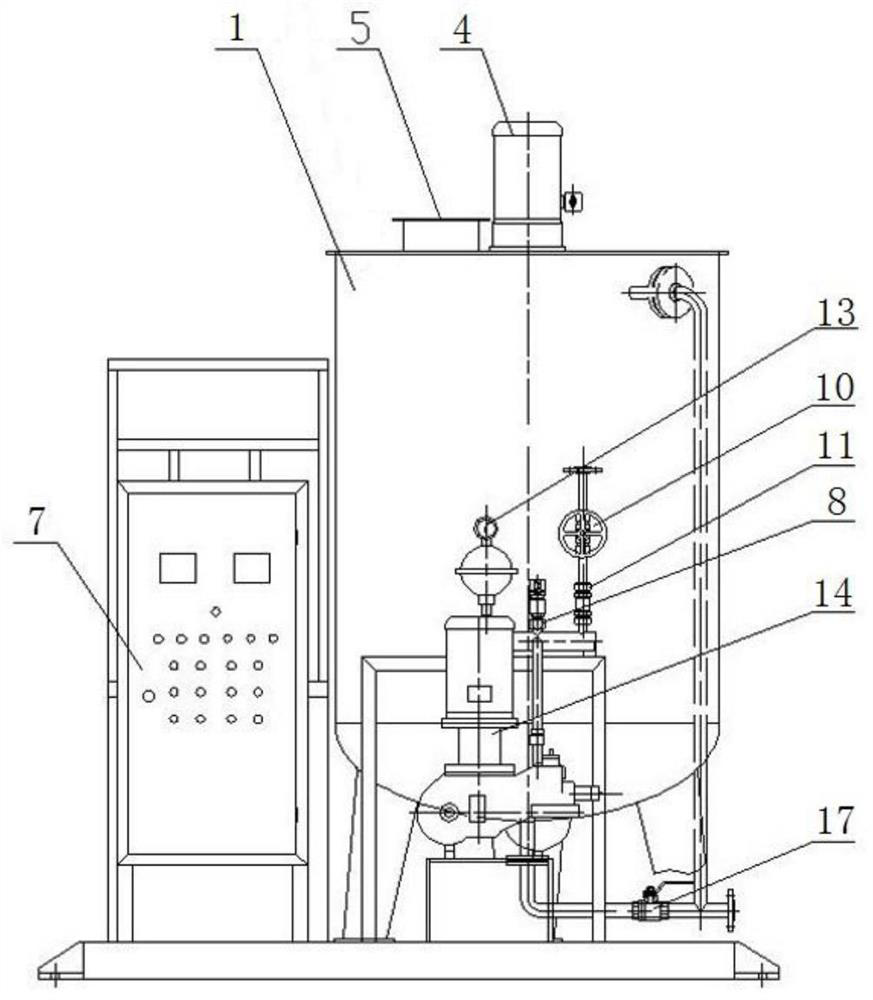

[0072] Such as figure 2 As shown, the process water pH adjustment device mainly includes a liquid storage tank 1, a pH detector 9, a control cabinet 7, and a liquid injection pipeline 19. The liquid storage tank 1 is used to store ...

Embodiment 1

[0101] In Example 1, the lye is formed by adding alkaline substances and water into the liquid storage tank and stirring. In the present embodiment, in actual use, also can buy the lye prepared on the market.

specific Embodiment 3

[0103] In Embodiment 1, a diaphragm metering pump is used to realize the precise delivery of lye. In this embodiment, a plunger or piston type metering pump can be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com