Automatic control system and automatic control method for trowelling machine

An automatic control system and troweling machine technology, applied in manufacturing tools, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems of weak troweling quality and low efficiency of wallboards, shorten the construction and debugging time, and reduce the failure rate. , reduce the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

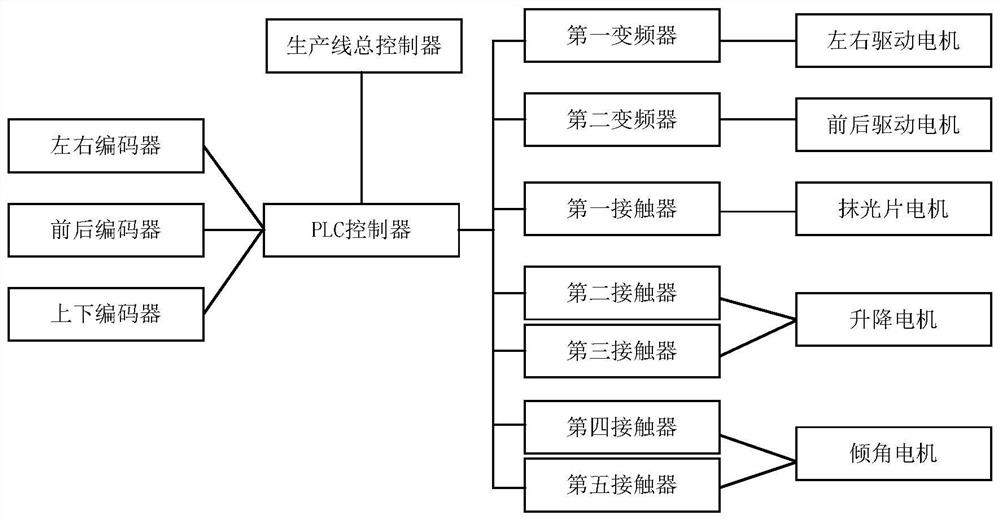

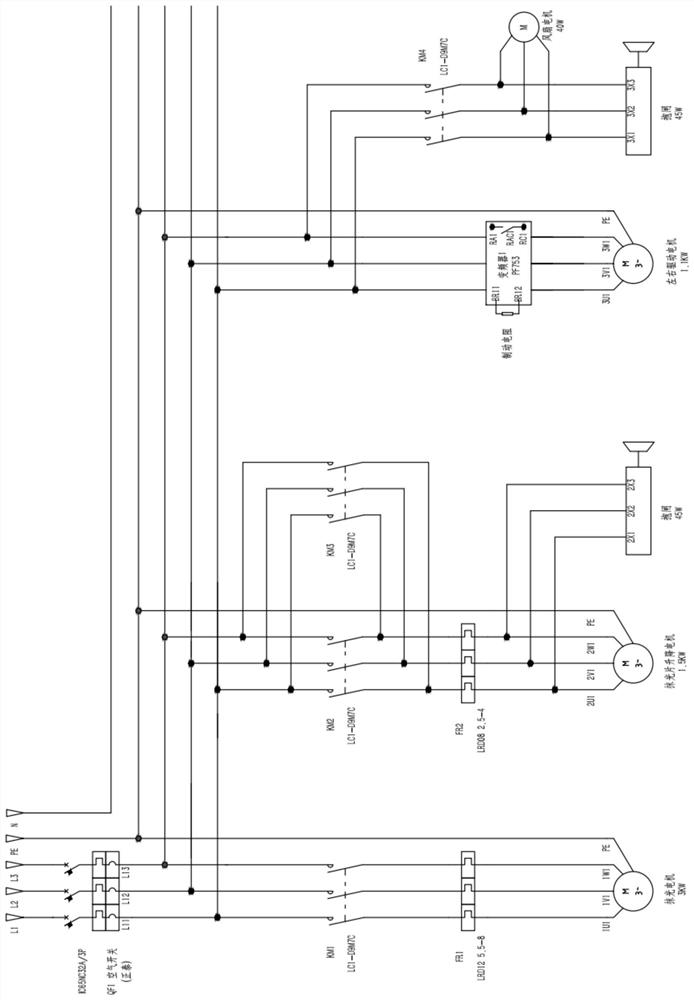

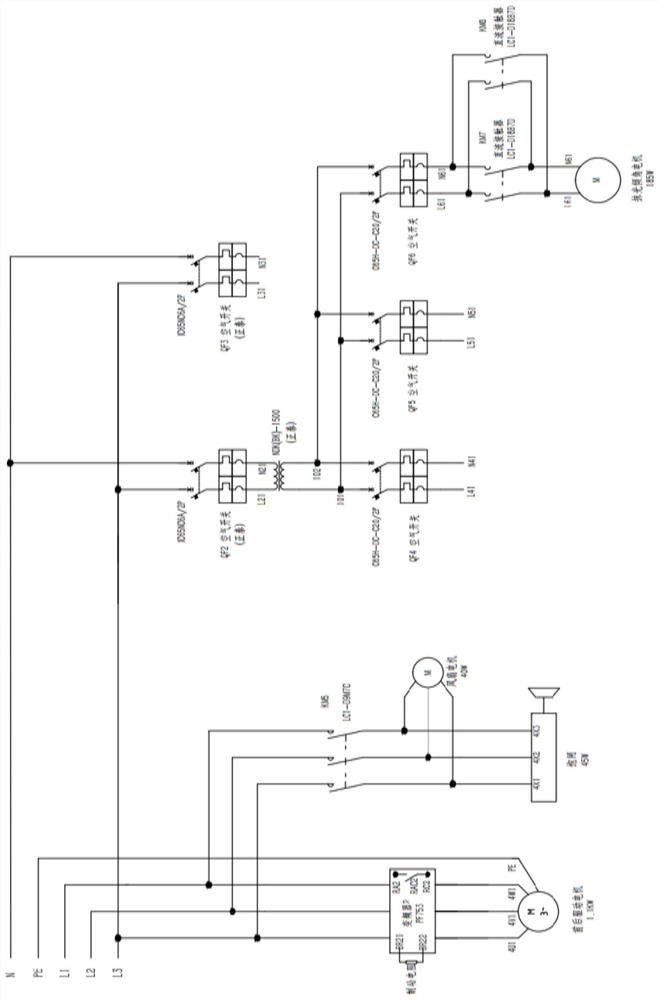

[0057] see Figure 2-Figure 7 It is a schematic diagram of the principle of an automatic control system provided by the present invention. The models and parameters of each component are shown in the figure, and X plus a number indicates the number of each terminal;

[0058] Among them, such as Figure 5 As shown, the PLC controller communicates with the general controller of the production line through the Ethernet communication port 1, and interacts control signals and parameter feedback signals in real time through the network protocol; the PLC controller communicates with each inverter through the Ethernet communication port 2, and communicates with each inverter through the network protocol Inverter 1 and Inverter 2 carry out command control, and then drive the variable frequency motor to start and stop, forward and reverse, speed regulation and other actions; among them, Inverter 1 controls the left and right drive motors, and Inverter 2 controls the front and rear drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com