Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Meet high-quality appearance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass cover plate, making method thereof and mobile terminal

InactiveCN105859115AImprove visual effectsMeet high-quality appearance requirementsDetails for portable computersGlass reforming apparatusGlass coverComputer terminal

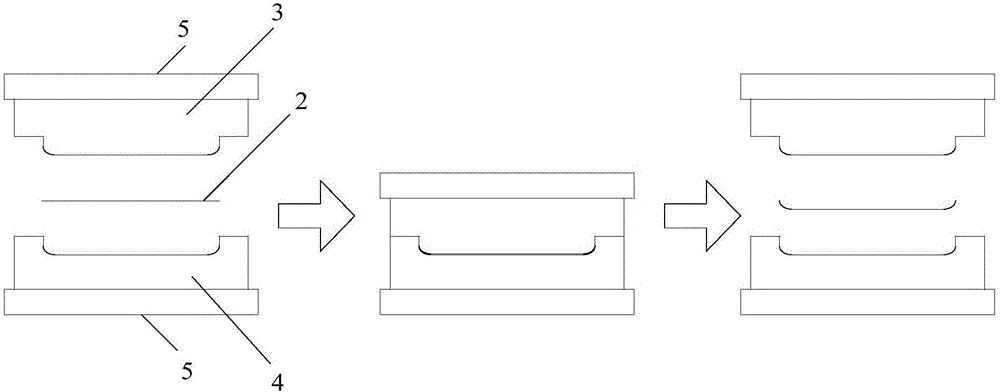

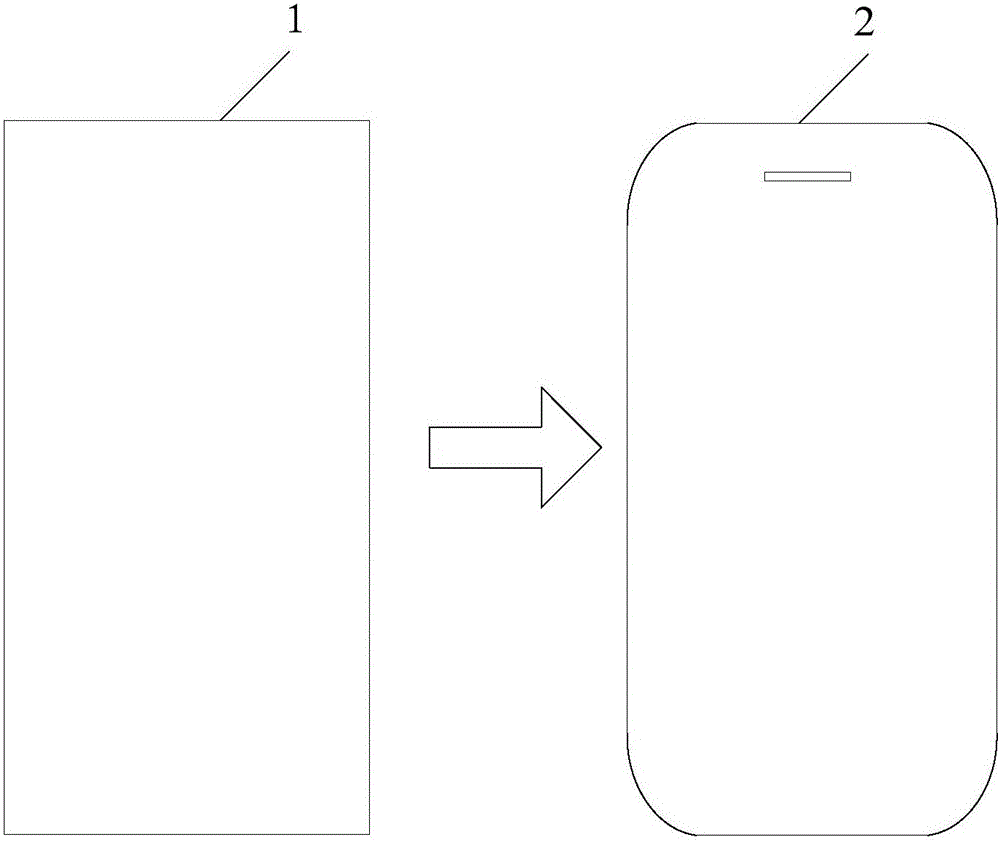

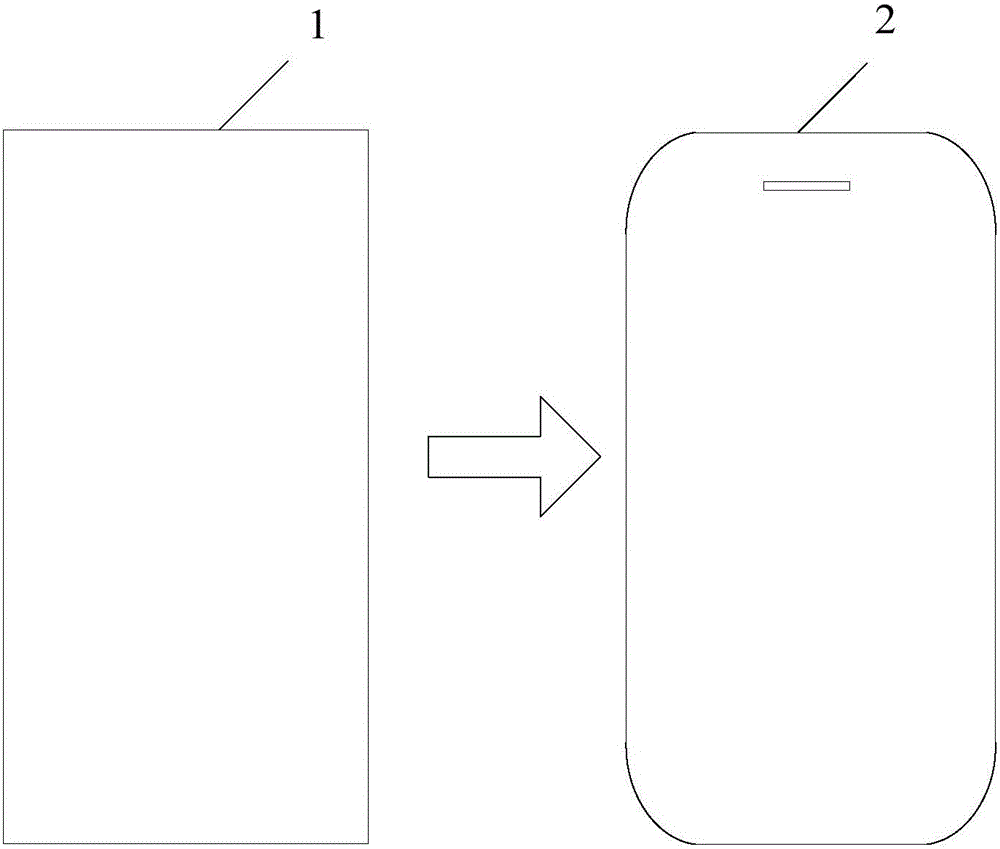

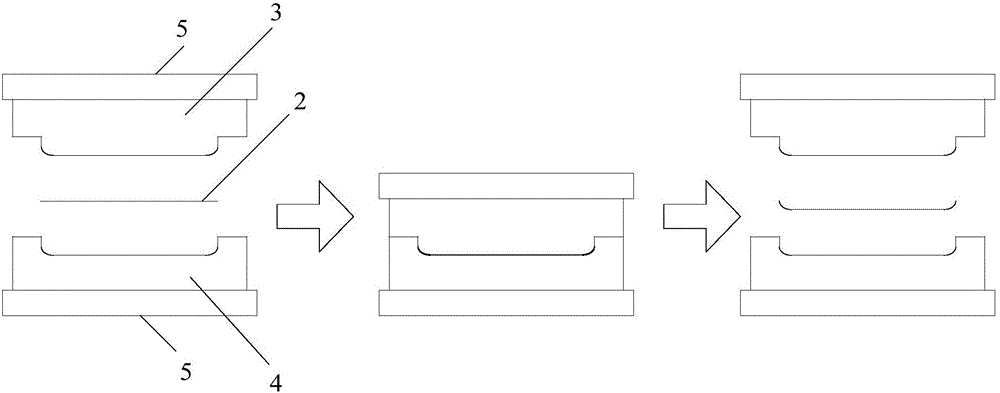

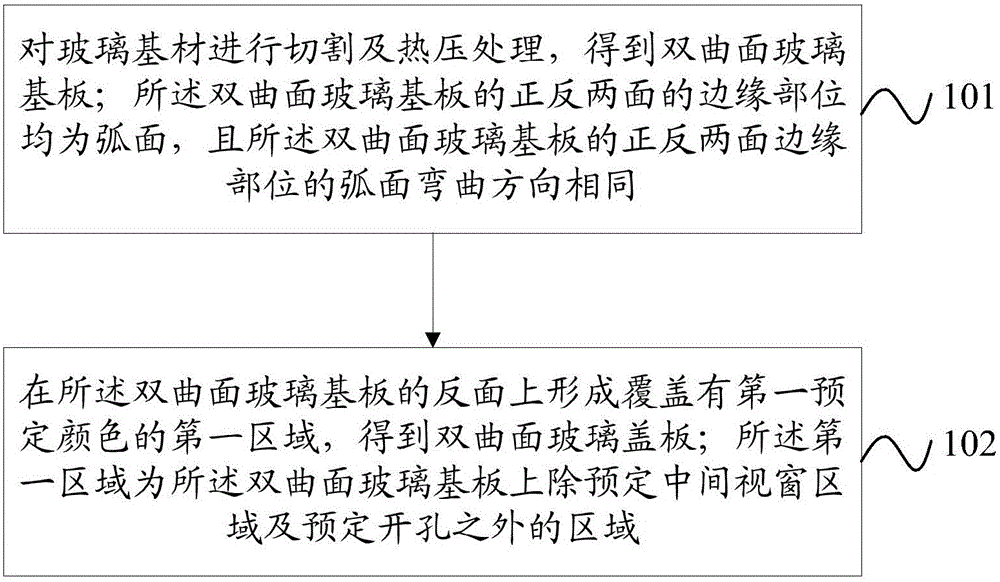

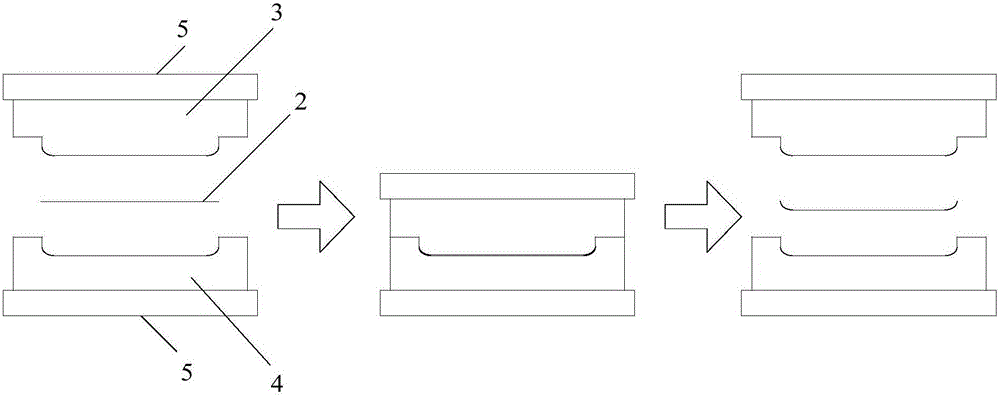

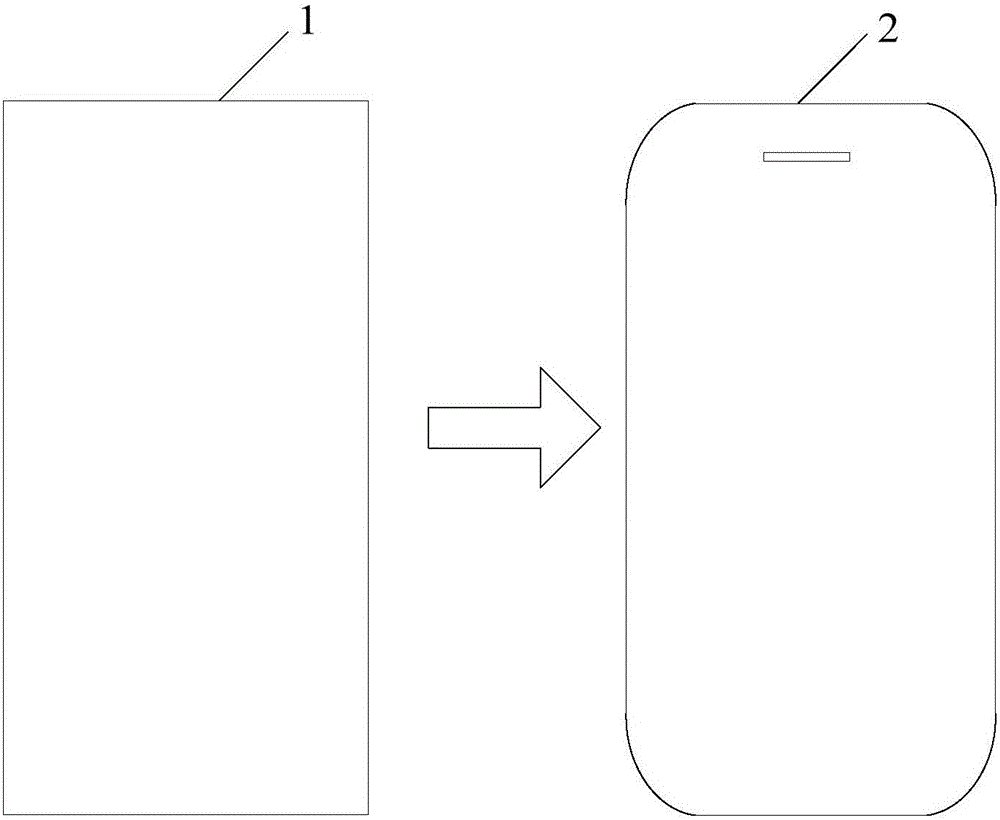

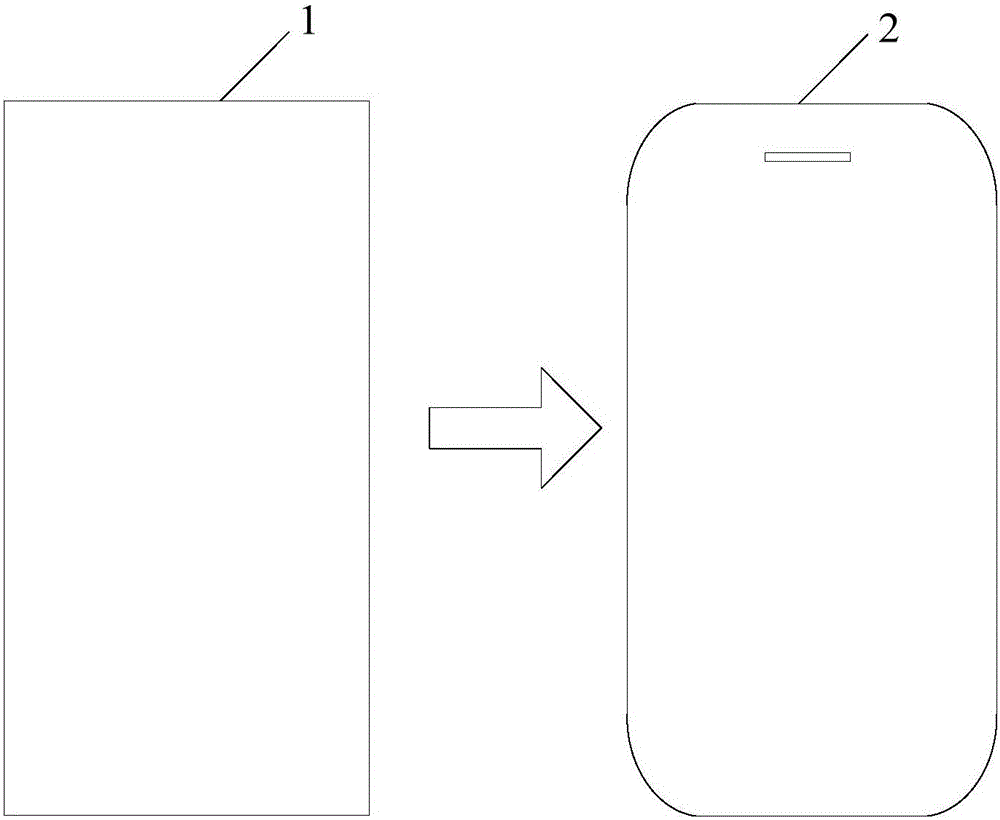

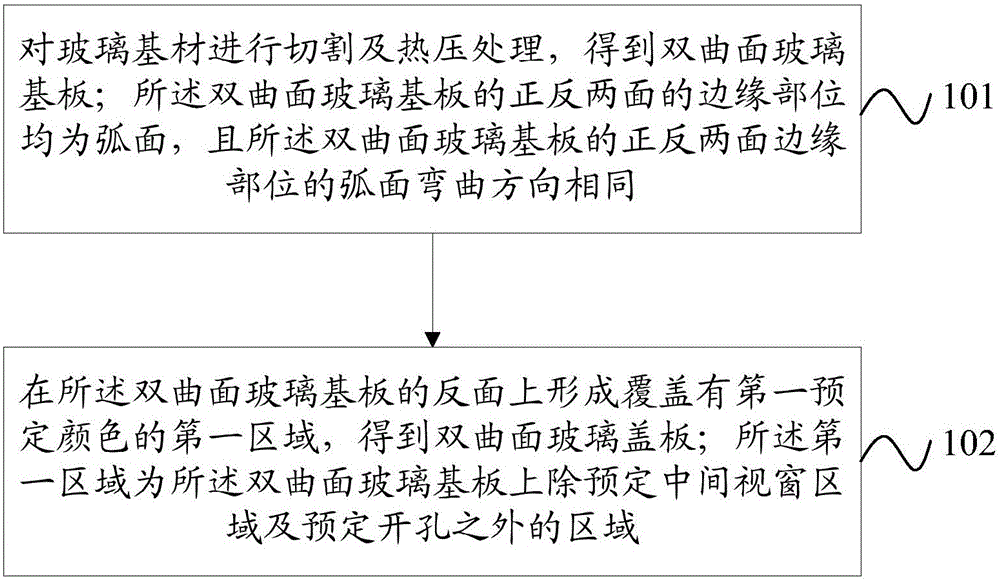

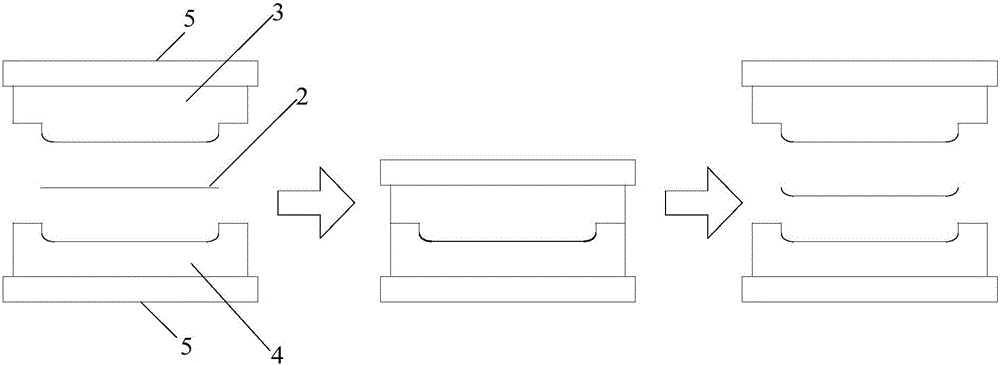

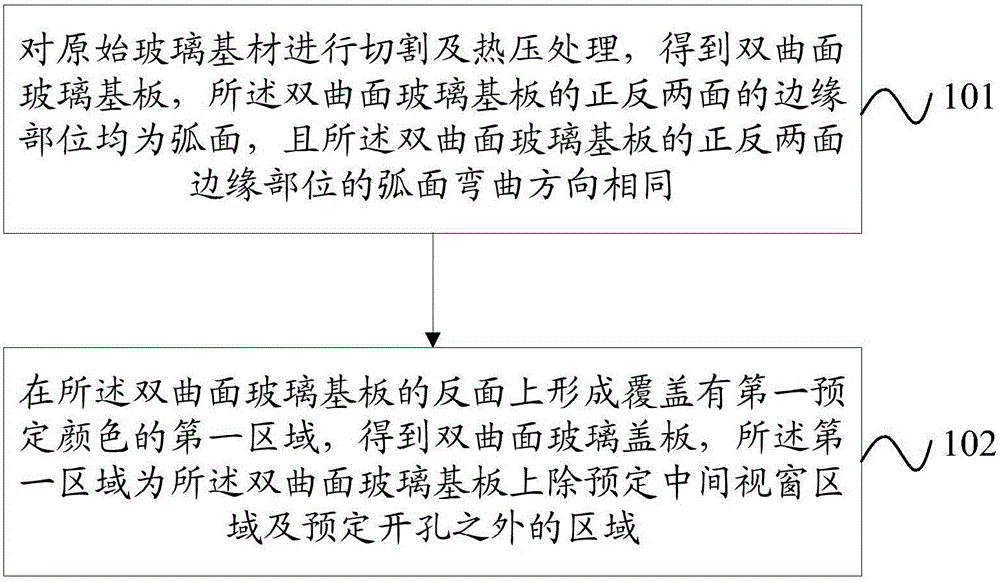

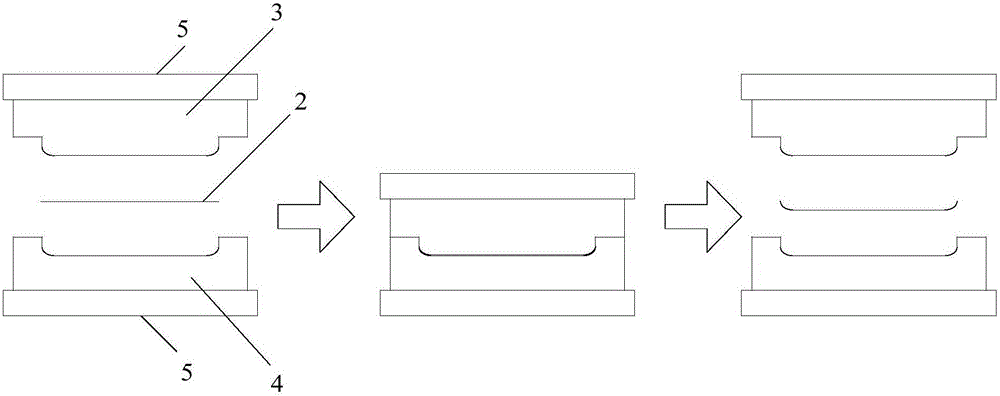

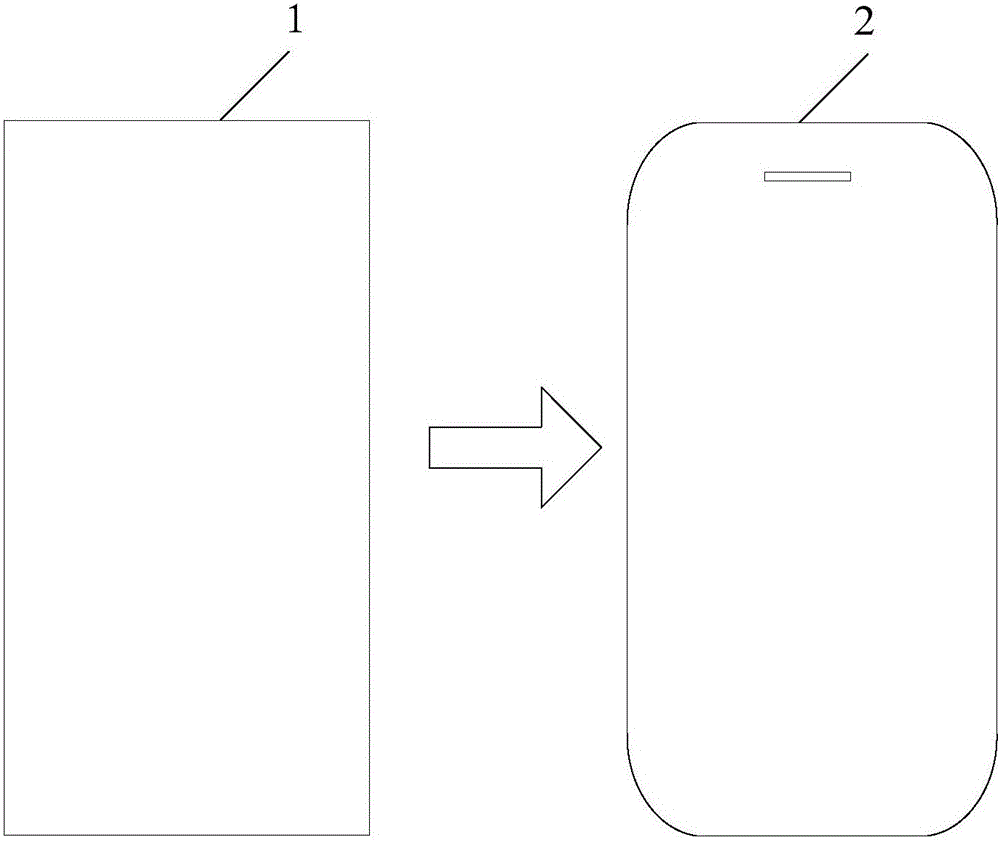

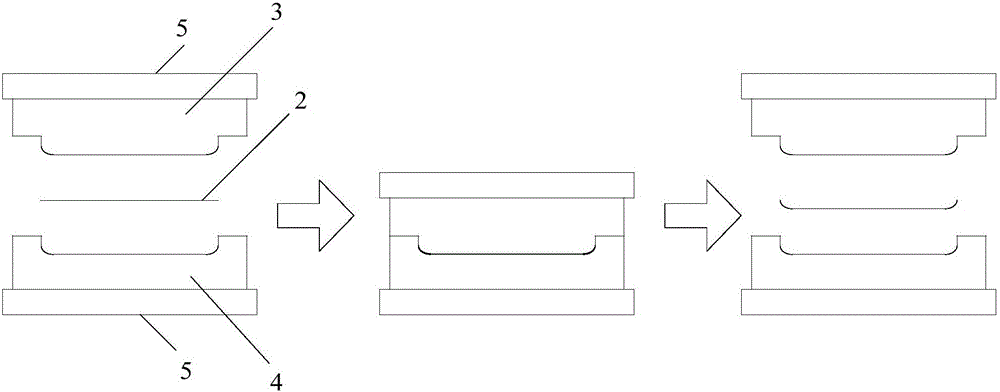

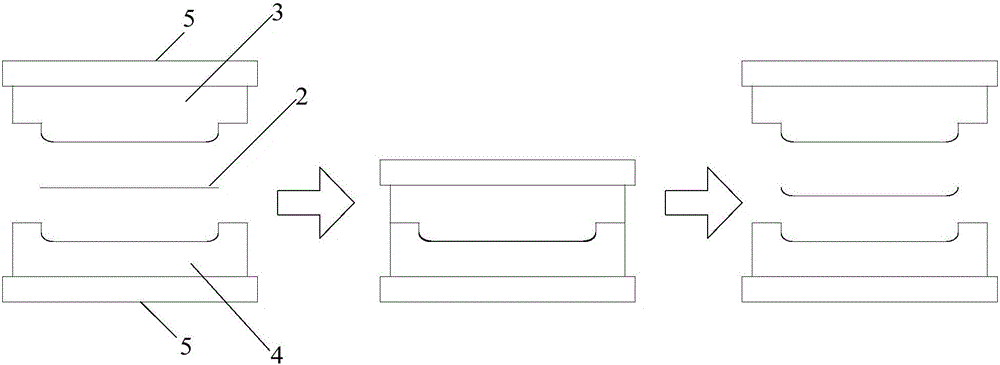

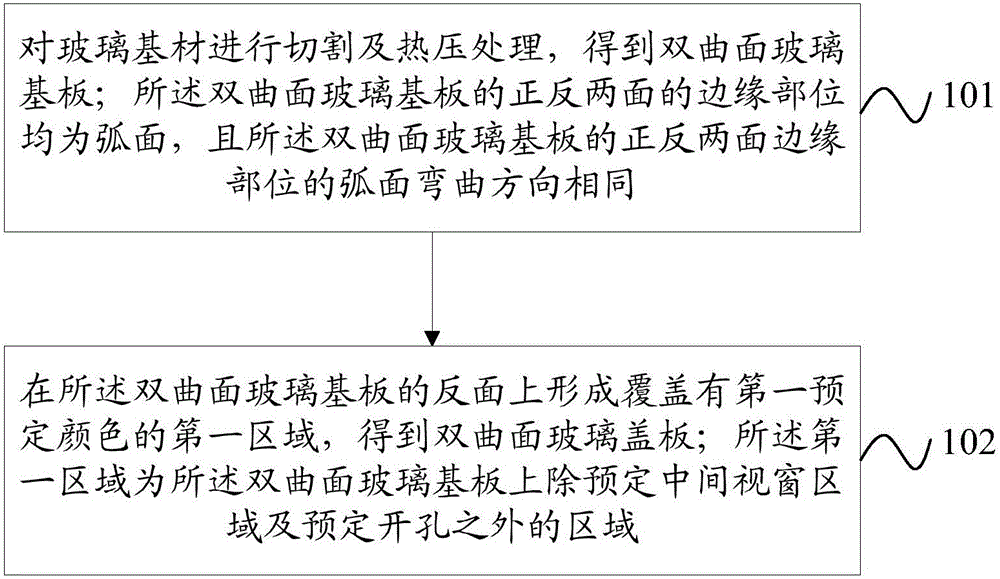

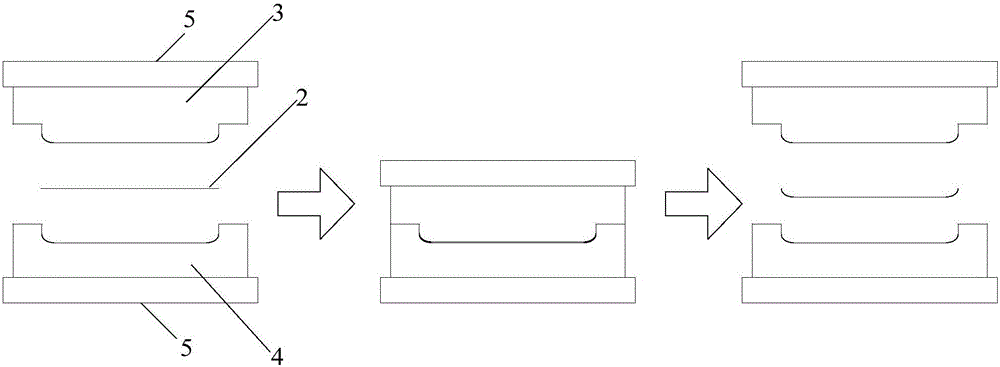

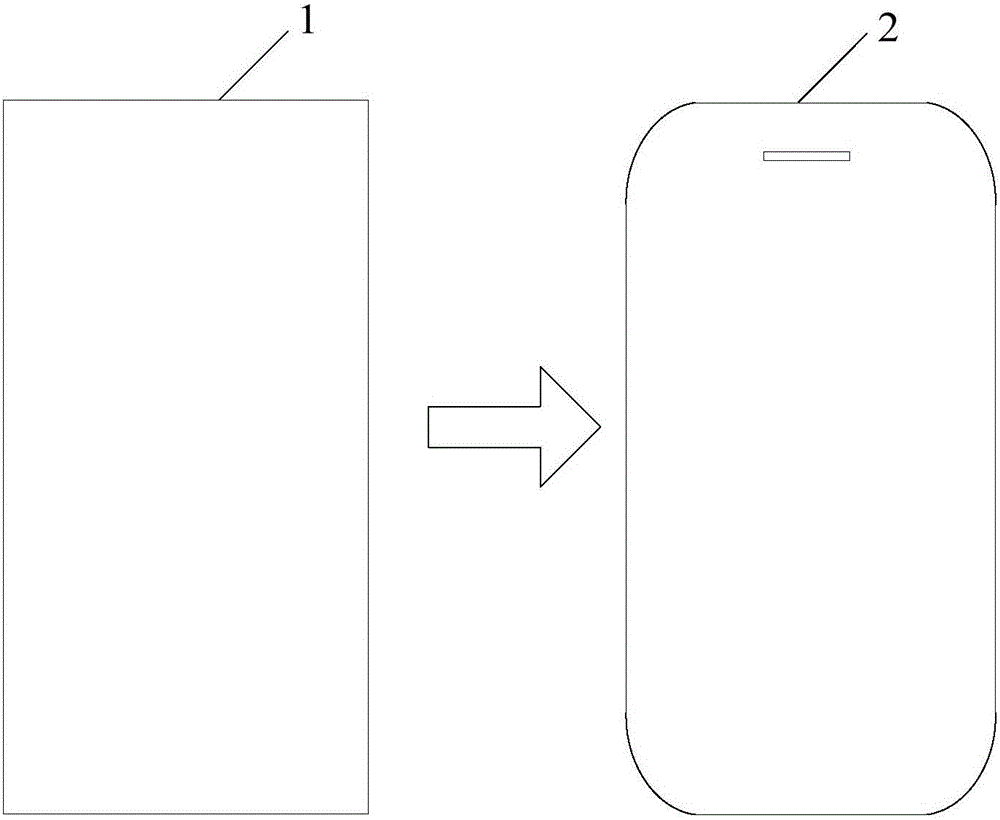

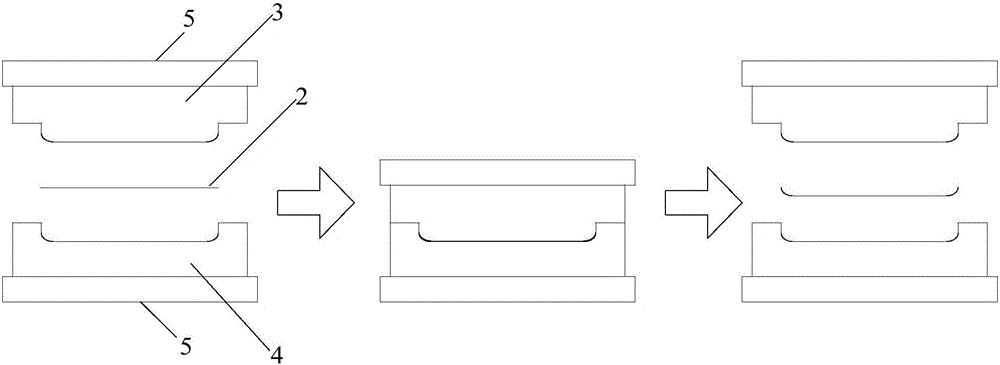

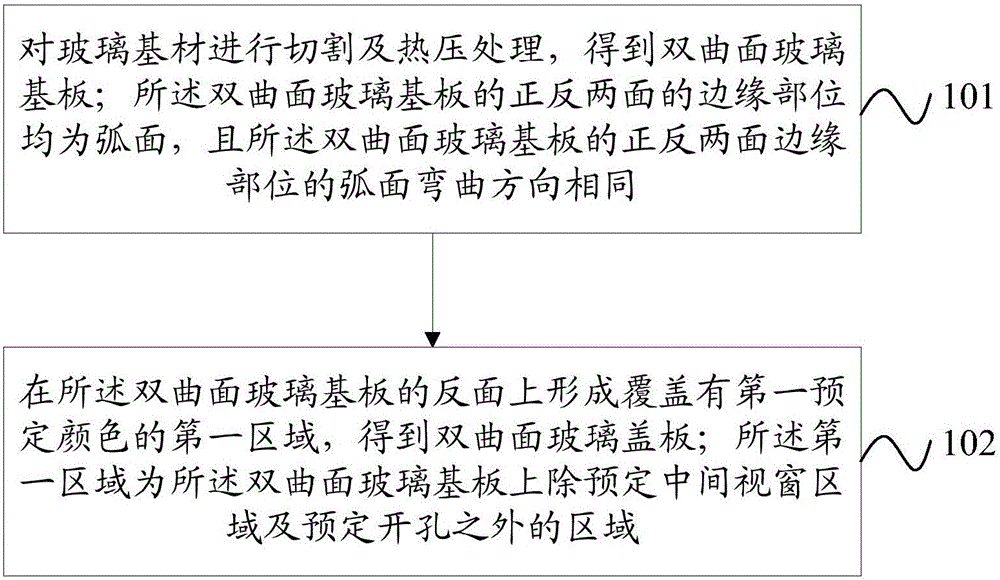

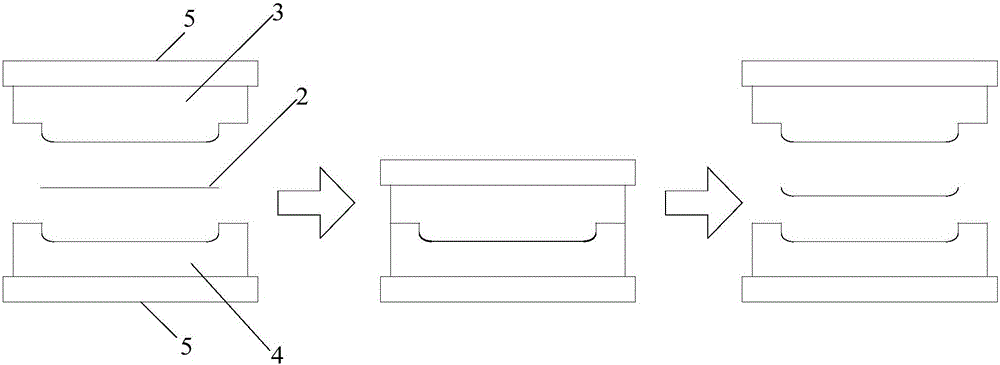

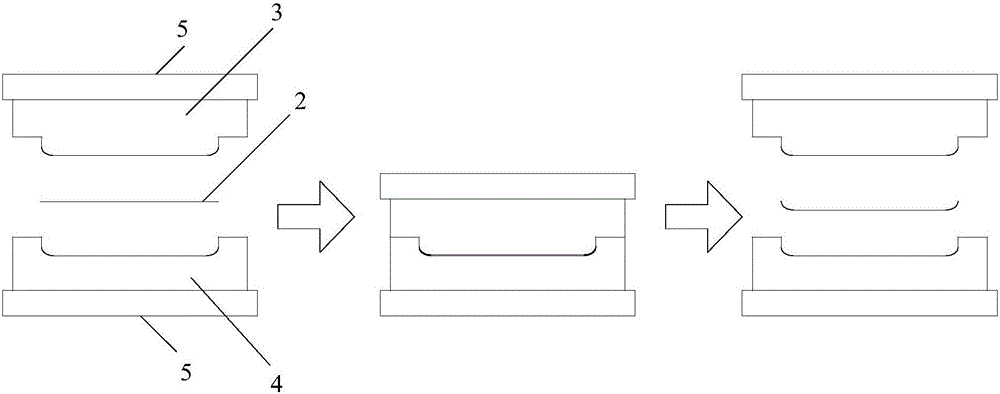

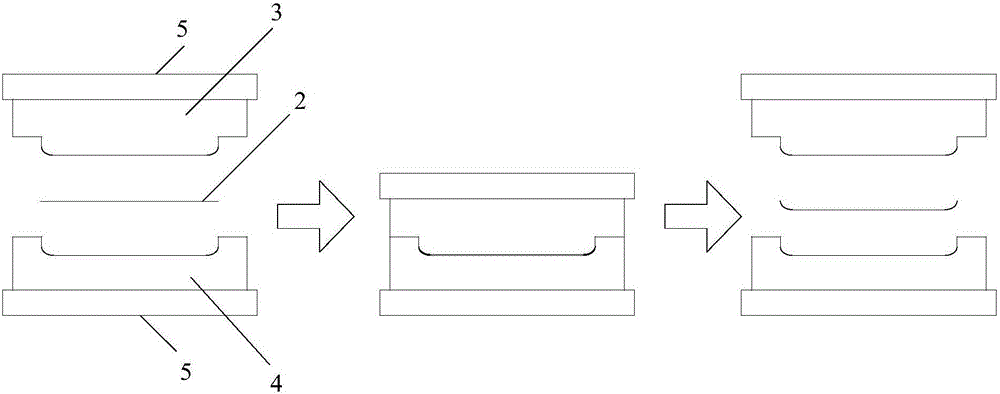

The invention provides a glass cover plate, a making method thereof and a mobile terminal, belongs to the technical field of terminal making and solves the problem that existing glass cover plates are basically planar or 2.5-dimensional, serious in homogenization and difficult to meet requirements of people on high-quality appearance. The making method includes: cutting and hot-pressing a glass substrate to obtain a double-curved-face glass substrate, wherein the edges of the front and the back of the double-curved-face glass substrate are arc faces which are identical in bending direction; forming a first area covered by a first preset color on the back of the double-curved-face glass substrate to obtain a double-curved-face glass cover plate, wherein the first area refers to an area, not including a preset middle window area and a preset hole, of the double-curved-face glass substrate. By the scheme, the 3D double-curved-face glass cover plate with a specific color is formed, is novel and attractive in appearance, meets the requirements of the people on high-quality appearance of the glass cover plate and is low in manufacturing cost.

Owner:VIVO MOBILE COMM CO LTD

Glass cover plate, production method thereof and mobile terminal

InactiveCN106219958AMeet high-quality appearance requirementsNovel shapeDetails for portable computersGlass reforming apparatusHyperboloidGlass cover

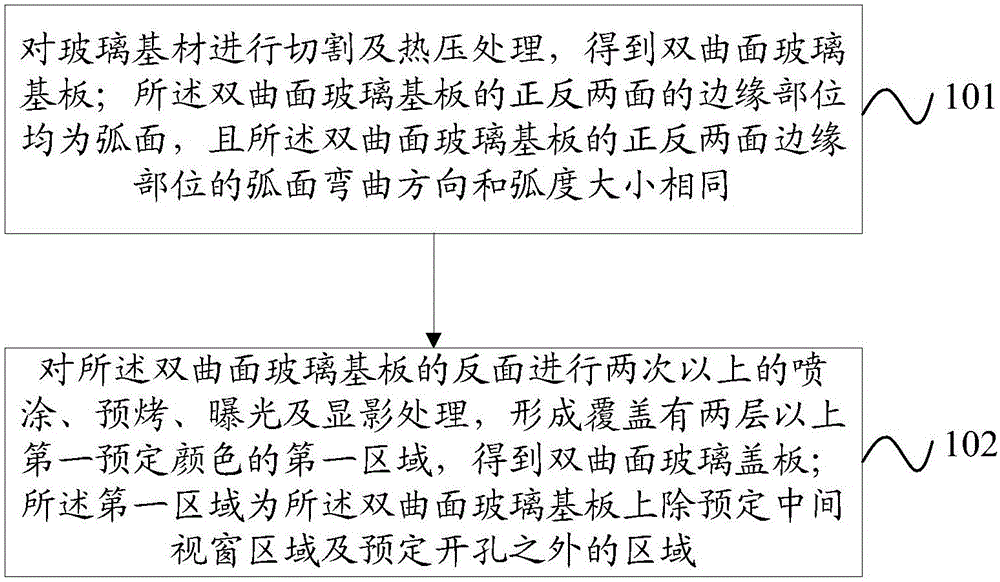

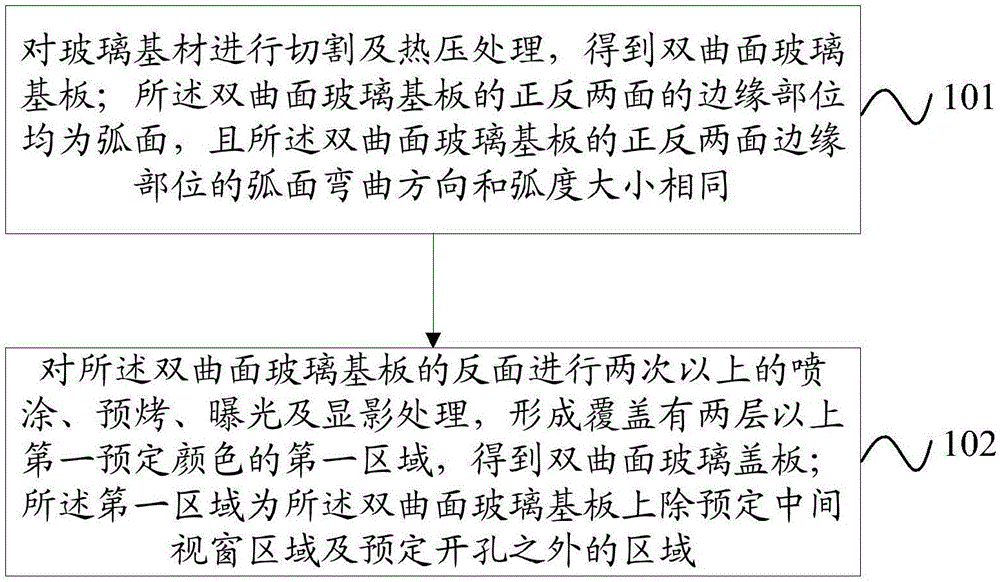

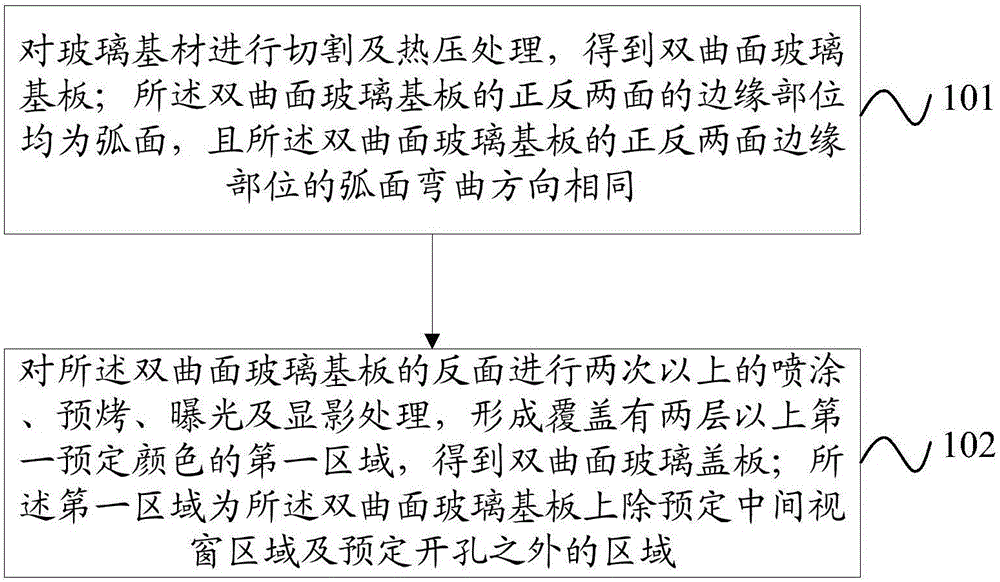

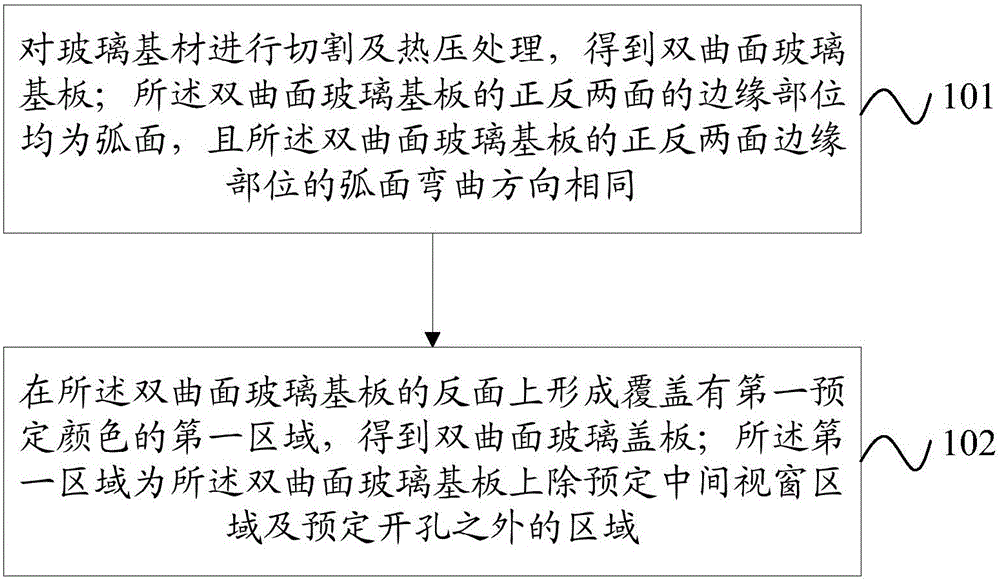

The invention provides a glass cover plate, a production method thereof and a mobile terminal. The glass cover plate and the production method thereof are used for solving the problem that the existing glass cover plates are planar or 2.5D fundamentally, the homogenization is serious, and the requirements of people on high-quality appearance are hardly met. The production method comprises the steps: carrying out cutting and hot-pressing treatment on a glass substrate so as to obtain a hyperboloid glass substrate, wherein edge portions of positive and negative faces of the hyperboloid glass substrate are cambered surfaces, and bending directions of the cambered surfaces of the edge portions of the positive and negative faces of the hyperboloid glass substrate are the same; carrying out spraying, pre-baking, exposure and development treatment on the negative face of the hyperboloid glass substrate for more than twice so as to form a first area covered with more than two layers of first predetermined color and obtain a hyperboloid glass cover plate, wherein the first area is an area, except for a predetermined middle observation window area and predetermined openings, of the hyperboloid glass substrate. According to the glass cover plate, the production method thereof and the mobile terminal, a 3D hyperboloid glass cover plate with specific colors is formed, the appearance is novel and attractive, and thus the requirements of people on high-quality appearance of the glass cover plate are met.

Owner:维沃通信科技有限公司

Manufacturing method of glass cover plate, glass cover plate and mobile terminal

InactiveCN106145626AMeet high-quality appearance requirementsNovel shapeDetails for portable computersGlass reforming apparatusEngineeringHot pressing

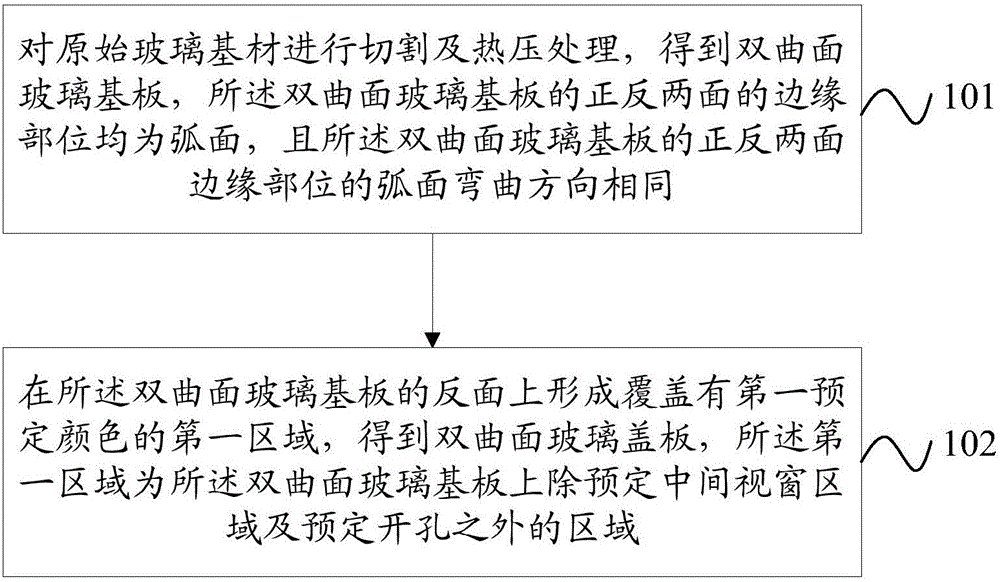

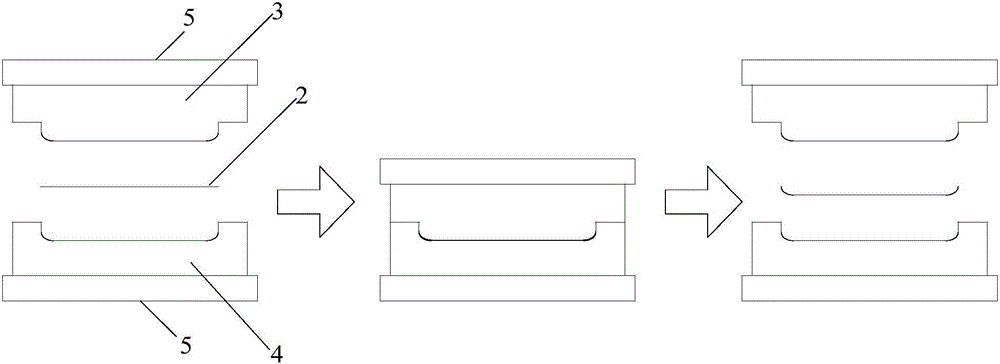

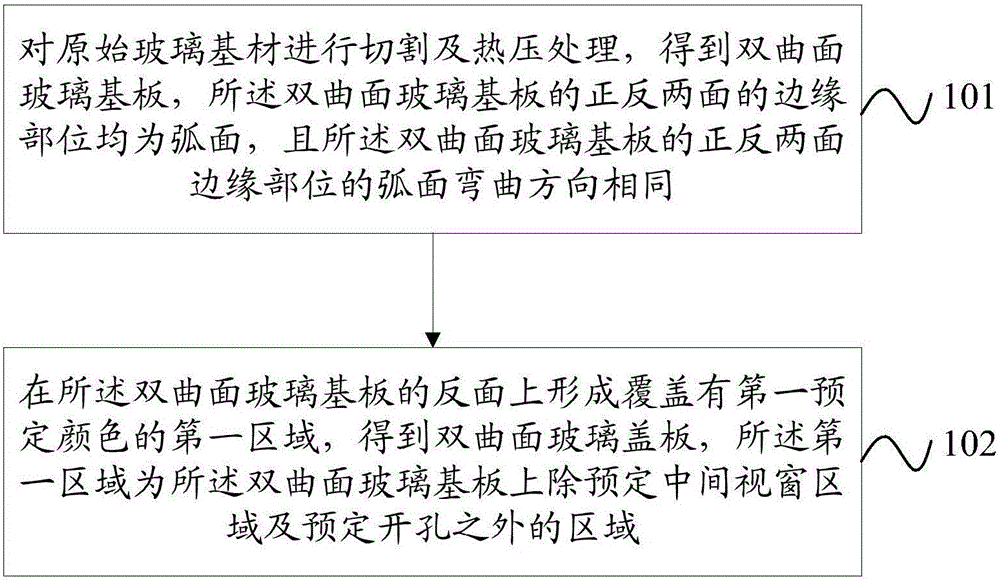

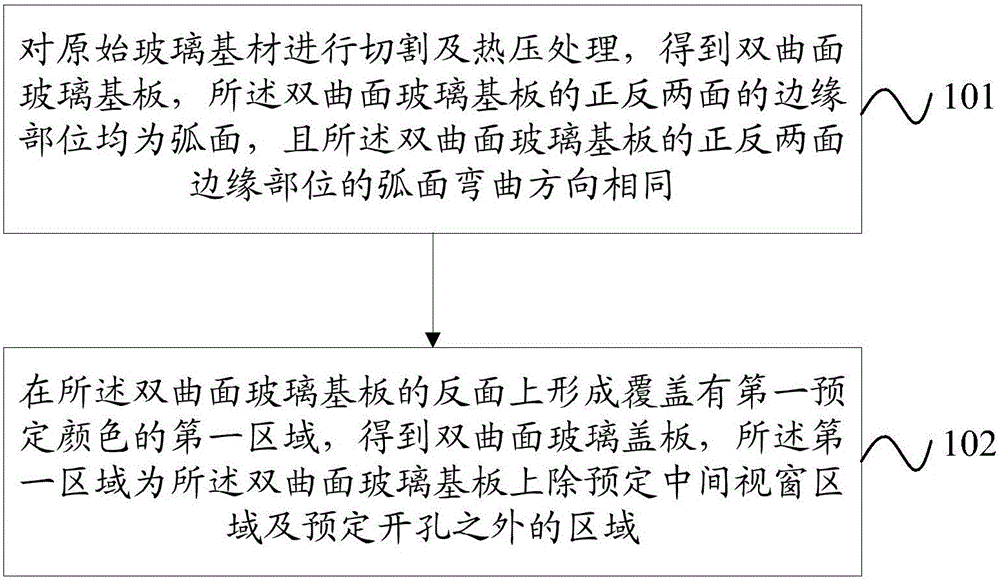

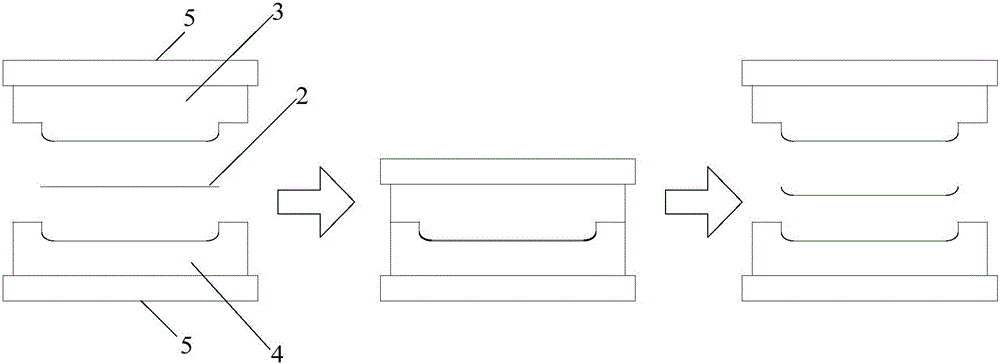

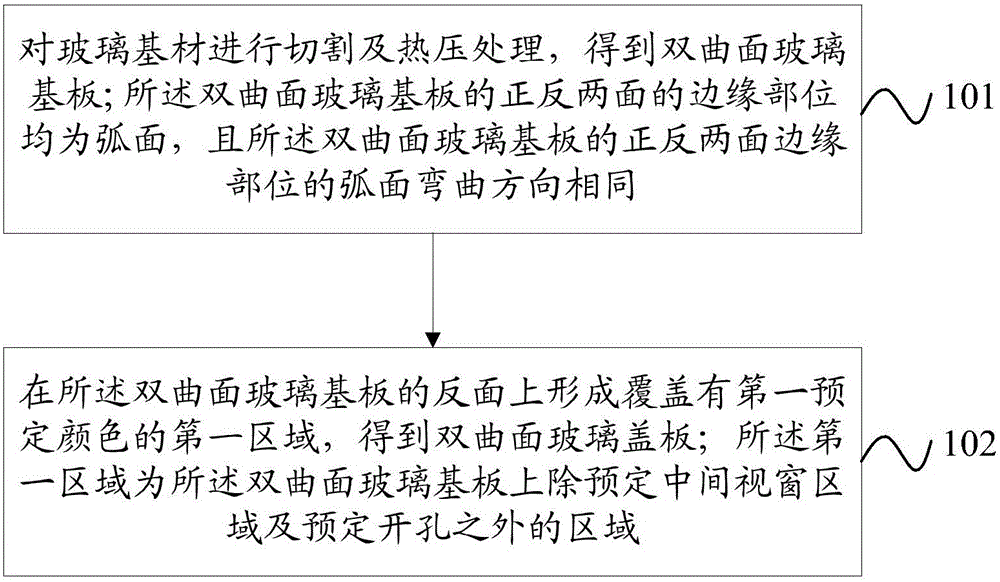

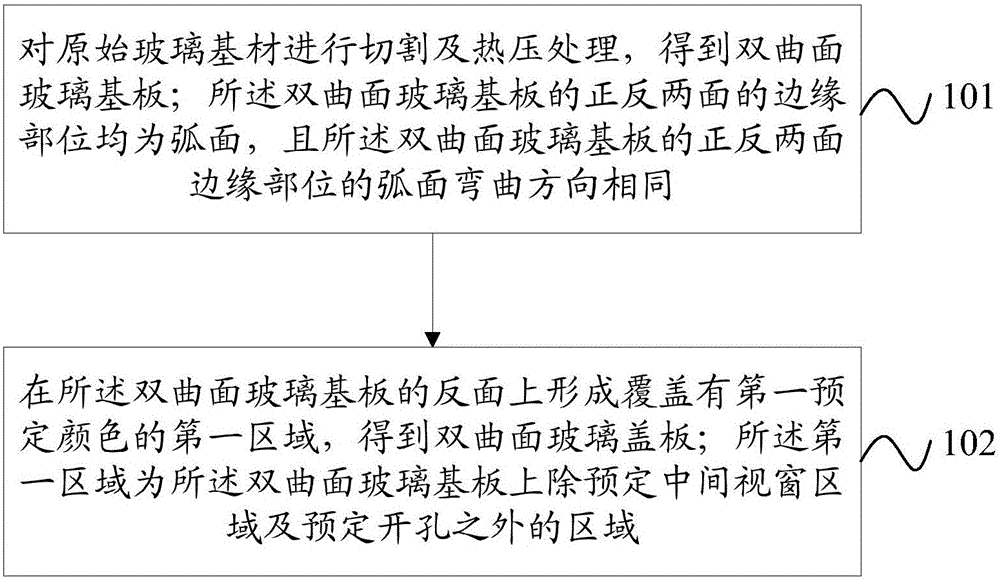

The invention provides a manufacturing method of a glass cover plate, the glass cover plate and a mobile terminal, relates to the technical field of terminal manufacturing and aims at solving the problems that existing glass cover plates are basically planar or 2.5D glass cover plates, are serious in homogenization and cannot meet the requirement of people on high-quality appearance. The manufacturing method comprises the steps that an original glass substrate is subjected to cutting and hot pressing treatment to obtain a hyperboloidal glass substrate, wherein the edge of the front face of the hyperboloidal glass substrate and the edge of the back face of the hyperboloidal glass substrate are arc-shaped surfaces of which the bending directions are same; a first area covered with a first preset color is formed on the back face of the hyperboloidal glass substrate to obtain the hyperboloidal glass cover plate, wherein the first area is the area, besides a preset middle window area and preset open pores, of the hyperboloidal glass substrate. According to the scheme, the 3D hyperboloidal glass cover plate with a specific color is formed, the appearance is novel and attractive, the high-quality appearance requirement of people on the glass cover plate is met, and the manufacturing cost is low.

Owner:VIVO MOBILE COMM CO LTD

Glass cover plate, production method thereof and mobile terminal

InactiveCN106145655AMeet high-quality appearance requirementsNovel shapeDetails for portable computersGlass reforming apparatusGlass coverComputer terminal

The invention provides a glass cover plate, a production method thereof and a mobile terminal. The production method comprises the following steps of: carrying out cutting and hot pressing a glass substrate, so as to obtain a double-curved surface glass substrate, wherein the edges of the front and rear surfaces of the double-curved surface glass substrate are arc-shaped surfaces, and the bending directions of the arc-shaped surfaces at the edges of the front and rear surfaces of the double-curved surface glass substrate are the same; and carrying out spraying, prebaking, exposure and development for at least two times on the rear surface of the double-curved surface glass substrate so as to obtain a first region covered with at least two first preset color layers, namely a double-curved surface glass cover plate, wherein the first region is the region, except a preset middle view window region and preset openings, on the double-curved surface glass substrate. According to the technical scheme, the 3D double-curved surface glass cover plate with specific colors is formed and has a novel and attractive appearance, so that the requirement of people on the high-grade appearance of the glass cover plate is met, and the problems that existing glass cover plate are planer or 2.5D, are seriously homogenized and are difficult to meet the requirement of people on the high-grade appearance are solved.

Owner:维沃通信科技有限公司

Manufacture method of glass cover plate, glass cover plate and mobile terminal

InactiveCN105948474ANovel shapeImprove visual effectsDetails for portable computersGlass reforming apparatusGlass coverEngineering

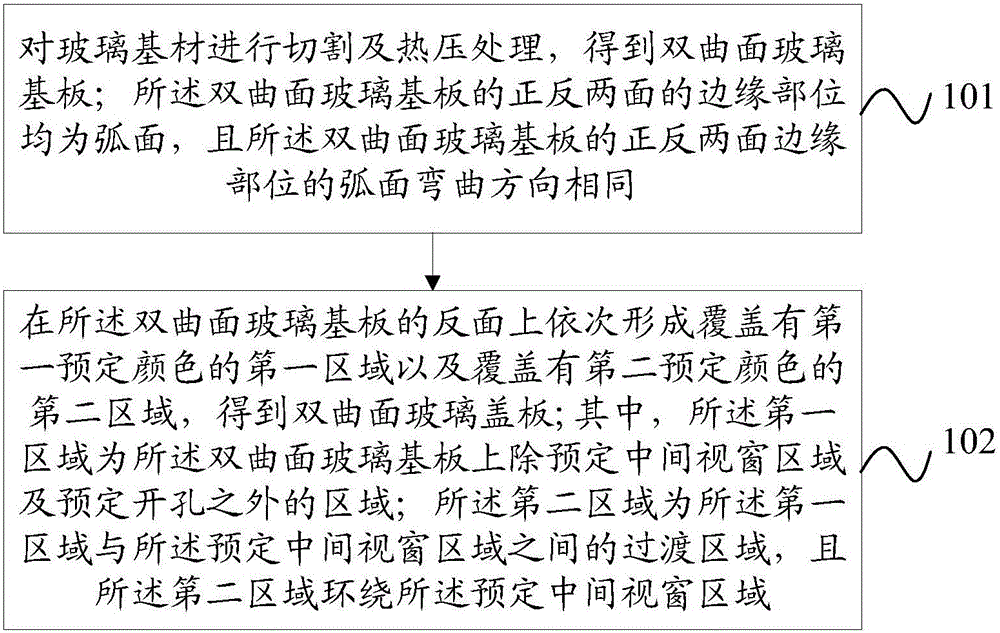

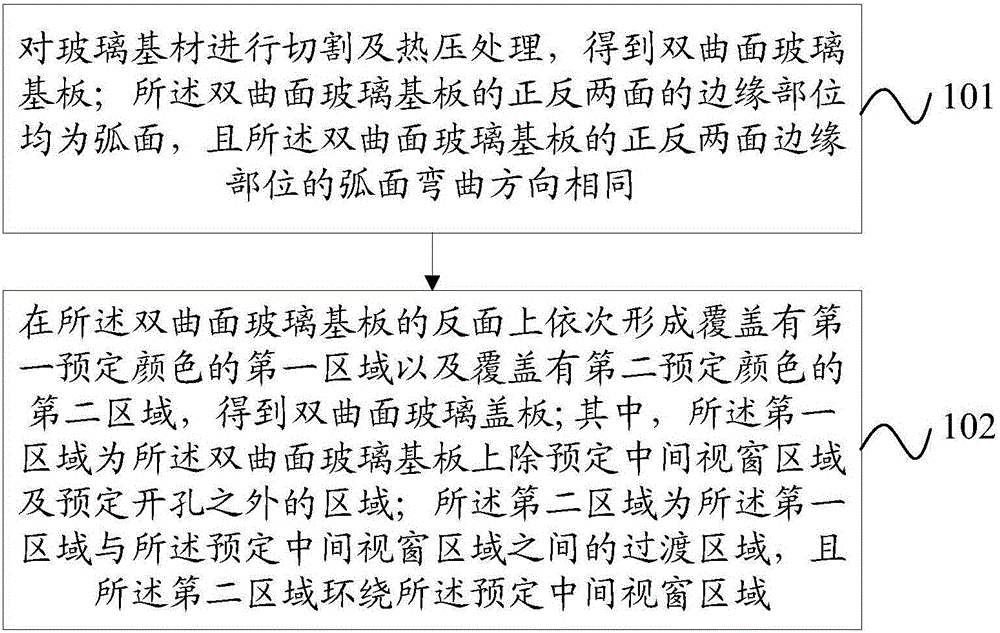

The invention provides a manufacture method of a glass cover plate, the glass cover plate and a mobile terminal, and relates to the technical field of terminal manufacture. The manufacture method comprises the following steps: performing cutting and hot-pressing treatment on an original glass substrate, so as to obtain a double-curved-surface glass substrate, and ensuring that the edge parts of the front surface and the back surface of the double-curved-surface glass substrate are arc, and the bending directions of the cambered surfaces of the edge parts of the front surface and the back surface of the double-curved-surface glass substrate are the same; ensuring that a first zone coated with a first preset color and a second zone coated with a second preset color are formed at the back surface of the double-curved-surface glass substrate, so as to obtain a double-curved-surface glass cover plate, and ensuring that both the first zone and the second zone are zones besides a preset middle window zone and a preset opening zone on the double-curved-surface glass substrate, and the second zone surrounds the preset middle window zone. The scheme ensures that a 3D double-curved-surface glass cover plate with specific colors and specific lines is formed, the appearance is novel and artistic, the requirements on the high-quality appearance of the glass cover plate by people are met, and the manufacture cost is low.

Owner:VIVO MOBILE COMM CO LTD

Glass cover plate, manufacturing method thereof and mobile terminal

InactiveCN106145656AMeet high-quality appearance requirementsGood colorDetails for portable computersGlass reforming apparatusGlass coverEngineering

The invention provides a glass cover plate, a manufacturing method thereof and a mobile terminal. The manufacturing method includes: subjecting a glass substrate to cutting and hot pressing to obtain a double-curved-surface glass substrate, wherein the edge of each of the front and the back of the double-curved-surface glass substrate is arc-surfaced, and the arc surfaces of the edges of the front and the back of the double-curved-surface glass substrate are identical in bending direction; performing more than two times of spraying, pre-baking, exposing and developing treatment on the back of the double-curved-surface glass substrate to form a first area covered with more than two layers of first preset color to obtain a double-curved-surface glass cover plate, wherein the first area refers to areas except for a preset middle window area and preset holes of the double-curved-surface glass substrate. Through the scheme, the 3D double-curved-surface glass substrate with a specific color is formed, is novel and attractive in appearance and meets the high-quality appearance requirements of people on the glass cover plate; the problem that existing glass cover plates are basically planar or 2.5D, serious in homogenization and difficult to meet high-quality appearance requirements of people is solved.

Owner:维沃通信科技有限公司

Manufacturing method of glass cover plate, glass cover plate and mobile terminal

InactiveCN105967508AMeet high-quality appearance requirementsNovel shapeDetails for portable computersGlass reforming apparatusGlass coverEngineering

The invention provides a manufacturing method of a glass cover plate, the glass cover plate and a mobile terminal, relates to the technical field of terminal manufacturing, and solves the problem that existing glass cover plates are planar or 2.5D, severely homogeneous and difficult to satisfy people's requirements of high-quality appearance. The manufacturing method includes: performing cutting and hot pressing on an original glass base material to obtain a double-curve-surface glass base plate, wherein the edge parts of the front side and the reverse side of the double-curve-surface glass base plate are cambered surfaces, and the bending directions of the cambered surfaces are identical; forming a first area covering with a first preset color on the reverse side of the double-curve-surface glass base plate to obtain a double-curve-surface glass cover plate, wherein the first area is an area other than a preset middle window area and preset holes. By the manufacturing method low in manufacturing cost, the 3D double-curve-surface glass cover plate with the specific color is formed, the glass cover plate is novel and attractive in appearance, and people's requirements of high-quality appearance of the glass cover plate are satisfied.

Owner:VIVO MOBILE COMM CO LTD

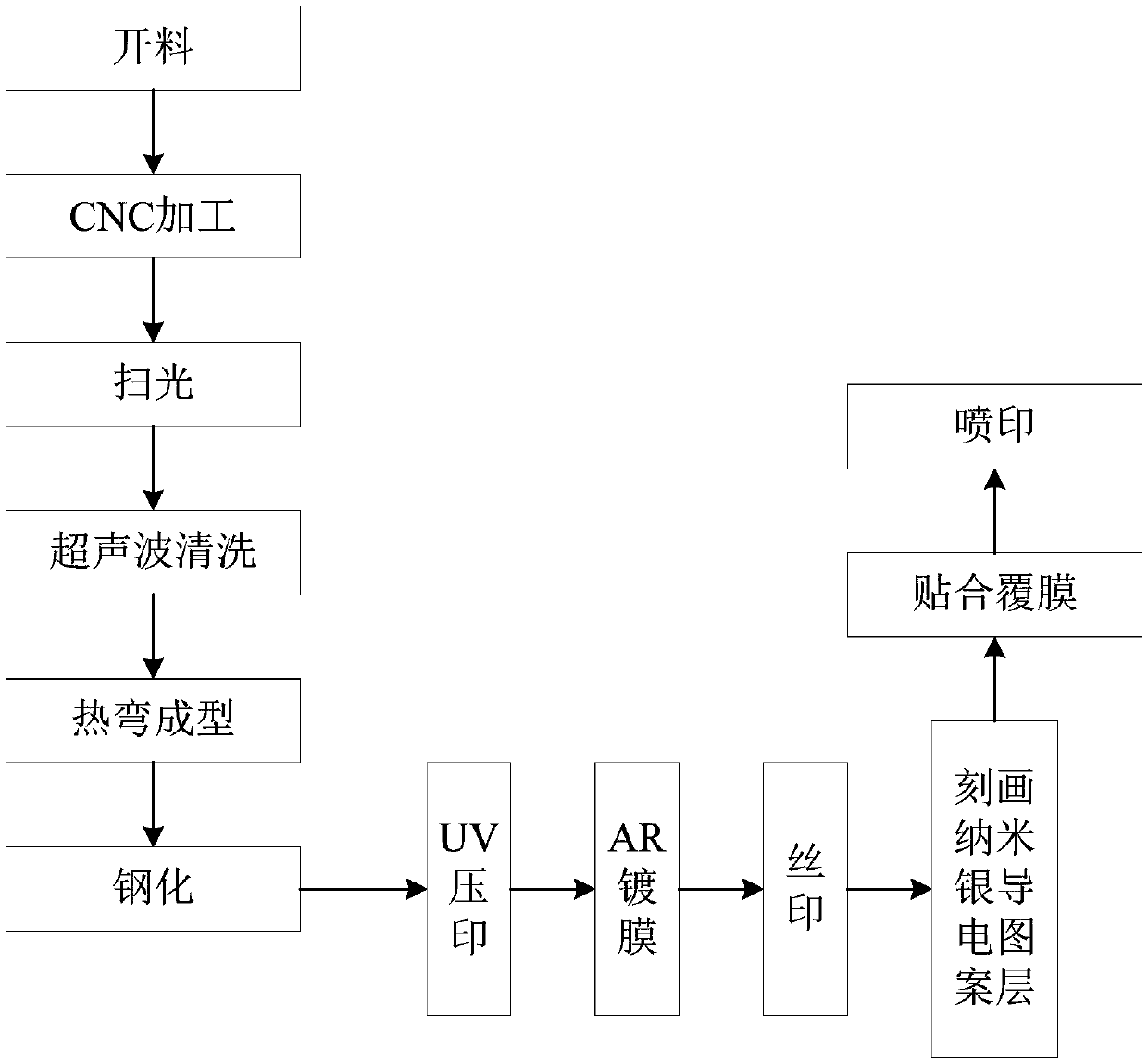

3D bent glass cover plate production technology

InactiveCN109590843AImprove plasticityImprove smoothnessOptical surface grinding machinesLayered productsElectricityGlass cover

The invention is applicable to a glass cover plate production technology and provides a 3D bent glass cover plate production technology. The production technology comprises the steps of rough shape cutting, CNC machining, thorough sweeping, ultrasonic wave washing, hot bending forming, tempering, UV coining, AR film plating, silk screening, engraving of a nanometer silver electricity conduction pattern layer, fitting laminating and jet printing. A 3D bent glass cover plate manufactured through the technology is novel in appearance and good in vision effect, meets the requirement of people forthe high-quality appearance of the glass cover plate, is low in manufacturing cost, can be produced in batch, and has a wide application prospect. The problems that a glass cover plate in the prior art is a planar or 2.5 D basically, homogenization is severe, novelty is lacked, and the requirement of people for the high-quality appearance of the product cannot be met easily are solved.

Owner:仙游县元生智汇科技有限公司

Manufacturing method of glass cover plate, glass cover plate and mobile terminal

InactiveCN106145625AImprove visual effectsMeet high-quality appearance requirementsDetails for portable computersGlass reforming apparatusGlass coverEngineering

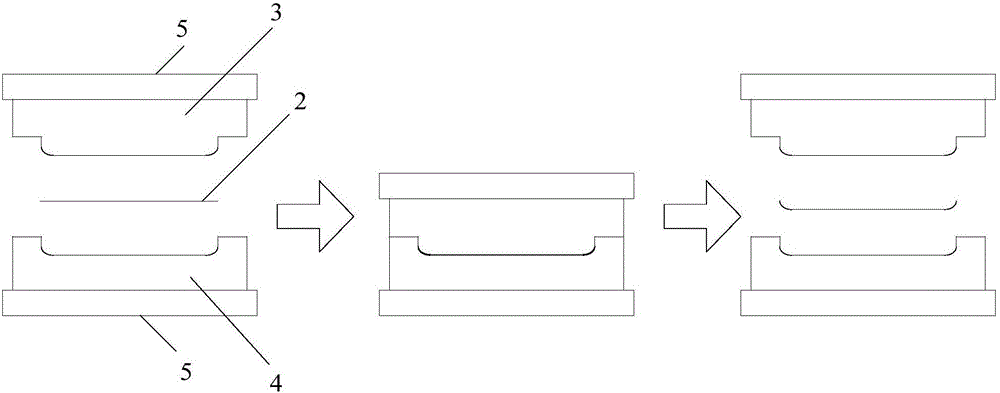

The invention provides a manufacturing method of a glass cover plate, the glass cover plate and a mobile terminal, relates to the technical field of terminal manufacturing and aims at solving the problems that existing glass cover plates are basically planar or 2.5D glass cover plates, are serious in homogenization and cannot meet the requirement of people on high-quality appearance. The manufacturing method comprises the steps that a glass substrate is subjected to cutting and hot pressing treatment to obtain a hyperboloidal glass substrate, wherein the edge of the front face of the hyperboloidal glass substrate and the edge of the back face of the hyperboloidal glass substrate are arc-shaped surfaces of which the bending directions are same; a first area covered with a first preset color is formed on the back face of the hyperboloidal glass substrate to obtain the hyperboloidal glass cover plate, wherein the first area is the area, besides a preset middle window area and preset open pores, of the hyperboloidal glass substrate. According to the scheme, the 3D hyperboloidal glass cover plate with a specific color is formed, the appearance is novel and attractive, the high-quality appearance requirement of people on the glass cover plate is met, and the manufacturing cost is low.

Owner:VIVO MOBILE COMM CO LTD

Manufacturing method of glass cover plate, glass cover plate and mobile terminal

InactiveCN106145647AMeet high-quality appearance requirementsNovel shapeDetails for portable computersGlass reforming apparatusGlass coverEngineering

The invention provides a manufacturing method of a glass cover plate, the glass cover plate and a mobile terminal, relates to the technical field of terminal manufacturing and aims at solving the problems that existing glass cover plates are basically planar or 2.5D glass cover plates, are serious in homogenization and cannot meet the requirement of people on high-quality appearance. The manufacturing method comprises the steps that a glass substrate is subjected to cutting and hot pressing treatment to obtain a hyperboloidal glass substrate, wherein the edge of the front face of the hyperboloidal glass substrate and the edge of the back face of the hyperboloidal glass substrate are arc-shaped surfaces of which the bending directions are same; a first area covered with a first preset color is formed on the back face of the hyperboloidal glass substrate to obtain the hyperboloidal glass cover plate, wherein the first area is the area, besides a preset middle window area and preset open pores, of the hyperboloidal glass substrate. According to the scheme, the 3D hyperboloidal glass cover plate with a specific color is formed, the appearance is novel and attractive, the high-quality appearance requirement of people on the glass cover plate is met, and the manufacturing cost is low.

Owner:VIVO MOBILE COMM CO LTD

Glass cover plate, manufacturing method thereof and mobile terminal

InactiveCN106145650AMeet high-quality appearance requirementsNovel shapeDetails for portable computersGlass reforming apparatusGlass coverEngineering

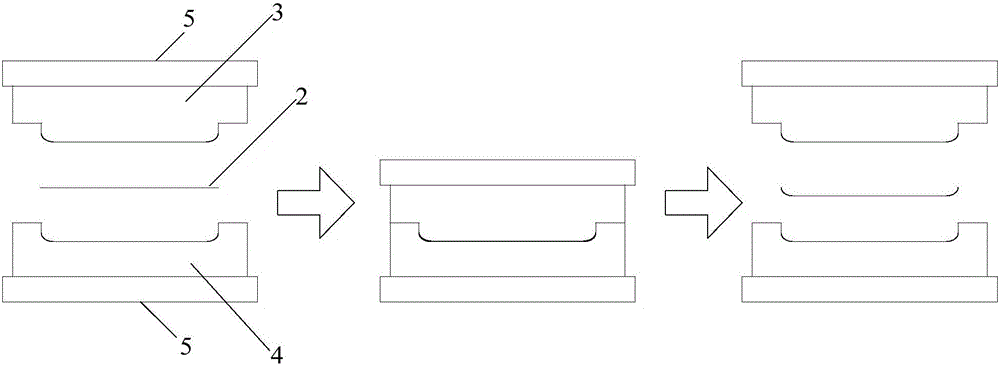

The invention provides a glass cover plate, a manufacturing method thereof and a mobile terminal, relates to the technical field of terminal manufacturing and aims at solving the problem that existing glass cover plates are basically planar or 2.5D, serious in homogenization and difficult to meet high-quality appearance requirements of people. The manufacturing method includes: subjecting an original glass substrate to cutting and hot pressing to obtain a double-curved-surface glass substrate, wherein the edge of each of the front and the back of the double-curved-surface glass substrate is arc-surfaced, and the arc surfaces of the edges of the front and the back of the double-curved-surface glass substrate are identical in bending direction; forming a first area covered with a first preset color on the back of the double-curved-surface glass substrate to obtain a double-curved-surface glass cover plate, wherein the first area refers to areas except for a preset middle window area and preset holes of the double-curved-surface glass substrate. Through the scheme, the 3D double-curved-surface glass substrate with a specific color is formed, is novel and attractive in appearance, meets the high-quality appearance requirements of people on the glass cover plate and is low in manufacturing cost.

Owner:VIVO MOBILE COMM CO LTD

Production method of glass cover plate, the glass cover plate, and mobile terminal

InactiveCN106365427AMeet high-quality appearance requirementsGood colorDetails for portable computersGlass reforming apparatusGlass coverSpray coating

The invention provides a production method of a glass cover plate, the glass cover plate, and a mobile terminal. The production method includes the steps of: 1) cutting and hot-pressing a glass base material to obtain double-curved glass base board, wherein the edges of both a front and a back surfaces of the double-curved glass base board are both arc-shaped surfaces, and the bending directions of the arc-shaped surfaces on the edges of the front and a back surfaces of the glass base board are same; 2) performing spray coating, pre-roasting, exposure and development treatments to the back surface of the glass base board for more than two times to form a first zone, which is covered by a first preset color in more than two layers, thereby obtaining a double-curved glass cover plate, wherein the first zone is the surface of the double-curved glass base board except a preset center view window zone and a preset holed zone. By means of the scheme, a 3D double-curved glass cover plate having specific color is produced. The glass cover plate has a novel and beautiful appearance and satisfies the user demand of high quality of appearance of the glass cover plate. The method solve a problem that the glass cover plates in the prior art are almost planar or 2.5-deminsional and have great problem of homogenization, and the user demand of high quality of appearance is difficult to satisfy.

Owner:VIVO MOBILE COMM CO LTD

Glass cover plate, manufacturing method thereof and mobile terminal

InactiveCN106145632AImprove visual effectsMeet high-quality appearance requirementsDetails for portable computersGlass reforming apparatusEngineeringHot pressing

The invention provides a glass cover plate, a manufacturing method thereof and a mobile terminal, relates to the technical field of terminal manufacturing and aims at solving the problem that existing glass cover plates are basically planar or 2.5D, serious in homogenization and difficult to meet high-quality appearance requirements of people. The manufacturing method includes: subjecting a glass substrate to cutting and hot pressing to obtain a double-curved-surface glass substrate, wherein the edge of each of the front and the back of the double-curved-surface glass substrate is arc-surfaced, and the arc surfaces of the edges of the front and the back of the double-curved-surface glass substrate are identical in bending direction; forming a first area covered with a first preset color on the back of the double-curved-surface glass substrate to obtain a double-curved-surface glass cover plate, wherein the first area refers to areas except for a preset middle window area and preset holes on the double-curved-surface glass substrate. Through the scheme, the 3D double-curved-surface glass substrate with a specific color is formed, is novel and attractive in appearance, meets the high-quality appearance requirements of people on the glass cover plate and is low in manufacturing cost.

Owner:VIVO MOBILE COMM CO LTD

Glass cover plate production method, glass cover plate and mobile terminal

InactiveCN106167352AImprove visual effectsMeet high-quality appearance requirementsDetails for portable computersGlass reforming apparatusHot pressEngineering

The present invention provides a glass cover plate production method, a glass cover plate and a mobile terminal, and relates to the technical field of terminal production. In the prior art, the existing glass cover plates generally are planar or 2.5D, the homogeneity is serious, and the high-quality appearance requirements of people on the glass cover plate can be difficultly met. A purpose of the present invention is to solve the problems in the prior art. The production method comprises: carrying out a cutting and hot-pressing treatment on a glass substrate to obtain a hyperbolic glass substrate, wherein the edge positions of the front surface and the back surface of the hyperbolic glass substrate are arc surfaces, and the bending directions of the arc surfaces are opposite; and forming a first region covered with a first predetermined color on the back surface of the hyperbolic glass substrate to obtain the hyperbolic glass cover plate, wherein the first region is the region excluding a predetermined middle window region and a predetermined opening hole on the hyperbolic glass substrate. With the technical scheme of the present invention, the 3D hyperbolic glass cover plate having the specific color is formed, the appearance is novel and beautiful, the high-quality appearance requirements of people on the glass cover plate are met, and the manufacturing cost is low.

Owner:VIVO MOBILE COMM CO LTD

Manufacturing method for glass cover plate, glass cover plate and mobile terminal

InactiveCN106145651AMeet high-quality appearance requirementsNovel shapeDetails for portable computersGlass reforming apparatusGlass coverEngineering

The invention provides a manufacturing method for a glass cover plate, the glass cover plate and a mobile terminal, relates to the technical field of terminal manufacturing, and solves the problems that existing glass cover plates are basically planar or 2.5D glass cover plates which are homogenized seriously, and the requirement of people on high-quality appearance is difficult to meet. The manufacturing method comprises the following steps: cutting and performing hot-pressing treatment on an original glass substrate to obtain a double-curved surface glass substrate, wherein both the front surface and the rear surface of the double-curved surface glass substrate are arc surfaces, and the bending directions of the arc surfaces at the edge positions of the front surface and the rear surface of the double-curved surface glass substrate are the same; forming a first area which is covered with a first preset colour on the rear surface of the double-curved surface glass substrate to obtain a double-curved surface glass cover plate, wherein the first area is the area, except a preset central view window area and a preset hole, on the double-curved surface glass substrate. According to the scheme of the invention, a 3D double-curved surface glass cover plate in a specific colour is formed; the appearance is novel and attractive; the requirement of the people on the high-quality appearance of the glass cover plate is met; moreover, the manufacturing cost is low.

Owner:VIVO MOBILE COMM CO LTD

Making method of glass cover plate, glass cover plate and mobile terminal

InactiveCN106167348AMeet high-quality appearance requirementsNovel shapeDetails for portable computersGlass reforming apparatusGlass coverHyperboloid

Relating to the technical field of terminal making, the invention provides a making method of a glass cover plate, the glass cover plate and a mobile terminal, and solves the problems that existing glass cover plates are basically planar or 2.5D, suffer serious homogenization and are difficult to satisfy the requirements of people for high quality appearance. The making method includes: conducting cutting and hot pressing treatment on an original glass substrate to obtain a hyperboloid glass substrate, wherein the edge parts of the front and back sides on the hyperboloid glass substrate are both camber surfaces, and the camber surfaces have a same bending direction; forming a first area covered with a first predetermine pigment on the back side of the hyperboloid glass substrate to obtain a hyperboloid glass cover plate, wherein the first area is the area except a predetermined middle window region and a predetermined opening on the hyperboloid glass substrate. According to the scheme provided by the invention, the 3D hyperboloid glass cover plate with specific color and a novel and beautiful appearance can be formed, satisfies the requirements of people for high quality glass cover plate, and the manufacturing cost is low.

Owner:VIVO MOBILE COMM CO LTD

Manufacturing method of glass cover plate, glass cover plate and mobile terminal

InactiveCN106145643AImprove visual effectsMeet high-quality appearance requirementsDetails for portable computersGlass reforming apparatusEngineeringHot pressing

The invention provides a manufacturing method of a glass cover plate, a glass cover plate and a mobile terminal, and relates to the technical field of terminal manufacturing. The problems that existing glass cover plates are almost planar or 2.5D, homogeneity is serious, and the requirement of high-quality appearance of people is difficult to meet are solved. The manufacturing method includes the steps that cutting and hot pressing treatment are carried out on a glass base material to obtain a hyperboloid glass substrate; the edges of the front and back faces of the hyperboloid glass substrate are cambered surfaces in the same bending direction; a first region covering first preset color is formed on the back face of the hyperboloid glass substrate to obtain the hyperboloid glass cover plate; the first region is a region, except a preset middle window region and preset pores, on the hyperboloid glass substrate. By means of the scheme, the 3D hyperboloid glass cover plate with specific color is formed, the appearance is novel and attractive, the requirement of high-quality appearance of people is met, and the manufacturing cost is low.

Owner:VIVO MOBILE COMM CO LTD

Manufacturing method of glass cover plate, glass cover plate and mobile terminal

InactiveCN106145633AMeet high-quality appearance requirementsNovel shapeDetails for portable computersGlass reforming apparatusGlass coverEngineering

The invention provides a manufacturing method of a glass cover plate, the glass cover plate and a mobile terminal, relates to the technical field of terminal manufacturing, and solves the problems that existing glass cover plates are basically planar or 2.5D, severe in homogenization and hard to satisfy people's requirements on high-quality appearance. The manufacturing method includes: performing cutting and hot pressing on a glass base material to obtain a double-curve-surface glass substrate, wherein the edge parts of the front side and the reverse side of the double-curve-surface glass substrate are arc faces, and the bending directions of the arc faces are identical; forming a first area covering a first preset color on the reverse side of the double-curve-surface glass substrate to obtain the double-curve-surface glass cover plate, wherein the first area is the area, except a preset middle window area and a preset opening, on the double-curve-surface glass substrate. By the manufacturing method, the 3D double-curve-surface glass cover plate with a specific color is formed, and the glass cover plate is novel and attractive in appearance, capable of satisfying people's requirements on high-quality appearance and low in manufacturing cost.

Owner:VIVO MOBILE COMM CO LTD

Manufacturing method of glass cover plate, glass cover plate and mobile terminal

InactiveCN106145629AImprove visual effectsMeet high-quality appearance requirementsDetails for portable computersGlass reforming apparatusGlass coverEngineering

The invention provides a manufacturing method of a glass cover plate, the glass cover plate and a mobile terminal and belongs to the technical field of terminal manufacturing in order to solve the problems that existing glass cover plates are basically planar or 2.5 D, homogenization is severe, and the requirement of people for high-quality product appearance is difficult to meet. The manufacturing method includes the steps that a glass base material is cut and hot-pressed to obtain a double-curved-surface glass substrate, wherein the edge of the front side and the edge of the back side of the double-curved-surface glass substrate are arc faces, and the bending directions of the arc faces on the edges of the front side and the back side of the double-curved-surface glass substrate are the same; a first area covered with a first preset color is formed on the back side of the double-curved-surface glass substrate to obtain the double-curved-surface glass cover plate, wherein according to the obtained double-curved-surface glass cover plate, the first area is the area, beyond a preset middle window area and a preset hole, on the double-curved-surface glass substrate. According to the scheme, the 3D double-curved-surface glass cover plate in a specific color is formed, is novel and attractive in appearance, meets the requirement of people for high-quality appearance of the glass cover plate, and is low in manufacturing cost.

Owner:VIVO MOBILE COMM CO LTD

Glass cover plate, manufacturing method thereof and mobile terminal

InactiveCN106145641AMeet high-quality appearance requirementsNovel shapeDetails for portable computersGlass reforming apparatusEngineeringHot pressing

The invention provides a glass cover plate, a manufacturing method thereof and a mobile terminal, relates to the technical field of terminal manufacturing and aims at solving the problem that existing glass cover plates are basically planar or 2.5D, serious in homogenization and difficult to meet high-quality appearance requirements of people. The manufacturing method includes: subjecting an original glass substrate to cutting and hot pressing to obtain a double-curved-surface glass substrate, wherein the edge of each of the front and the back of the double-curved-surface glass substrate is arc-surfaced, and the arc surfaces of the edges of the front and the back of the double-curved-surface glass substrate are identical in bending direction; forming a first area covered with a first preset color on the back of the double-curved-surface glass substrate to obtain a double-curved-surface glass cover plate, wherein the first area refers to areas except for a preset middle window area and preset holes of the double-curved-surface glass substrate. Through the scheme, the 3D double-curved-surface glass substrate with a specific color is formed, is novel and attractive in appearance, meets the high-quality appearance requirements of people on the glass cover plate and is low in manufacturing cost.

Owner:VIVO MOBILE COMM CO LTD

Glass cover plate, manufacturing method thereof and mobile terminal

InactiveCN106145654AMeet high-quality appearance requirementsNovel shapeDetails for portable computersGlass reforming apparatusGlass coverEngineering

The invention provides a glass cover plate, a manufacturing method thereof and a mobile terminal, relates to the technical field of terminal manufacturing and aims at solving the problem that existing glass cover plates are basically planar or 2.5D, serious in homogenization and difficult to meet high-quality appearance requirements of people. The manufacturing method includes: subjecting an original glass substrate to cutting and hot pressing to obtain a double-curved-surface glass substrate, wherein the edge of each of the front and the back of the double-curved-surface glass substrate is arc-surfaced, and the arc surfaces of the edges of the front and the back of the double-curved-surface glass substrate are identical in bending direction; forming a first area covered with a first preset color on the back of the double-curved-surface glass substrate to obtain a double-curved-surface glass cover plate, wherein the first area refers to areas except for a preset middle window area and preset holes of the double-curved-surface glass substrate. Through the scheme, the 3D double-curved-surface glass substrate with a specific color is formed, is novel and attractive in appearance, meets the high-quality appearance requirements of people on the glass cover plate and is low in manufacturing cost.

Owner:VIVO MOBILE COMM CO LTD

Manufacturing process of 3D glass cover plate

InactiveCN109574514AImprove plasticityImprove smoothnessGlass reforming apparatusEngravingNumerical controlScreen printing

The invention is suitable for a manufacturing process of a glass cover plate, and provides a manufacturing process of a 3D glass cover plate. The manufacturing process includes the steps of cleaning,cutting, loading and cleaning, hot bending forming, cleaning and taking out, CNC numerical control machine carving forming, tempering, silk screen printing, AF coating and ultrasonic cleaning. The 3Dglass cover plate manufactured by the process has novel appearance and good visual effect, meets the appearance requirements of people on high quality of the glass cover plate, has low manufacturing cost, can be produced in batch, has a wide application prospect, and effectively solves the problems that the glass cover plates are basically flat or 2.5D, are seriously homogeneous, lack novelty, andare difficult to meet the appearance requirements of people for high quality products in the prior art.

Owner:仙游县元生智汇科技有限公司

Manufacturing method of glass cover plate, glass cover plate and mobile terminal

InactiveCN106145645AMeet high-quality appearance requirementsNovel shapeDetails for portable computersGlass reforming apparatusGlass coverEngineering

The invention provides a method for manufacturing a glass cover, a glass cover and a mobile terminal, and relates to the technical field of terminal production. A matter of high-quality appearance requirements. The manufacturing method includes: cutting and hot-pressing the original glass substrate to obtain a hyperboloid glass substrate, the edges of the front and back sides of the hyperboloid glass substrate are arc surfaces, and the edges of the front and back sides of the hyperboloid glass substrate are The curvature direction of the curved surface is the same; on the opposite side of the hyperboloid glass substrate, a first region covered with a first predetermined color is formed to obtain a hyperboloid glass cover plate. The first region is the hyperboloid glass substrate except for the predetermined middle window region and the predetermined area outside the opening. The scheme of the present invention forms a 3D hyperboloid glass cover plate with a specific color, which has a novel and beautiful appearance, meets people's high-quality appearance requirements for the glass cover plate, and has low manufacturing cost.

Owner:VIVO MOBILE COMM CO LTD

Manufacturing method of glass cover plate, glass cover plate and mobile terminal

InactiveCN106145648AImprove visual effectsMeet high-quality appearance requirementsDetails for portable computersGlass reforming apparatusGlass coverEngineering

The invention provides a manufacturing method of a glass cover plate, the glass cover plate and a mobile terminal, relates to the technical field of terminal manufacturing, and solves the problems that existing glass cover plates are basically planar or 2.5D, severe in homogenization and hard to satisfy people's requirements on high-quality appearance. The manufacturing method includes: performing cutting and hot pressing on a glass base material to obtain a double-curve-surface glass substrate, wherein the edge parts of the front side and the reverse side of the double-curve-surface glass substrate are arc faces, and the bending directions of the arc faces are identical; forming a first area covering a first preset color on the reverse side of the double-curve-surface glass substrate to obtain the double-curve-surface glass cover plate, wherein the first area is the area, except a preset middle window area and a preset opening, on the double-curve-surface glass substrate. By the manufacturing method, the 3D double-curve-surface glass cover plate with a specific color is formed, and the glass cover plate is novel and attractive in appearance, capable of satisfying people's requirements on high-quality appearance and low in manufacturing cost.

Owner:VIVO MOBILE COMM CO LTD

Manufacturing method of glass cover plate, glass cover plate and mobile terminal

InactiveCN106145644AImprove visual effectsMeet high-quality appearance requirementsDetails for portable computersGlass reforming apparatusGlass coverEngineering

The invention provides a method for manufacturing a glass cover, a glass cover and a mobile terminal, and relates to the technical field of terminal production. A matter of high-quality appearance requirements. The manufacturing method comprises: cutting and hot-pressing the glass substrate to obtain a hyperboloid glass substrate; the edges of the front and back sides of the hyperboloid glass substrate are curved surfaces, and the edges of the front and back sides of the hyperboloid glass substrate are curved. The curvature direction of the curved surface is the same; a first region covered with a first predetermined color is formed on the reverse surface of the hyperboloid glass substrate to obtain a hyperboloid glass cover plate; area outside the hole. The scheme of the present invention forms a 3D hyperboloid glass cover plate with a specific color, which has a novel and beautiful appearance, meets people's high-quality appearance requirements for the glass cover plate, and has low manufacturing cost.

Owner:VIVO MOBILE COMM CO LTD

Shell manufacturing method, shell and electronic equipment

ActiveCN112492811AImprove color depthColorfulEdge grinding machinesPolishing machinesManufacturing engineeringHot pressing

The invention discloses a shell manufacturing method, a shell and electronic equipment. The manufacturing method of the shell comprises the steps of carrying out hot pressing on a glass base material,and obtaining a double-curved-surface glass substrate, wherein the double-curved-surface glass substrate is provided with a first surface and a second surface which are opposite in the thickness direction, and the four corners of the double-curved-surface glass substrate are all cambered surfaces; carrying out surface pretreatment on the first surface and the second surface of the double-curved-surface glass substrate to obtain a double-curved-surface glass cover plate, the surface treatment comprising dull polish treatment; and polishing the cambered surfaces of the four corners of the double-curved-surface glass cover plate and the edges of the two opposite long edges of the first surface and the second surface, and forming gradient texture layers of a first preset color on the camberedsurfaces of the four corners and the edges of the two opposite long edges of the first surface and the second surface to obtain the shell. The shell with the edge part having the gradual change effect is formed, and the requirement of a user for the high-quality appearance of the electronic equipment shell can be met.

Owner:VIVO MOBILE COMM CO LTD

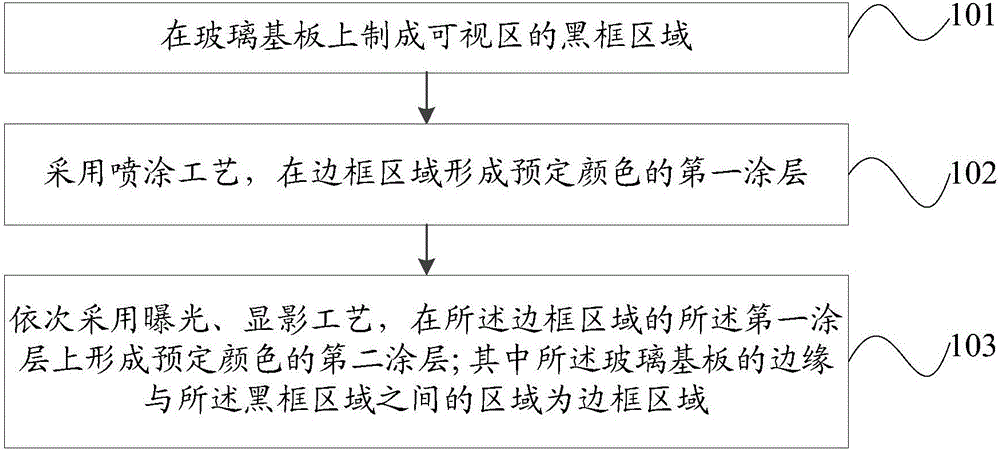

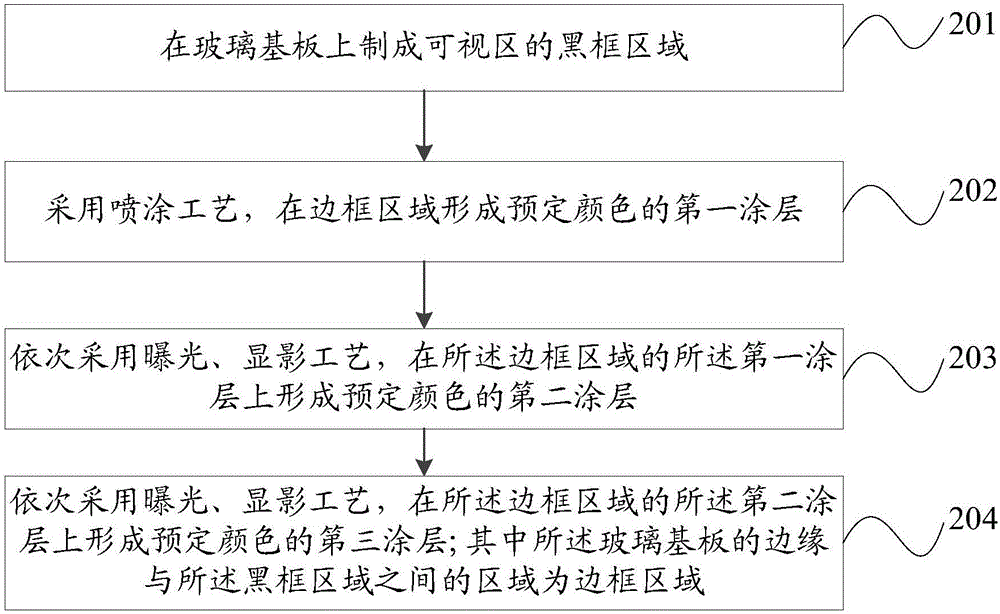

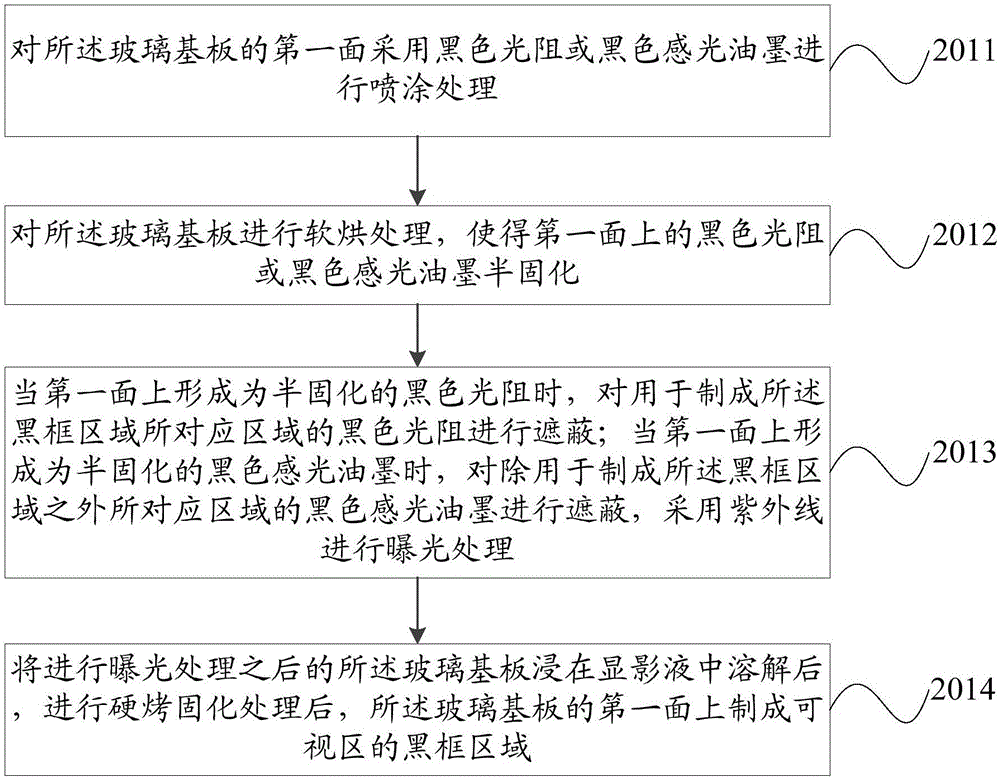

Production method of glass cover plate, glass cover plate and mobile terminal

InactiveCN106431007AGood visual effectMeet the high-qualityDigital data processing detailsPhotomechanical exposure apparatusEngineeringColor film

The invention provides a production method of a glass cover plate, the glass cover plate and a mobile terminal. The preparation method comprises the following steps: making a visible black frame area on a glass substrate; forming a first coating of a predetermined color in the frame area by a spraying technology; and forming a second coating of a predetermined color on the first coating in the frame area sequentially by exposure and development technologies, wherein the area between the edge of the glass substrate and the black frame area is a frame area. In the invention, the glass cover plate with a specific color and specific lines is produced by a brand-new technology, the visual effect is good, the requirements of people on the high-quality appearance of the glass cover plate are met, and the problems of the prior art that folds and bubbles are easily generated in a color film coloring process of a 3D glass cover plate are effectively solved.

Owner:VIVO MOBILE COMM CO LTD

Production method of glass cover plate, glass cover plate and mobile terminal

InactiveCN106145653AImprove visual effectsMeet high-quality appearance requirementsDetails for portable computersGlass reforming apparatusGlass coverHyperboloid

The invention provides a method for manufacturing a glass cover, a glass cover and a mobile terminal, and relates to the technical field of terminal production. A matter of high-quality appearance requirements. The manufacturing method comprises: cutting and hot-pressing the glass substrate to obtain a hyperboloid glass substrate, the edges of the front and back sides of the hyperboloid glass substrate are arc surfaces, and the edges of the front and back sides of the hyperboloid glass substrate are The curvature direction of the curved surface is the same; on the opposite side of the hyperboloid glass substrate, a first region covered with a first predetermined color is formed to obtain a hyperboloid glass cover plate. area outside the hole. The scheme of the present invention forms a 3D hyperboloid glass cover plate with a specific color, which has a novel and beautiful appearance, meets people's high-quality appearance requirements for the glass cover plate, and has low manufacturing cost.

Owner:VIVO MOBILE COMM CO LTD

Manufacturing method of glass cover plate, glass cover plate and mobile terminal

InactiveCN106145628ANovel shapeImprove visual effectsDetails for portable computersGlass reforming apparatusGlass coverEngineering

The invention provides a manufacturing method of a glass cover plate, the glass cover plate and a mobile terminal. The manufacturing method includes the steps that a glass base material is cut and hot-pressed to obtain a double-curved-surface glass substrate, the edge portions of the front face and the reverse face of the double-curved-surface glass substrate are both arc surfaces, and the bending directions of the arc surfaces of the edge portions of the front face and the reverse face of the double-curved-surface glass substrate are identical. A first region covered with a first preset color and a second region covered with a second preset color are sequentially formed on the reverse face of the double-curved-surface glass substrate to obtain the double-curved-surface glass cover plate. The first region is the region, except for a preset middle window region and a preset open hole, of the double-curved-surface glass substrate, the second region is a transition region between the first region and the preset middle window region, and the second region surrounds the preset middle window region. According to the scheme, the 3D double-curved-surface glass cover plate with the specific colors and specific grain is formed, the requirements of people for the high-quality appearance of the glass cover plate are met, and the manufacturing cost is low.

Owner:VIVO MOBILE COMM CO LTD

Production method of glass cover plate, glass cover plate and mobile terminal

InactiveCN106145631AMeet high-quality appearance requirementsNovel shapeDetails for portable computersGlass reforming apparatusGlass coverEngineering

The invention provides a method for manufacturing a glass cover, a glass cover and a mobile terminal. The manufacturing method comprises: cutting and hot-pressing the glass substrate to obtain a hyperboloid glass substrate, the edges of the front and back sides of the hyperboloid glass substrate are arc surfaces, and the edges of the front and back sides of the hyperboloid glass substrate are The curvature direction of the curved surface is the same; on the opposite surface of the hyperboloid glass substrate, a first region covered with a first predetermined color and a second region covered with a second predetermined color are sequentially formed to obtain a hyperboloid glass cover plate, and the first region is double-curved. In the area on the curved glass substrate except the predetermined middle window area and the predetermined opening, the second area is a transition area between the first area and the predetermined middle window area, and the second area surrounds the predetermined middle window area. The solution of the present invention forms a 3D hyperboloid glass cover plate with specific color and specific texture, which meets people's high-quality appearance requirements for the glass cover plate, and has low manufacturing cost.

Owner:VIVO MOBILE COMM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com