Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65 results about "Ductor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ductor is an extinct genus of prehistoric bony fish that lived from the early to middle Eocene. Fossils have been found in Monte Bolca. In life, species of Ductor would have resembled pilot fish, though, they are more closely related to the jackfish. Some experts place Ductor into its own family, "Ductoridae," while others place the genus within the closely related Carangidae.

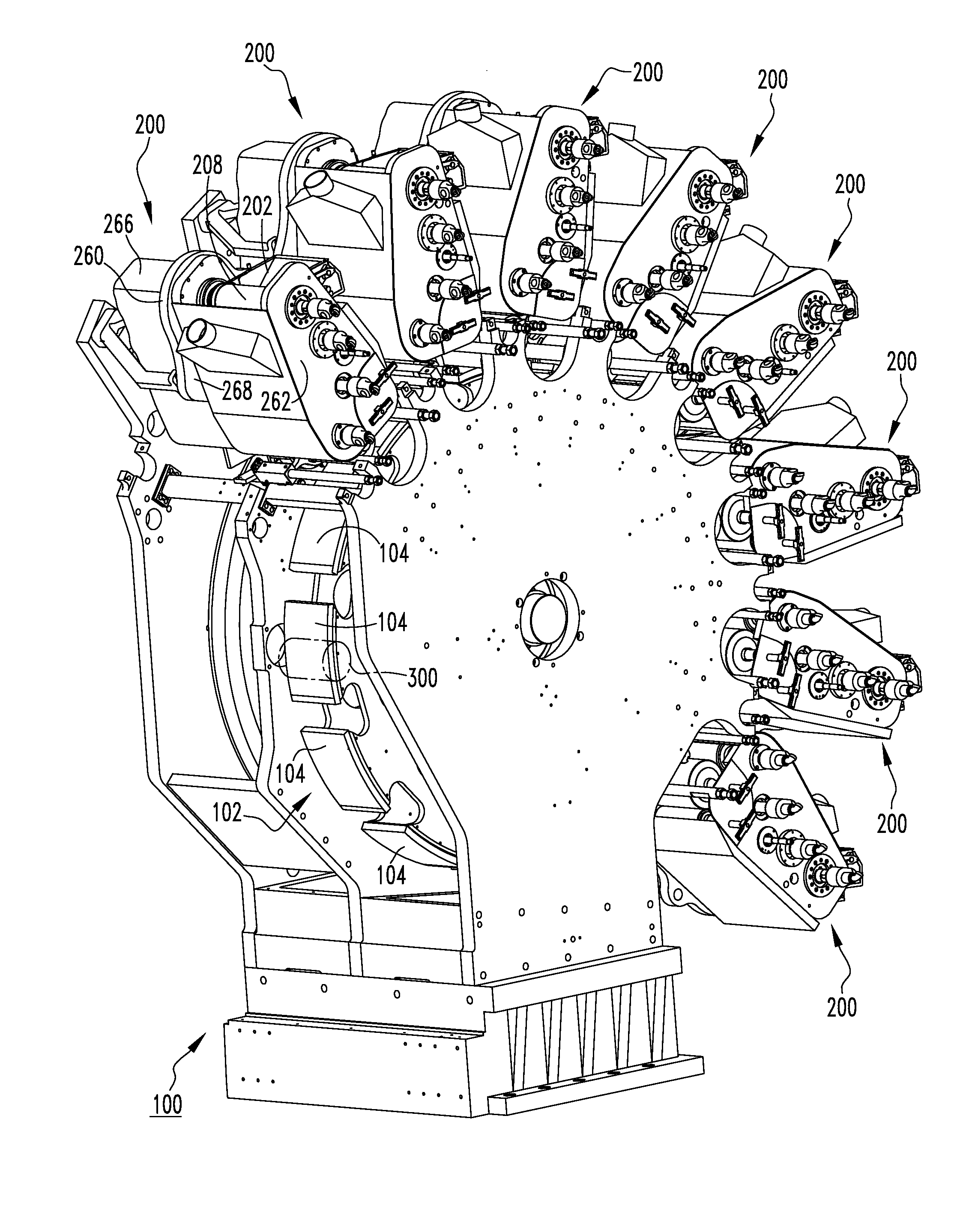

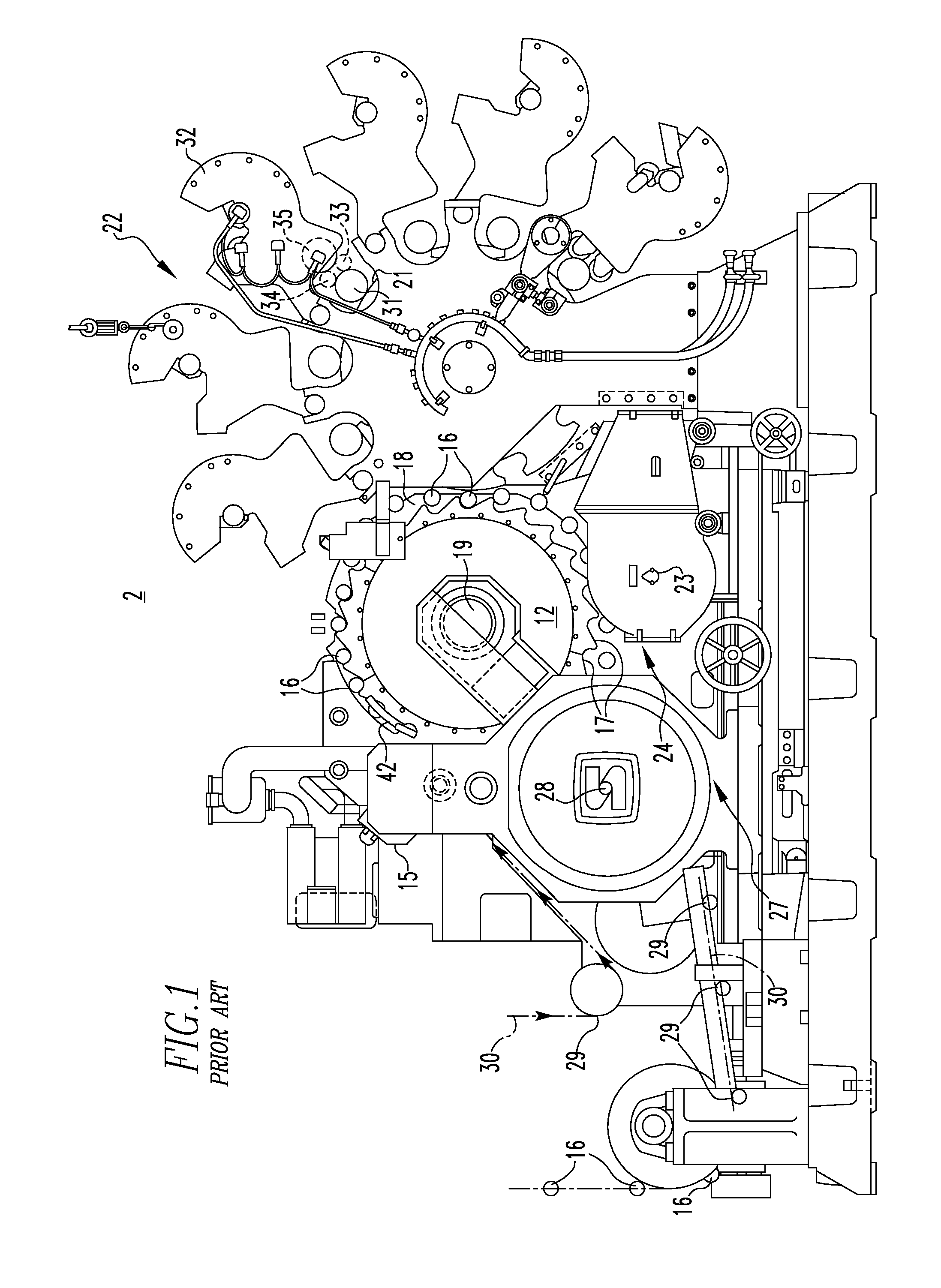

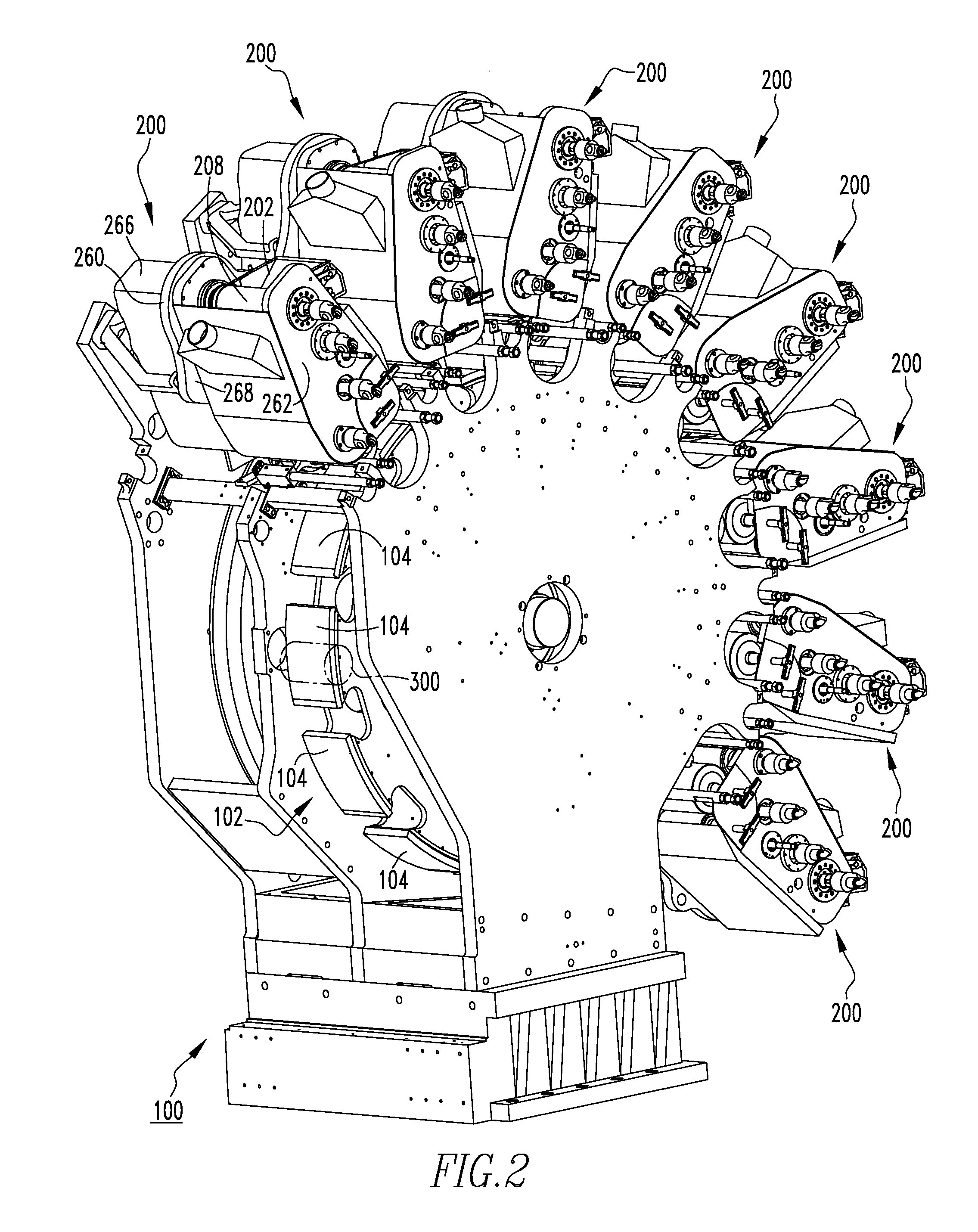

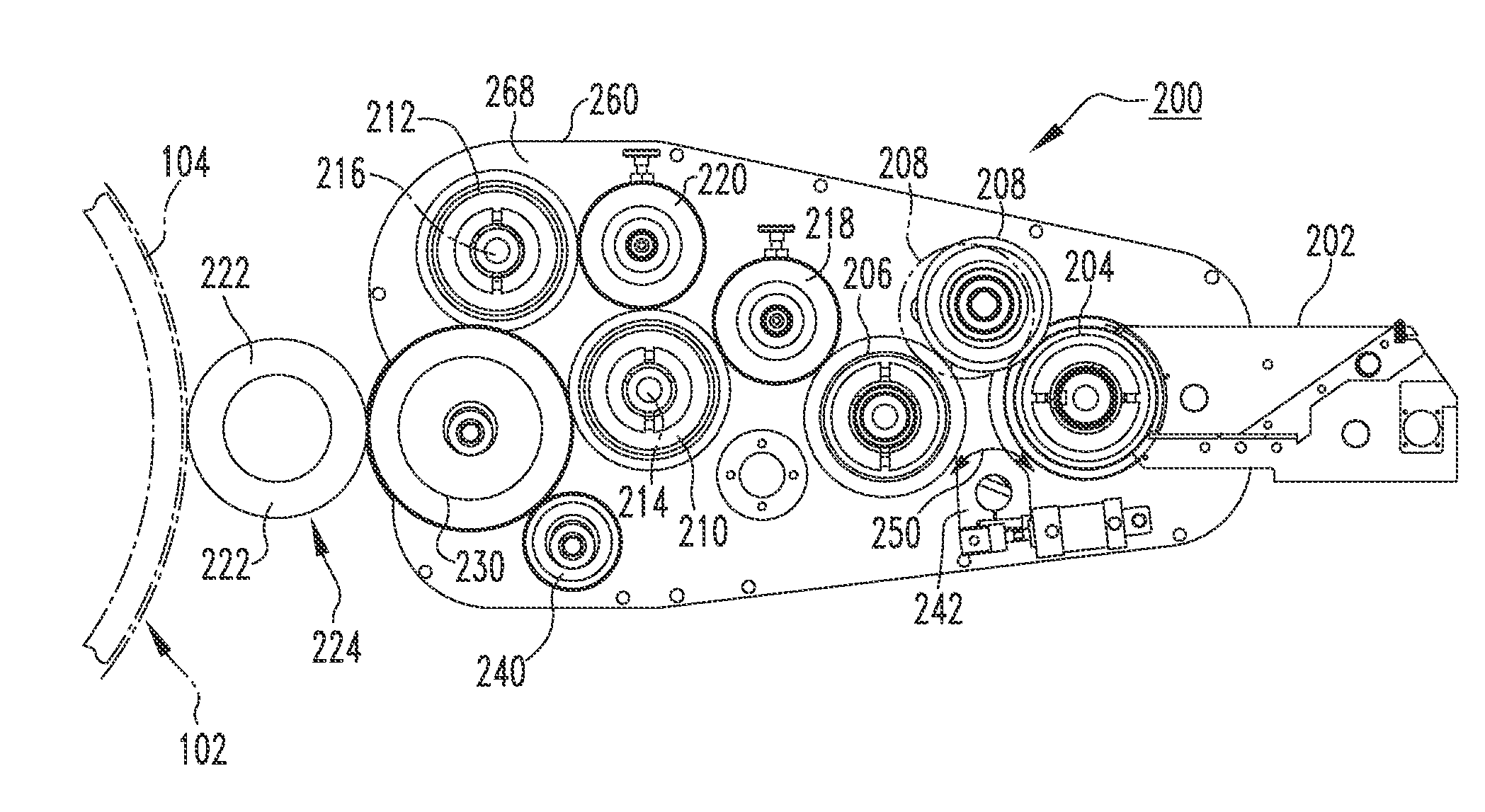

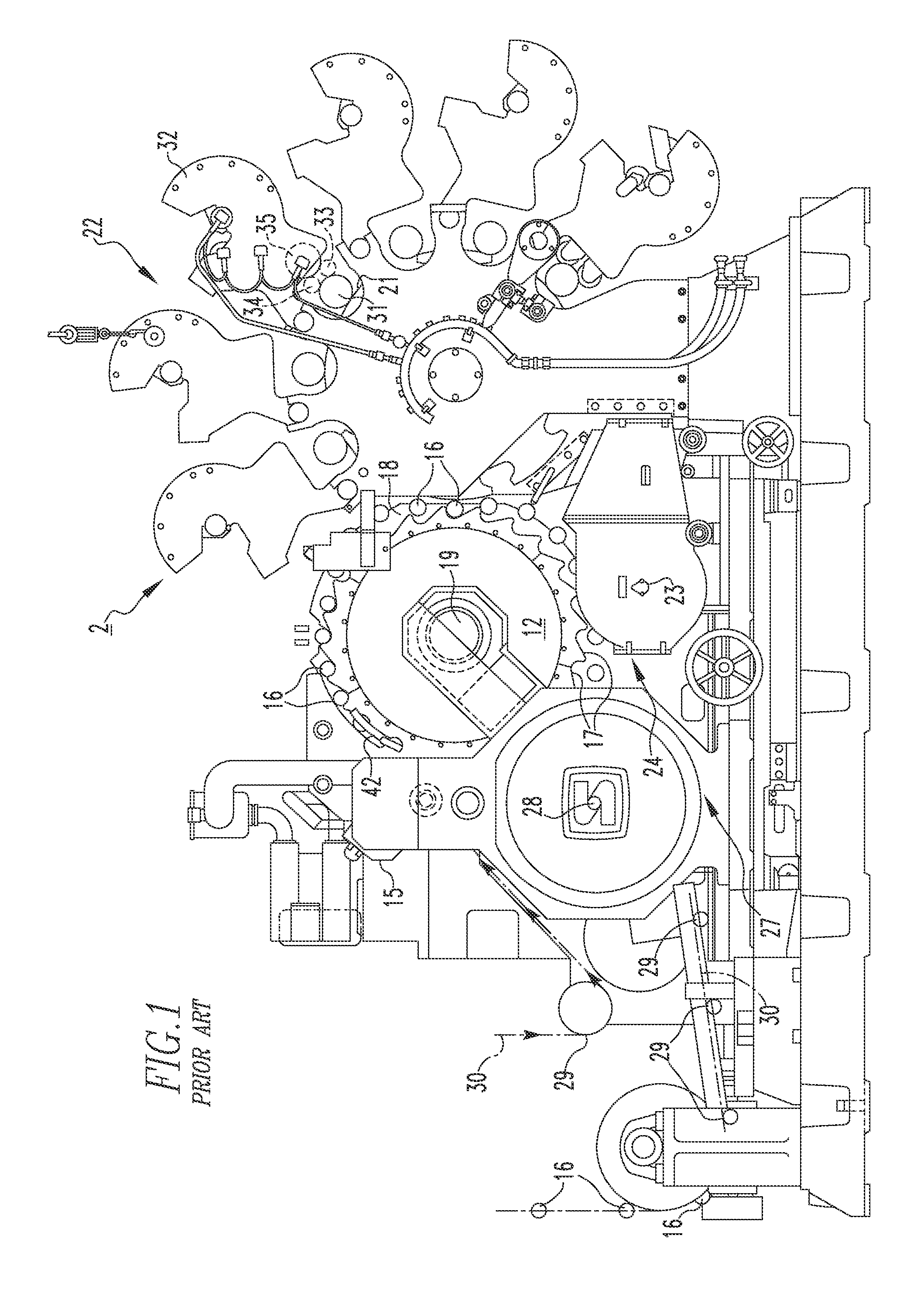

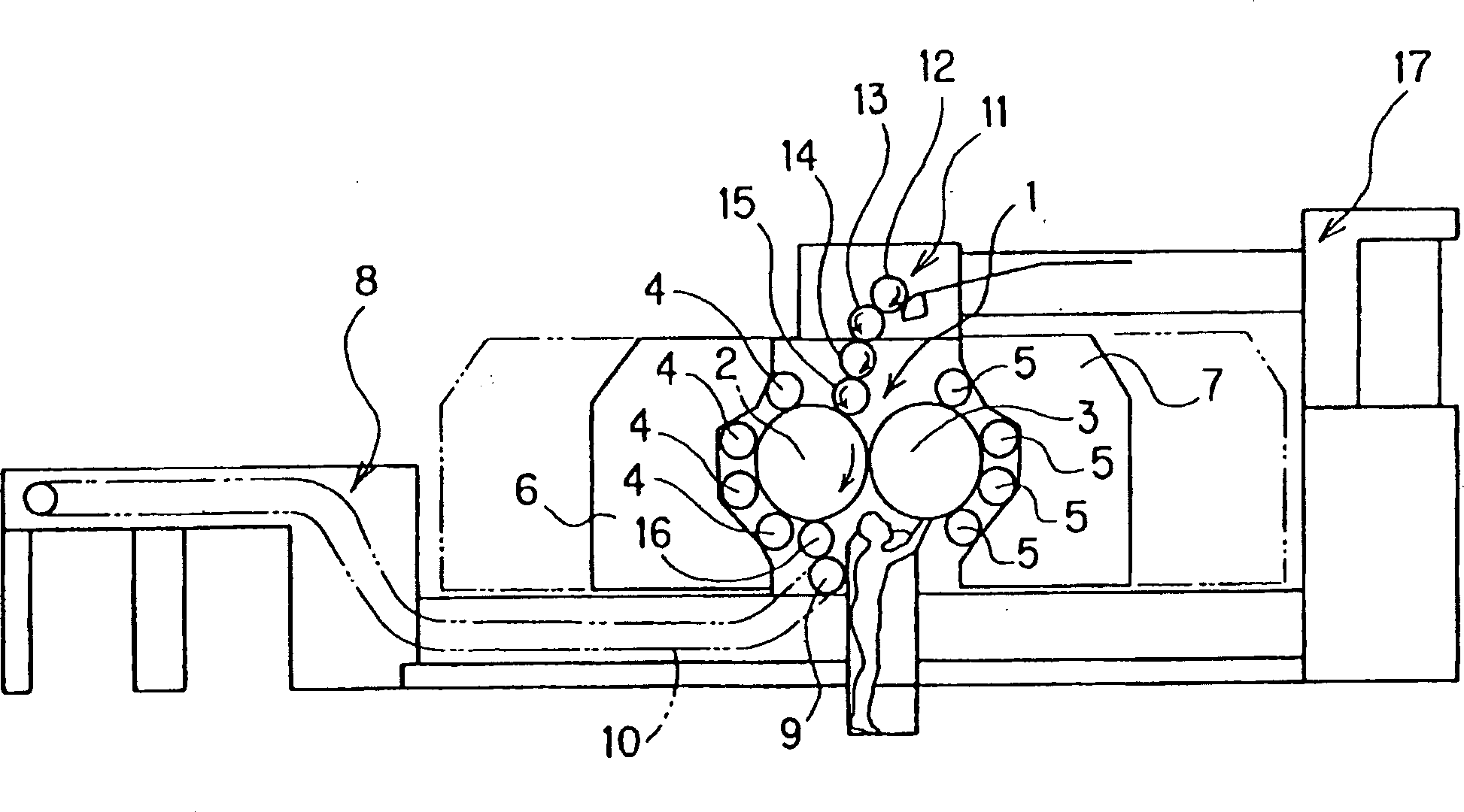

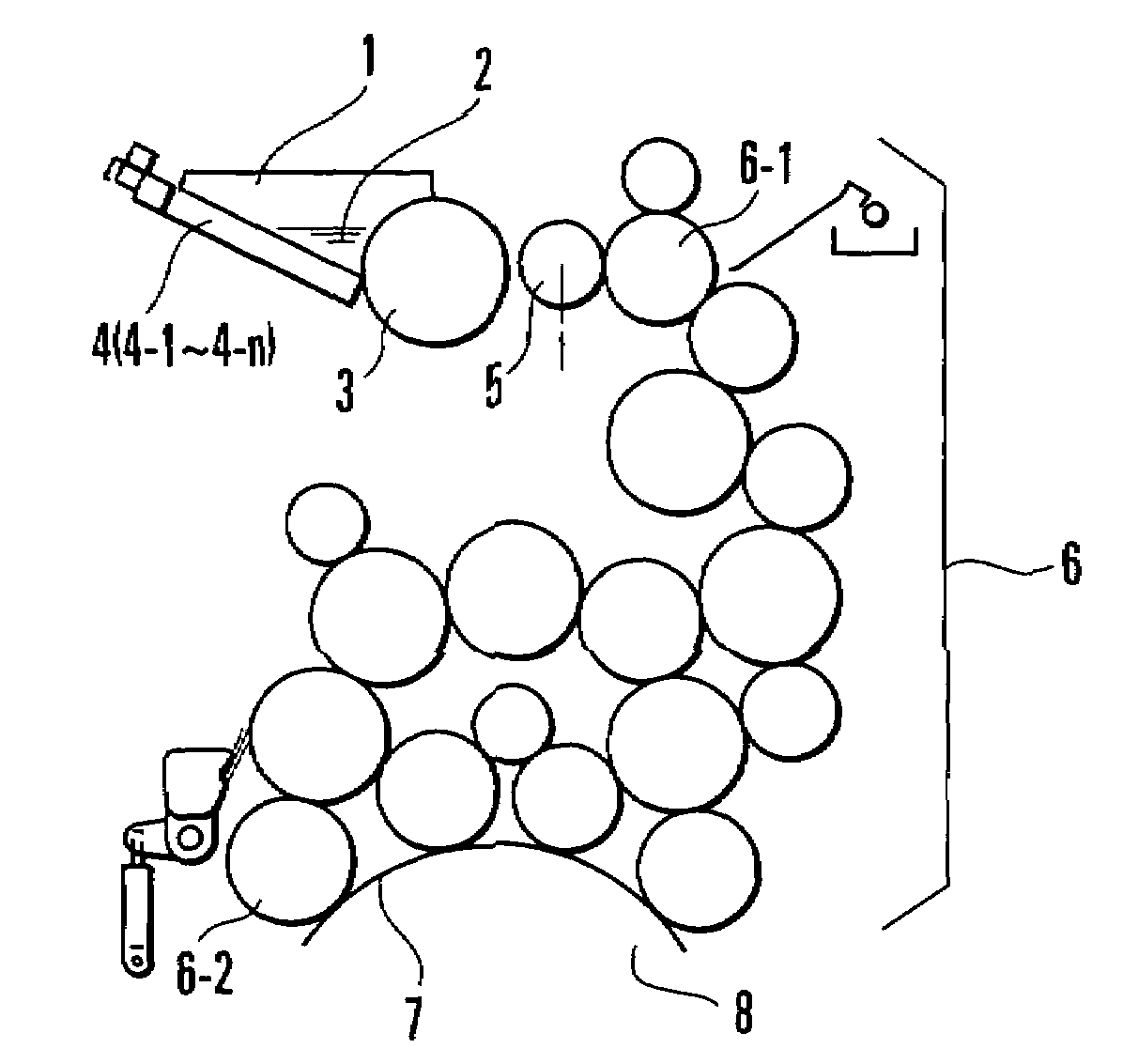

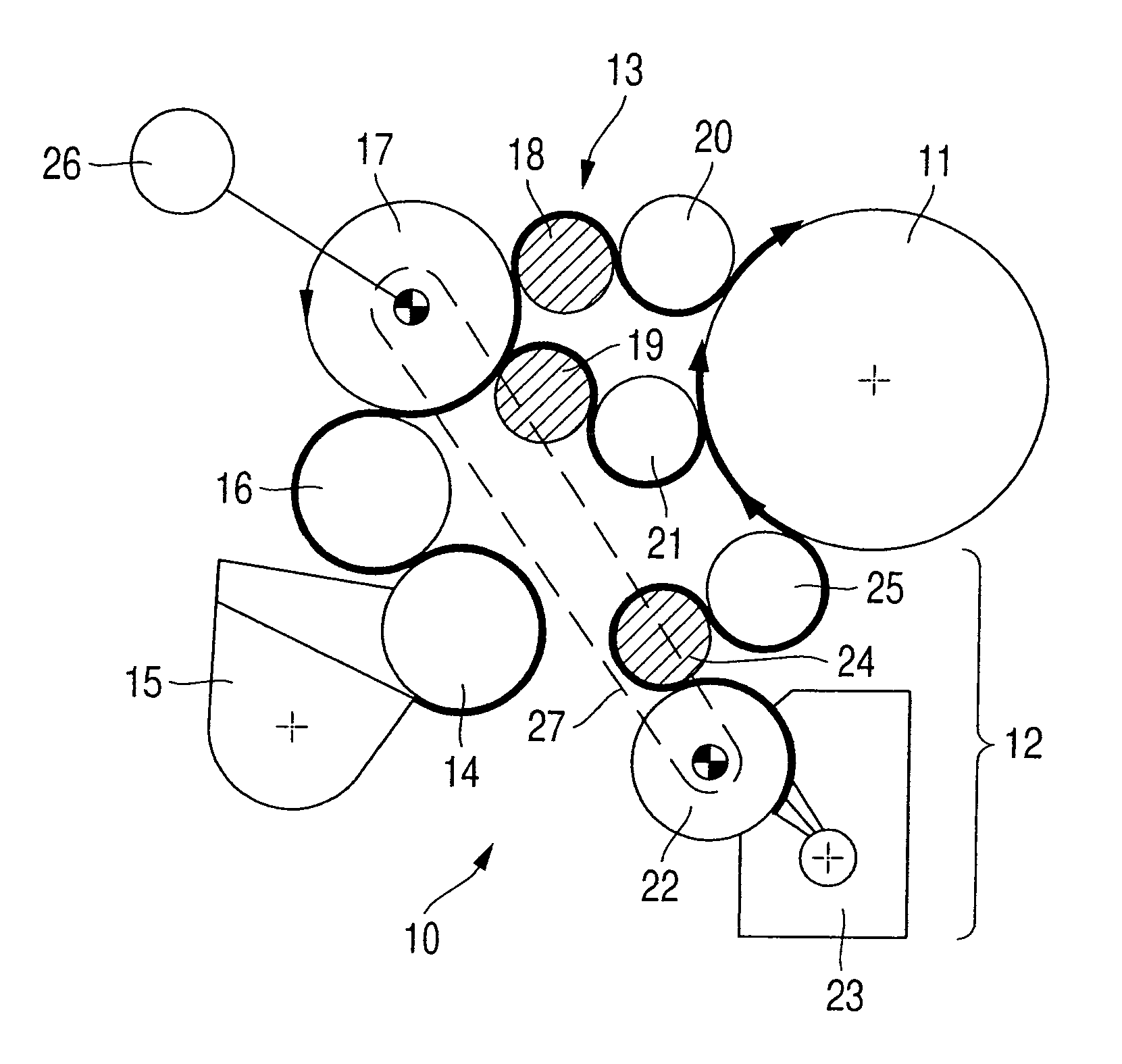

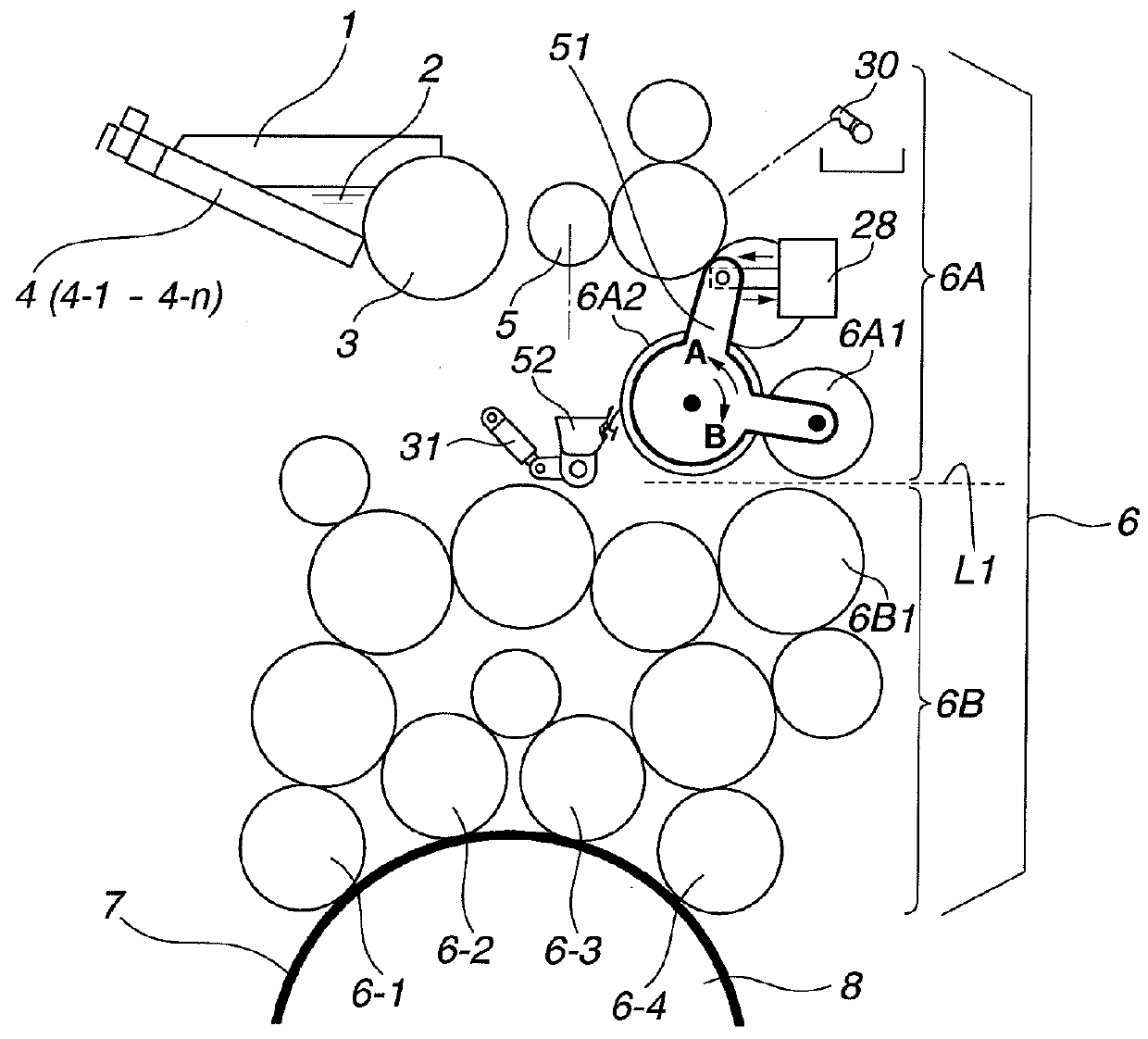

Can decorator machine, ink station assembly therefor, and can decorating method employing same

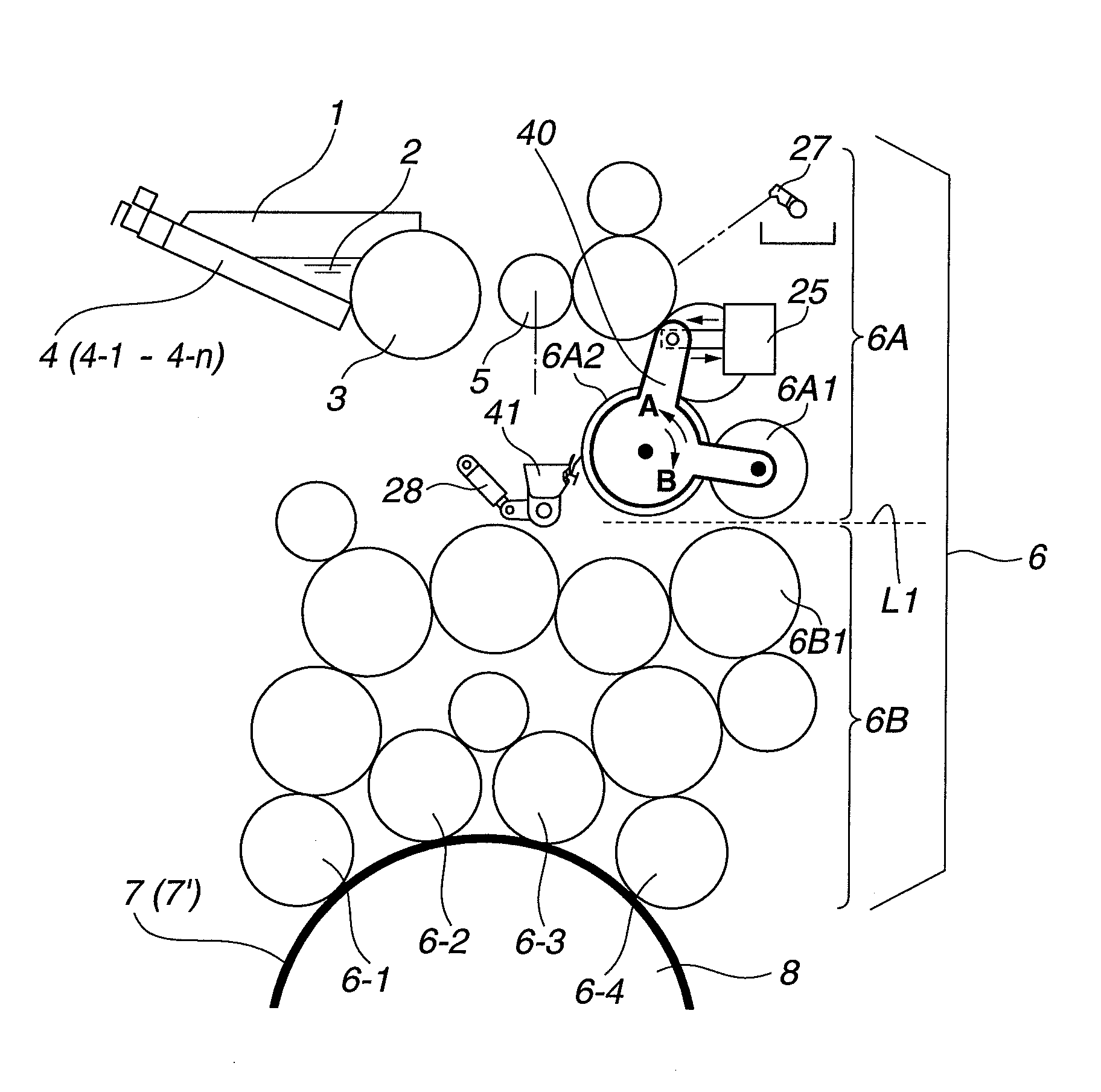

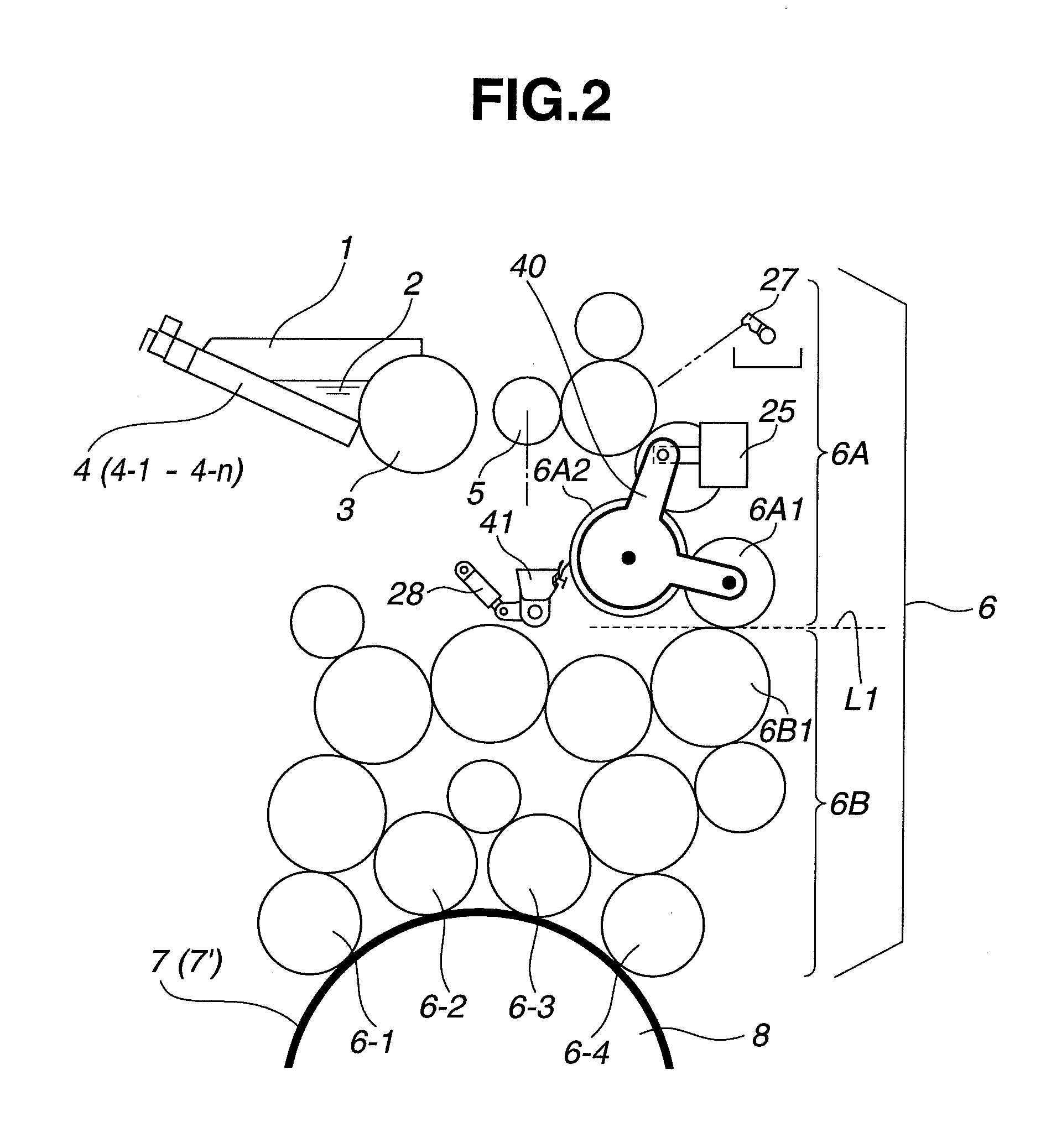

An ink station assembly is provided for a can decorator machine. The ink station assembly includes an ink fountain providing a supply of ink, a fountain roll, a distributor roll, a ductor roll cooperable with the fountain roll and the distributor roll, a number of oscillator rolls having longitudinal axis and oscillating back and forth along such axis, a number of transfer rolls cooperating with the oscillator rolls, a printing plate cylinder including a printing plate, and a single form roll cooperating with the printing plate cylinder to apply the ink to the printing plate. The diameter of the single form roll is greater than the diameter of the printing plate cylinder such that the printing plate cylinder makes a complete revolution before the single form roll makes a complete revolution. Accordingly, no portion of the single form roll contacts the printing plate more than once per revolution.

Owner:STOLLE MACHINERY

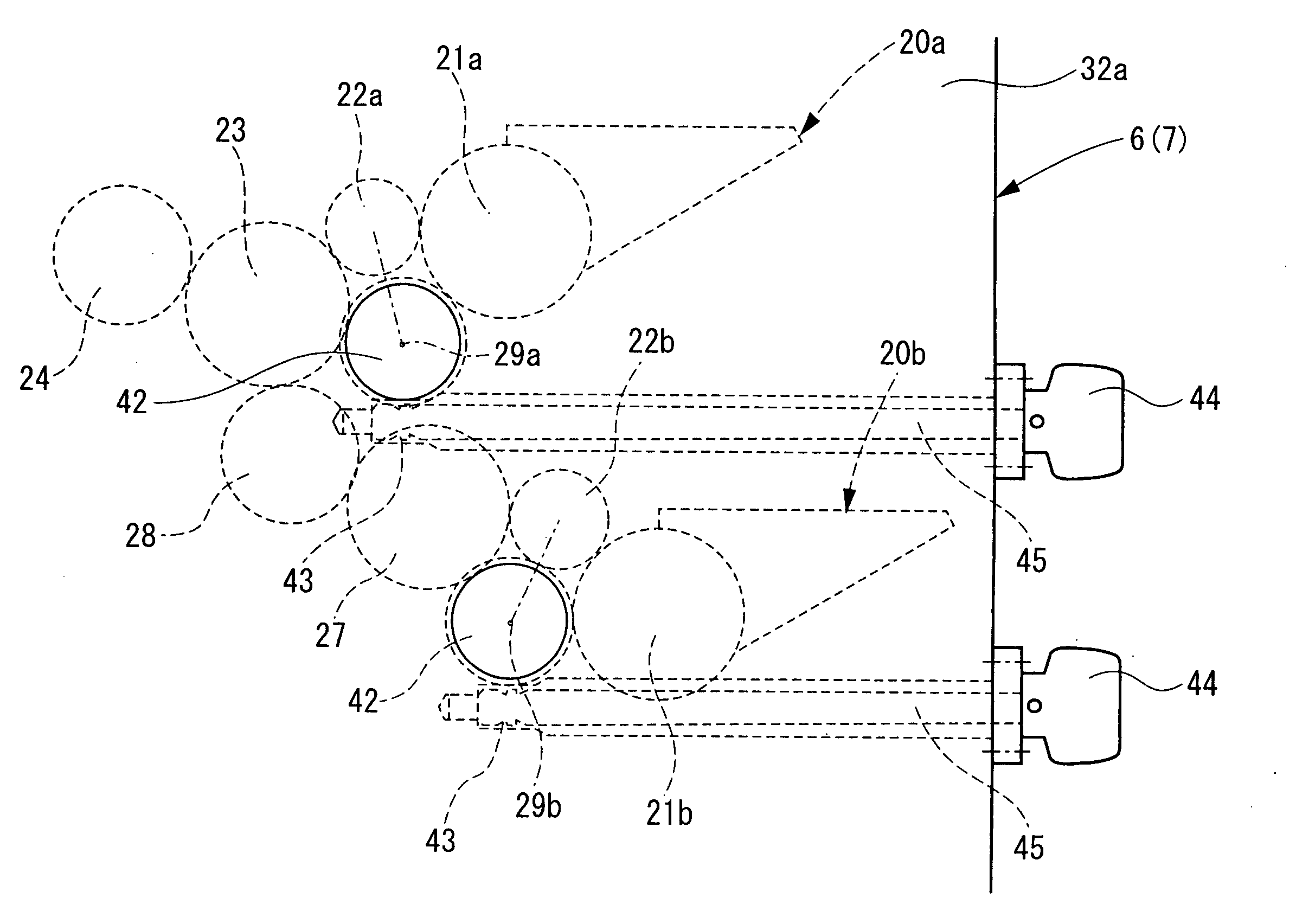

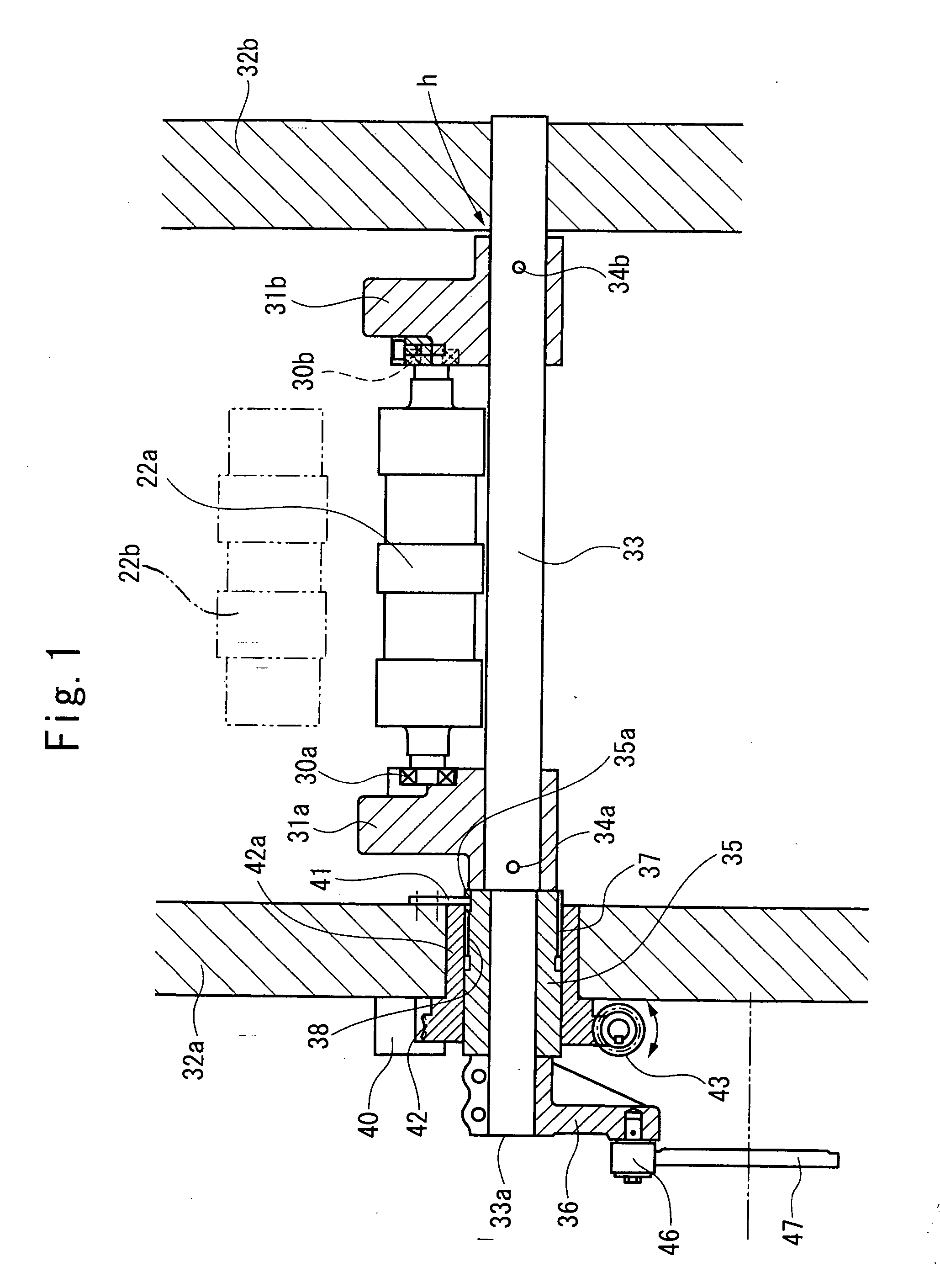

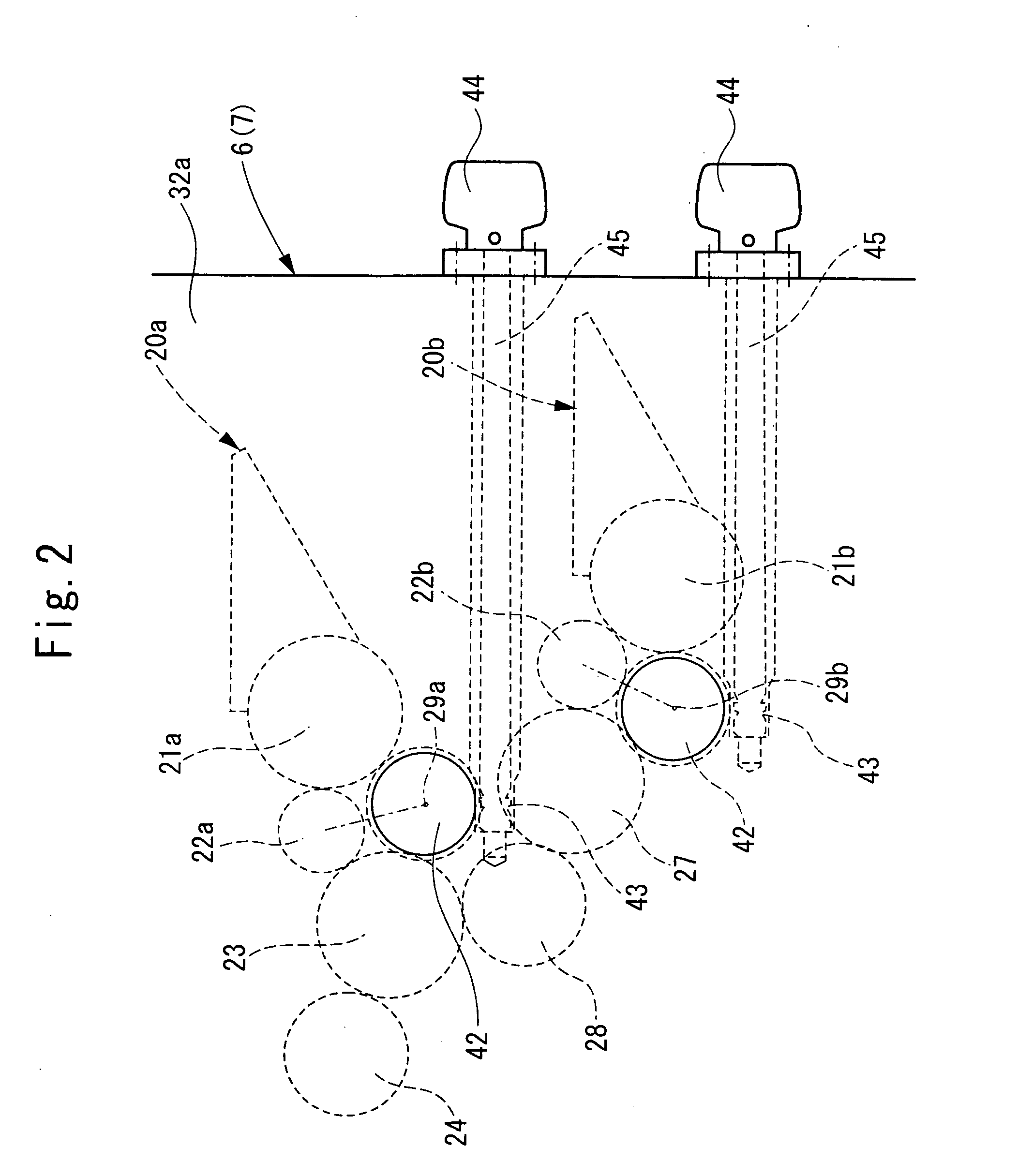

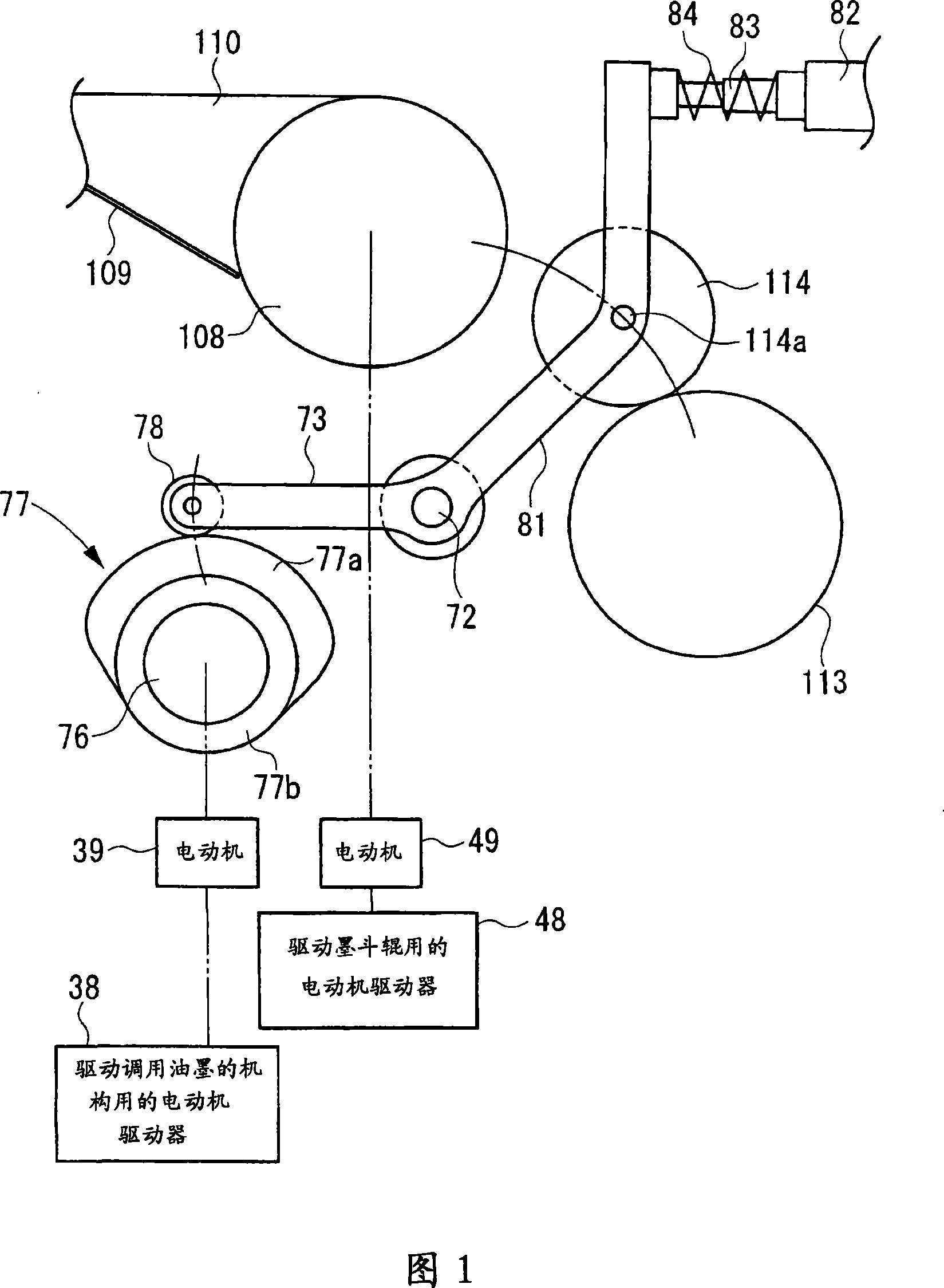

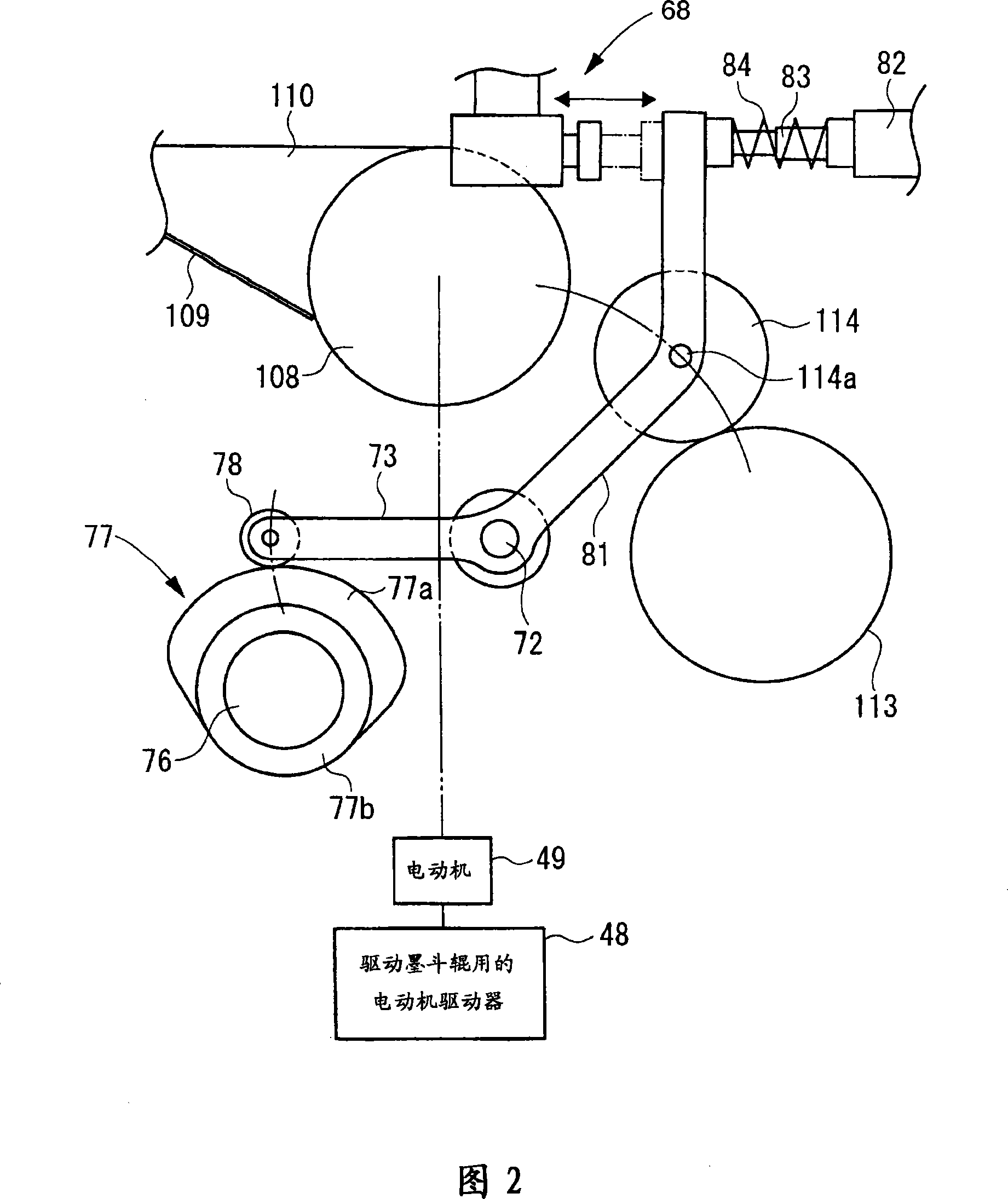

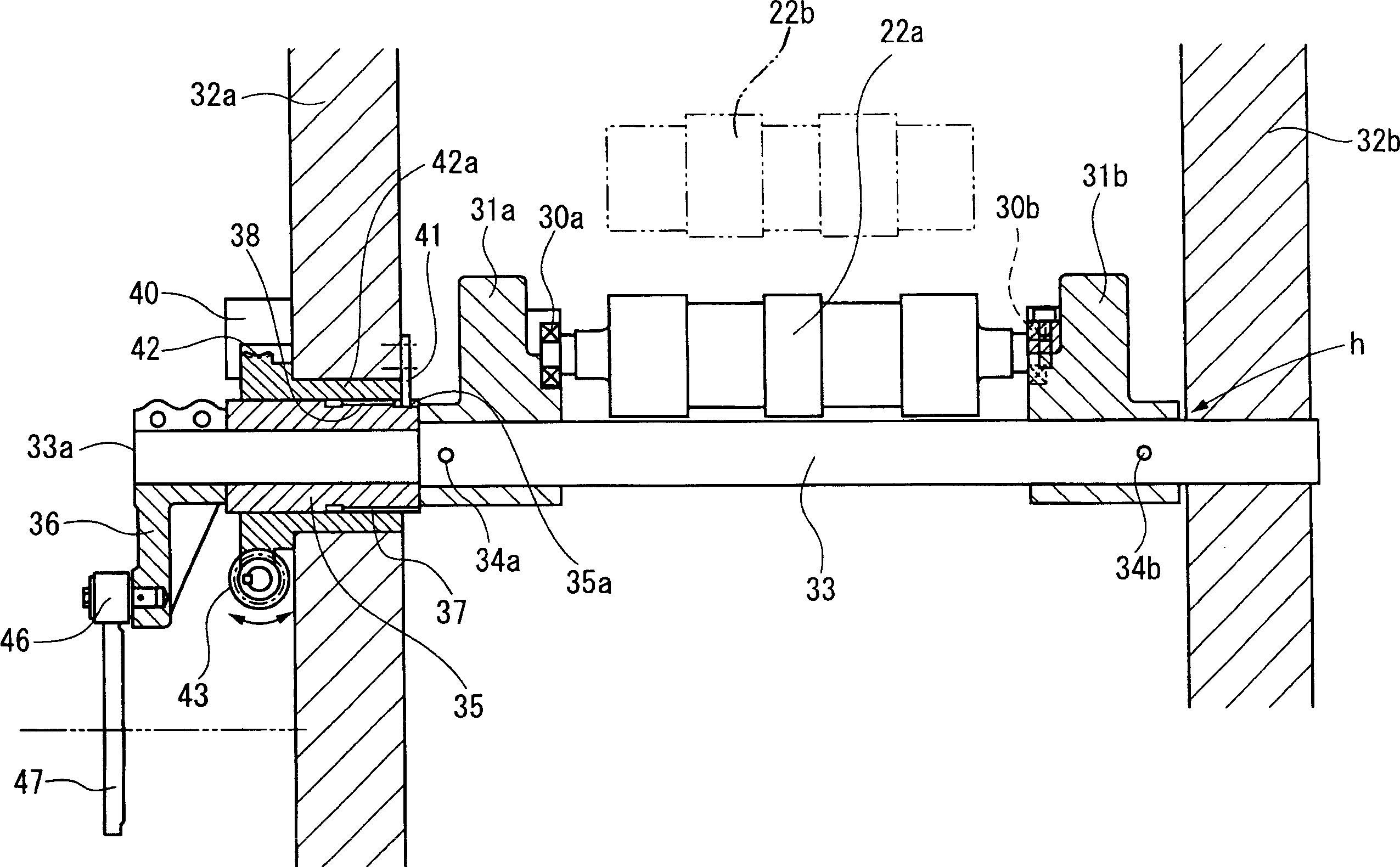

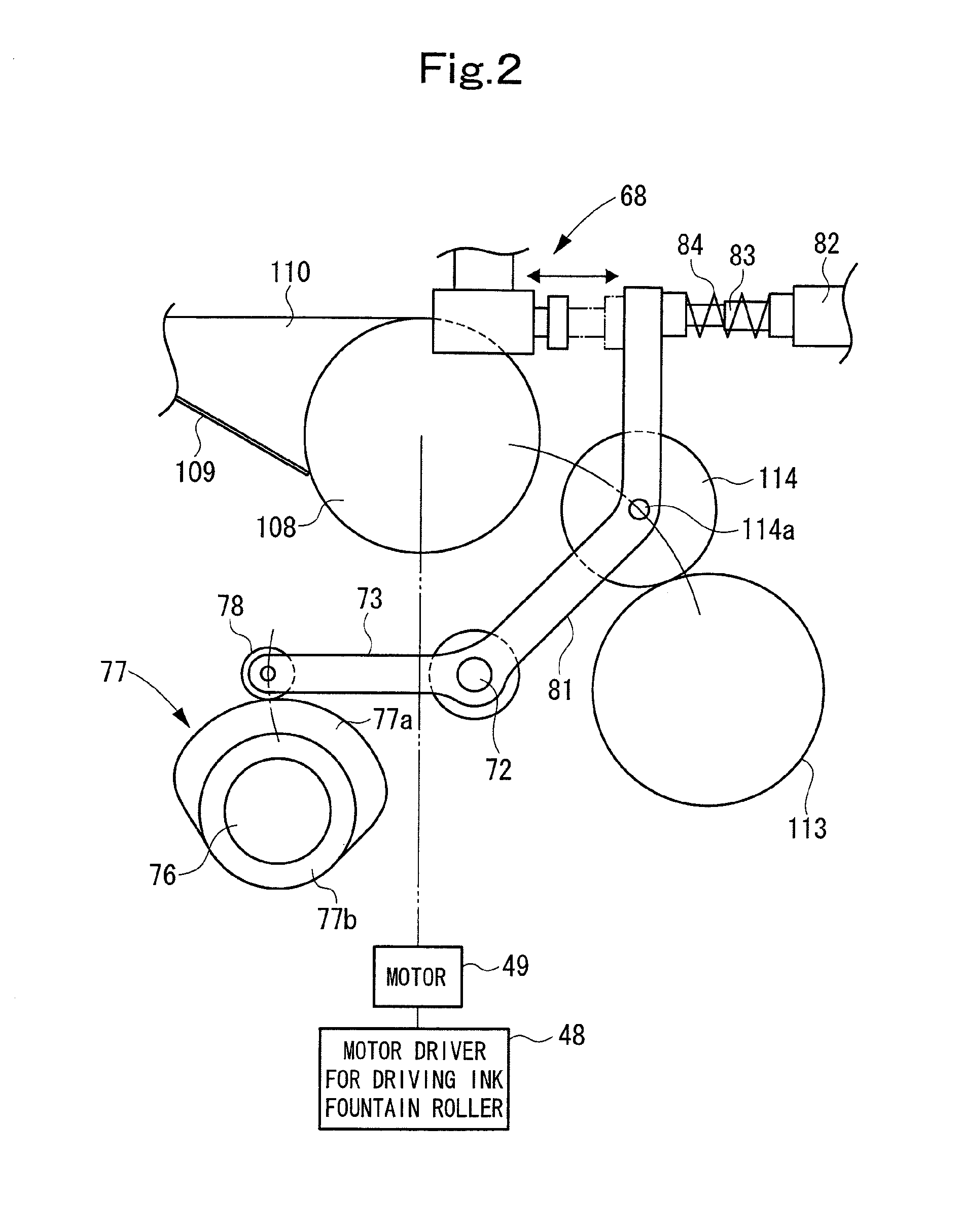

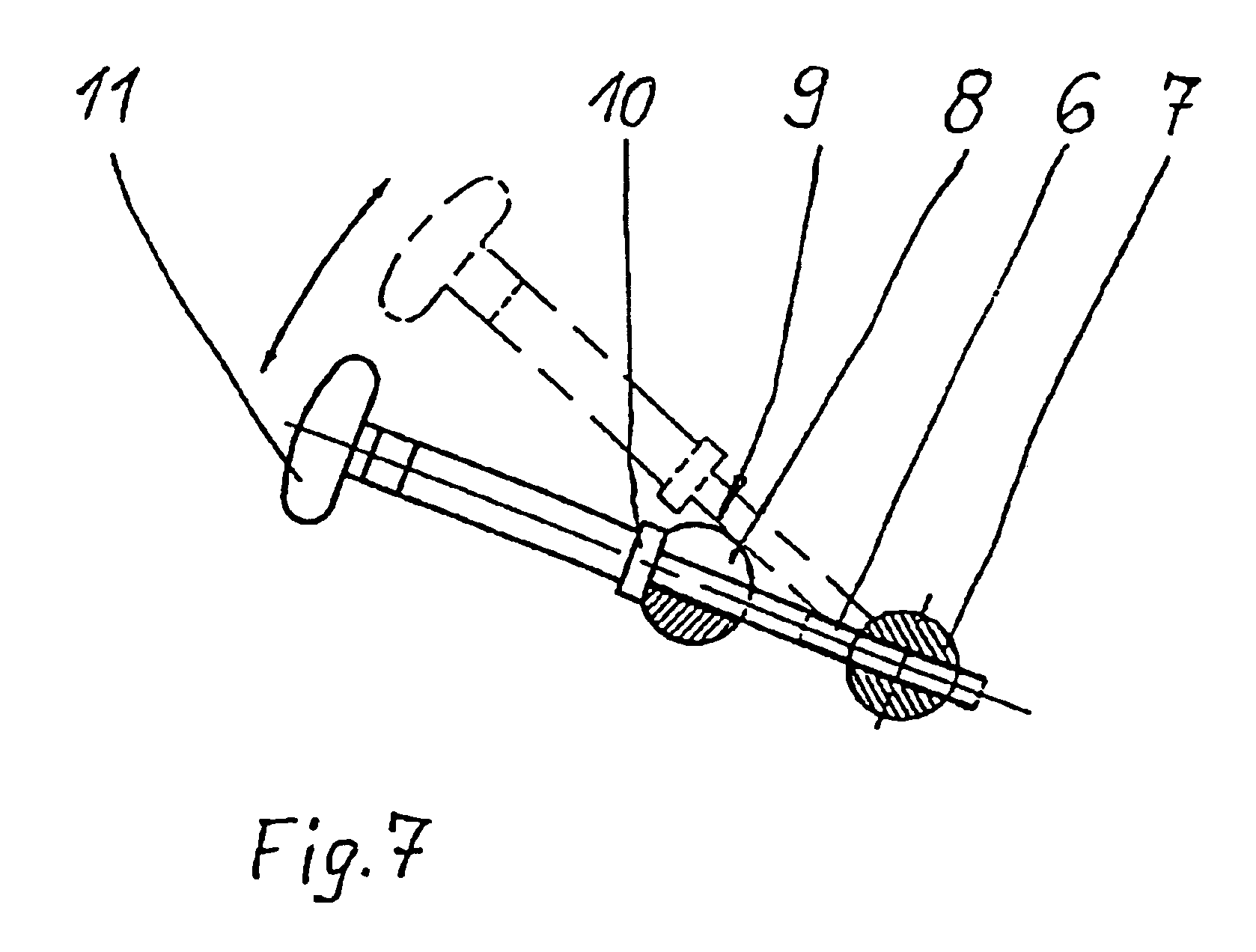

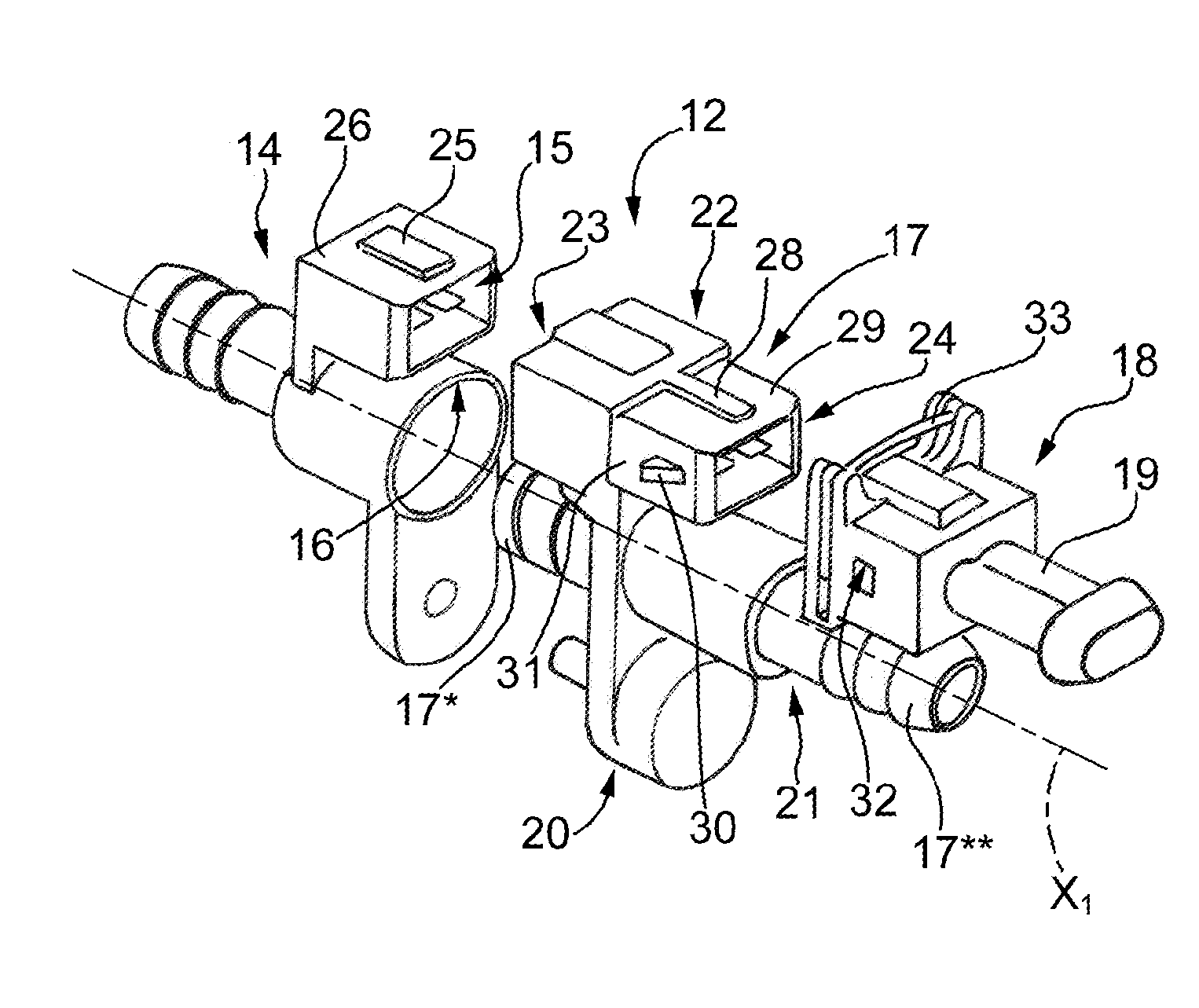

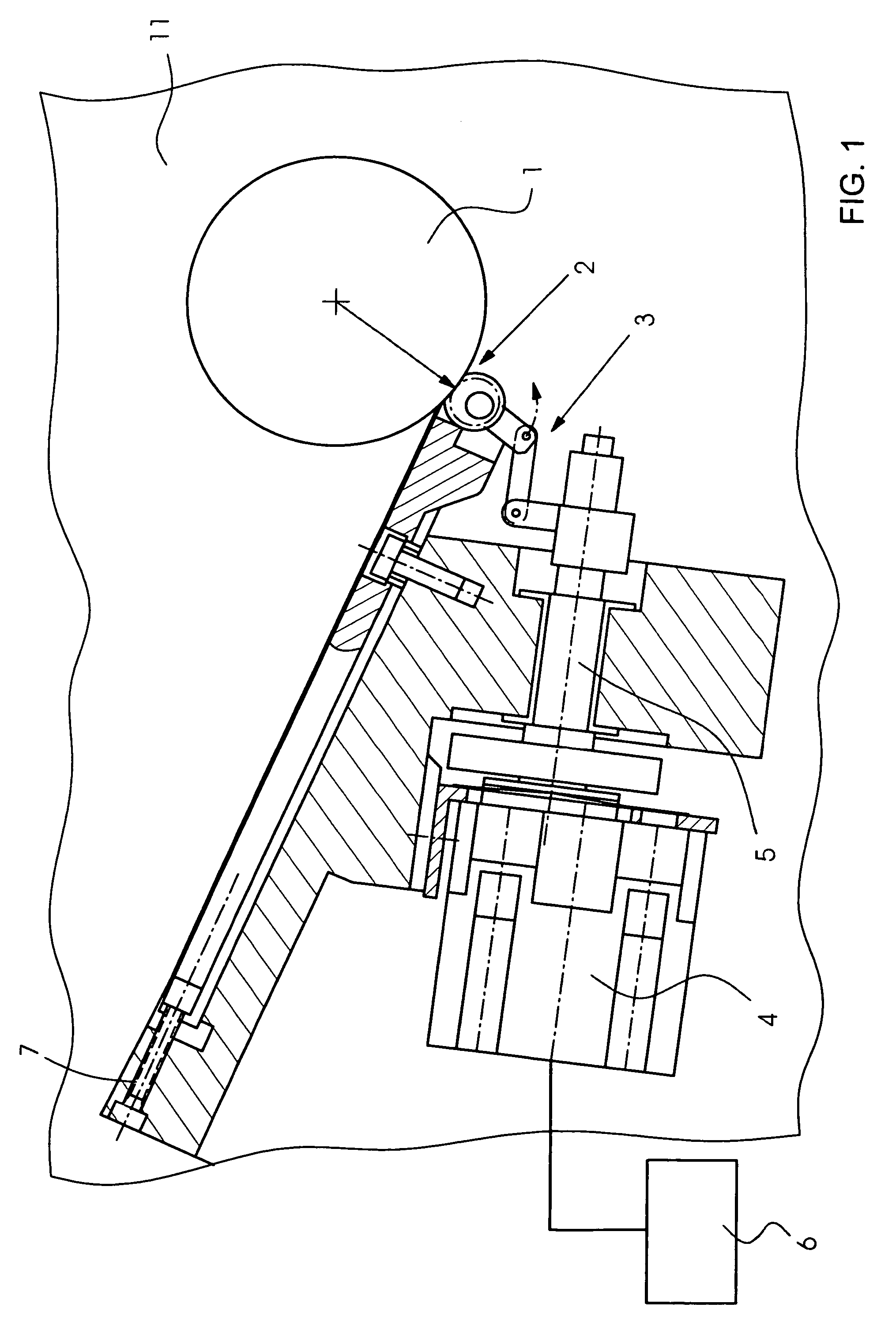

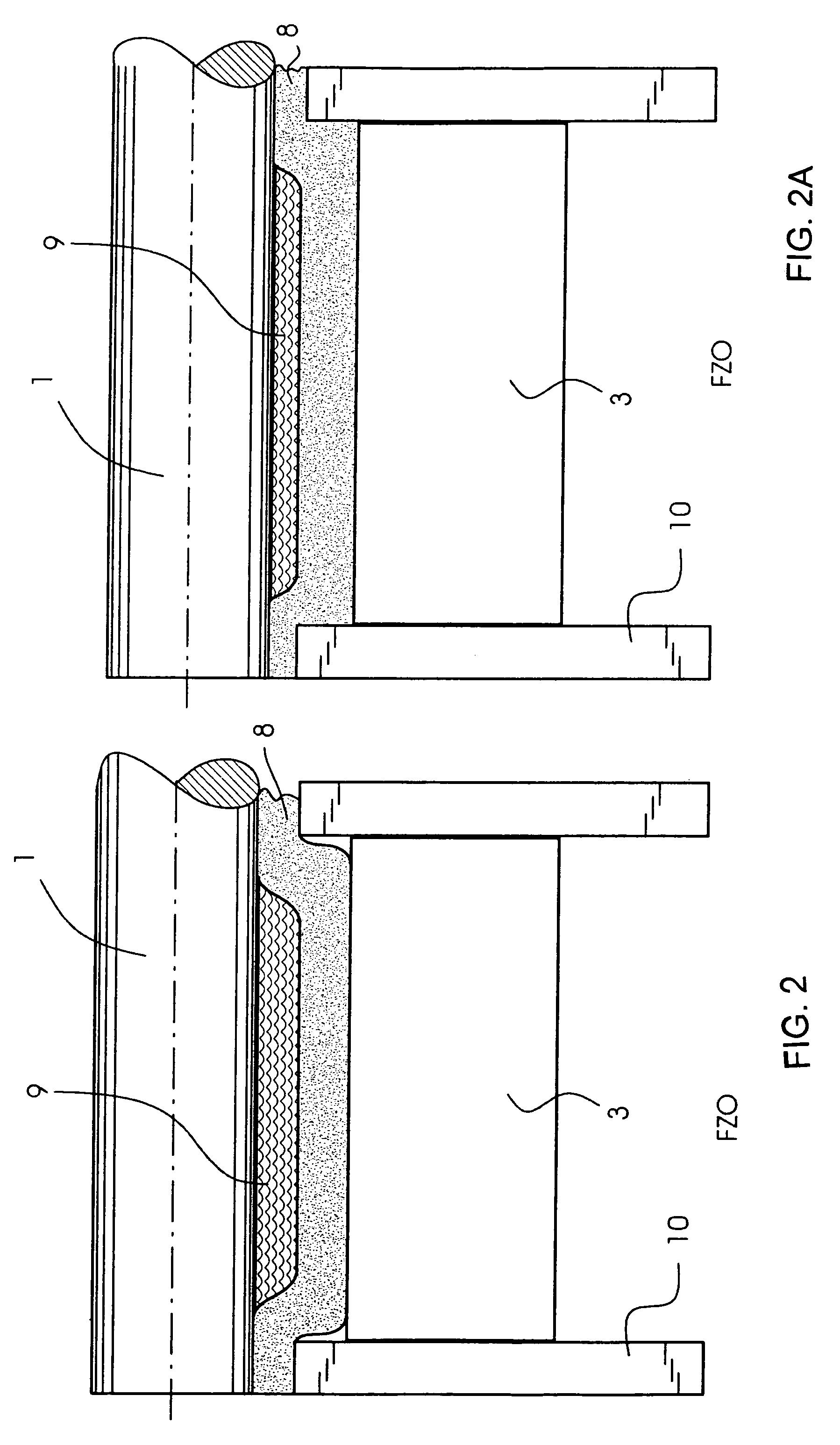

Inking device of printing press

An inking device of a printing press, including an ink ductor roller reciprocating between a receipt position, at which the ink ductor roller contacts an ink fountain roller to receive ink, and a transfer position, at which the ink ductor roller contacts an ink distribution roller or a first intermediate roller located downstream in an ink transfer direction to pass the ink on to the roller, comprises: a pair of split clamping holders supporting the ink ductor roller and supported swingably; and moving means, comprising a shaft, a sleeve, a bearing portion, a worm wheel, a worm shaft, and an operating shaft having a dial-equipped handle, for moving the pair of split clamping holders in the axial direction of the ink ductor roller.

Owner:KOMORI CORP

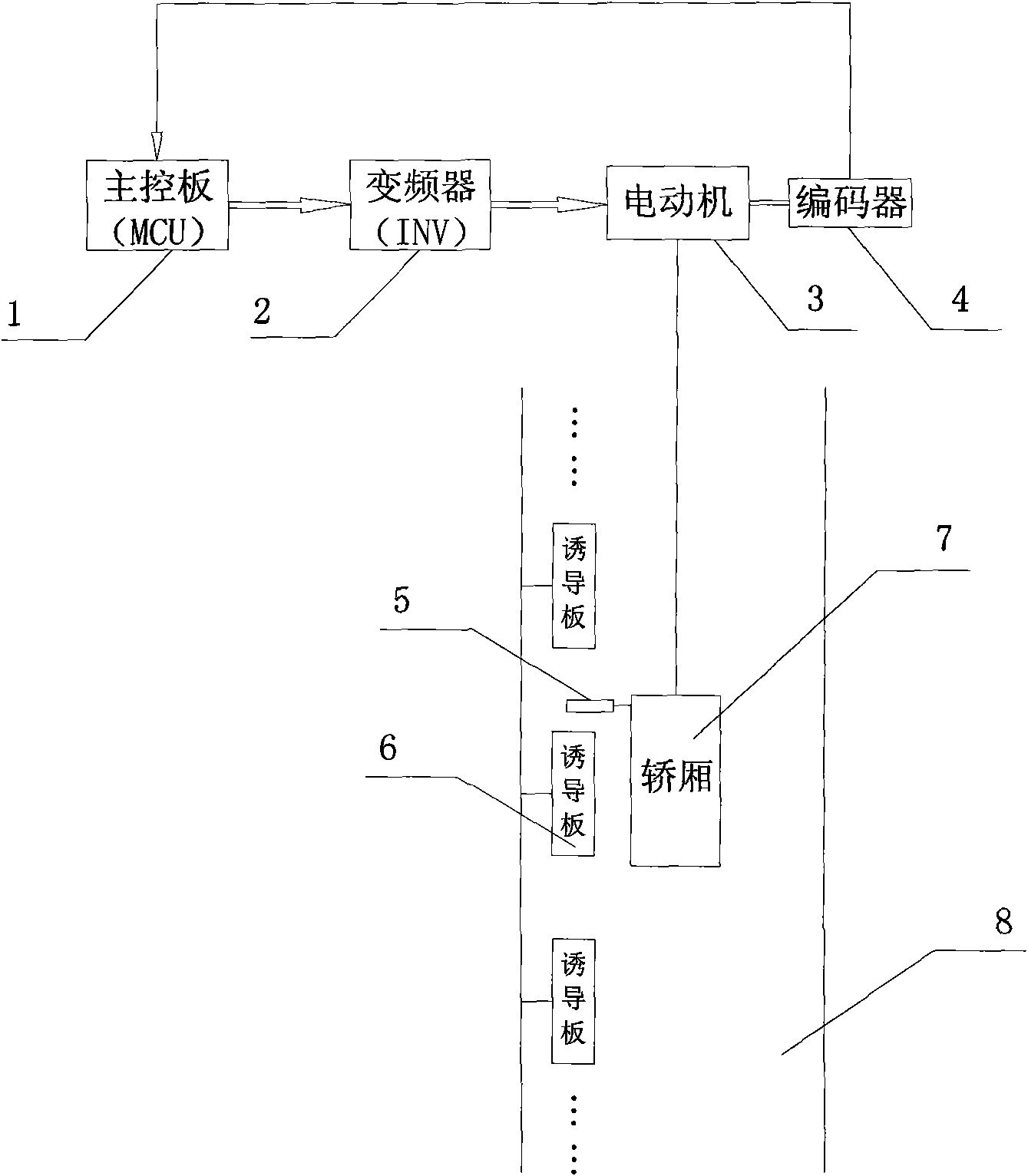

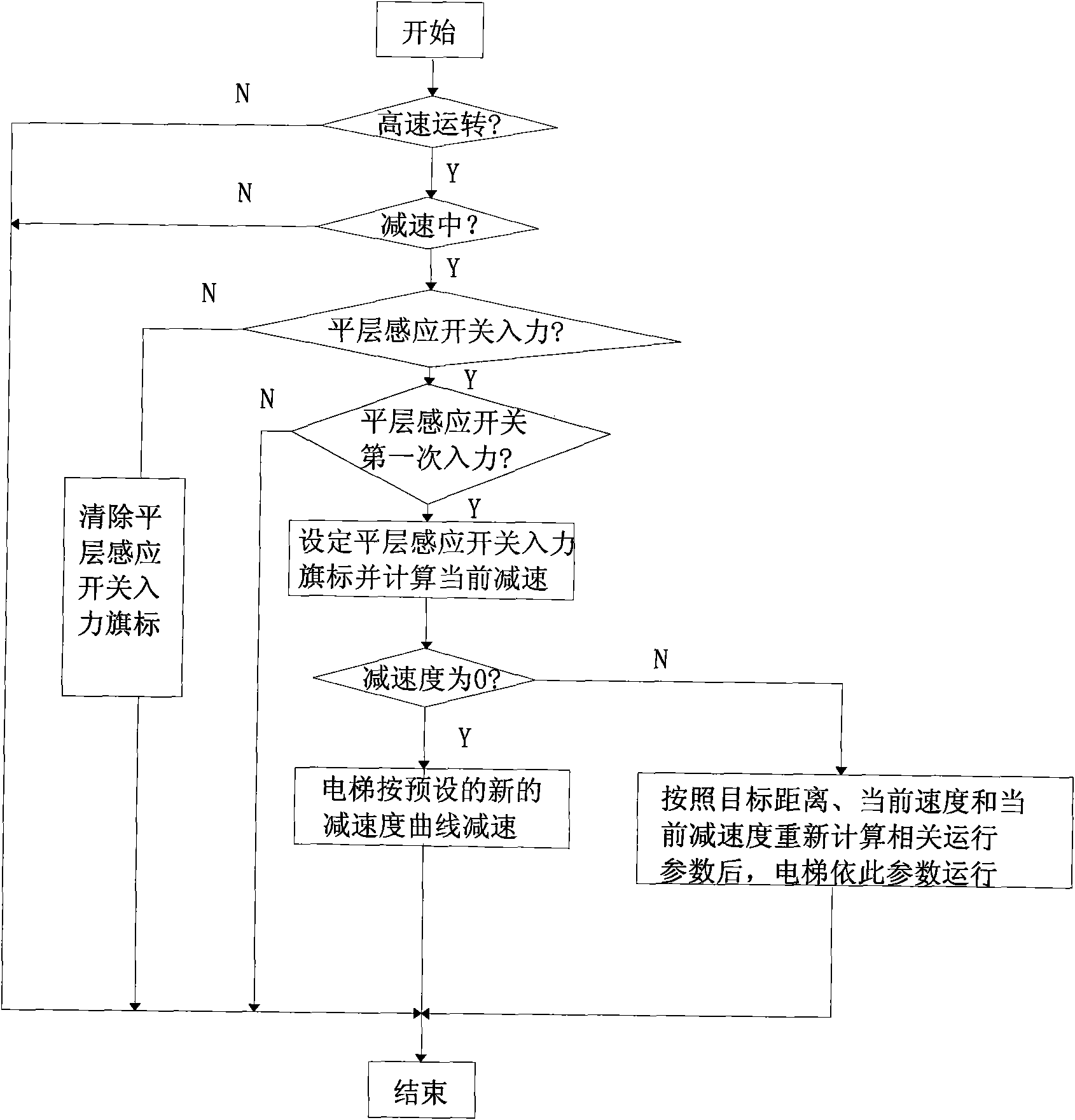

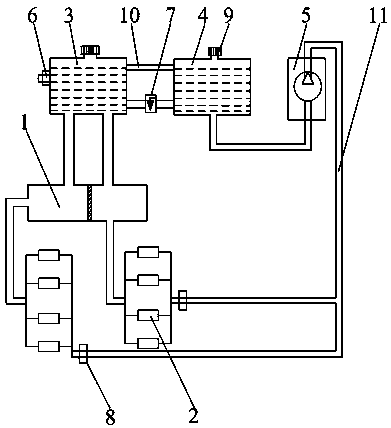

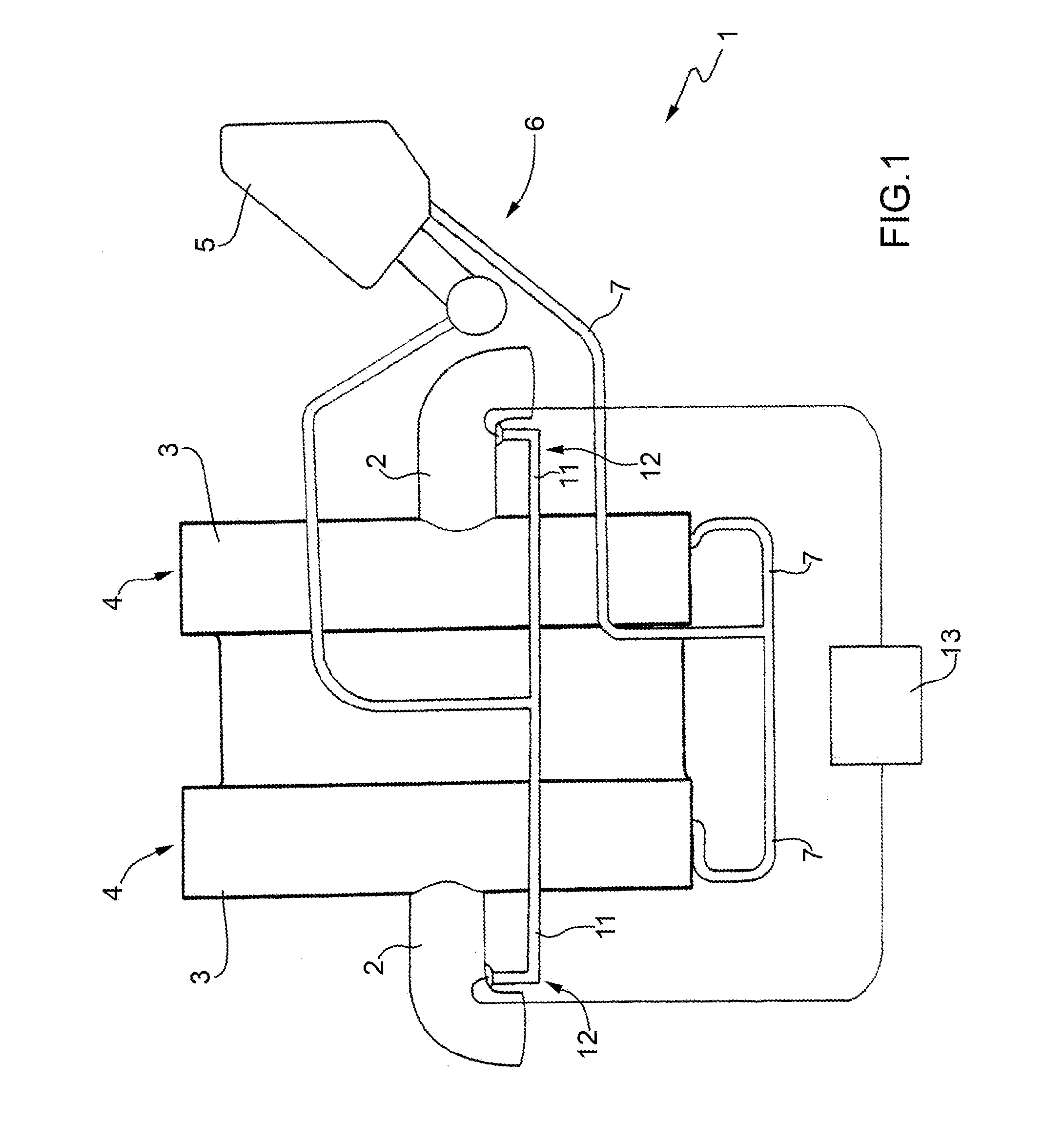

System for realizing direct stopping of elevator and control method thereof

InactiveCN101549821AImprove operational efficiencyImprove leveling stabilityElevatorsBuilding liftsSignal onSimulation

The invention discloses a system for realizing direct stopping of elevator and the implement method thereof, The system comprises a master control board, a frequency converter, an electromotor, an encoder, a flat layer inductive switch, a ductor, a car and a hoistway; the master control board acquires the accurate position of each layer and the absolute location of the car in the hoistway by the signals on the flat layer inductive switch, the doctor and the encoder, and control the start and stop of the frequency converter; the electromotor controlled by the frequency converter drives the elevator car to move up and down; the master control board acquires the object residual distance an the speed of the elevator by the encoder signal, determines the elevator speed curve and the deceleration points, acquires the actual distance to the target layer station by the flat layer inductive switch mounted on the car side wall and the inductors mounted on all the layer positions on the side wall of the hoistway when the elevator is approaching the target layer station, and corrects the speed and acceleration of the elevator thereby to cause the elevator to stop at the target position stably.

Owner:YUNGTAY ELEVATOR EQUIP CHINA

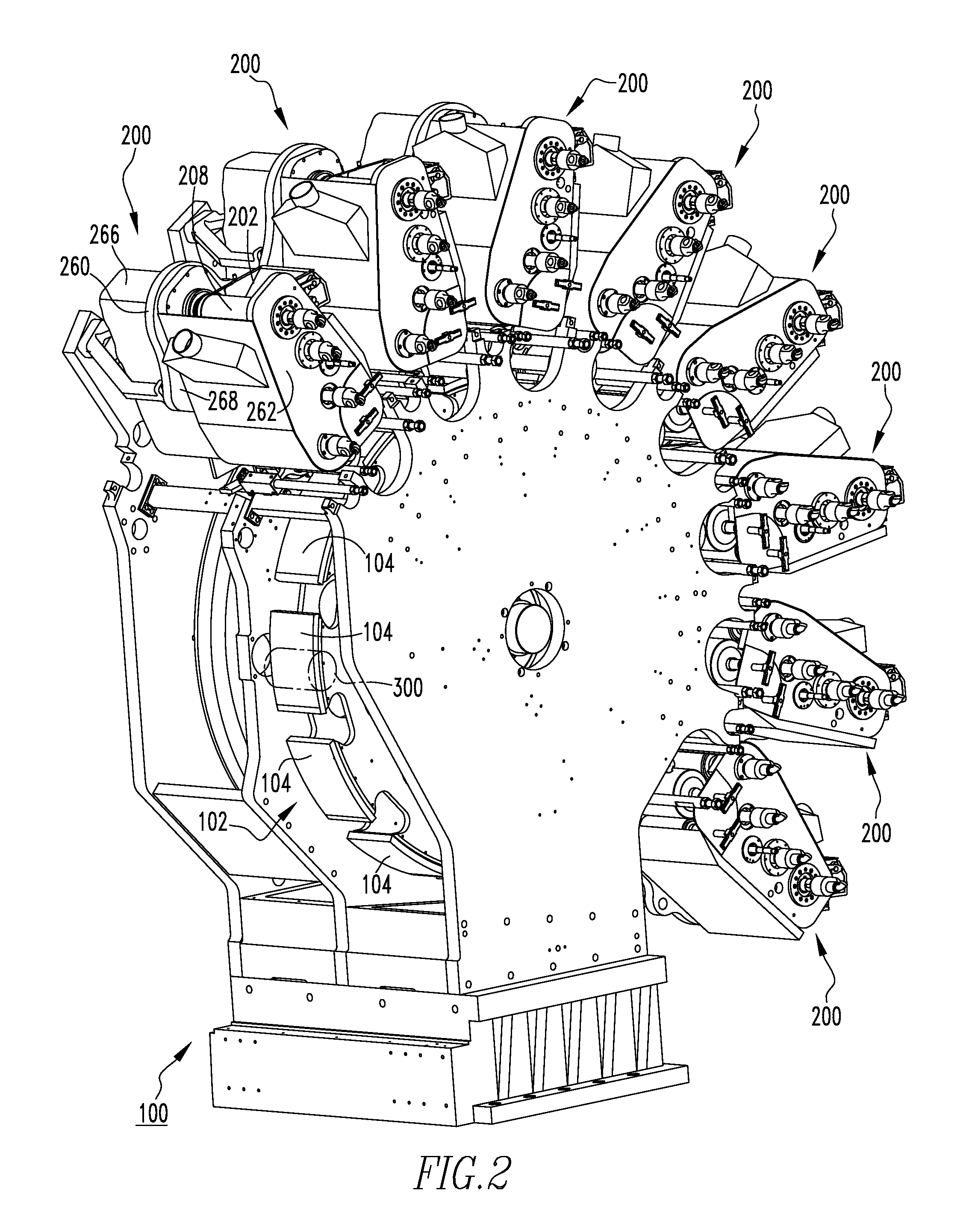

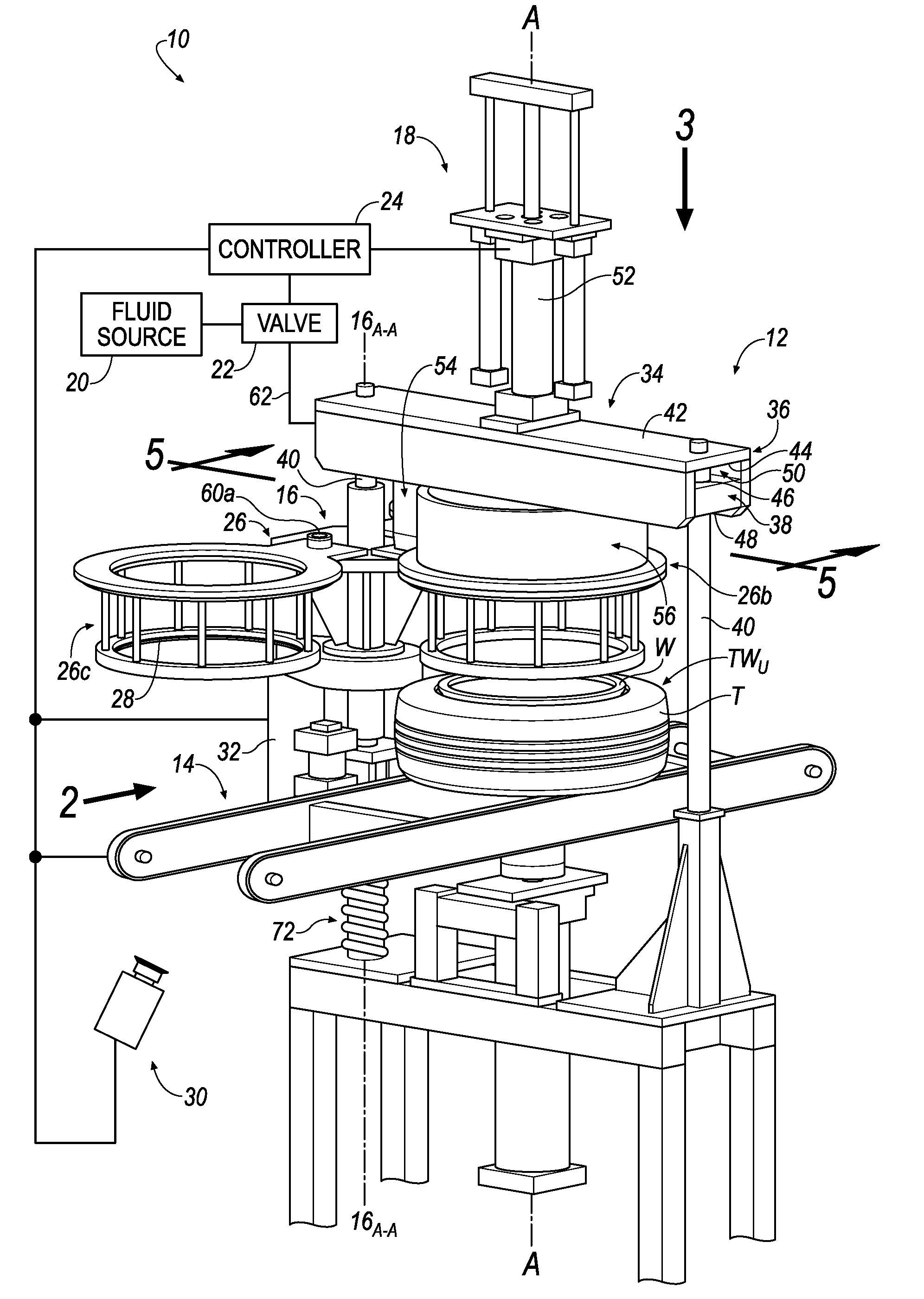

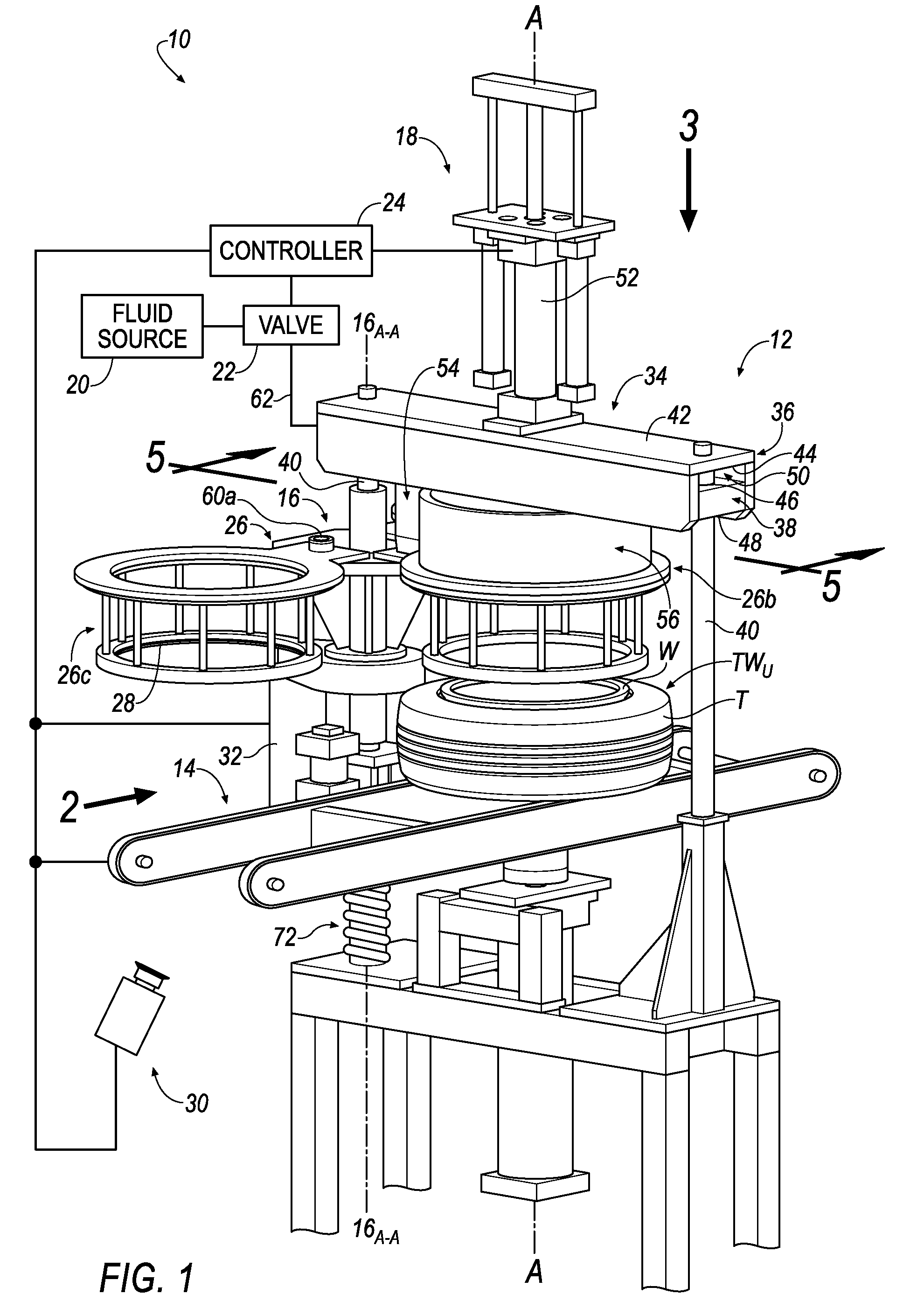

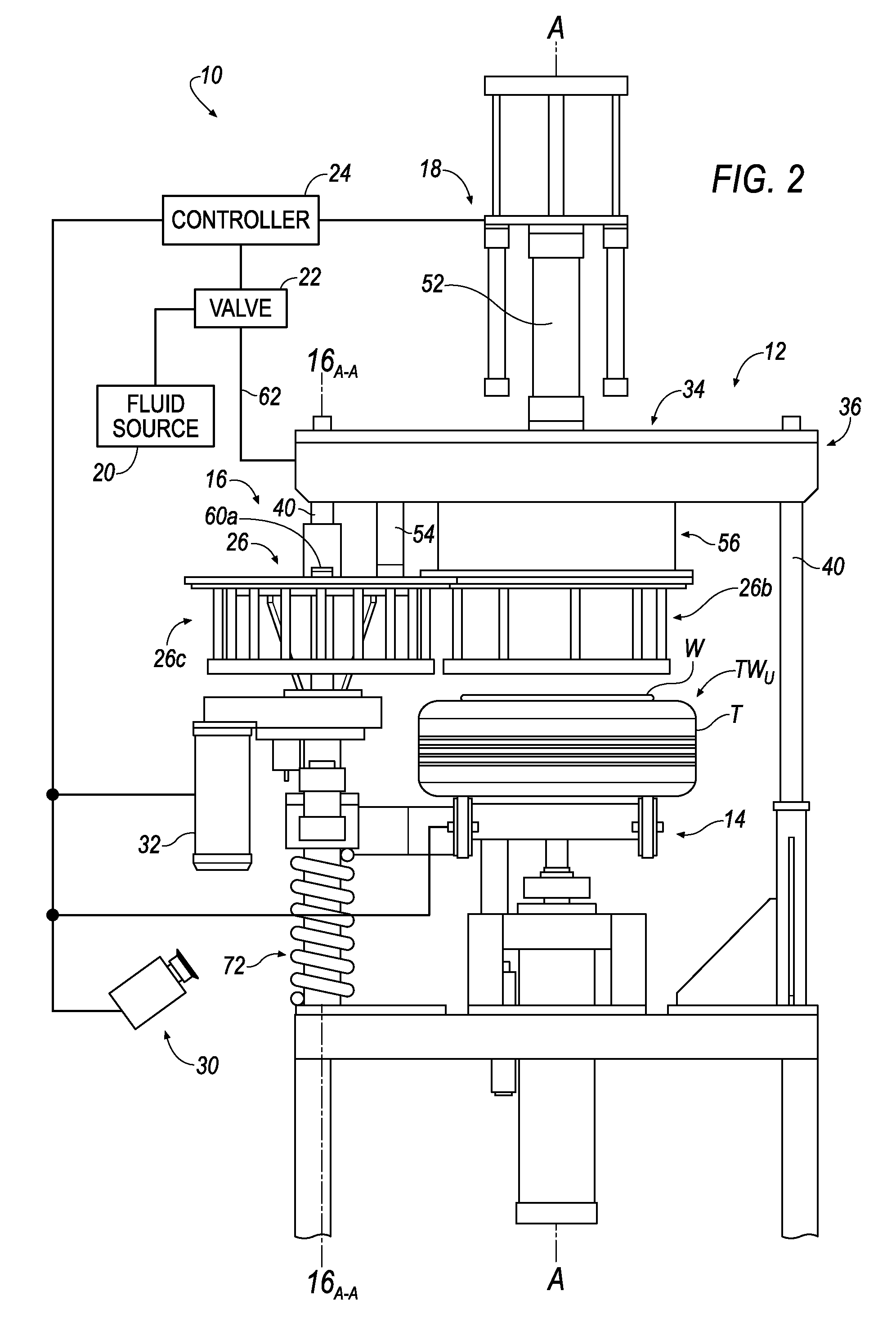

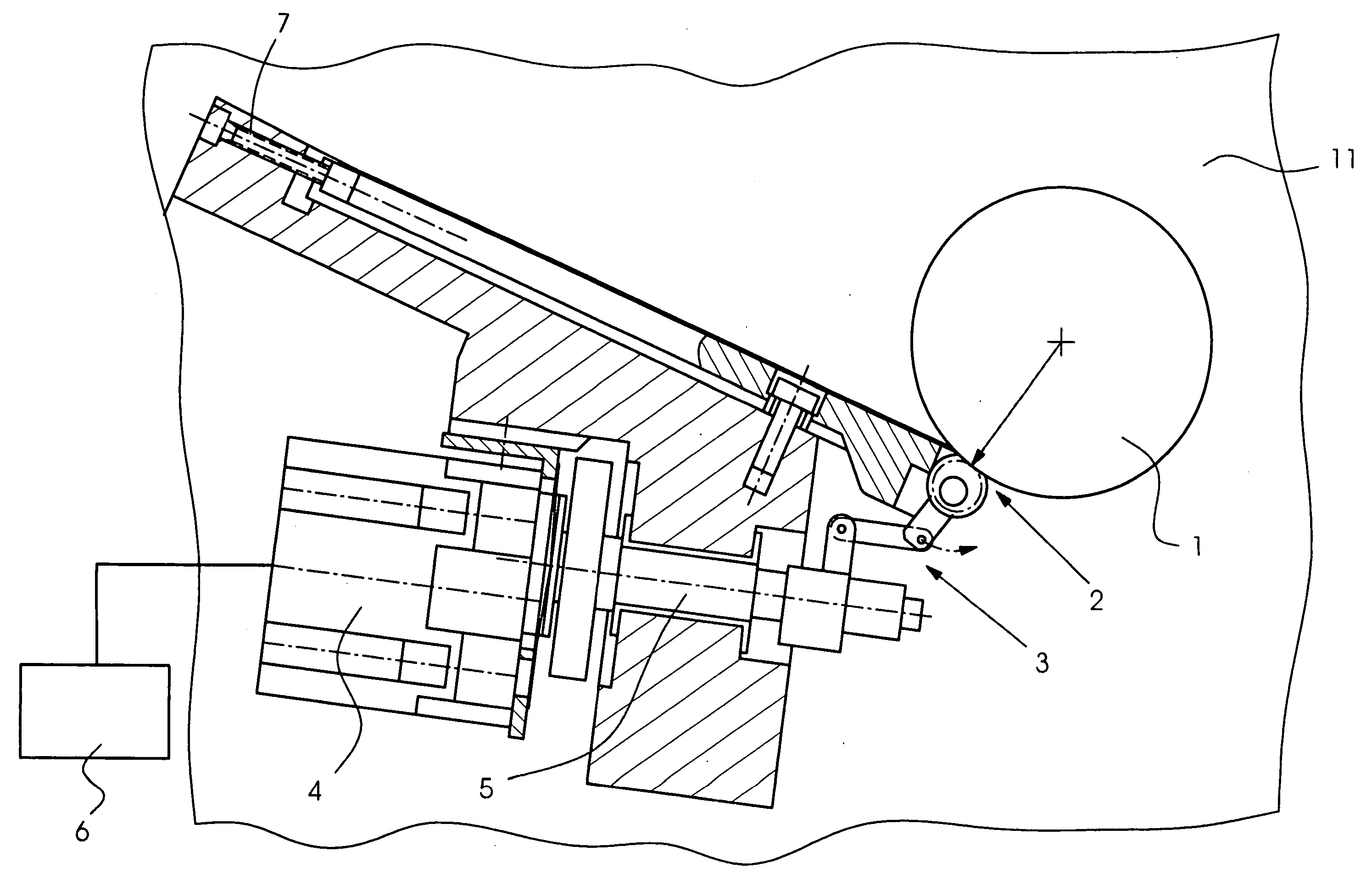

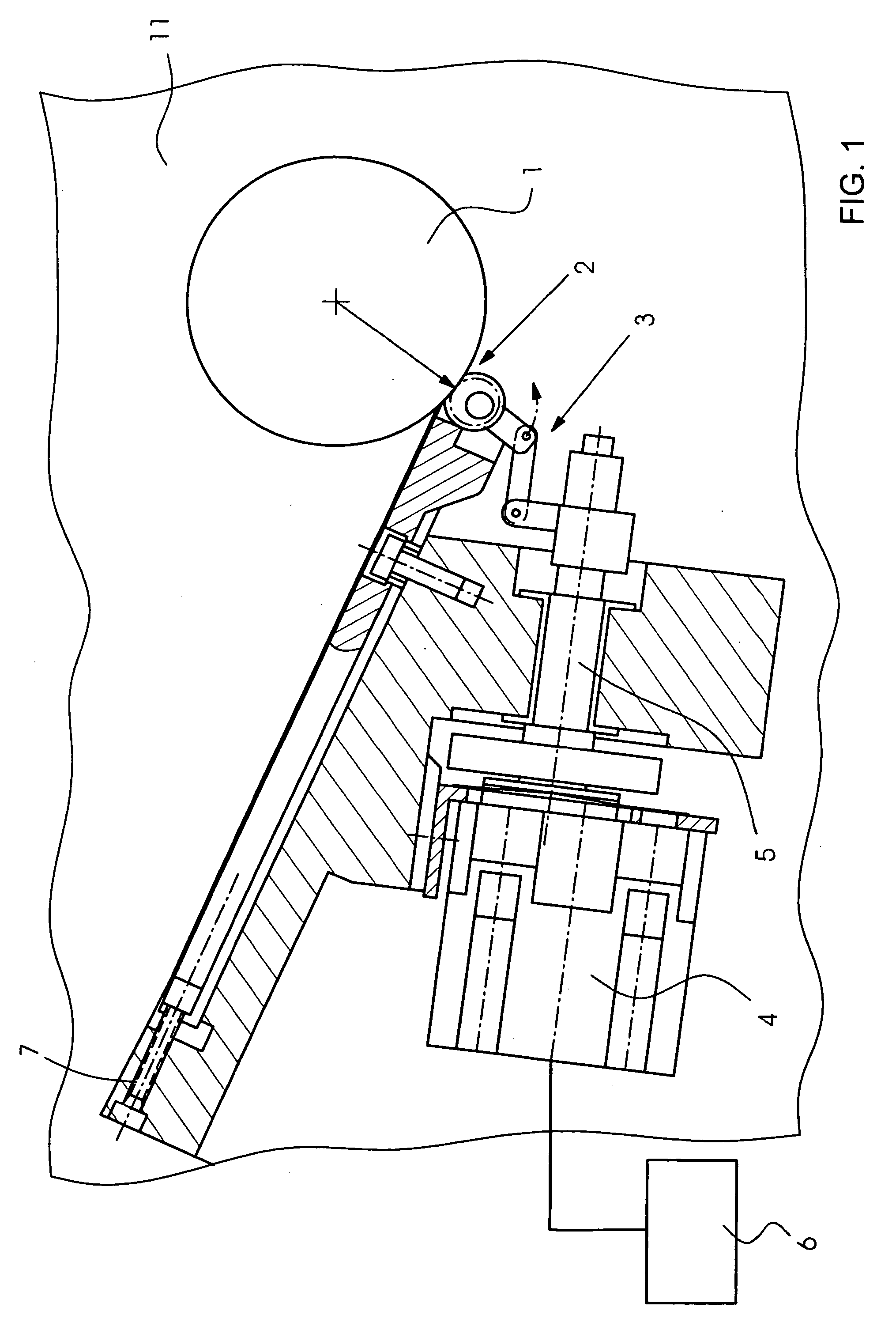

System and method for monitoring and adjusting a decorator for containers

ActiveUS20180201011A1Cost-effective and fast and reliableChange quantityTransfer printingOther printing apparatusControl systemEngineering

An apparatus and methods of monitoring and adjusting a decorator for metallic containers are provided. More specifically, the present invention relates to apparatus and methods used to provide a decoration on a predetermined portion of a metallic container body. The decorator includes a sensor that senses decorations on metallic containers. A control system receives information related to the sensed decorations from the sensor and then determines if the decorations at least meet predetermined color, density, thickness, orientation, and consistency targets. The control system can optionally automatically adjust elements of the decorator to correct a deficient decoration. In one embodiment, the control system can automatically send a signal to the decorator to adjust the color, density, orientation, positioning, and consistency of decorations transferred to the metallic containers. In another embodiment, the control system can send a signal to adjust a position of an inking assembly, an ink roller, a ductor roller a plate cylinder, a printing plate, a blanket cylinder, and a transfer blanket of the decorator.

Owner:BALL CORP

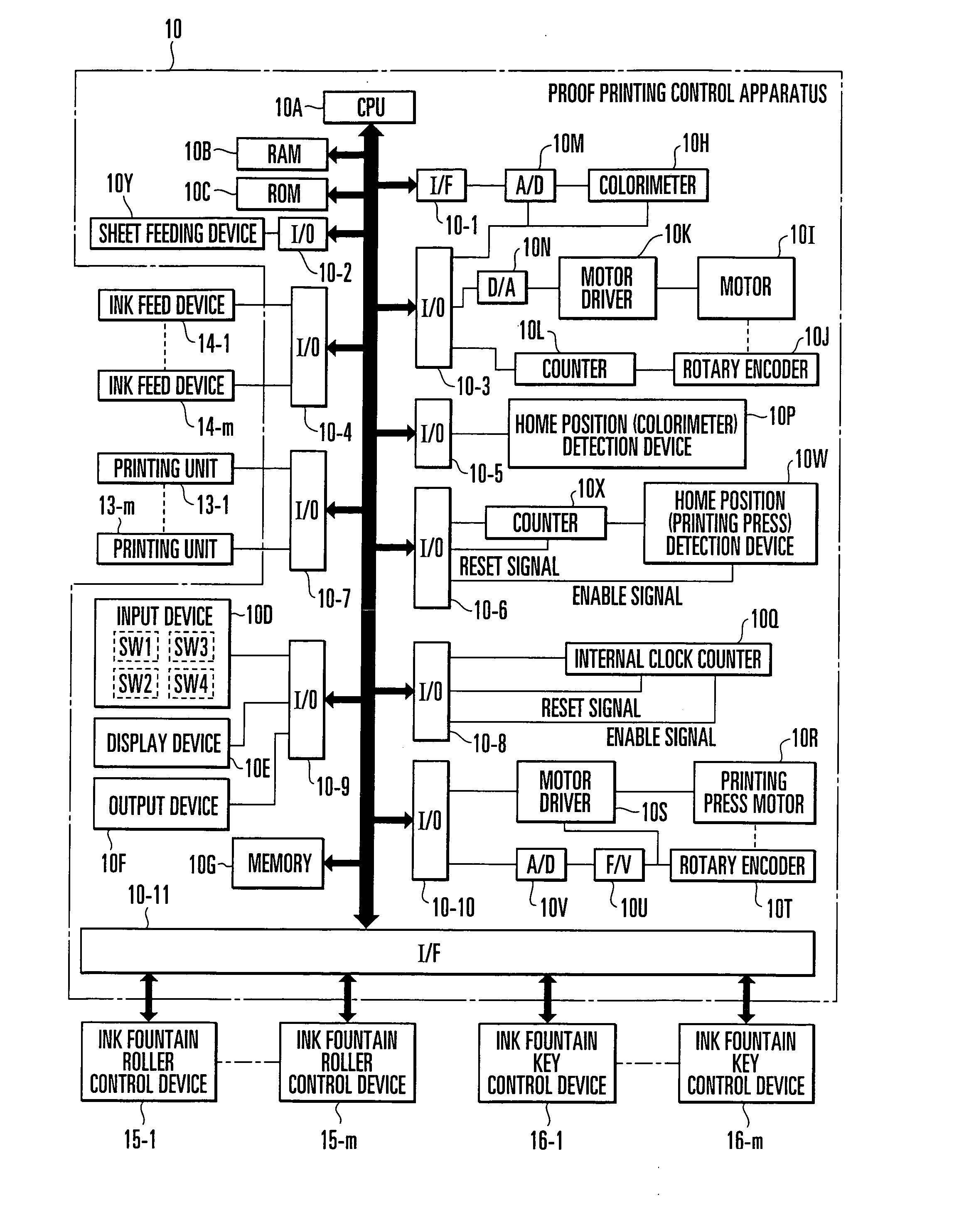

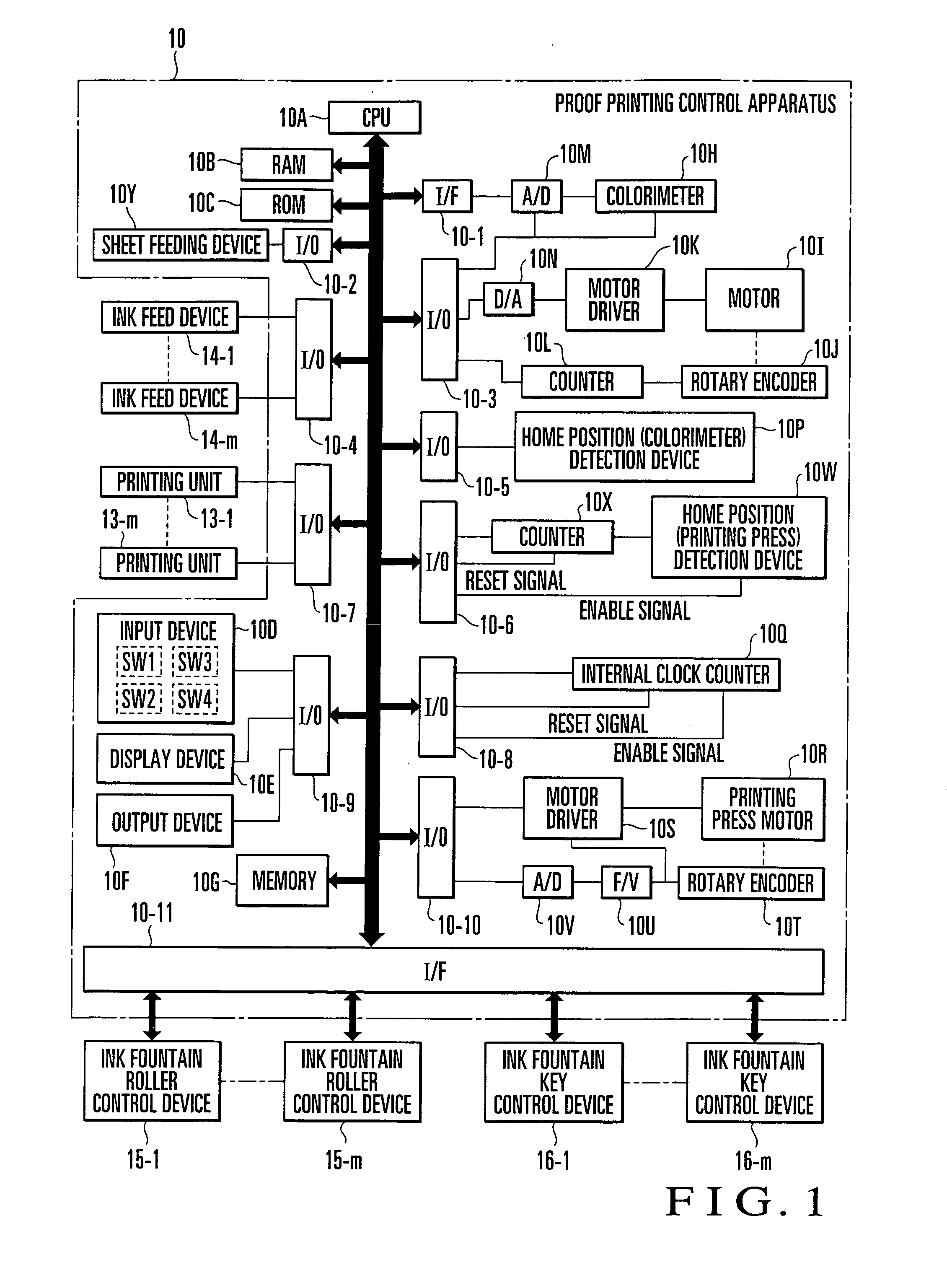

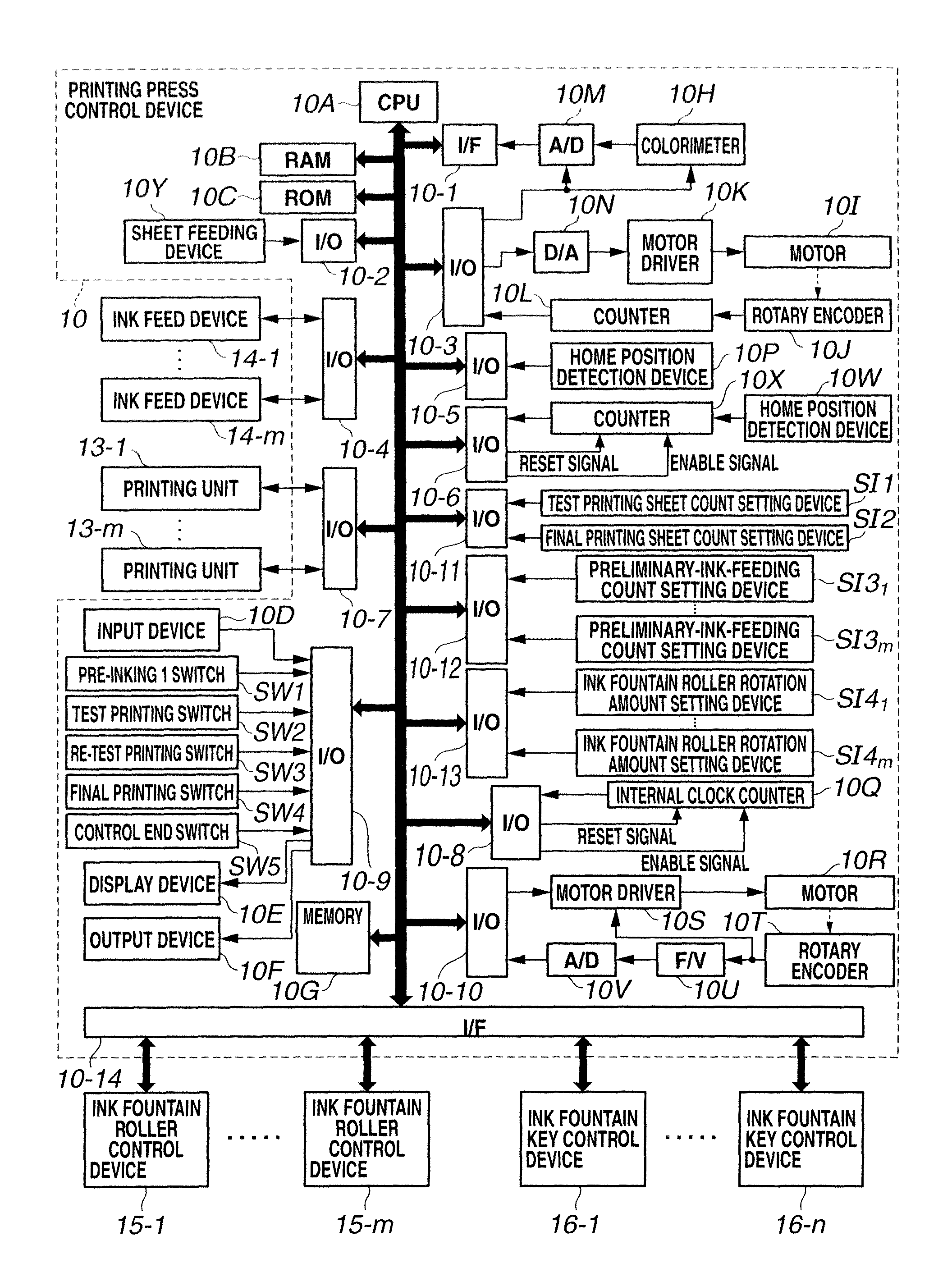

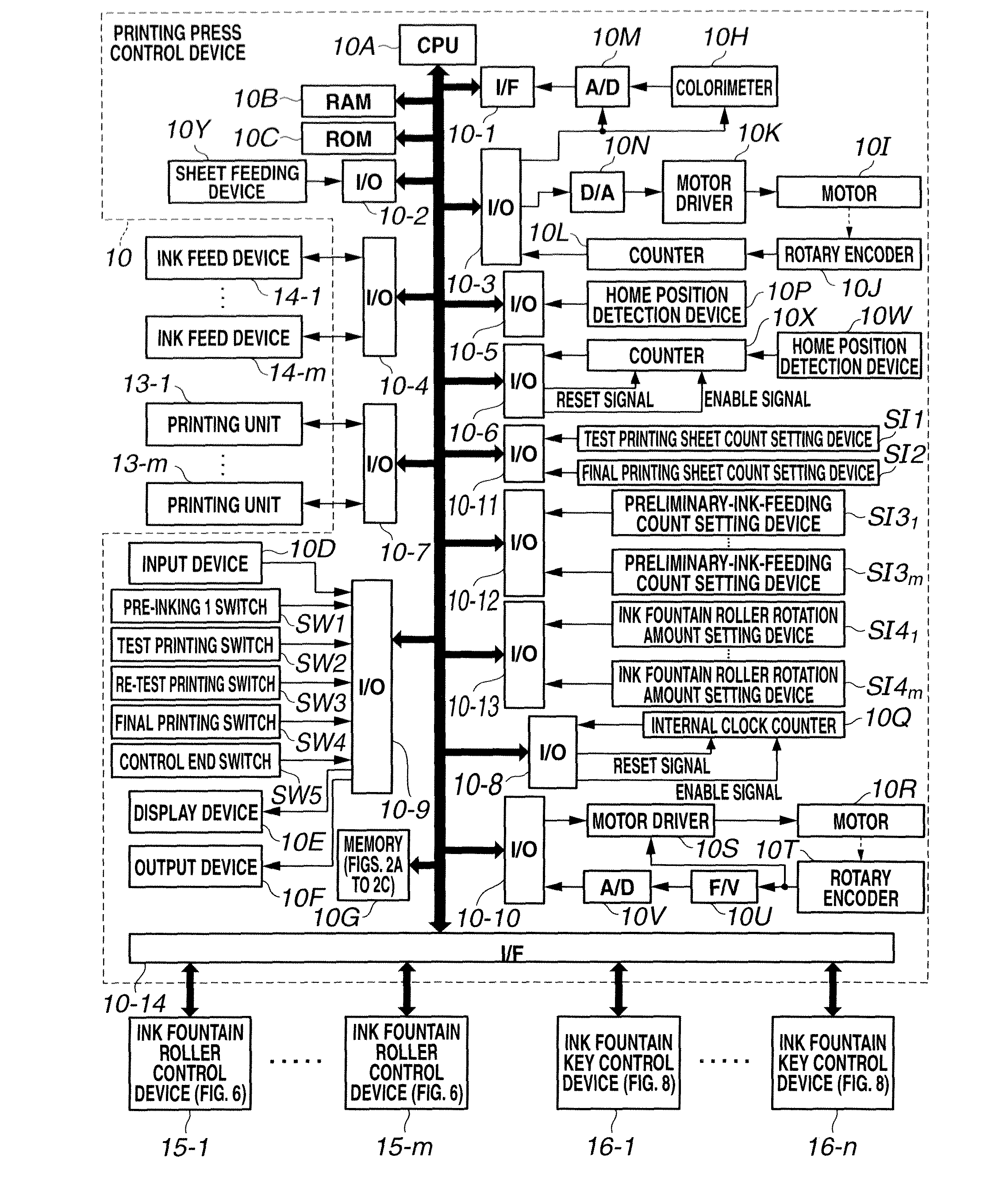

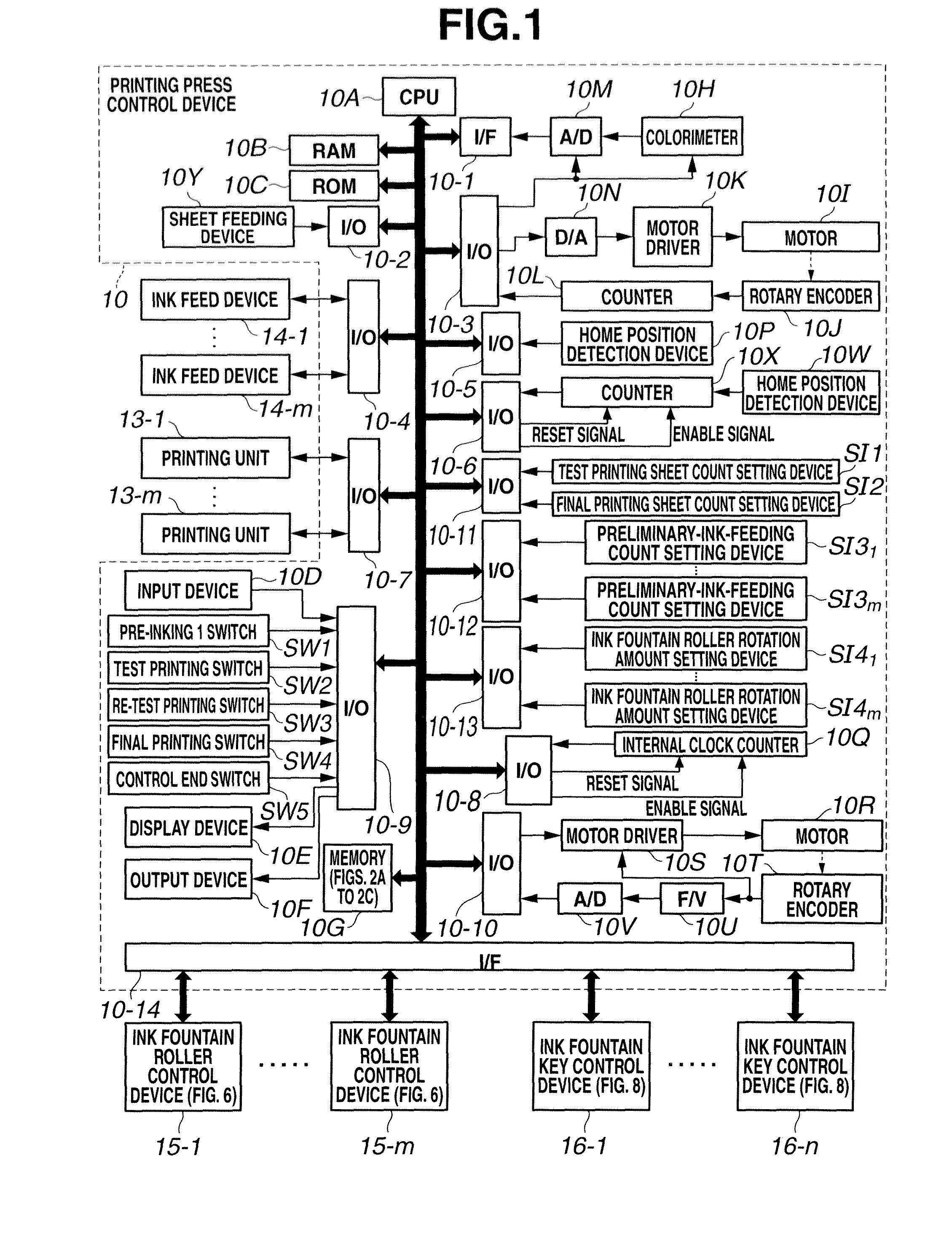

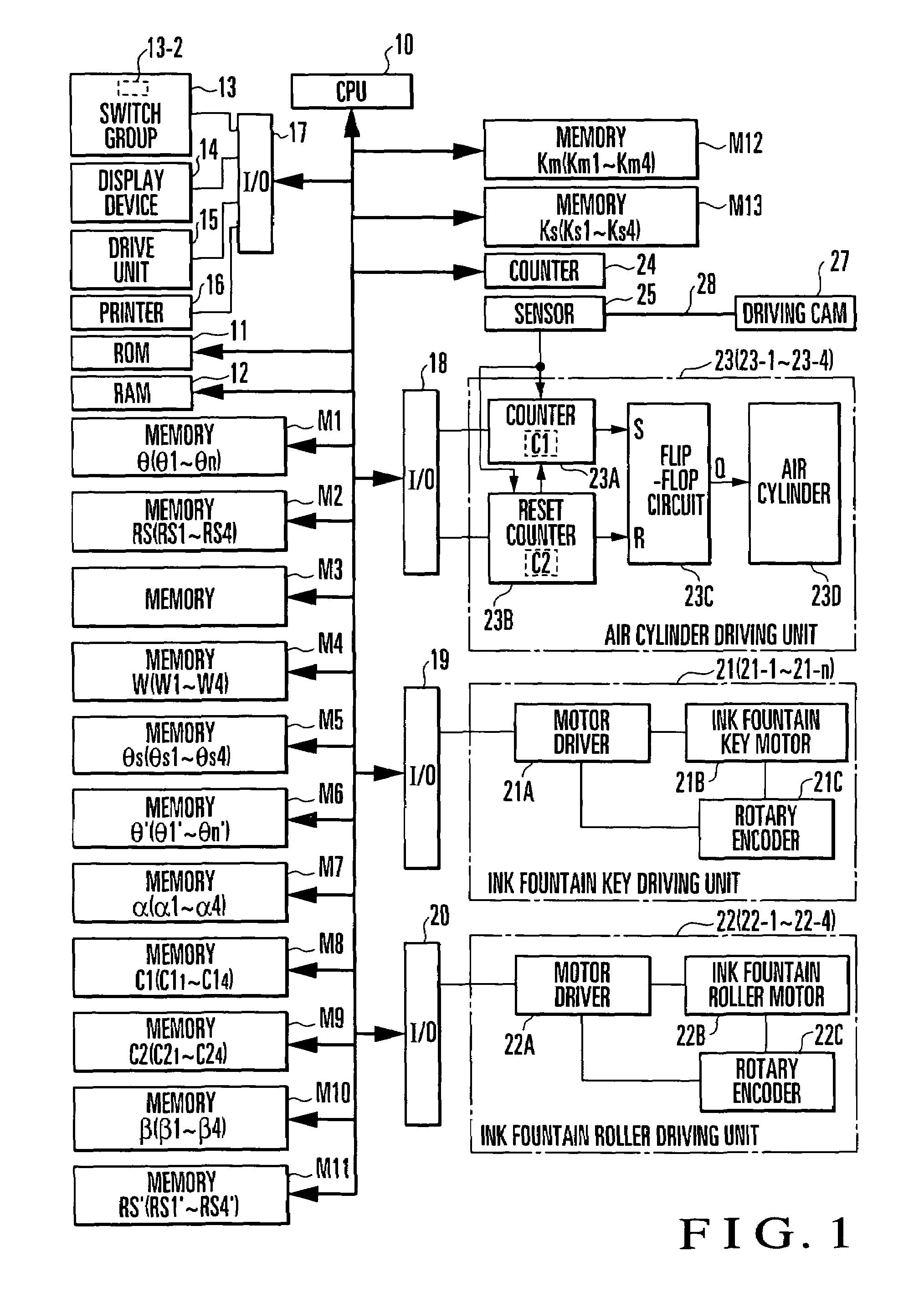

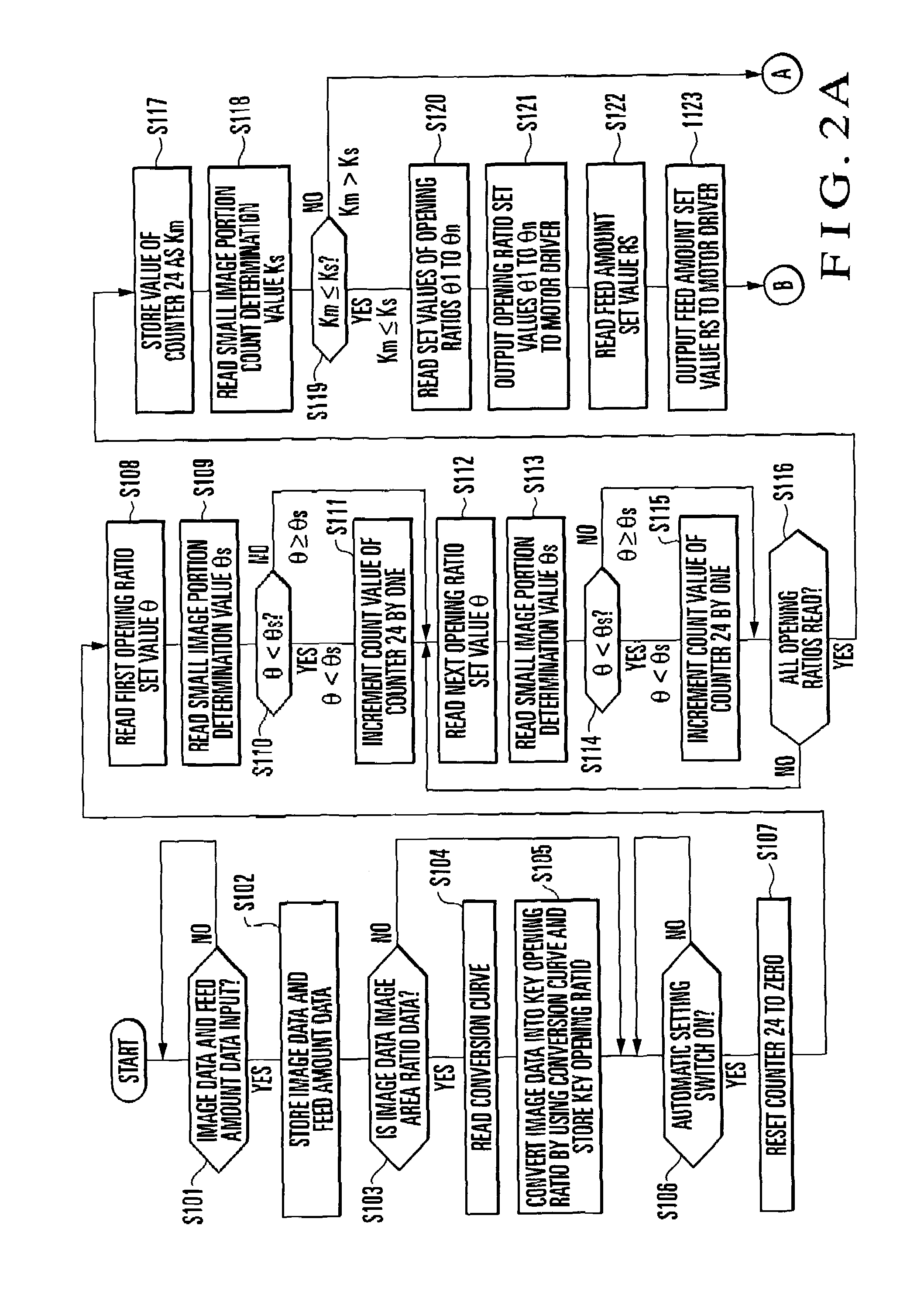

Ink supply amount adjustment method and apparatus for printing press

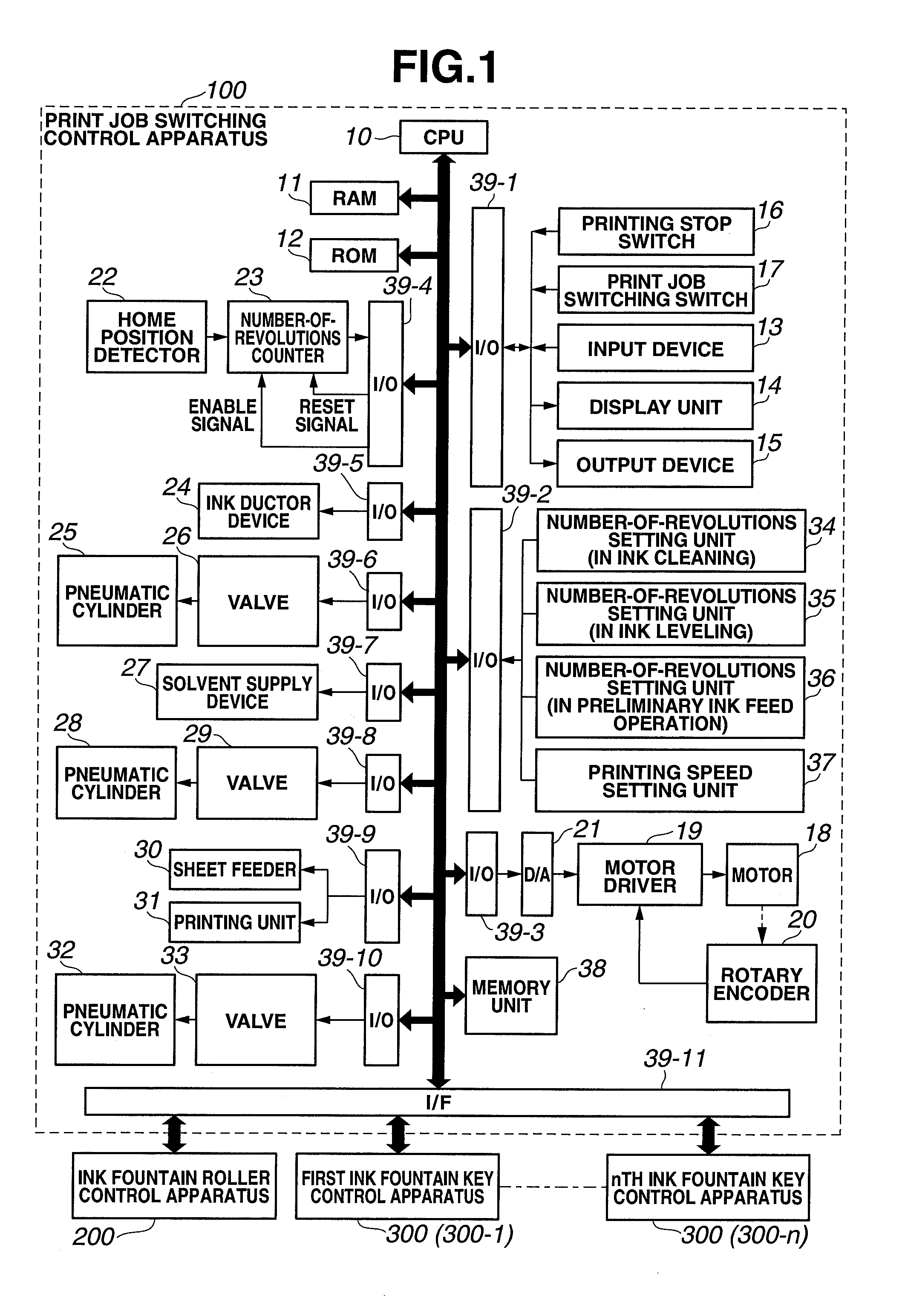

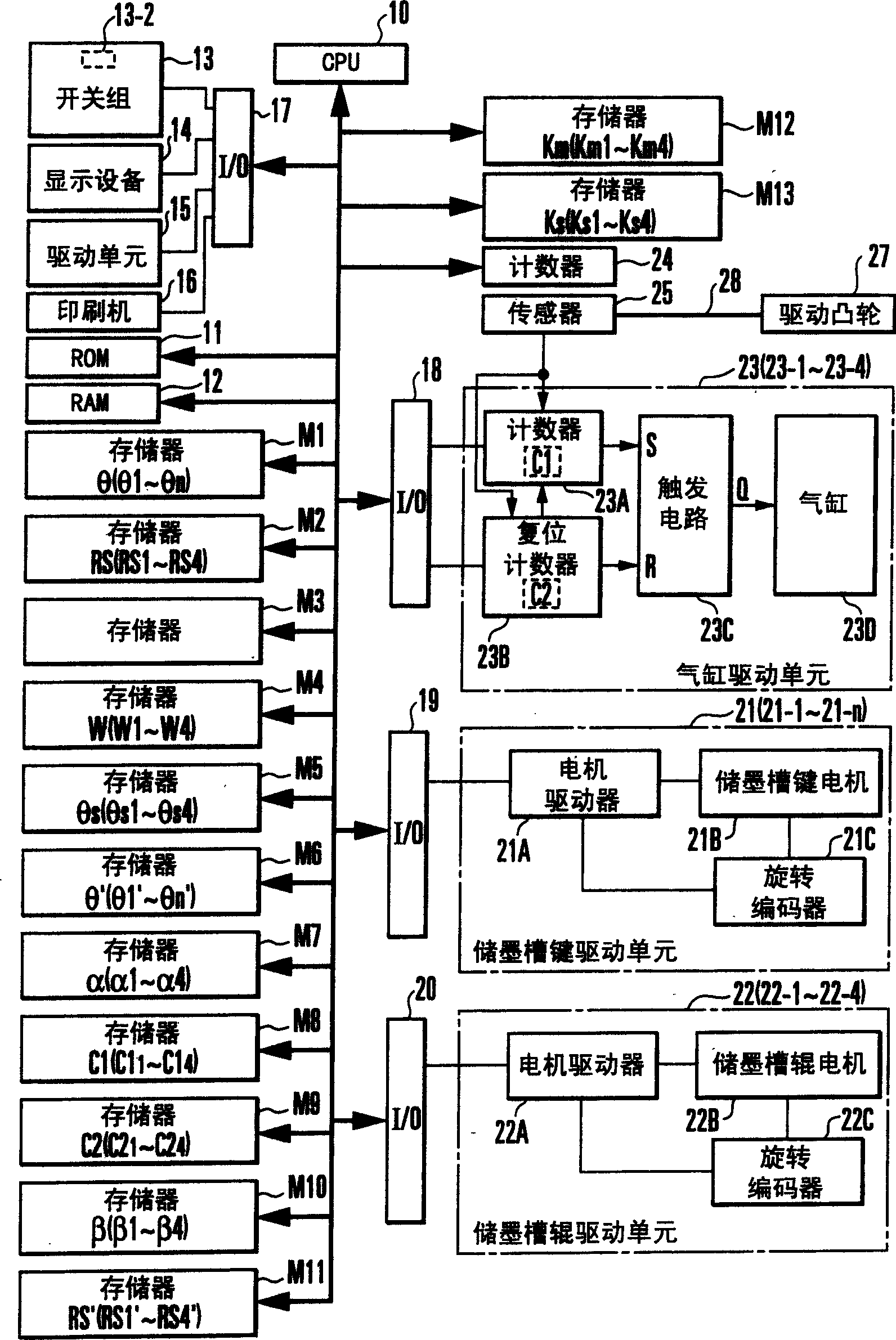

In an ink supply amount adjustment method, a density value of a printed paper sheet is measured. The ink fountain key opening ratio is corrected on the basis of a difference between the measured density value of the printed paper sheet and a preset reference density value. The ink feed operation of the ink ductor roller is performed without printing after correction of the ink fountain key opening ratio to increase or decrease the amount of ink on the ink rollers.

Owner:KOMORI CORP

Can decorator machine, ink station assembly therefor, and can decorating method employing same

Owner:STOLLE MACHINERY CO LLC

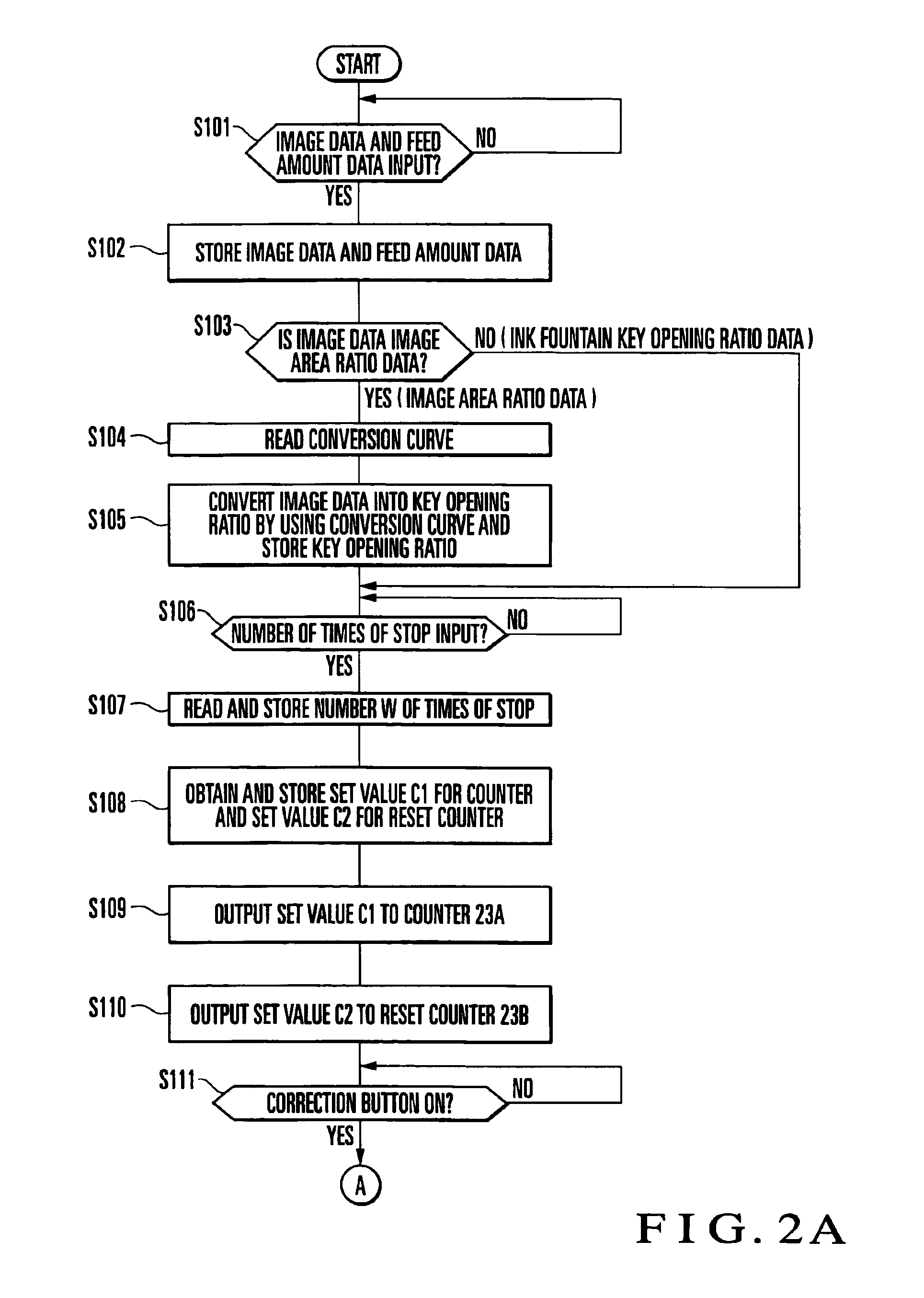

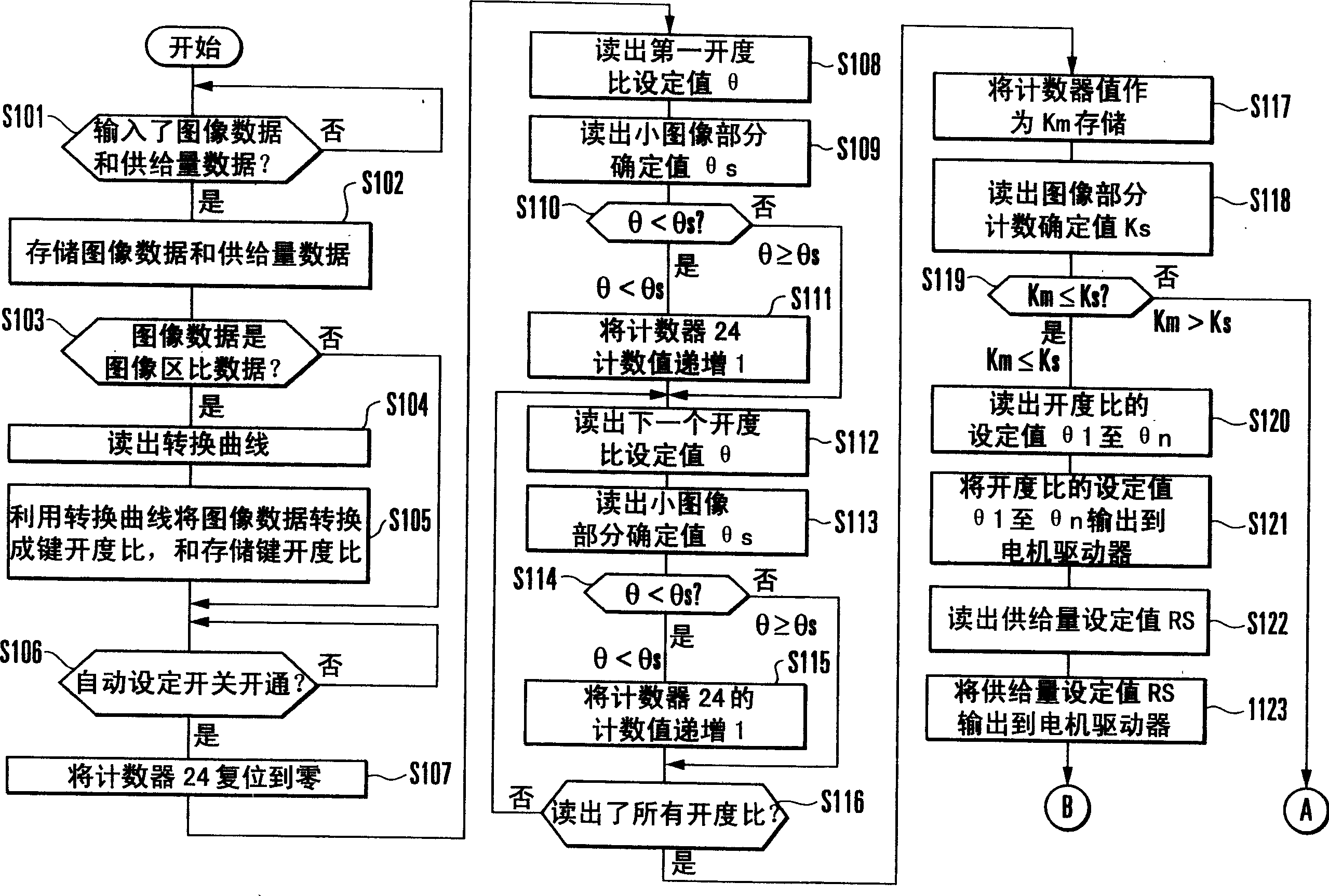

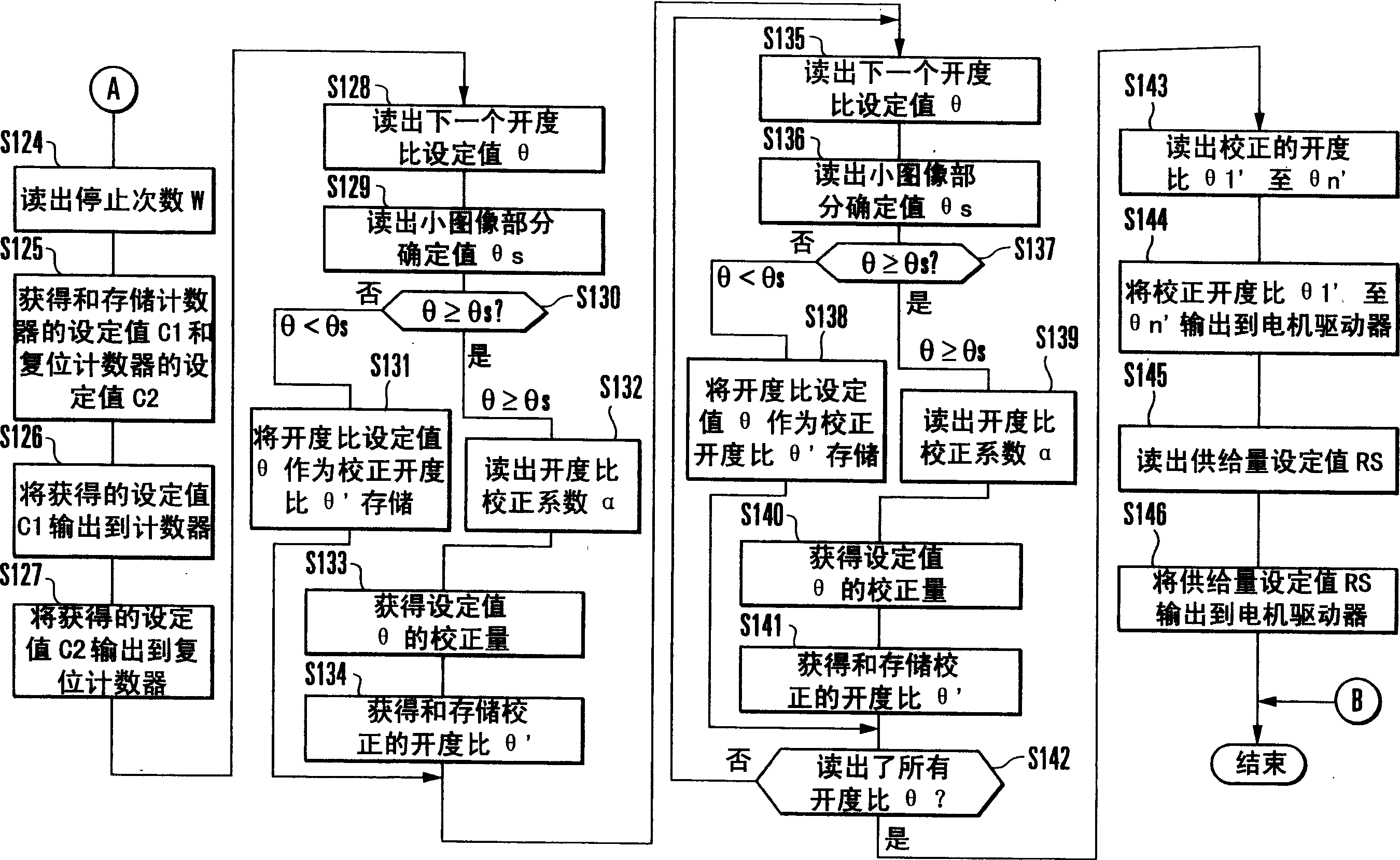

Ink feed control method and ink feed control system

InactiveCN101172414AReduce in quantityImprove protectionPrinting press partsControl systemPrinting press

Owner:KOMORI CORP

Inking device of printing press

An inking device of a printing press, including an ink ductor roller reciprocating between a receipt position, at which the ink ductor roller contacts an ink fountain roller to receive ink, and a transfer position, at which the ink ductor roller contacts an ink distribution roller or a first intermediate roller located downstream in an ink transfer direction to pass the ink on to the roller, comprises: a pair of split clamping holders supporting the ink ductor roller and supported swingably; and moving means, comprising a shaft, a sleeve, a bearing portion, a worm wheel, a worm shaft, and an operating shaft having a dial-equipped handle, for moving the pair of split clamping holders in the axial direction of the ink ductor roller.

Owner:KOMORI CORP

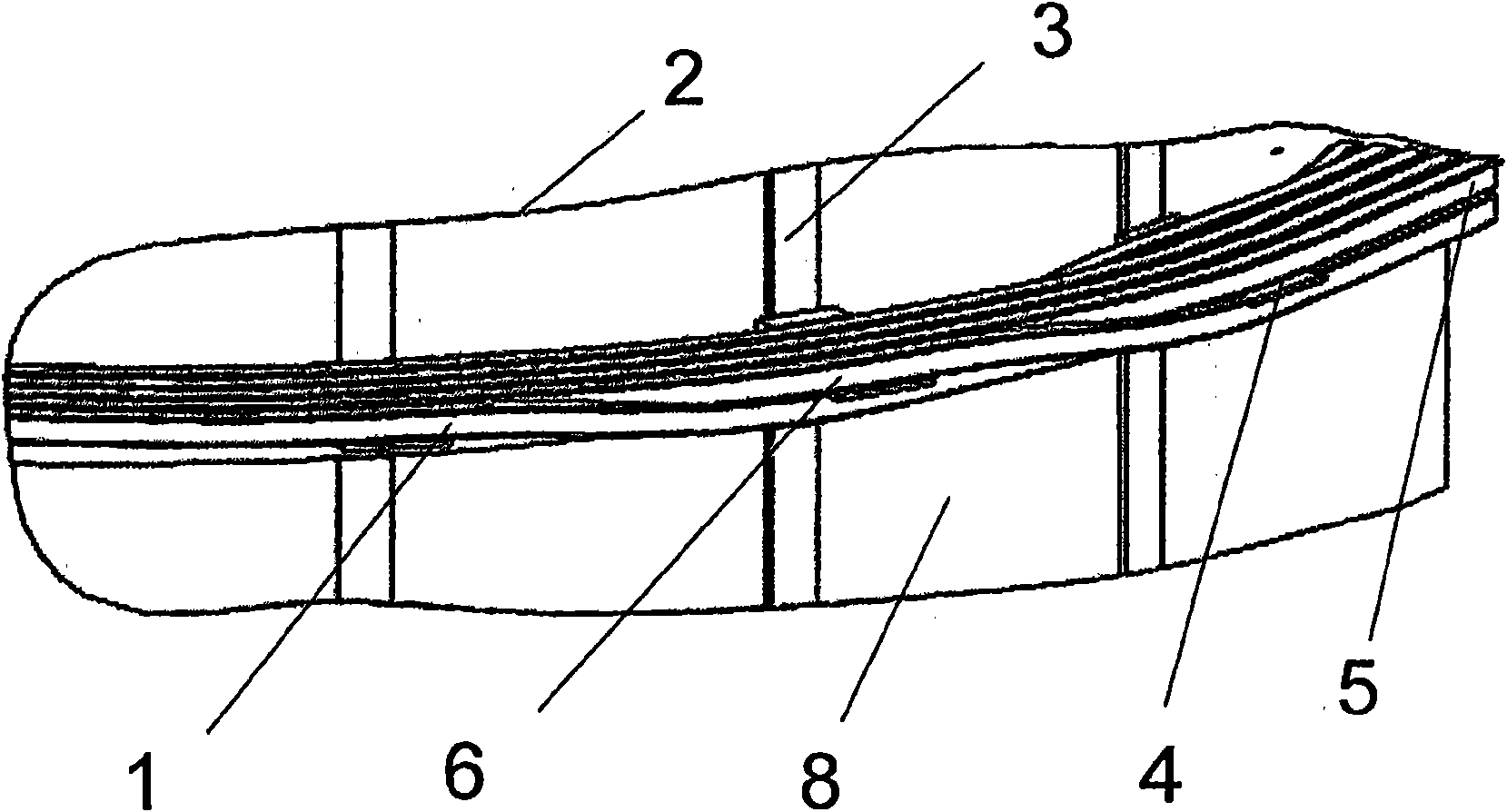

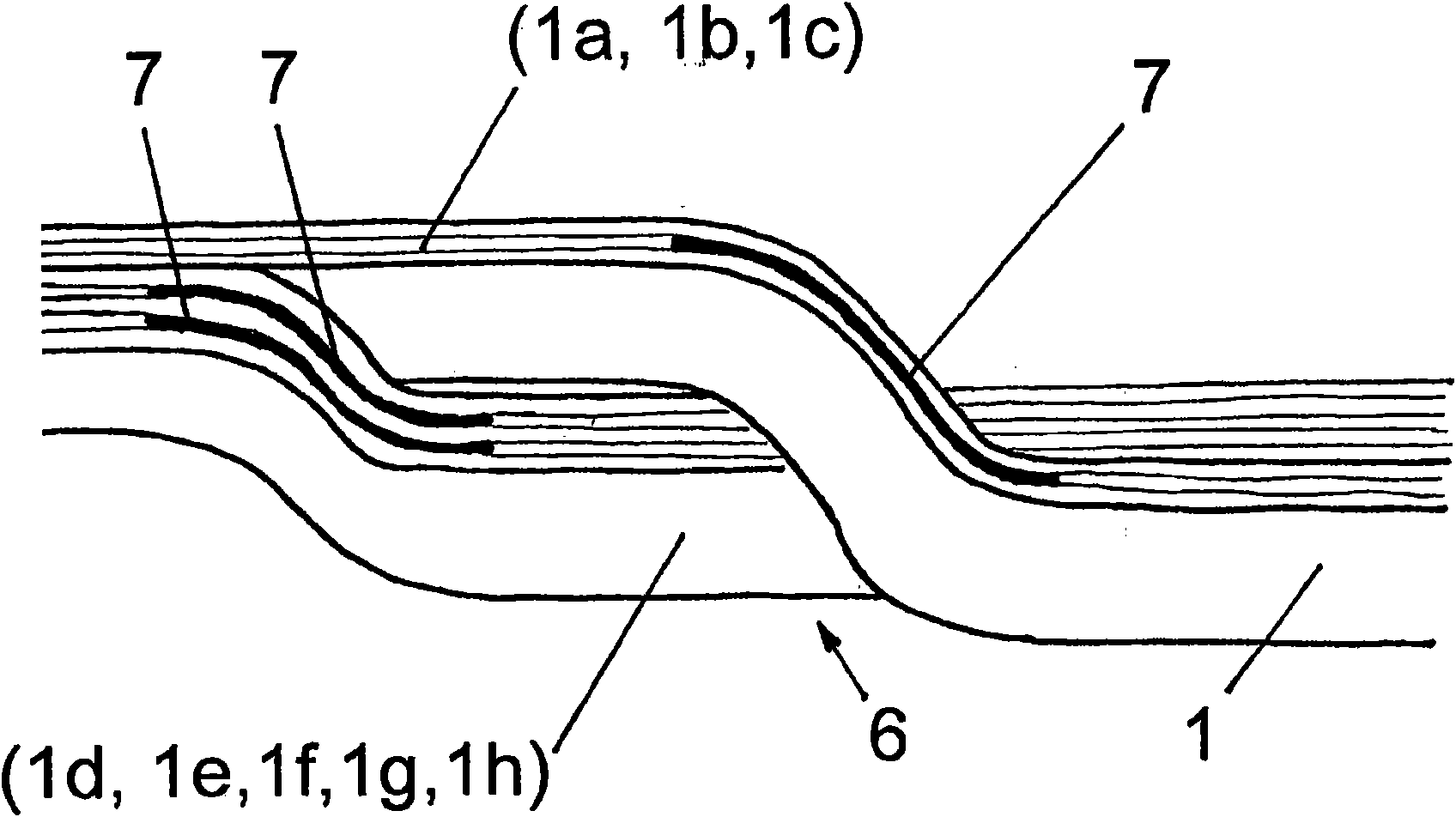

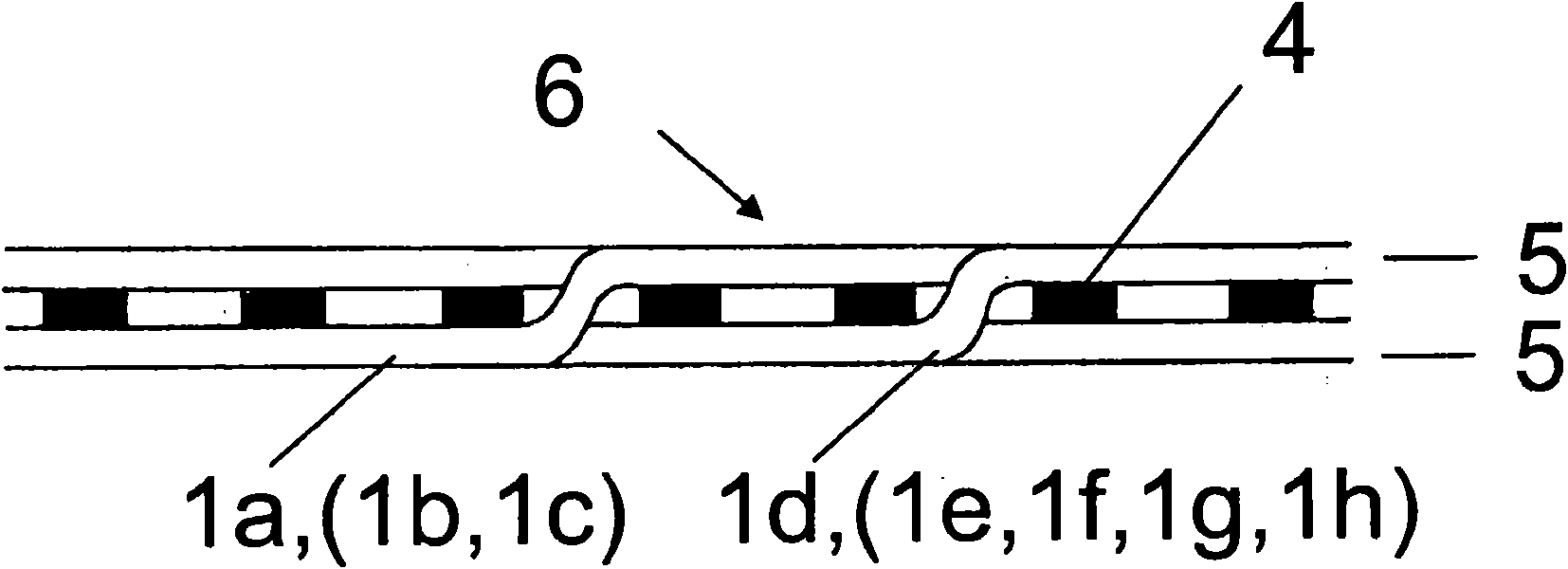

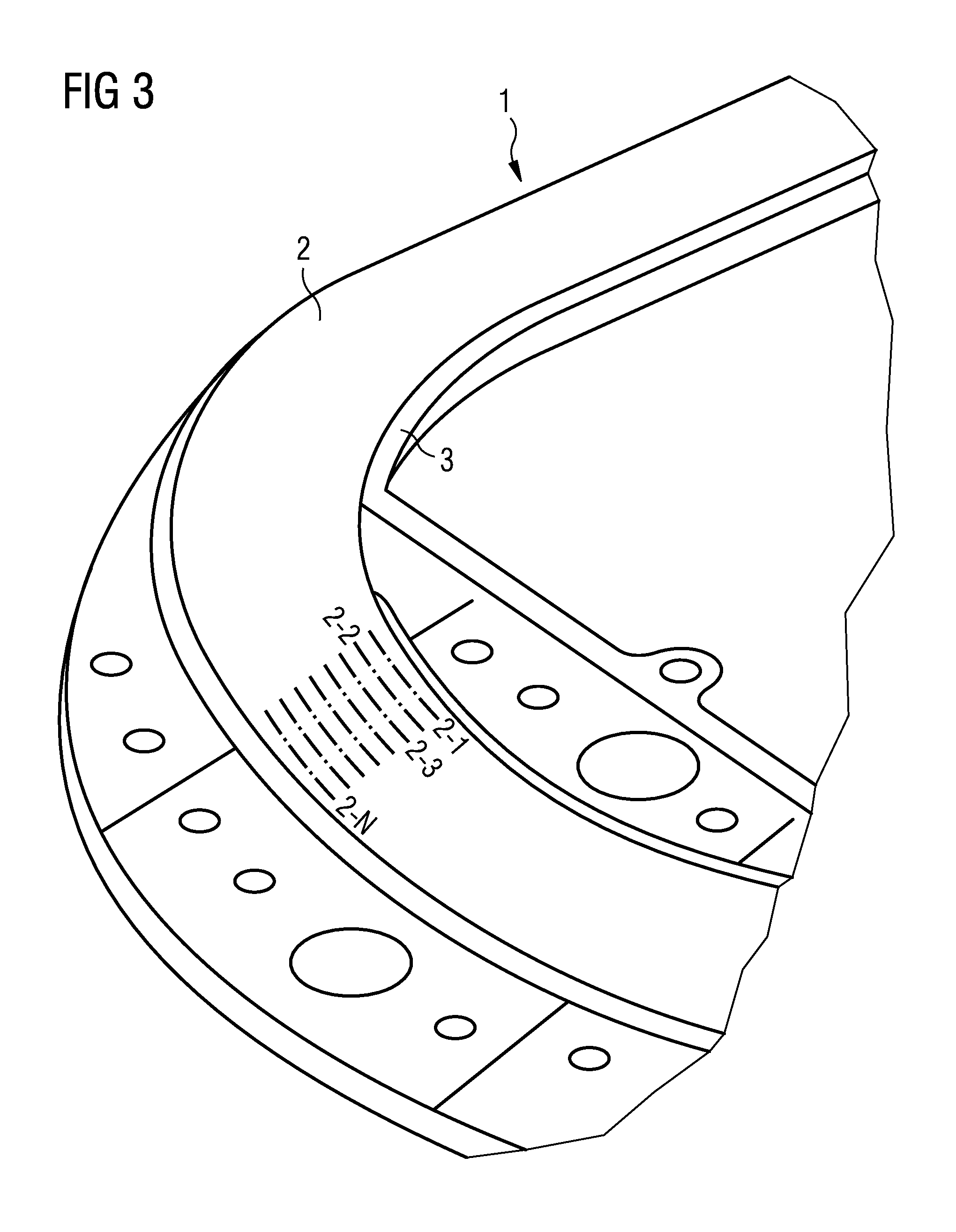

Disc winding

ActiveCN101960541ACross normalizationNormalized transposition crossoverTransformers/inductances coils/windings/connectionsElectrical conductorSingle strand

Owner:HITACHI ENERGY LTD

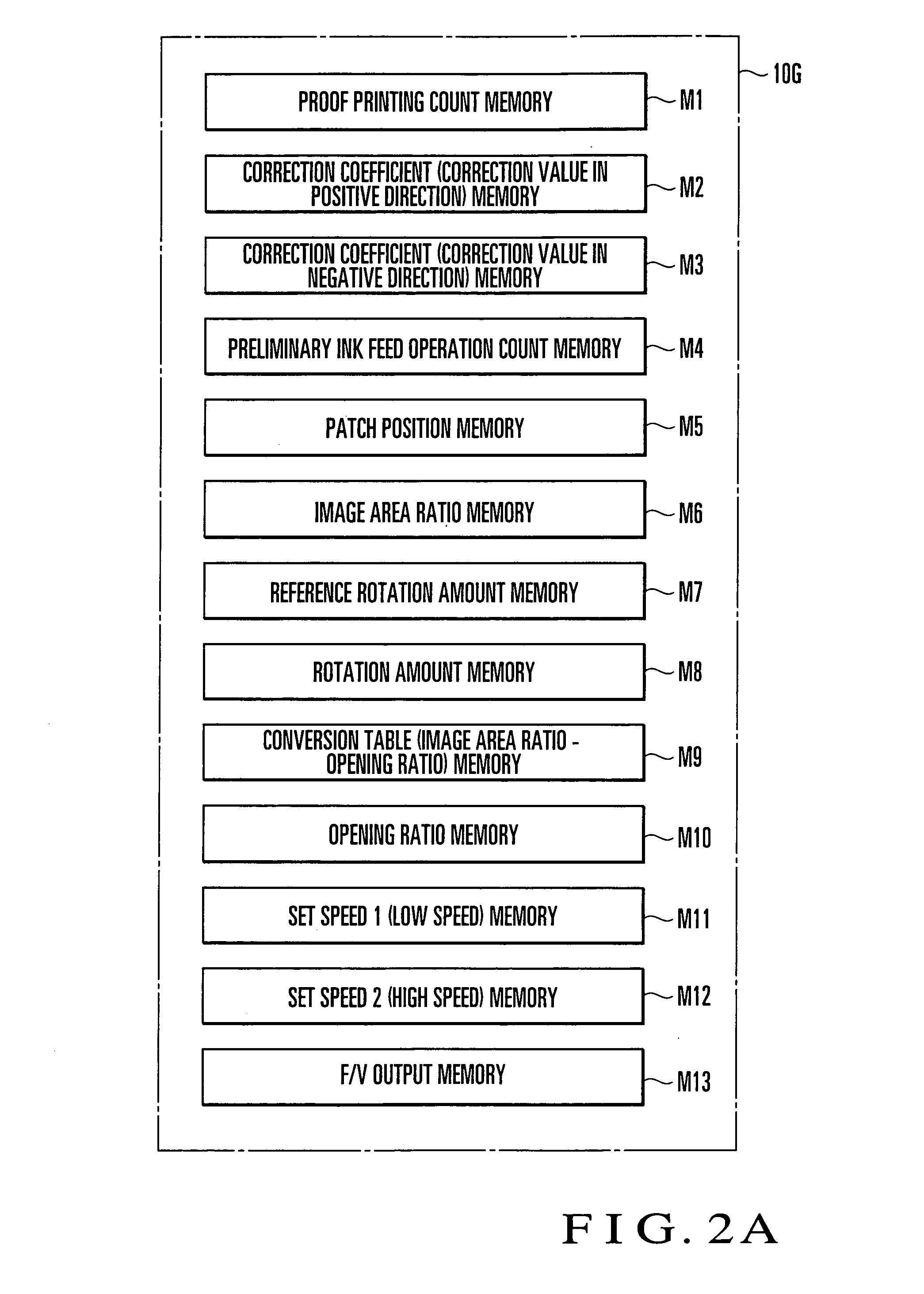

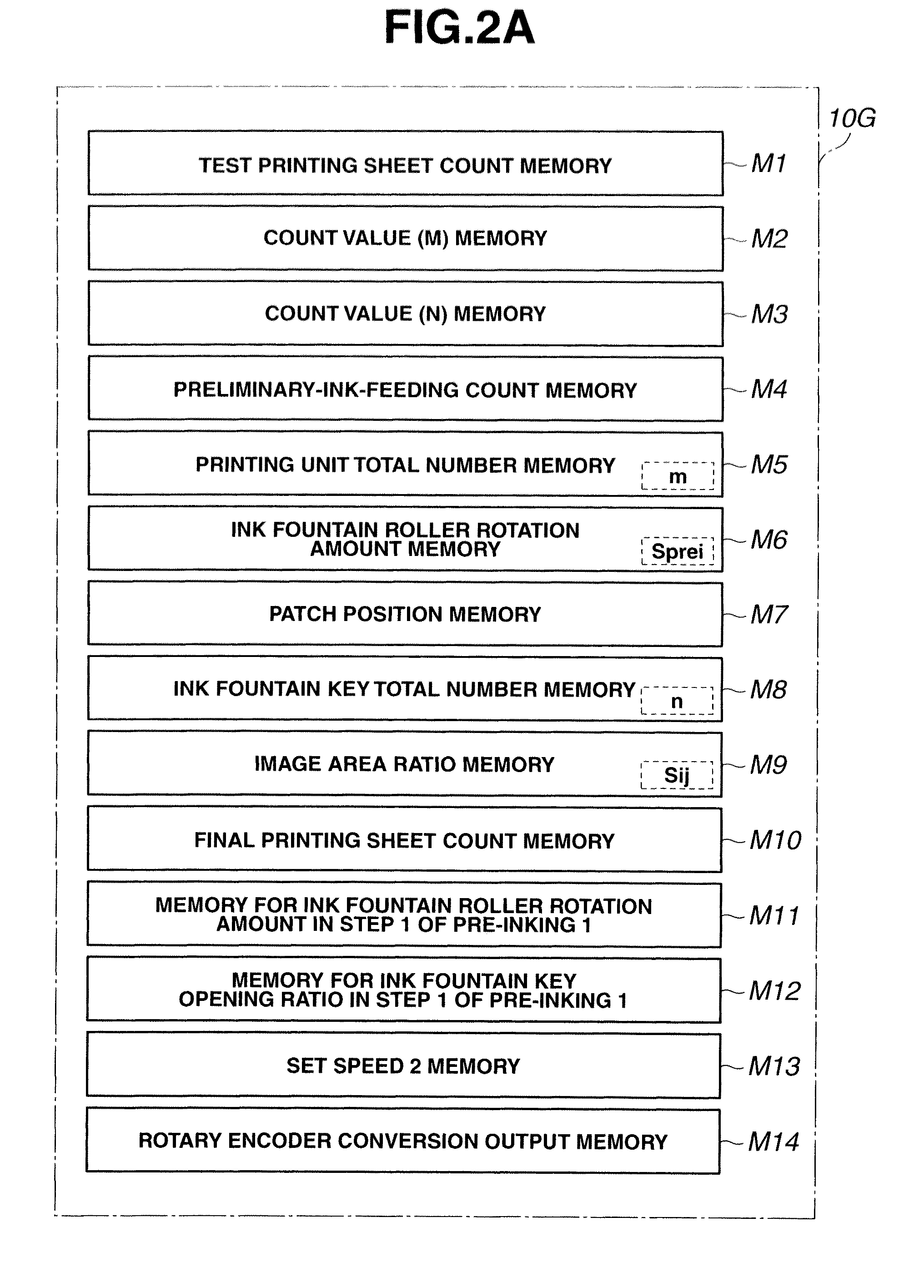

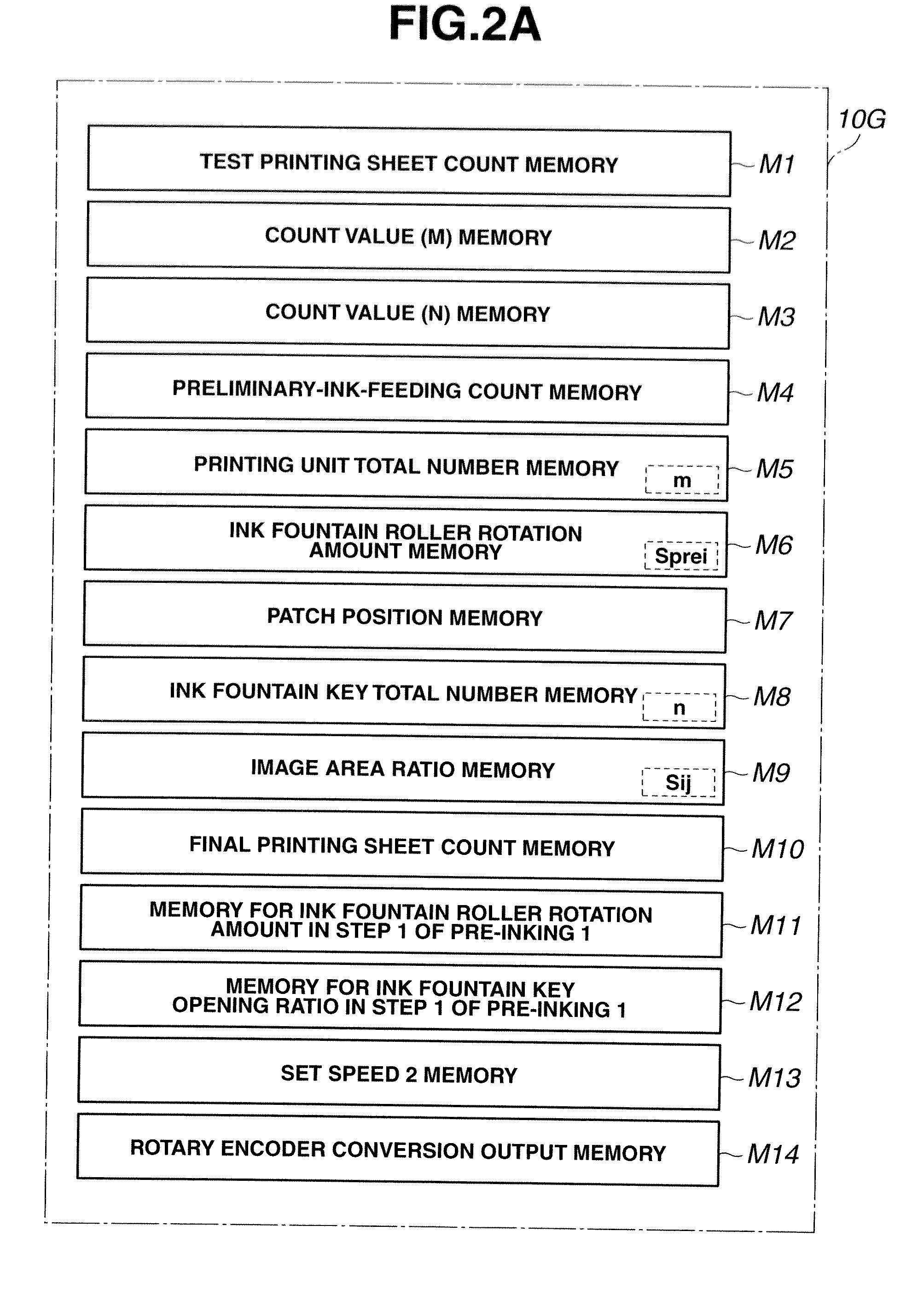

Ink supply amount adjustment method and apparatus for printing press

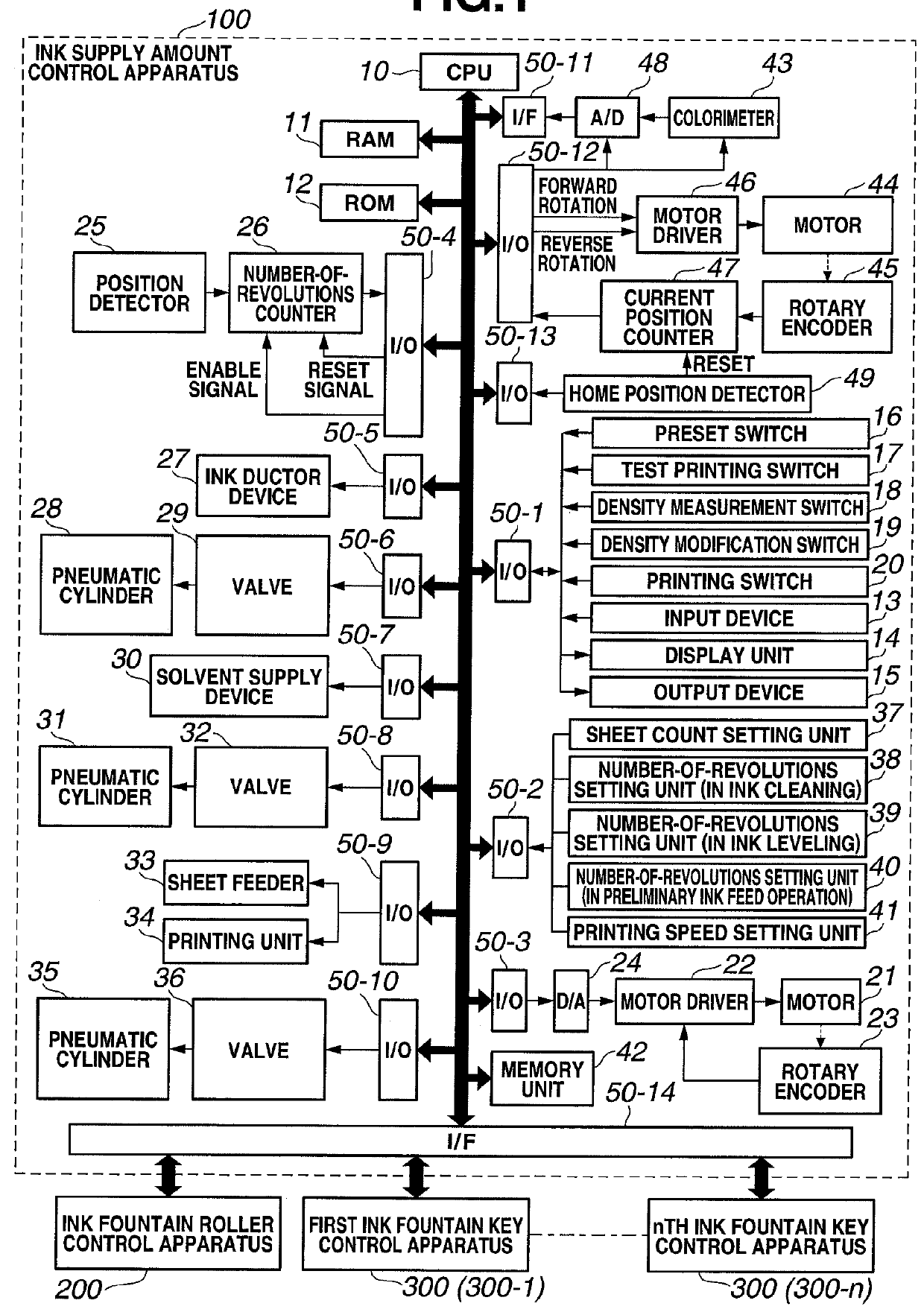

An ink supply amount adjustment method for a printing press includes steps of measuring the density value of each density measurement patch printed in a range corresponding to each ink fountain key on a printed printing sheet, obtaining the opening ratio of each ink fountain key in preliminary ink feeding, based on the difference between the measured density value of a patch and a preset reference density value, and the current opening ratio of each ink fountain key or image data in the range corresponding to each ink fountain key, and performing the ink feed operation of an ink ductor roller while printing is suspended, after setting the opening ratio of each ink fountain key to the obtained opening ratio in preliminary ink feeding. An ink supply amount adjustment apparatus for a printing press is also disclosed.

Owner:KOMORI CORP

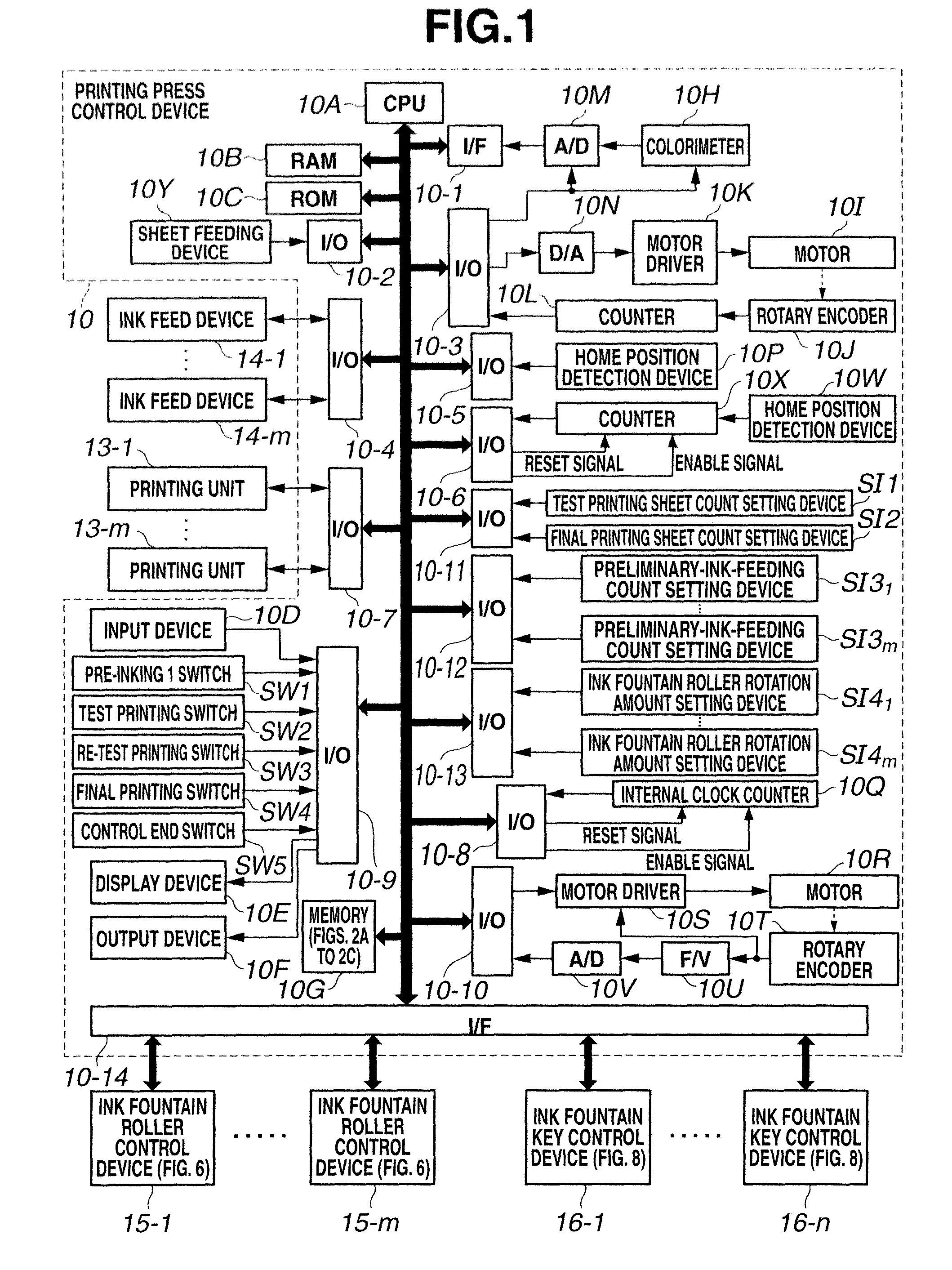

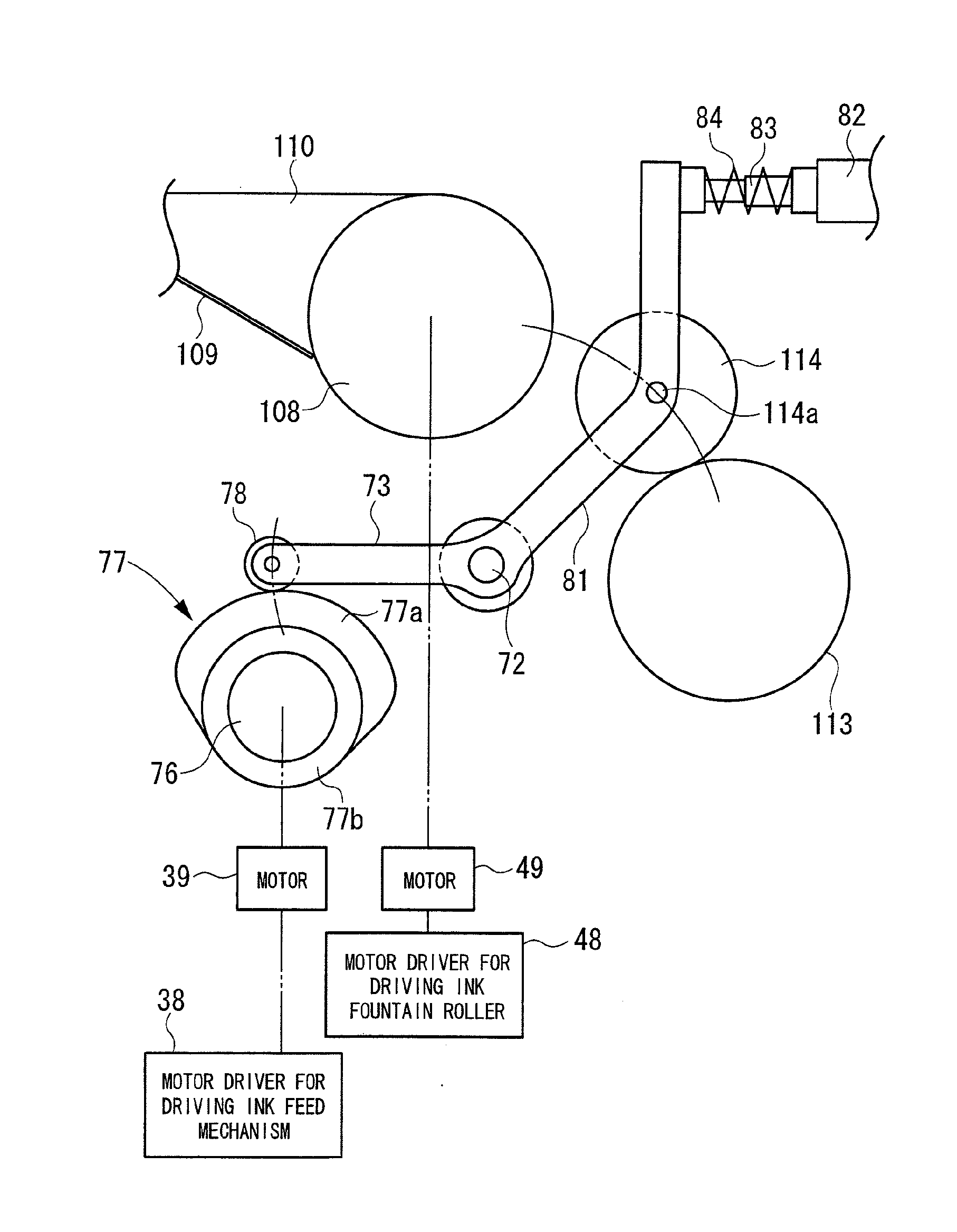

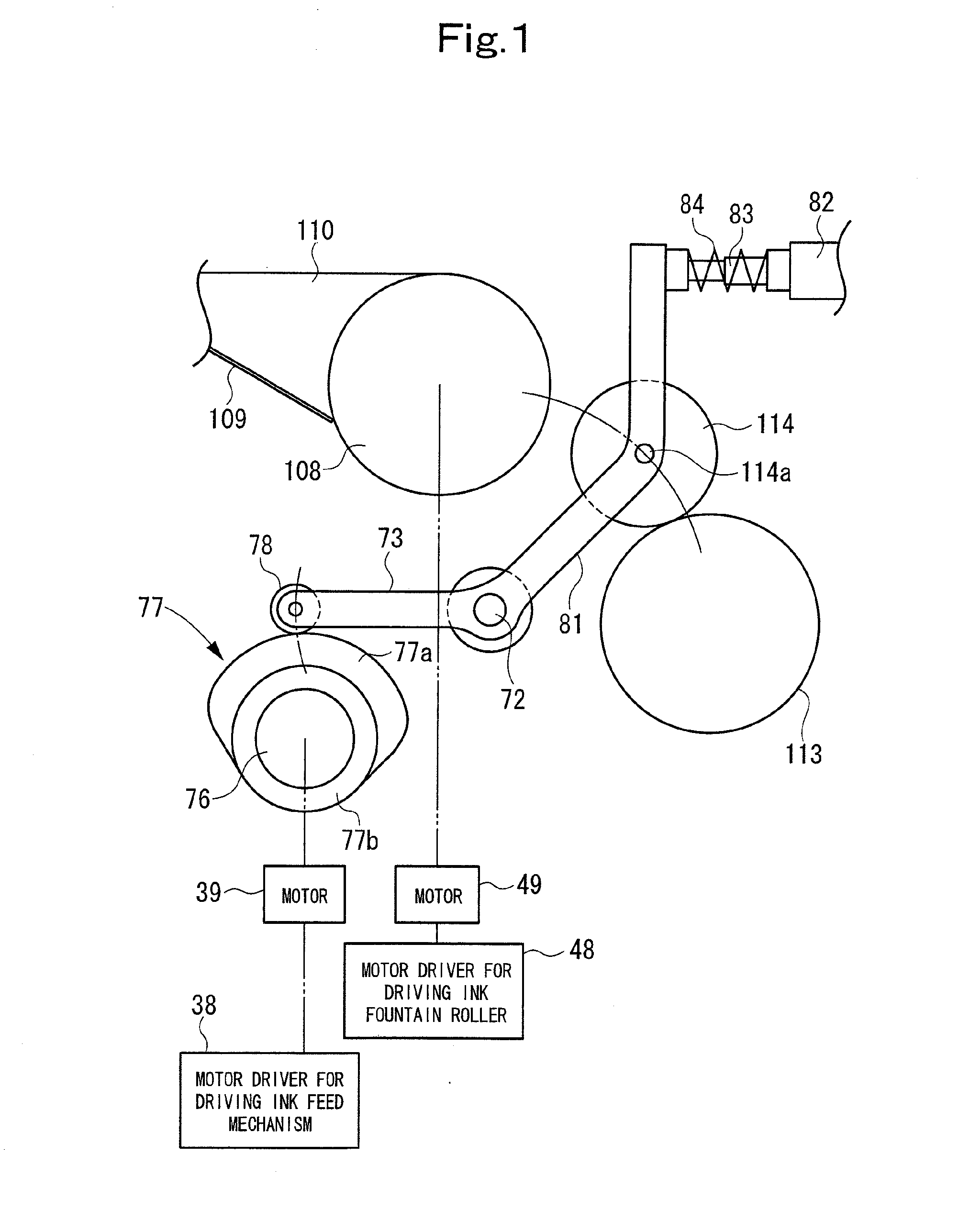

Ink supply amount control method and apparatus for printing press

ActiveUS6915737B2Reduce loadSupply will become excessiveInking apparatusAddressographsEngineeringPrinting press

In an ink supply amount control method for a printing press, ink is supplied from the gap between a plurality of ink fountain keys and an ink fountain roller to an ink supply path in accordance with rotation of the ink fountain roller. The swing operation of an ink ductor roller is temporarily stopped. When the swing operation should intermittently be stopped, the operation of the ink fountain key or the ink fountain roller is controlled to control the ink supply amount to the ink ductor roller. Ink in a corrected amount is supplied to a printing plate attached to a plate cylinder through the ink supply path by the swing operation of the ink ductor roller. An ink supply amount control apparatus is also disclosed.

Owner:KOMORI CORP

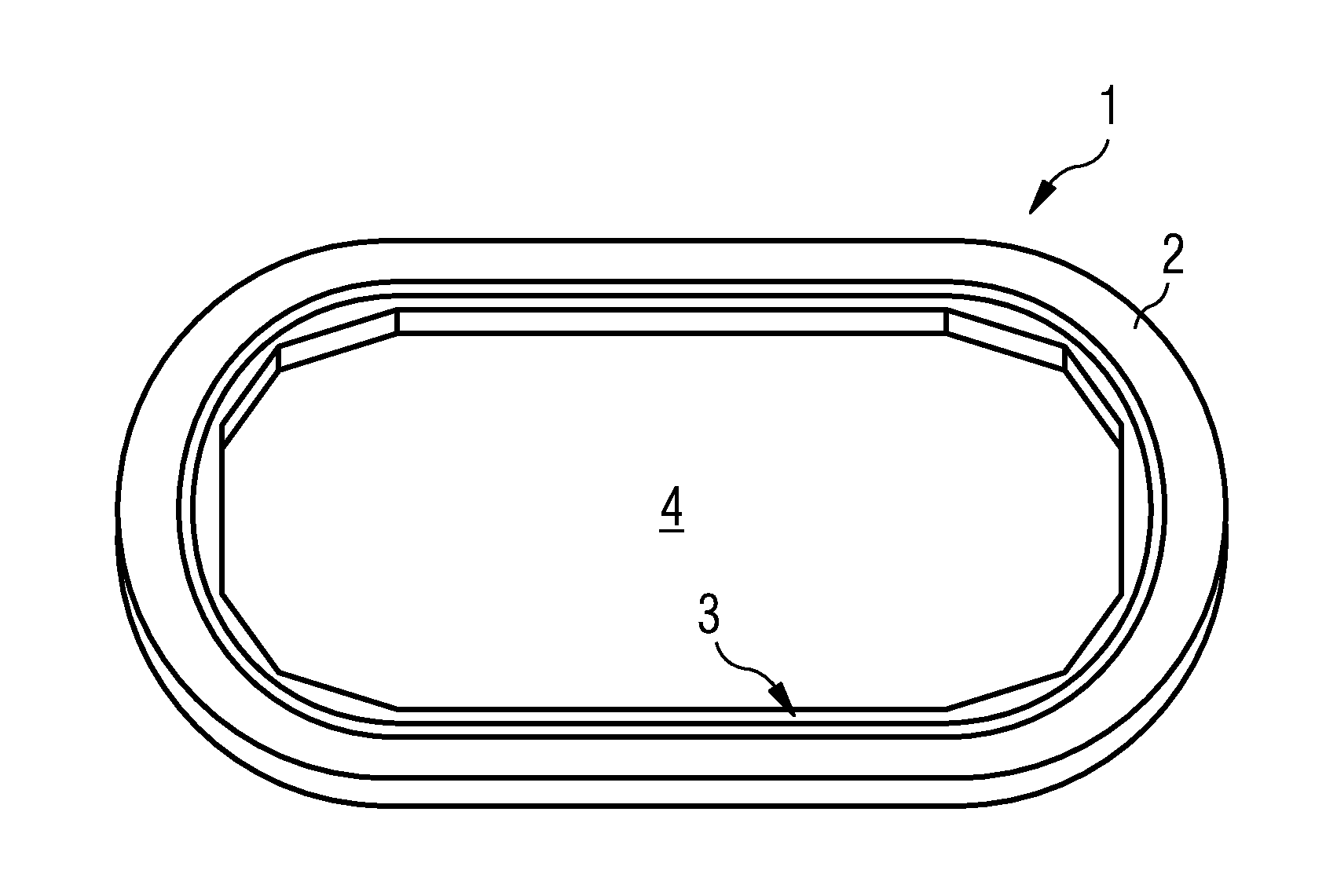

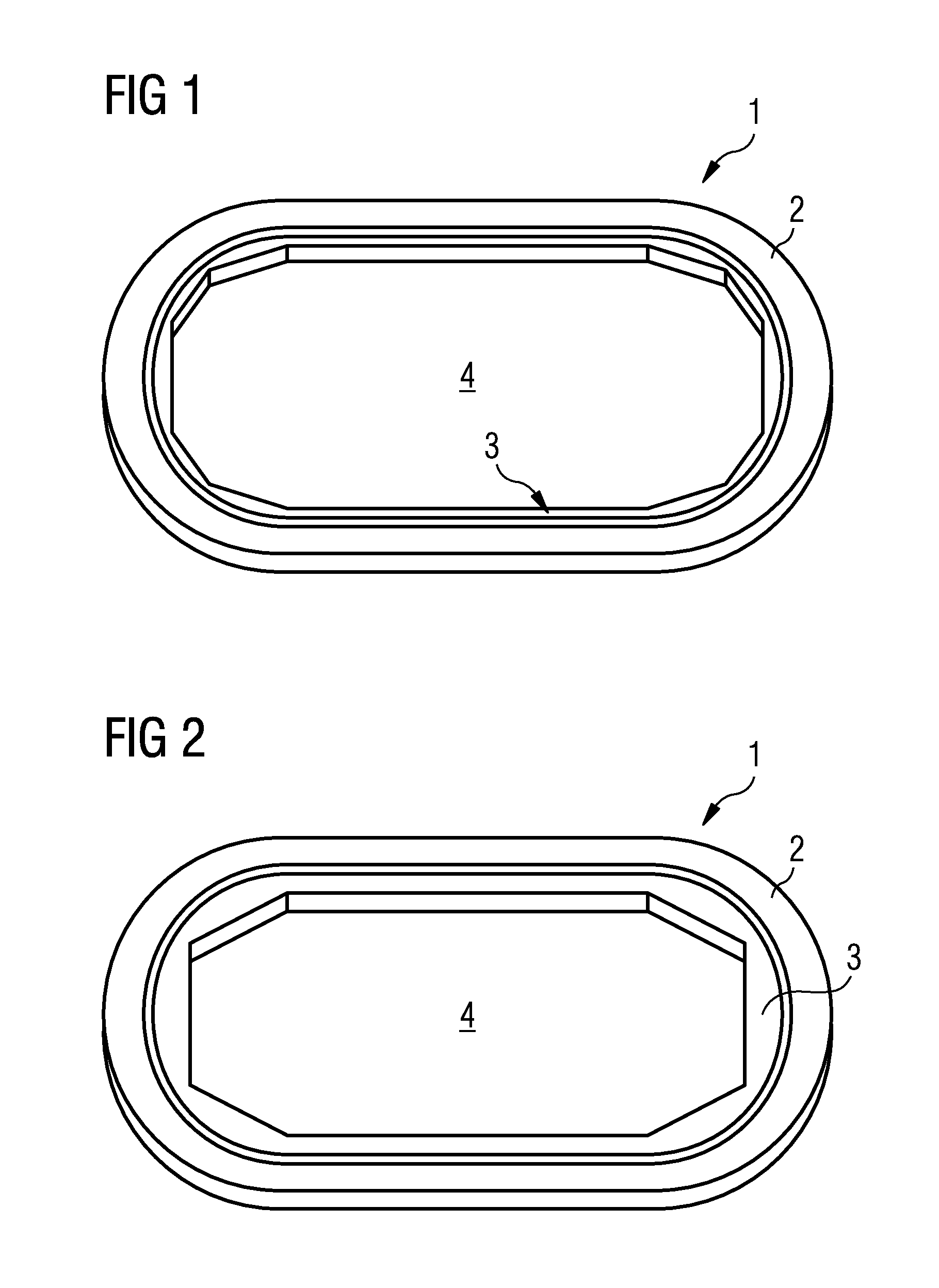

High-temperature superconductor (HTS) coil

ActiveUS20130172196A1Avoid and reduce longitudinal compressionPrevent degradationSynchronous machinesAsynchronous induction motorsHigh-temperature superconductivityRoom temperature

A high-temperature superconductor (HTS) coil includes a coil winding with a superconducting material and a coil former for carrying the coil winding. When the high-temperature supercon-ductor (HTS) coil cools down from a room temperature to an operating temperature, the coil winding or the coil former counteract a thermal shrinkage of the coil winding in order to avoid or reduce a longitudinal compression of the superconducting material of the coil winding.

Owner:SIEMENS AG

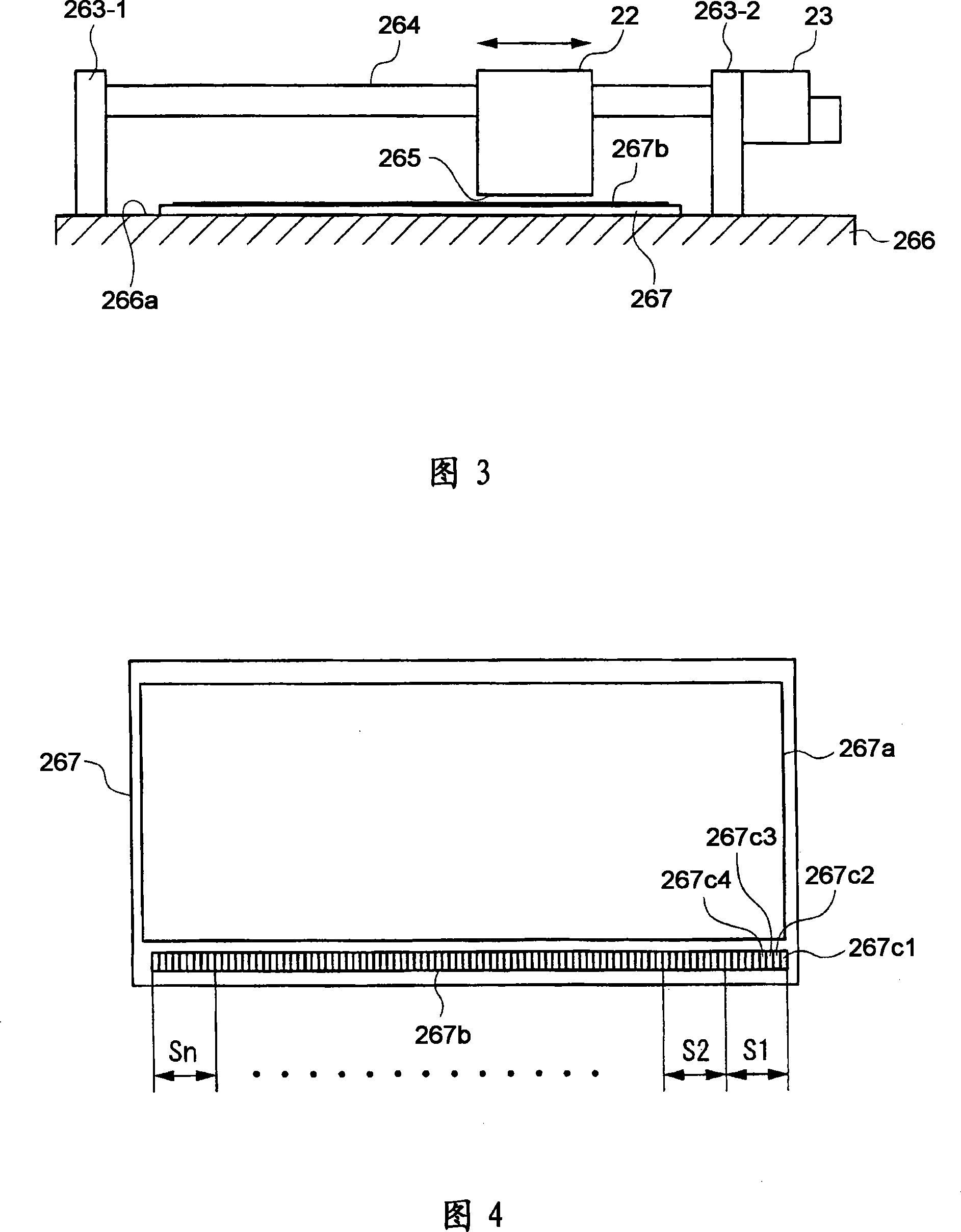

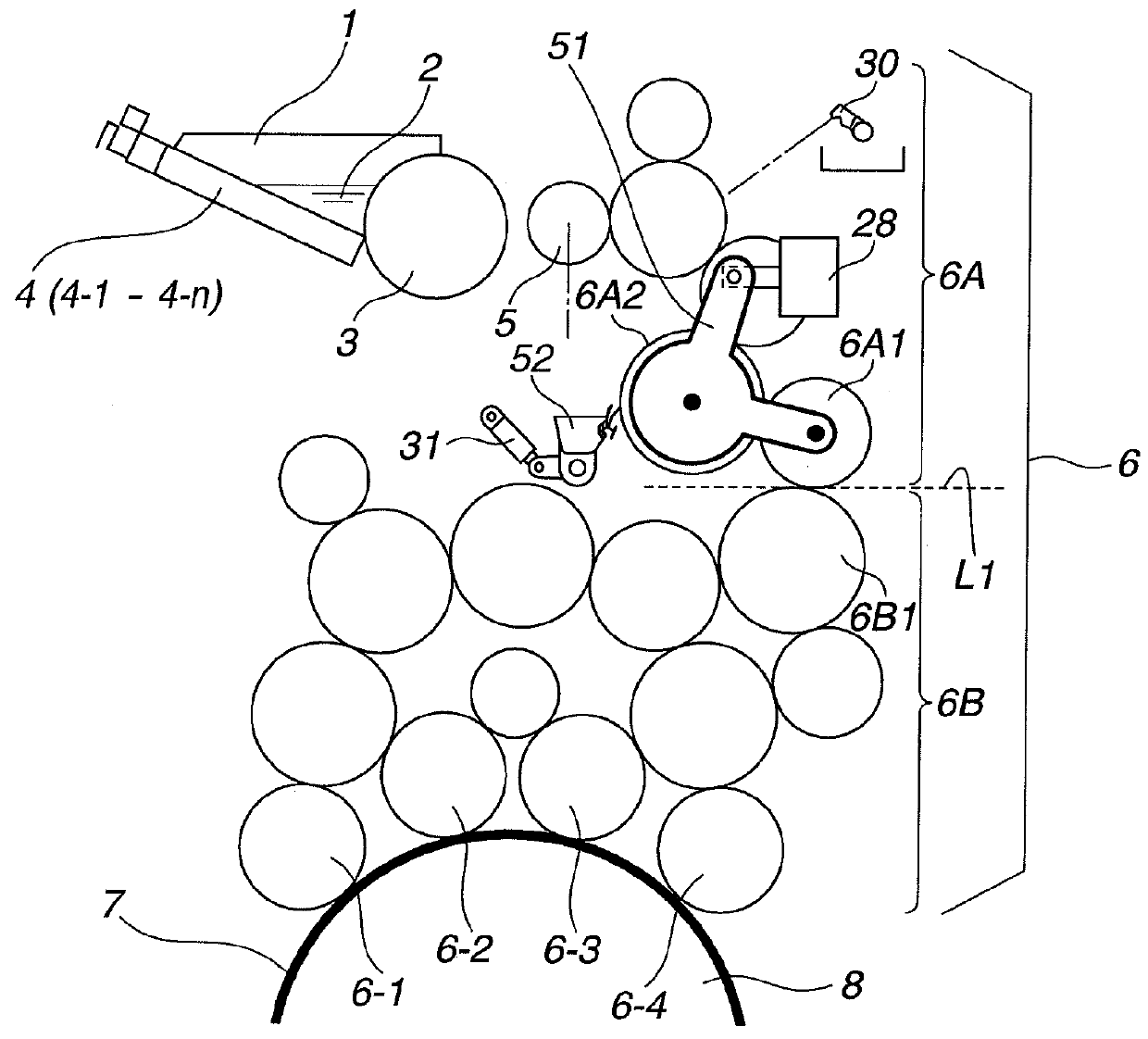

Ink film thickness distribution forming method and apparatus

An ink film thickness distribution forming method in an ink supply apparatus including an ink fountain. A plurality of ink fountain keys are arranged in the ink fountain. Ink is supplied to an ink fountain roller in accordance with the opening ratios of the plurality of ink fountain keys. Ink is transferred to an ink ductor roller from the ink fountain roller. Ink from the ink doctor roller is transferred to an ink roller group including at least one ink form roller. A throw-off operation of the ink form roller positioned at an end of the ink roller group is performed after the end of a print job. The ink roller group is divided into a plurality of roller subgroups after the end of the print job. The ink in at least one of roller subgroups is removed. An ink film thickness distribution forming apparatus is also disclosed.

Owner:KOMORI CORP

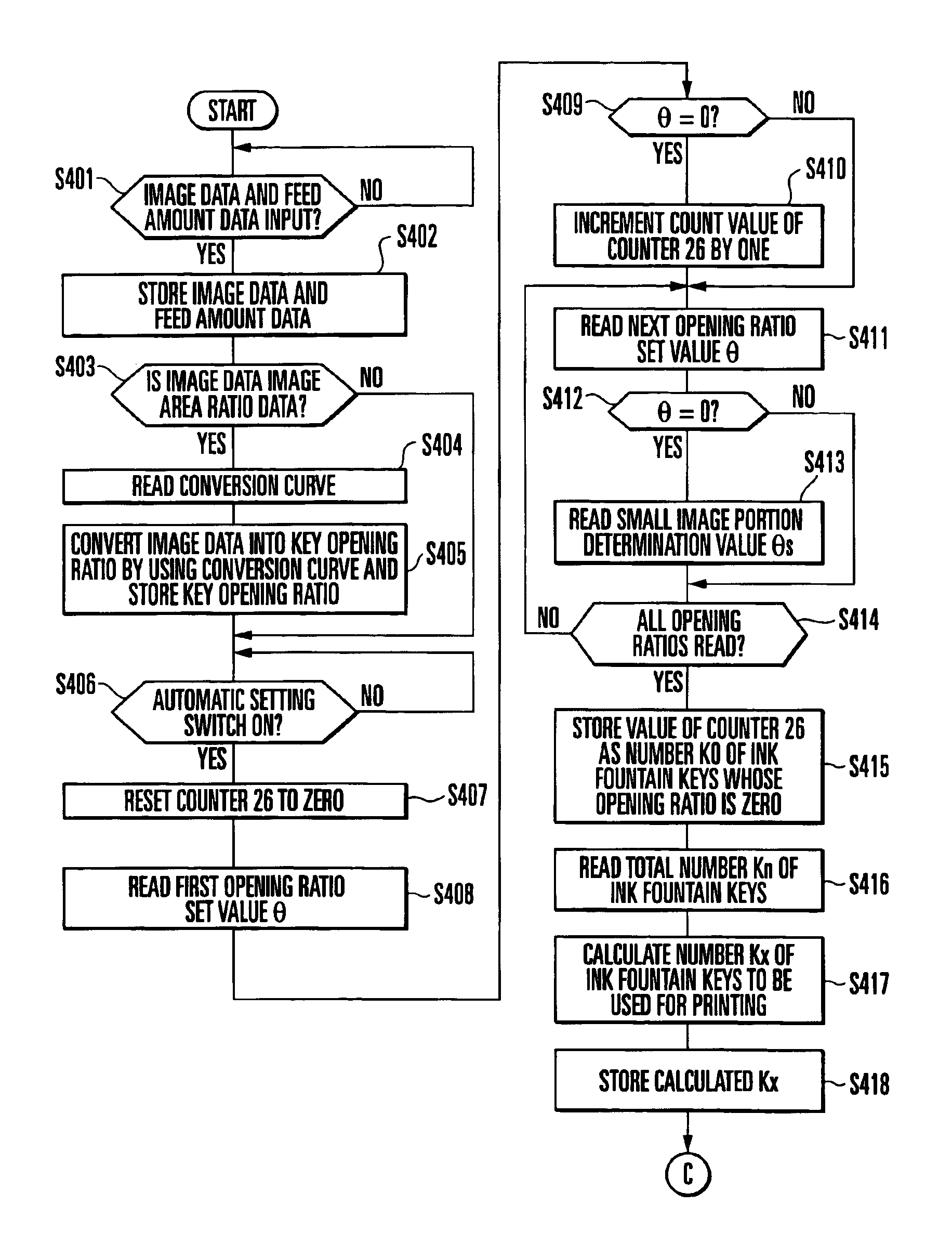

Method and device for controlling ink supply amount for printer

In an ink supply amount control method for a printing press, the number of ink fountain keys whose gap amount with respect to an ink fountain roller falls within a predetermined range is counted. On the basis of the count value, the swing operation of an ink ductor roller which is arranged in an ink supply path and swings in synchronism with rotation of the printing press is controlled. Ink is supplied from the gap between the plurality of ink fountain keys and the ink fountain roller to the ink supply path in accordance with rotation of the ink fountain roller at the time of printing. The ink is supplied to a printing plate attached to a plate cylinder through the ink supply path by the swing operation of the ink ductor roller. An ink supply amount control apparatus and a printing press are also disclosed.

Owner:KOMORI CORP

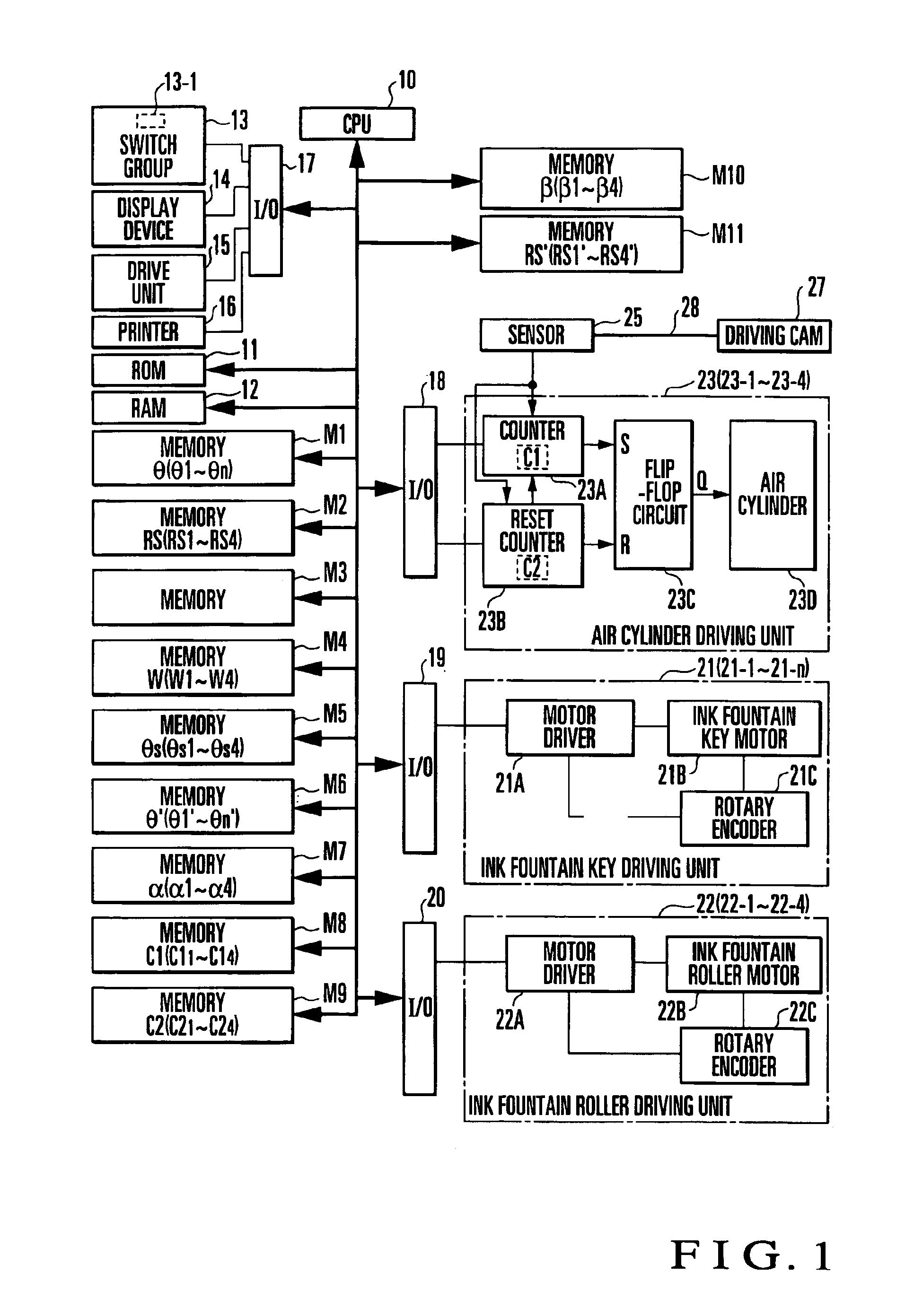

Ink feed control method and ink feed control system

An ink feed control method for a printing press in which ink, supplied to an ink fountain roller from a gap between each ink fountain key and the ink fountain roller by the rotation of the ink fountain roller, is supplied to the printing plate by swing operation of an ink ductor roller, so that a print is eventually made on a print sheet with the ink supplied to the printing plate, the method including the steps of: measuring any one of the density and the ink film thickness of a first printing product made by the printing press; and controlling the number of times of the swing operation of the ink ductor roller relative to the rotation of the printing press in accordance with the value of the measured one of the density and the ink film thickness of the first printing product.

Owner:KOMORI CORP

Ink supply amount adjustment method and apparatus for printing press

An ink supply amount adjustment method for a printing press includes steps of measuring the density value of each density measurement patch printed in a range corresponding to each ink fountain key on a printed printing sheet, obtaining the opening ratio of each ink fountain key in preliminary ink feeding, based on the difference between the measured density value of a patch and a preset reference density value, and the current opening ratio of each ink fountain key or image data in the range corresponding to each ink fountain key, and performing the ink feed operation of an ink ductor roller while printing is suspended, after setting the opening ratio of each ink fountain key to the obtained opening ratio in preliminary ink feeding. An ink supply amount adjustment apparatus for a printing press is also disclosed.

Owner:KOMORI CORP

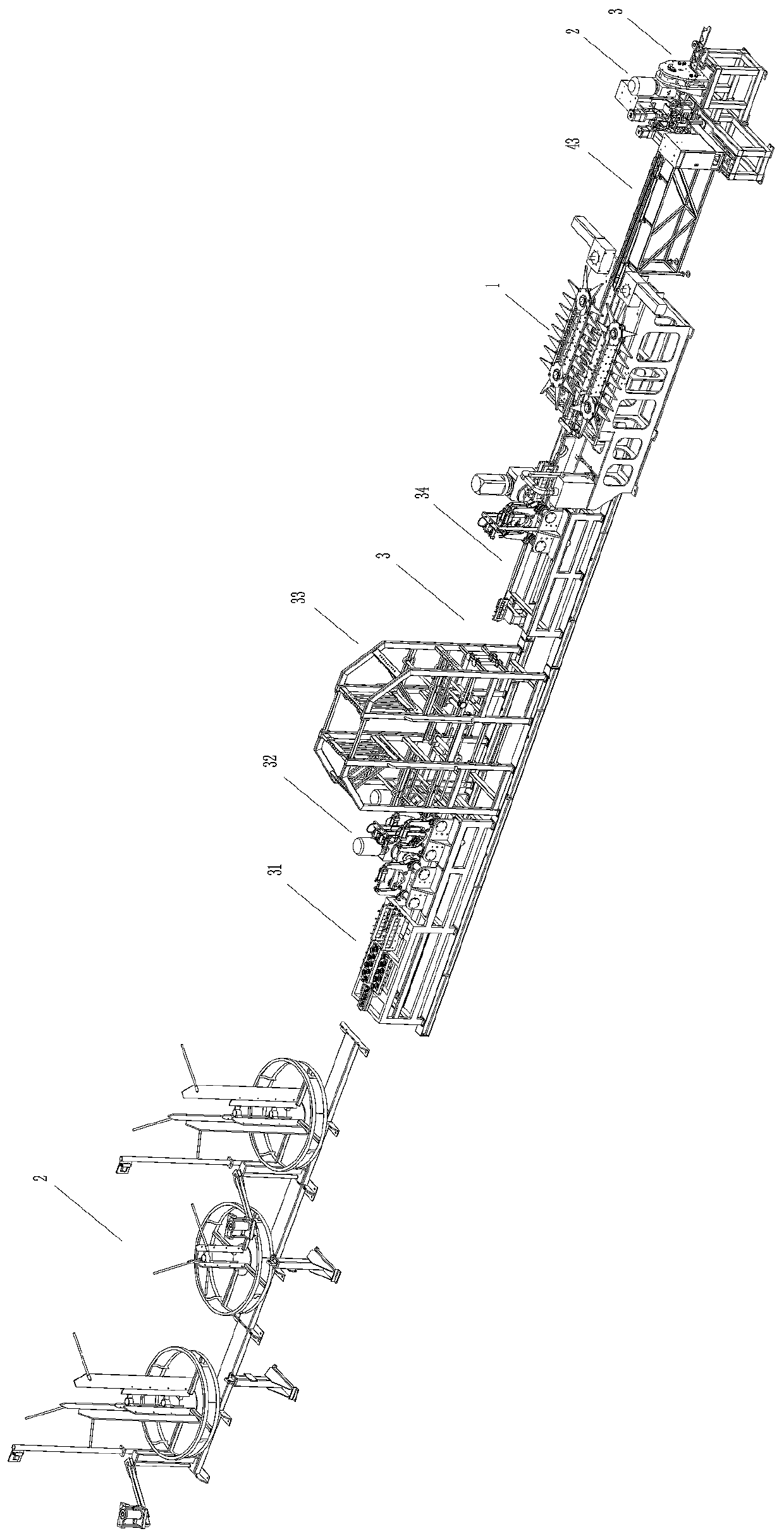

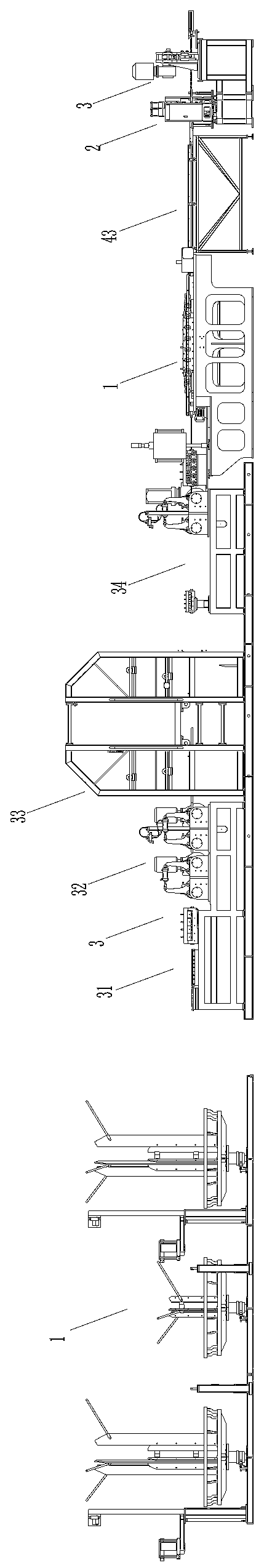

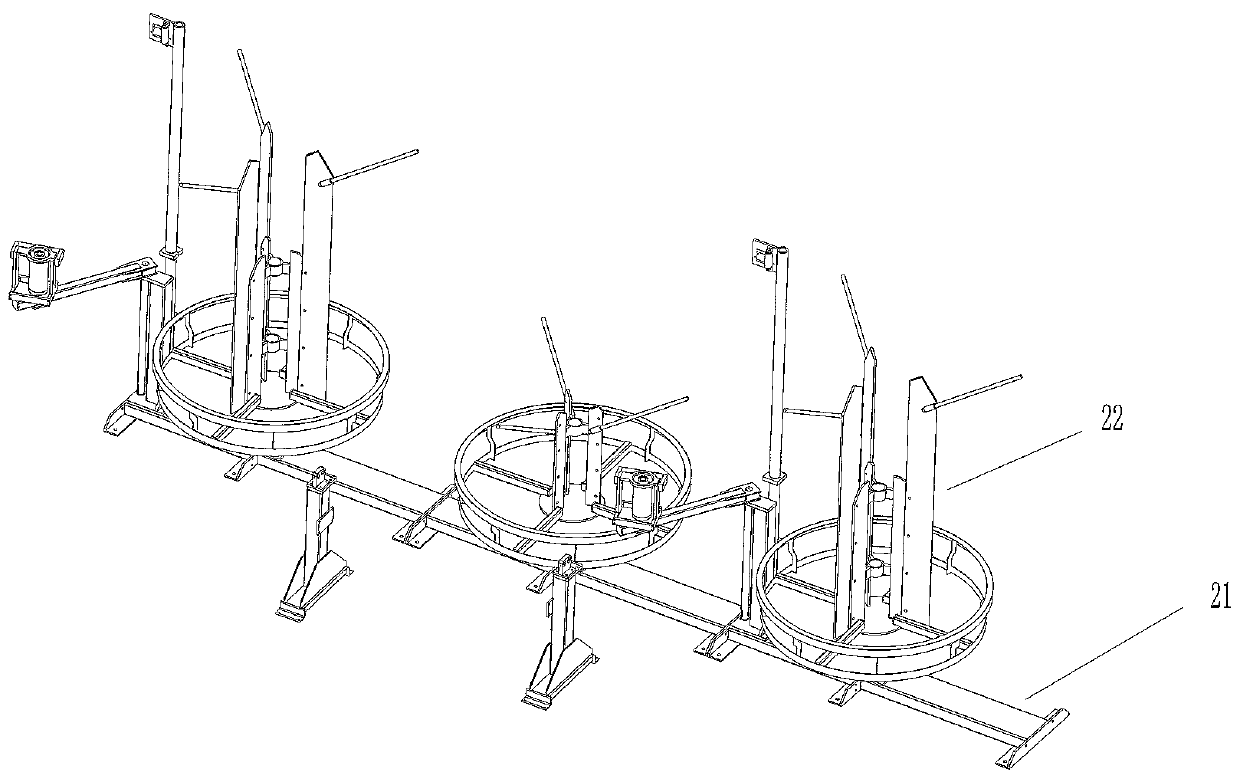

Plane truss production line

PendingCN109648007AQuick bendingThe style is fixed and beautifulMetal working apparatusProduction lineRebar

The invention belongs to the field of plane truss production, and particularly relates to a plane truss production line. The plane truss production line comprises a placing device, a straightening roller pressing device, a waving device, a welding device and a shearing device, wherein the waving device comprises a waving base, a waving drive, a side steel bar guide pipe, a fixed waving device anda movable waving device, and the fixed waving device comprises a first rotating shaft and a first crawler belt, triangular plates are fixed on the outer side of the first crawler belt, and the movablewaving device comprises a sliding guide rail, a sliding base, a second rotary shaft and a second crawler belt, triangular plates are fixed on the outer side of the second crawler belt, and the wavingdrive is connected with the first rotary shaft and the second rotary shaft; the welding device comprises a welding frame and welding heads; the shearing device comprises a shearing base and a cutterframe, and a cutter rotating shaft is arranged on the cutter frame, a cutter connecting part sleeves the cutter rotating shaft, and a shearing cutter is hinged to the lower part of the cutter connecting part. According to the plane truss production line, the steel bar can be processed into the plane truss, the processing process is automatic, the efficiency is high, and the method is suitable forlarge-scale plane truss processing.

Owner:浙江亿洲机械科技有限公司

Ink supply amount control method and apparatus for printing press

InactiveUS7028616B2Reduce loadOther printing apparatusPrinting press partsPrinting pressMechanical engineering

In an ink supply amount control method for a printing press, the number of ink fountain keys whose gap amount with respect to an ink fountain roller falls within a predetermined range is counted. On the basis of the count value, the swing operation of an ink ductor roller which is arranged in an ink supply path and swings in synchronism with rotation of the printing press is controlled. Ink is supplied from the gap between the plurality of ink fountain keys and the ink fountain roller to the ink supply path in accordance with rotation of the ink fountain roller at the time of printing. The ink is supplied to a printing plate attached to a plate cylinder through the ink supply path by the swing operation of the ink ductor roller. An ink supply amount control apparatus and a printing press are also disclosed.

Owner:KOMORI CORP

Automatic exhaust system of clutch and exhaust method implemented by automatic exhaust system

ActiveCN103697082ADoes not affect normal workRealize automatic dischargeFluid actuated clutchesFluid-pressure actuator componentsMaster cylinderLiquid storage tank

The invention discloses an automatic exhaust system of a clutch. The automatic exhaust system comprises a clutch master cylinder, clutch slave cylinders, a liquid storage tank, a compensation tank and an electric oil pump. The clutch master cylinder is communicated with the clutch slave cylinders, the liquid storage tank is communicated with the clutch master cylinder, the compensation tank is communicated with the liquid storage tank via an air guide pipe, the electric oil pump is communicated with each clutch slave cylinder by a liquid delivery pipeline, and the compensation tank is further communicated with the electric oil pump via another liquid delivery pipeline; a gas hole is further formed in the top of the compensation tank. The invention further discloses an exhaust method implemented by the automatic exhaust system of the clutch. According to the scheme, the automatic exhaust system and the exhaust method have the advantages that residual gas in an operating system of the clutch can be conveniently, efficiently, safely and thoroughly exhausted, accordingly, the problem of incomplete clutch separation due to incomplete exhaust can be solved, normal work of the operating system of the clutch can be guaranteed, faults can be prevented, and the automatic exhaust system and the exhaust method have extremely high application value and an excellent market prospect.

Owner:陈小伟

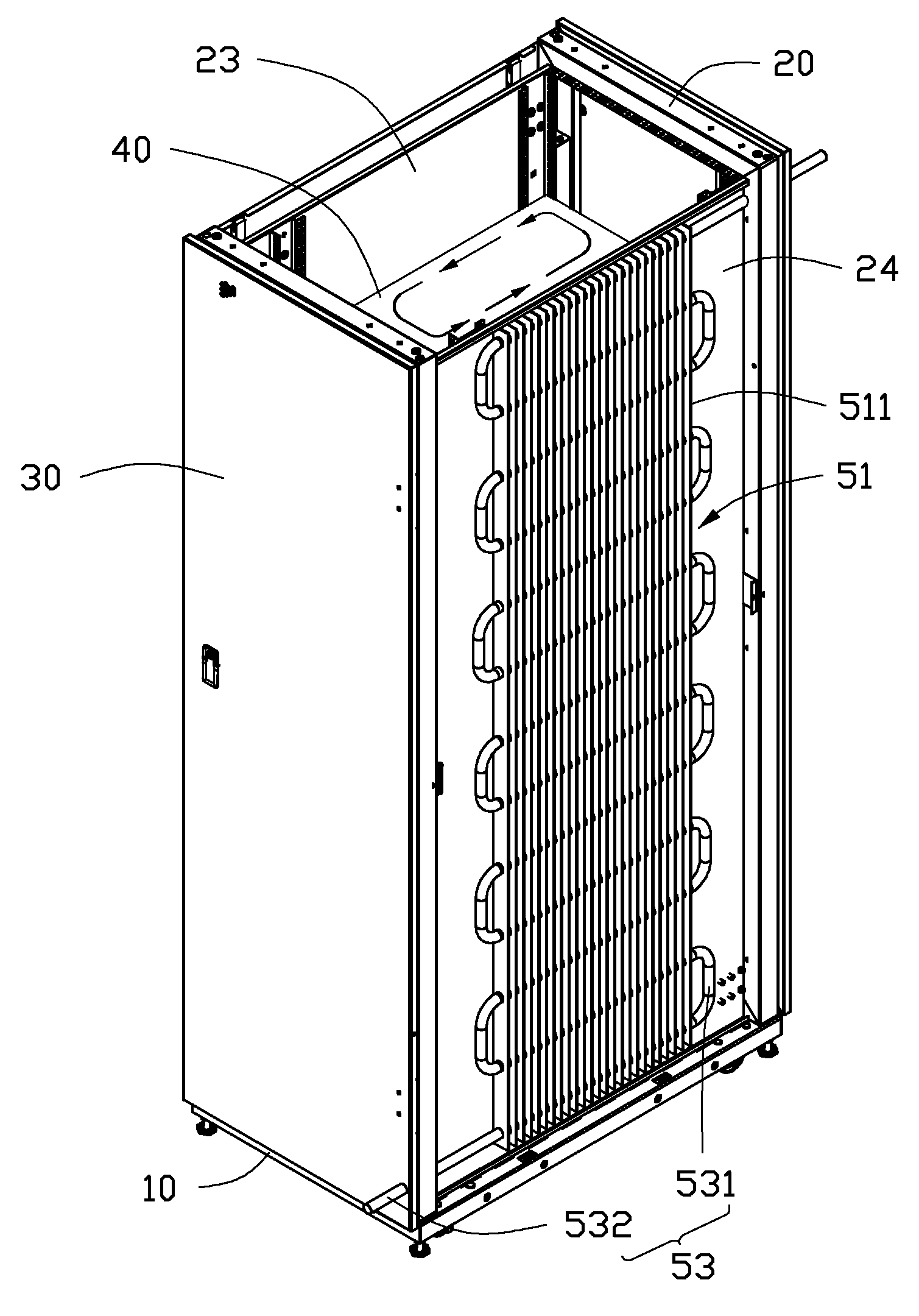

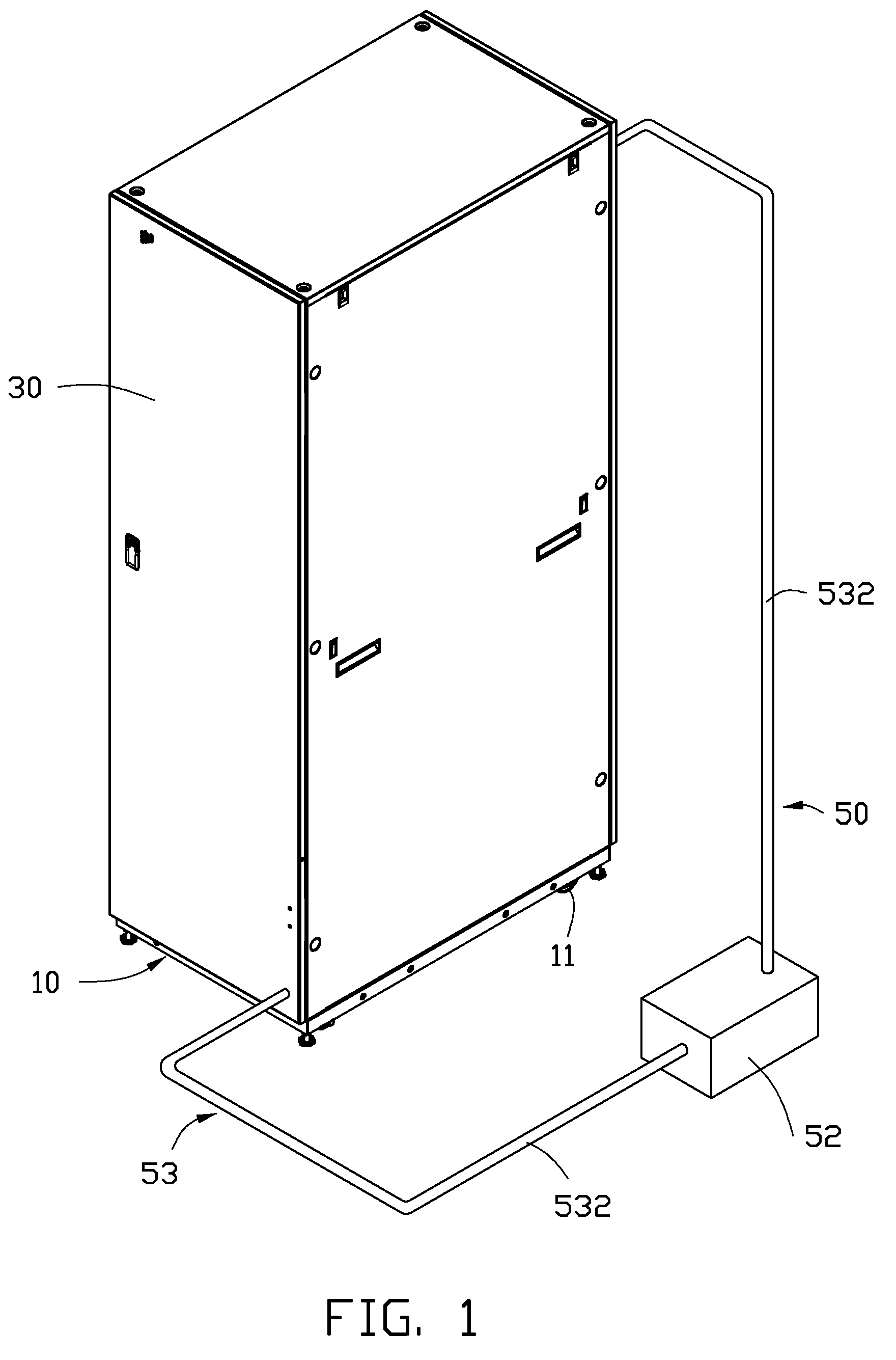

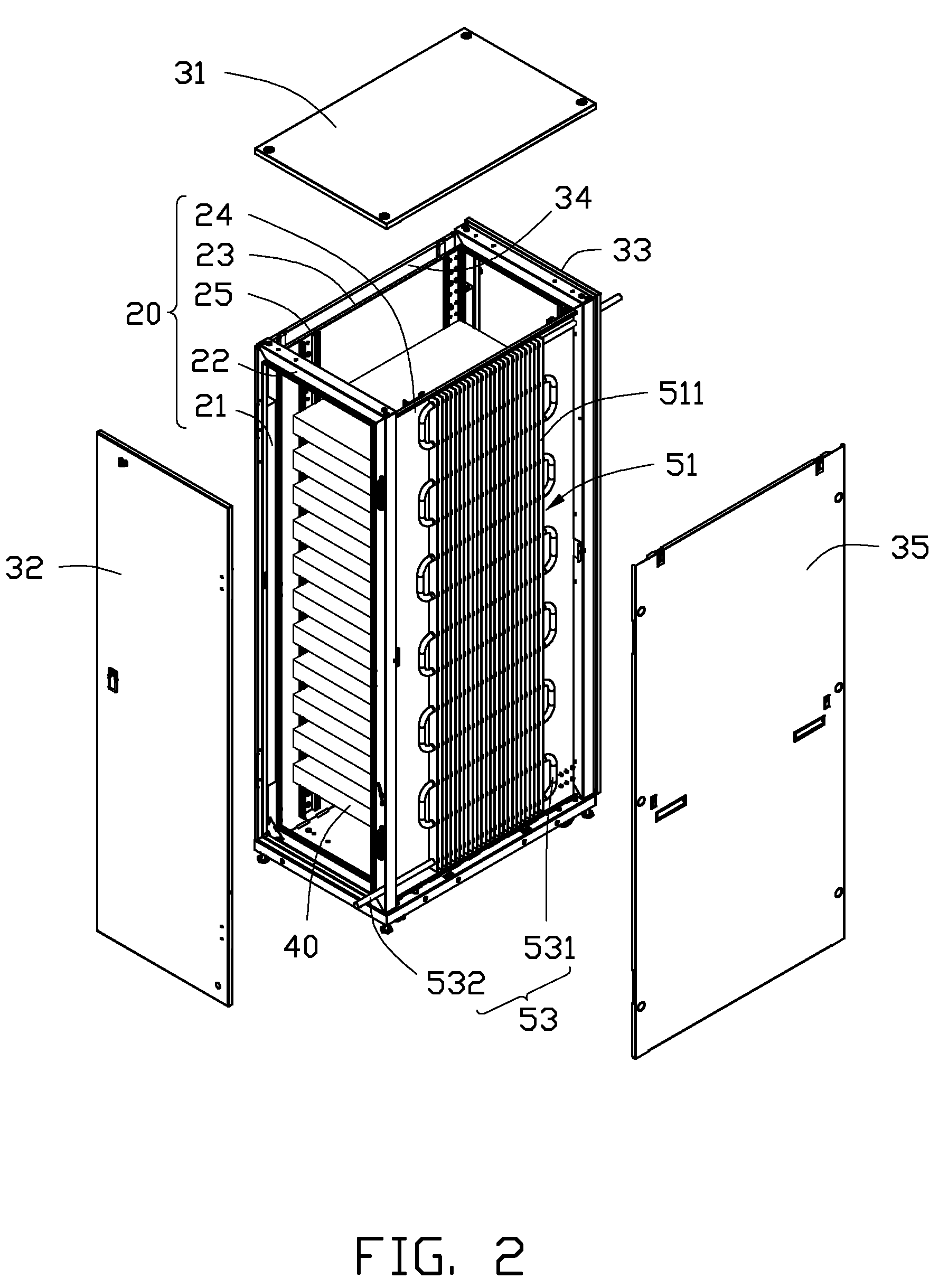

Server cabinet with liquid cooling system

InactiveUS8432692B2Domestic cooling apparatusDigital data processing detailsLiquid cooling systemEngineering

An exemplary server cabinet includes an enclosure configured to house multiple servers therein, and a liquid cooling system. A heat conductive plate is positioned in the enclosure to be adjacent to the servers. The liquid cooling system includes a cooler located outside the enclosure, a conduit thermally connecting the cooler with the heat conductive plate, and a working liquid circulating in the conduit and the cooler. Heat generated by the servers is absorbed by the heat conductive plate and transferred to the cooler by the working liquid for dissipation.

Owner:HON HAI PRECISION IND CO LTD

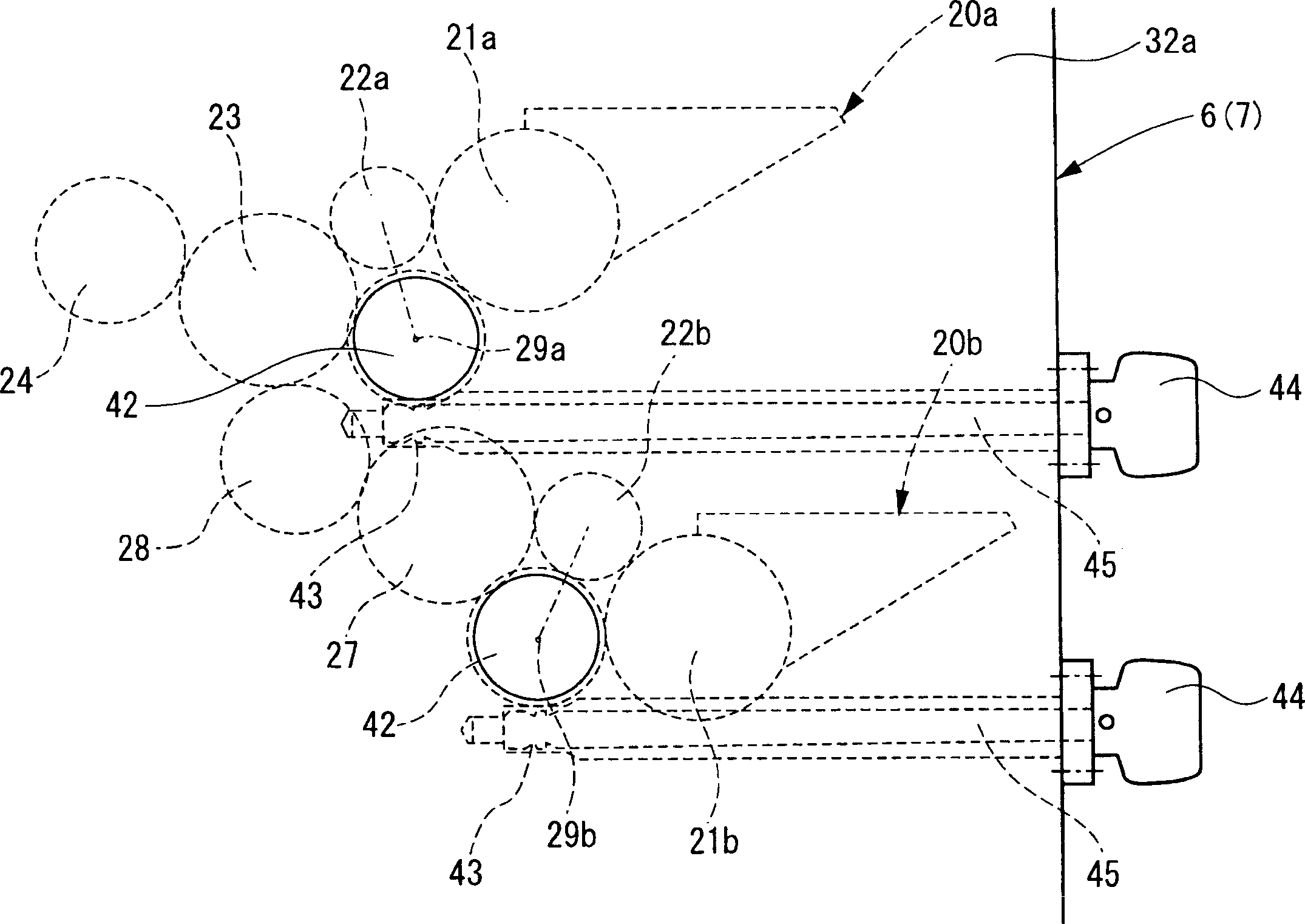

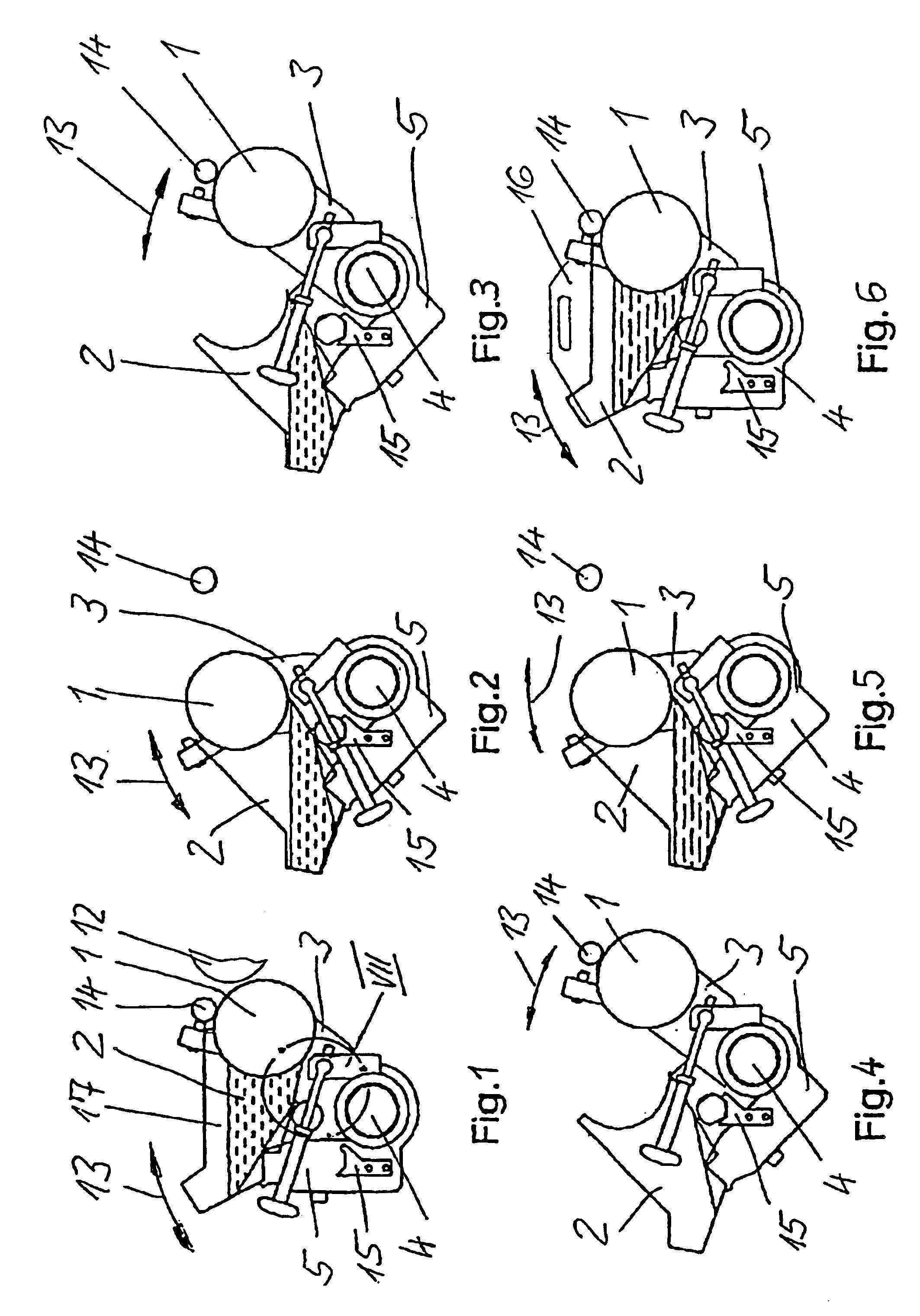

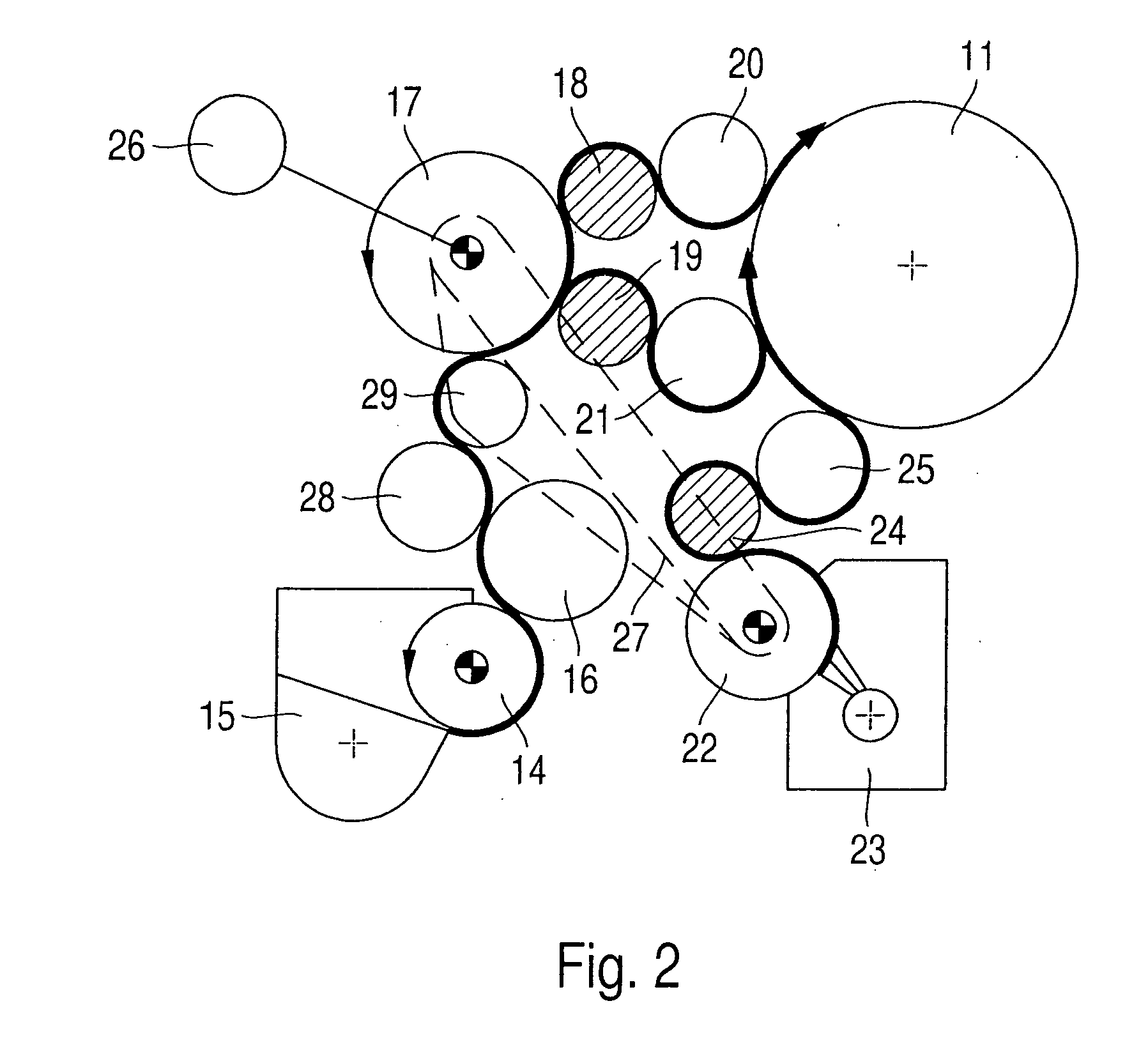

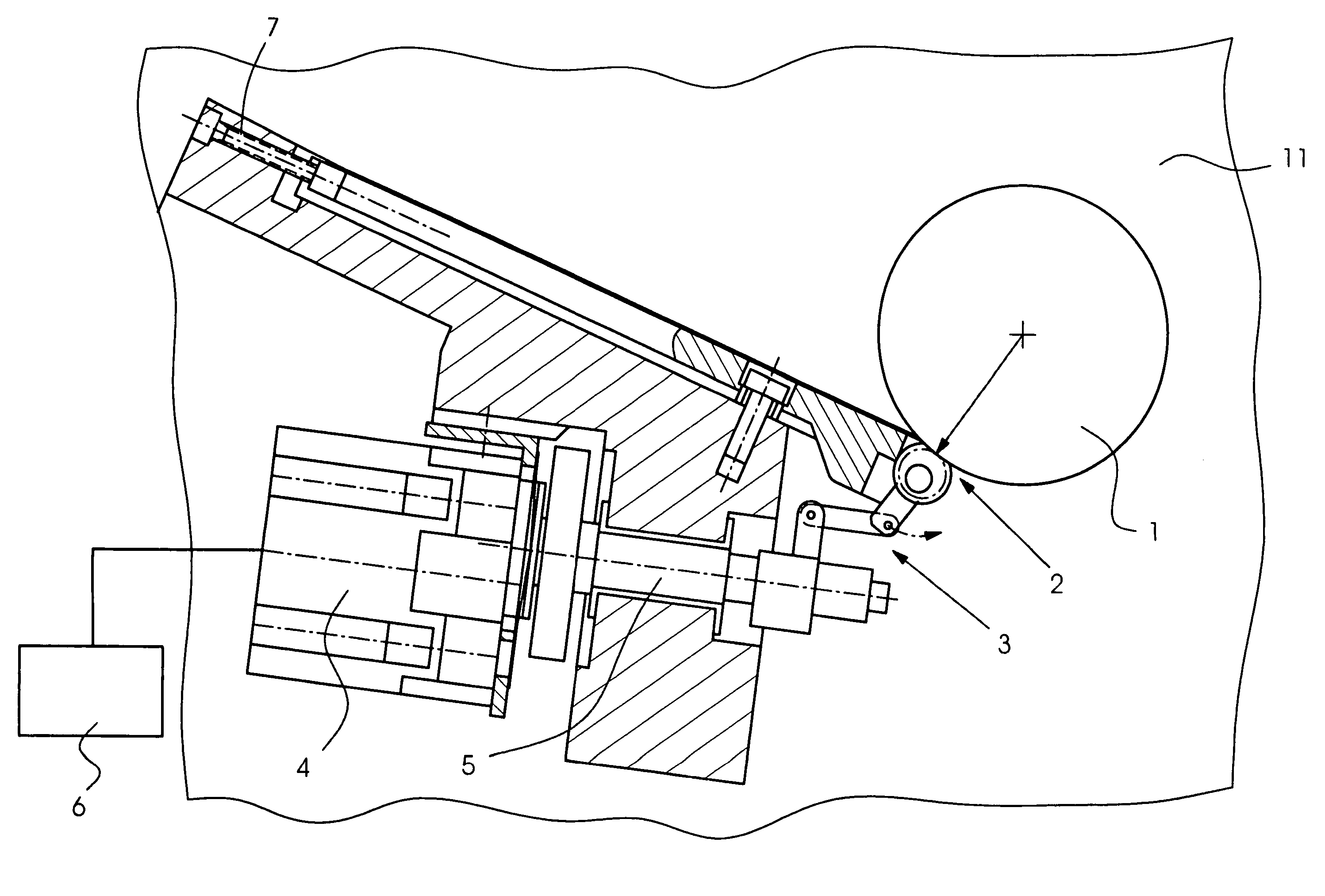

Printing unit and inking unit

InactiveUS7568426B2Simpler andLess-expensive constructionInking apparatusPlaten pressesEngineeringPrinting ink

A printing unit includes a press unit having a forme cylinder, a transfer cylinder, an inking unit and, preferably, a damping unit. The inking unit of each press unit applies printing ink to a forme cylinder of the respective press unit in such a way that a ductor roll of an inking unit picks up printing ink kept ready in an ink fountain and applies it to the forme cylinder of the respective press unit by a film roll interacting with the ductor roll, inking unit rolls arranged downstream of the film roll, and at least one ink applicator roll rolling on the forme cylinder. Inking unit rolls driven in rotation and inking unit rolls driven in oscillation are are driven independently from one another on the drive side.

Owner:MANROLANAD AG

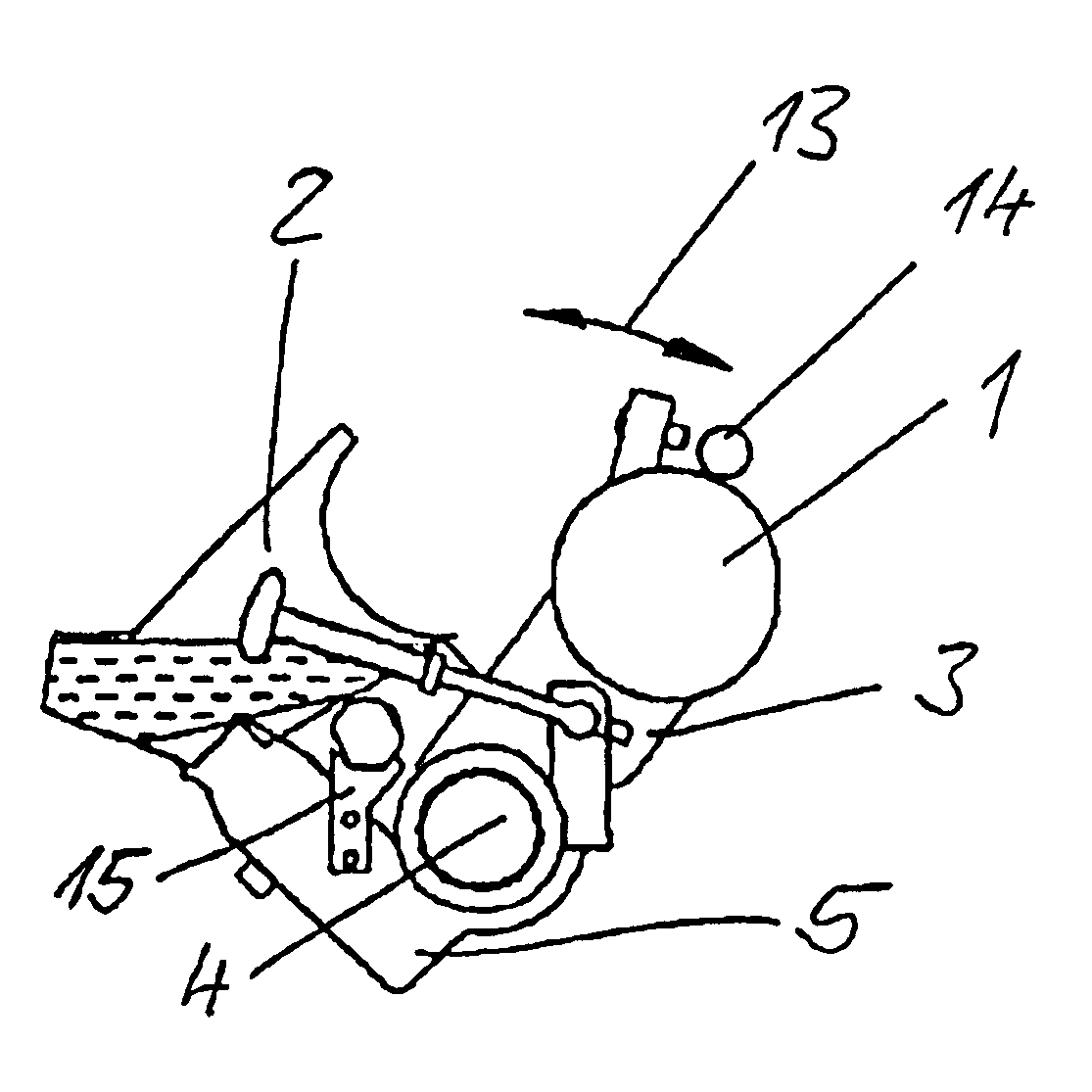

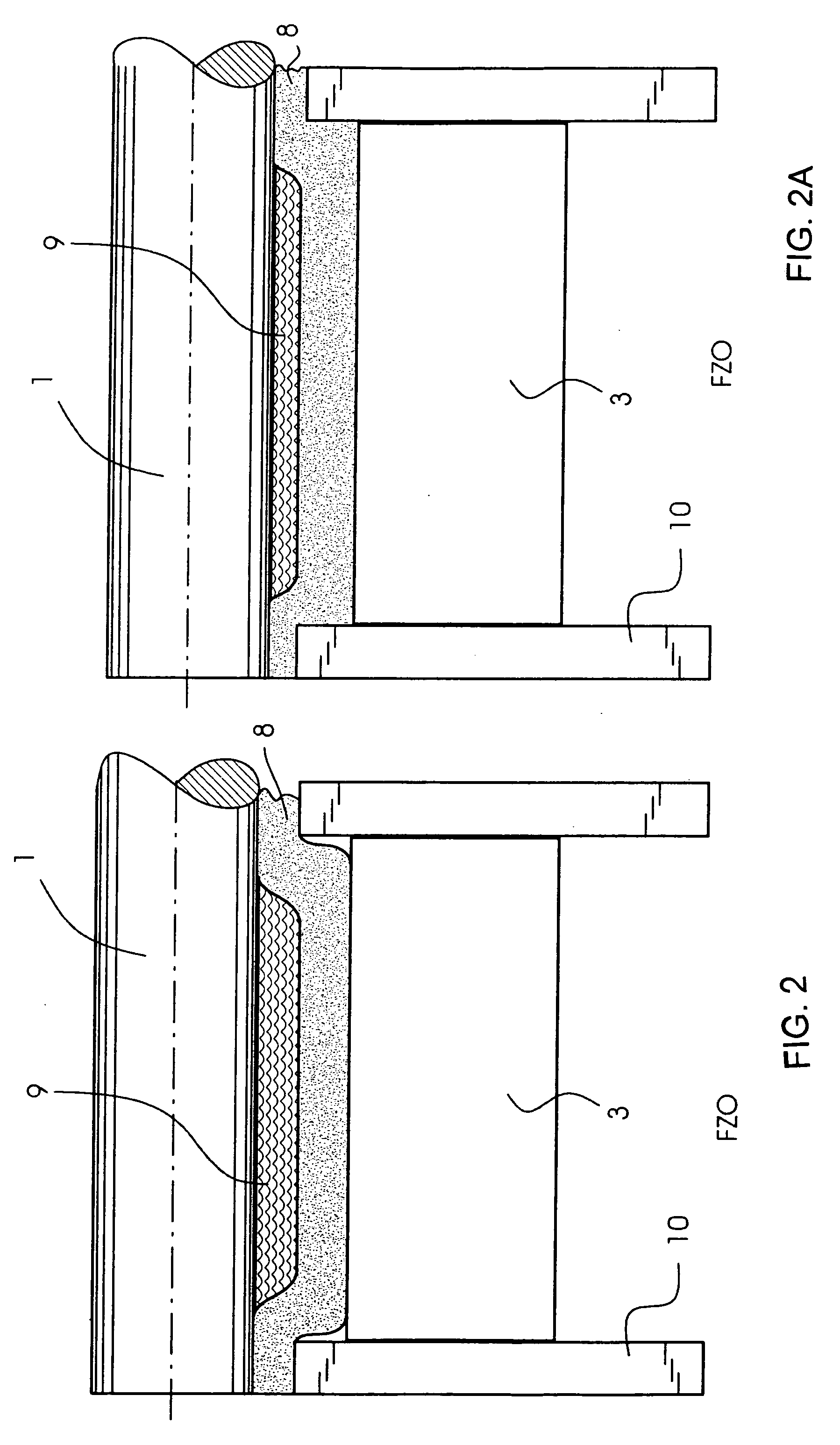

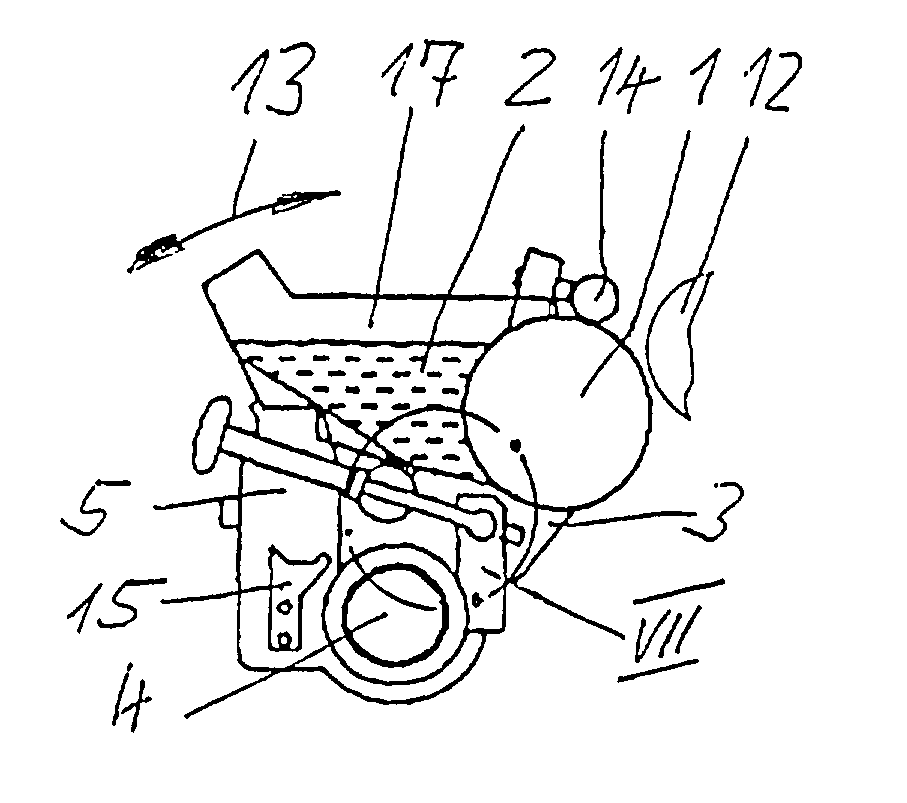

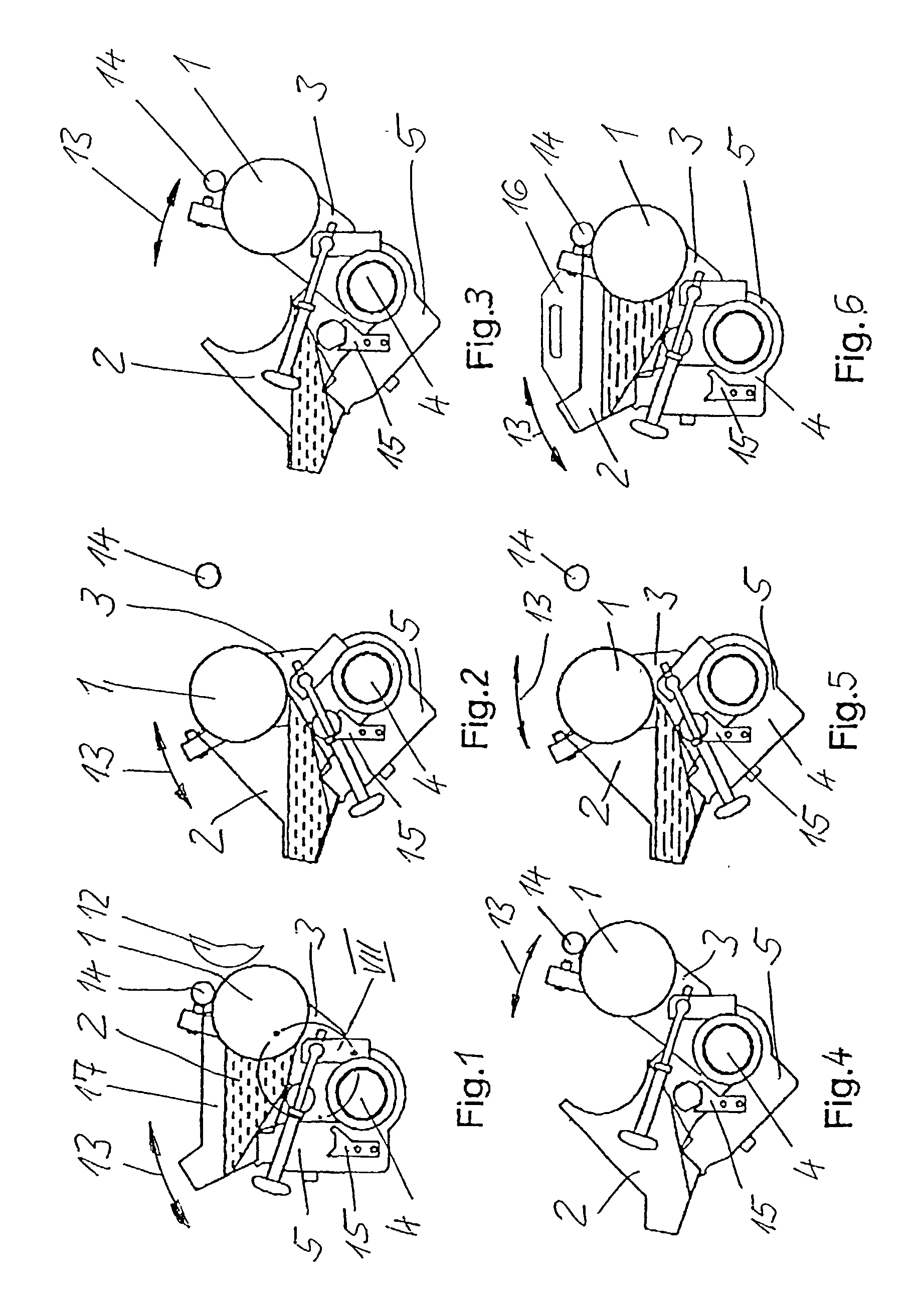

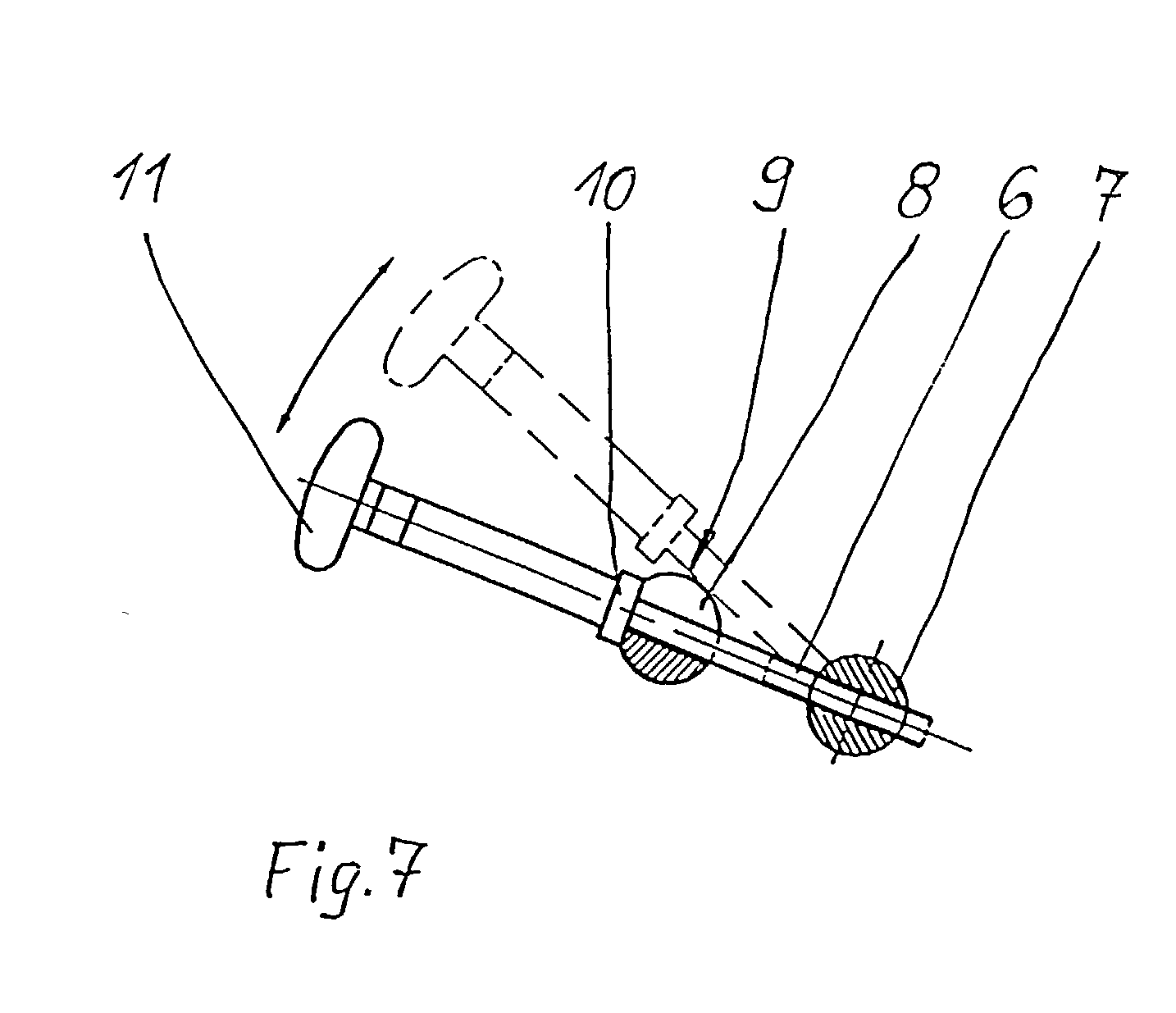

Inking unit for rotary printing machine

InactiveUS6862988B2Possible changeGap is providedPlaten pressesPrinting press partsEngineeringMechanical engineering

An inking unit for a rotary printing machine includes an ink fountain, a pivotable ink fountain holder in which the ink fountain is mounted, an ink ductor, and a pivotable ink ductor holder in which the ink ductor is mounted. The ink ductor holder and the ink fountain holder are connected by an operating cylinder so that ductor and the ink fountain can be pivoted jointly to a first position in which ink flows out of the ductor without flowing out of the fountain, and so that the ductor can be pivoted away from the first position to a second position while the ink fountain remains in the first position, thereby creating a gap between the ductor and the ink fountain.

Owner:MANROLANAD AG

Inflator apparatus, system and method for utilizing the same

ActiveUS8770236B2Solid materialPackaging under special atmospheric conditionsBiomedical engineeringDuctor

An inflator apparatus for inflating more than one un-inflated tire-wheel assembly is disclosed. The inflator apparatus includes a support structure; an interface portion rotatably-attached to the support structure, wherein the interface portion includes a plurality of inflator heads, wherein each inflator head of the plurality of inflator heads includes a fluid inlet; a plunger portion movably-connected to the support structure, wherein the plunger portion is movably-connected to the support structure to permit selectively coupling of the plunger portion with one inflator head of the plurality of inflator heads; and a fluid conduit connected to the plunger portion, wherein the fluid conduit is fluidly connectable with the fluid inlet of the one inflator head of the plurality of inflator heads. A system for processing more than one un-inflated tire-wheel assembly is also disclosed. A method for utilizing an inflator apparatus for inflating more than one un-inflated tire-wheel assembly is also disclosed.

Owner:ANDROID INDS OF MICHIGAN

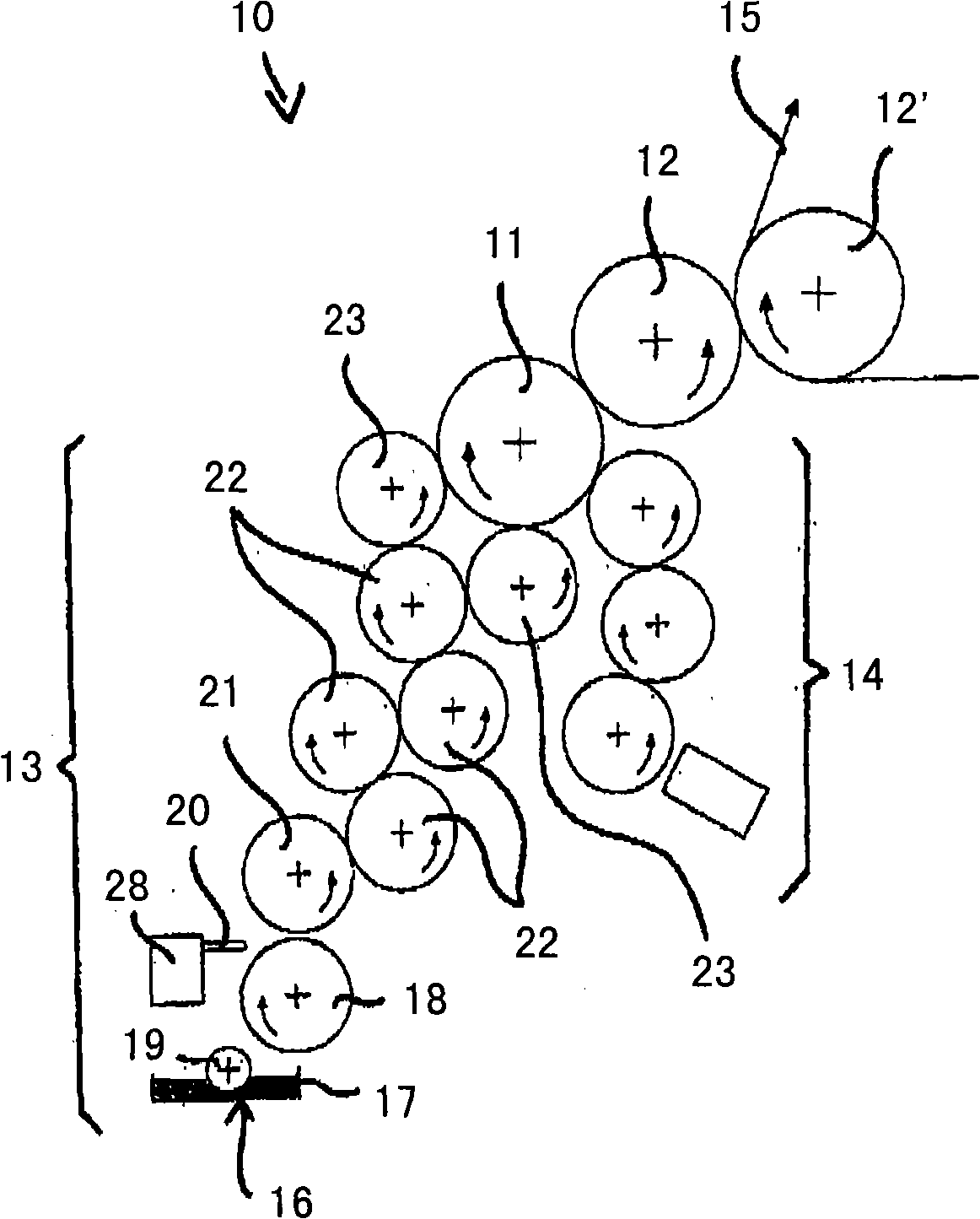

Method for operating inking device of printer

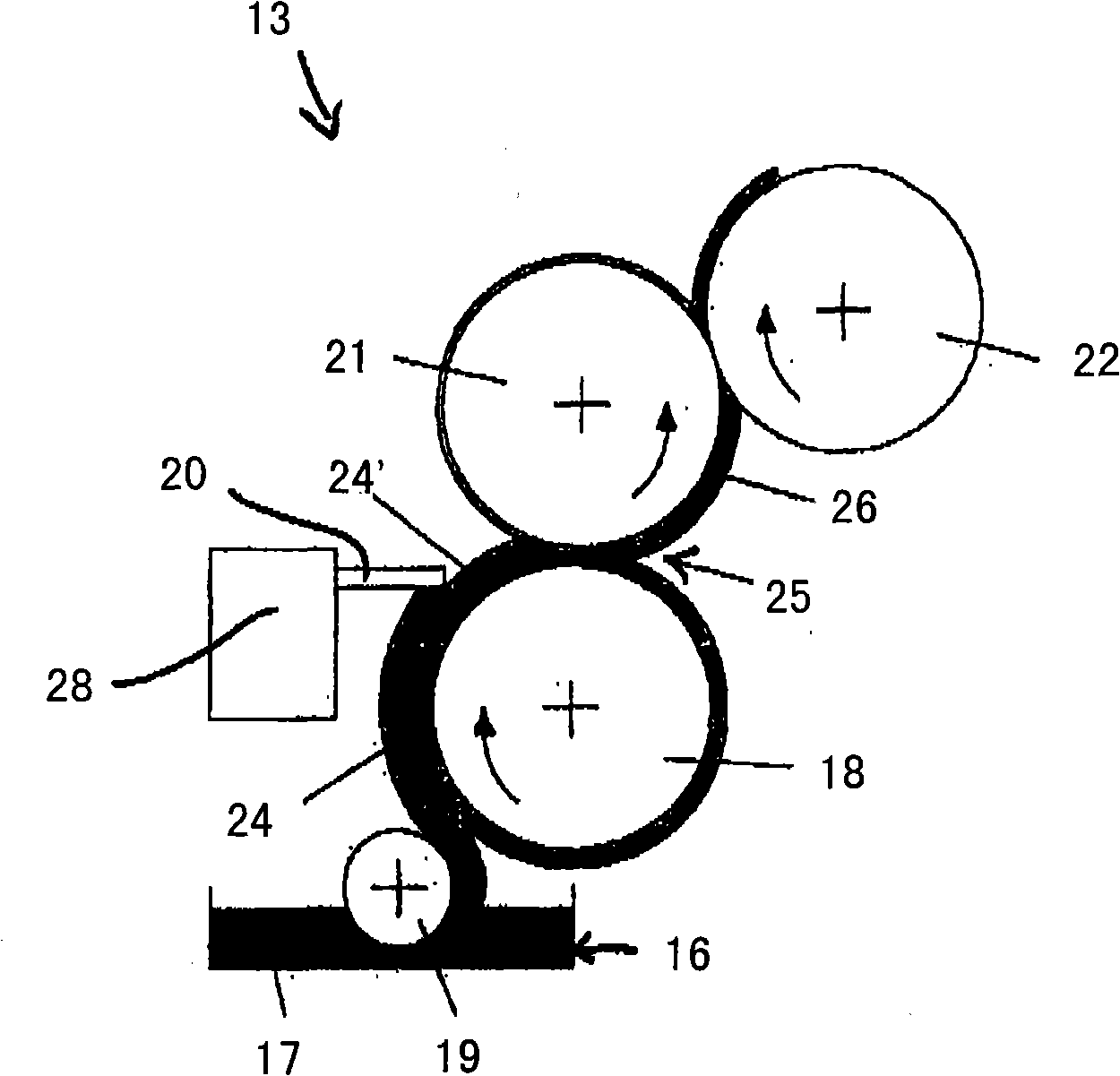

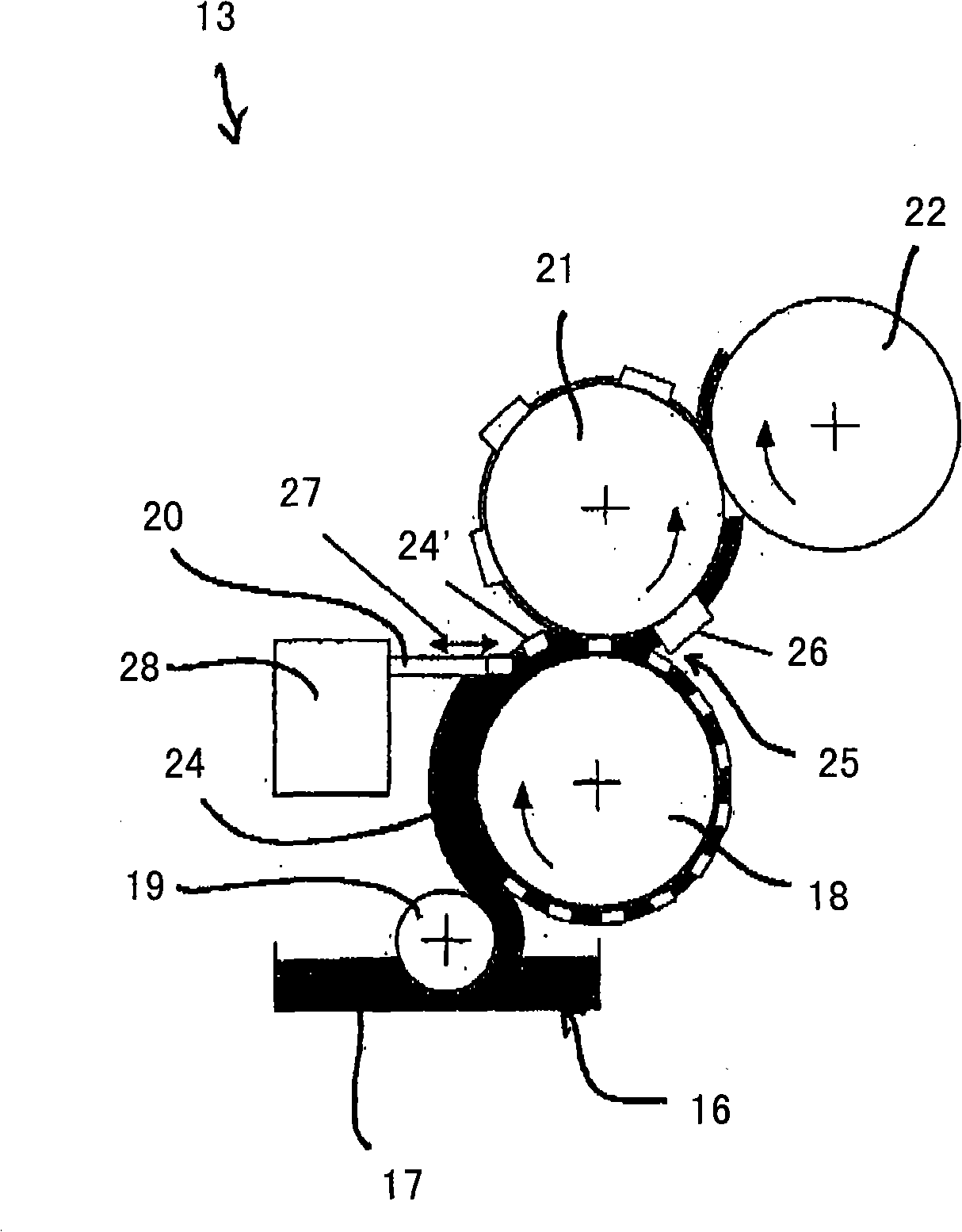

The method involves receiving a printing ink provided in a color box (16) of an inking system in a ductor-roller (18). A color zone from the color box to the ductor roller is adjusted to a color quantity to be transferred. The printing ink is transferred from the ductor roller to an inking system roller that is downstream to a film roller. A color slider or ink-ductor blade (20) is controlled such that zonal changes the color quantity at a circumference of the ductor roller, where the color quantity is transferred to the ductor roller.

Owner:M A N ROLAND DRUCKMASCHINEN AG

Ink film thickness distribution correction method and apparatus

An ink film thickness distribution correction method in an ink supply apparatus including an ink fountain storing an ink, a plurality of ink fountain keys, an ink fountain roller to which the ink is supplied from the ink fountain, an ink ductor roller to which the ink is transferred from the ink fountain roller, and an ink roller group including at least one ink form roller to which the ink transferred to the ink ductor roller is supplied. A throw-off operation of the ink form roller positioned at the end of the ink roller group is performed during test printing or final printing. An ink film thickness distribution correction apparatus is also disclosed.

Owner:KOMORI CORP

Printing unit and inking unit

InactiveUS20060037504A1Less-expensive constructionSimpler andInking apparatusPlaten pressesEngineeringPrinting ink

A printing unit includes a press unit having a forme cylinder, a transfer cylinder, an inking unit and, preferably, a damping unit. The inking unit of each press unit applies printing ink to a forme cylinder of the respective press unit in such a way that a ductor roll of an inking unit picks up printing ink kept ready in an ink fountain and applies it to the forme cylinder of the respective press unit by a film roll interacting with the ductor roll, inking unit rolls arranged downstream of the film roll, and at least one ink applicator roll rolling on the forme cylinder. Inking unit rolls driven in rotation and inking unit rolls driven in oscillation are are driven independently from one another on the drive side.

Owner:MANROLANAD AG

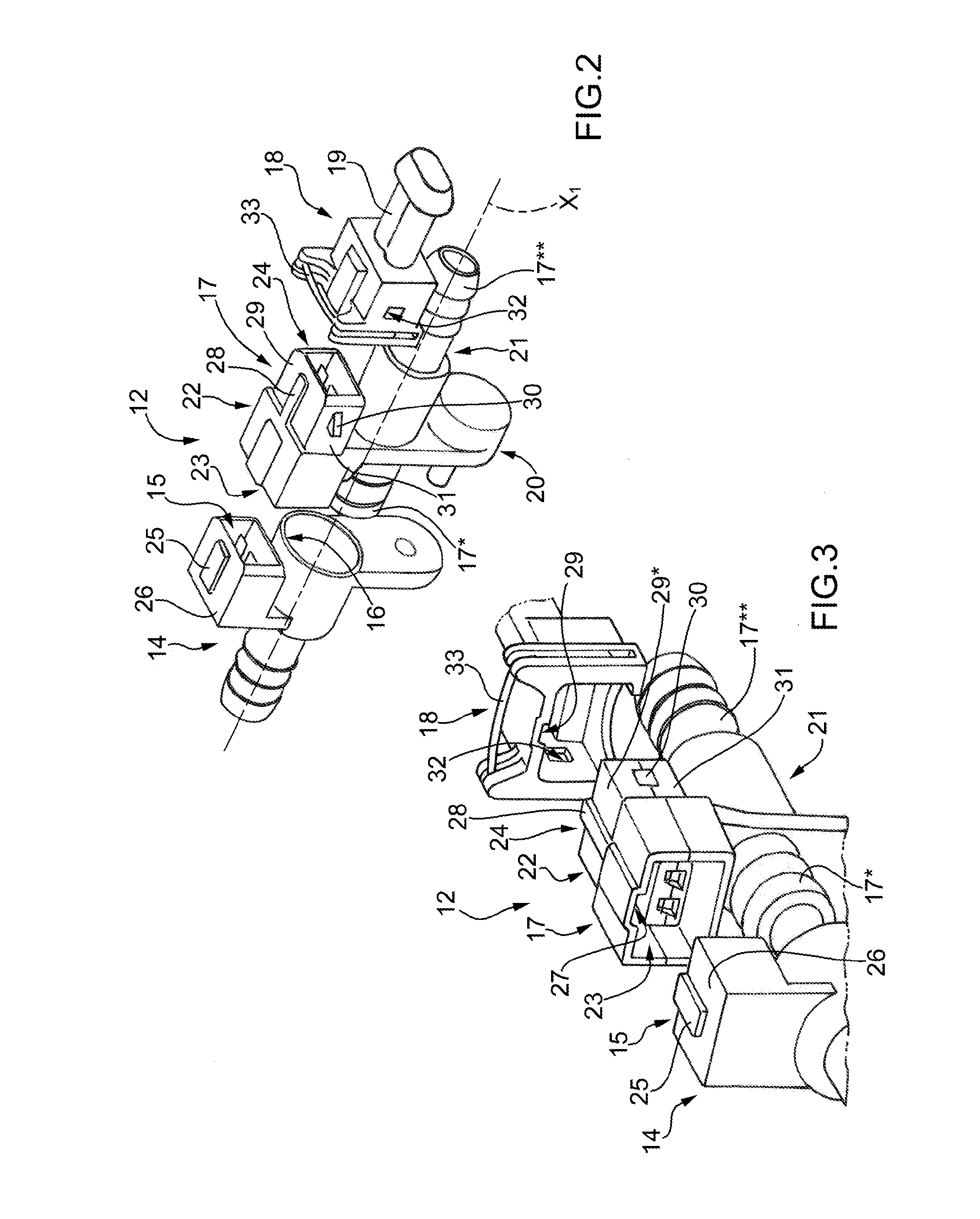

Connecting device for the fluid-tight connection between two pipes in an internal combustion engine

ActiveUS20130196524A1Easy and inexpensiveEngagement/disengagement of coupling partsNon-fuel substance addition to fuelDuctorElectricity

A connecting device for the fluid-tight connection of a first and a second duct provided with a connector having a fixed electrical connection terminal; a mobile electrical connector for establishing an electrical connection with the fixed electrical connection terminal; a control unit suited to check the presence of a connection between the fixed electrical connection terminal and the mobile electrical connector; and an intermediate connecting body interposed in use between the connector and the mobile electrical connector, suited to establish an electrical connection between the fixed electrical connection terminal and the mobile electrical connector and suited to allow the fixed electrical connection terminal and the mobile electrical connector to be coupled to each other, only when there is a fluid-tight joint between the two ducts.

Owner:SPAN FERRARI SPA

Wear detector for ink fountain films

ActiveUS20070131125A1Improve the immunityInexpensive solutionPrinting processesPrinting press partsEngineeringPrinting press

Owner:HEIDELBERGER DRUCKMASHINEN AG

Inking unit for rotary printing machine

An inking unit for a rotary printing machine includes an ink fountain, a pivotable ink fountain holder in which the ink fountain is mounted, an ink ductor, and a pivotable ink ductor holder in which the ink ductor is mounted. The ink ductor holder and the ink fountain holder are connected by an operating cylinder so that ductor and the ink fountain can be pivoted jointly to a first position in which ink flows out of the ductor without flowing out of the fountain, and so that the ductor can be pivoted away from the first position to a second position while the ink fountain remains in the first position, thereby creating a gap between the ductor and the ink fountain.

Owner:MANROLANAD AG

Wear detector for ink fountain films

ActiveUS7574957B2Avoid damageReduce quality problemsPlaten pressesPrinting processesPrinting pressMechanical engineering

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com