Stretch wrap films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

The following example describes the properties of films prepared using a blend of a metallocene-catalyzed polyethylene (PE) resin with a linear low density polyethylene (LLDPE) resin. These blends can be used to construct the puncture resistant film layer of the multilayer films of the present invention.

Various films were prepared from a resin blend containing a LLDPE resin, Resin A, and a metallocene-catalyzed PE resin, Resin B. The LLDPE resin, Resin A, was a resin having a density of 0.918 g / cm.sup.3, a 3.3 MI, a M.sub.n of 22,000 and a M.sub.w of 77,000. The metallocene-catalyzed PE resin, Resin B, was a hexene co-polymer polyethylene having a 3.3 MI, 0.918 g / cm.sup.3 density, a M.sub.n of 26,000 and a M.sub.w of 73,000. The resins were blended together and melted to form a homogeneous blend, and then extruded into a cast film having a thickness of about 0.8 mils. The film was then tested for various properties as set forth in Table 1.1.

The films were also tested for performance...

example 2

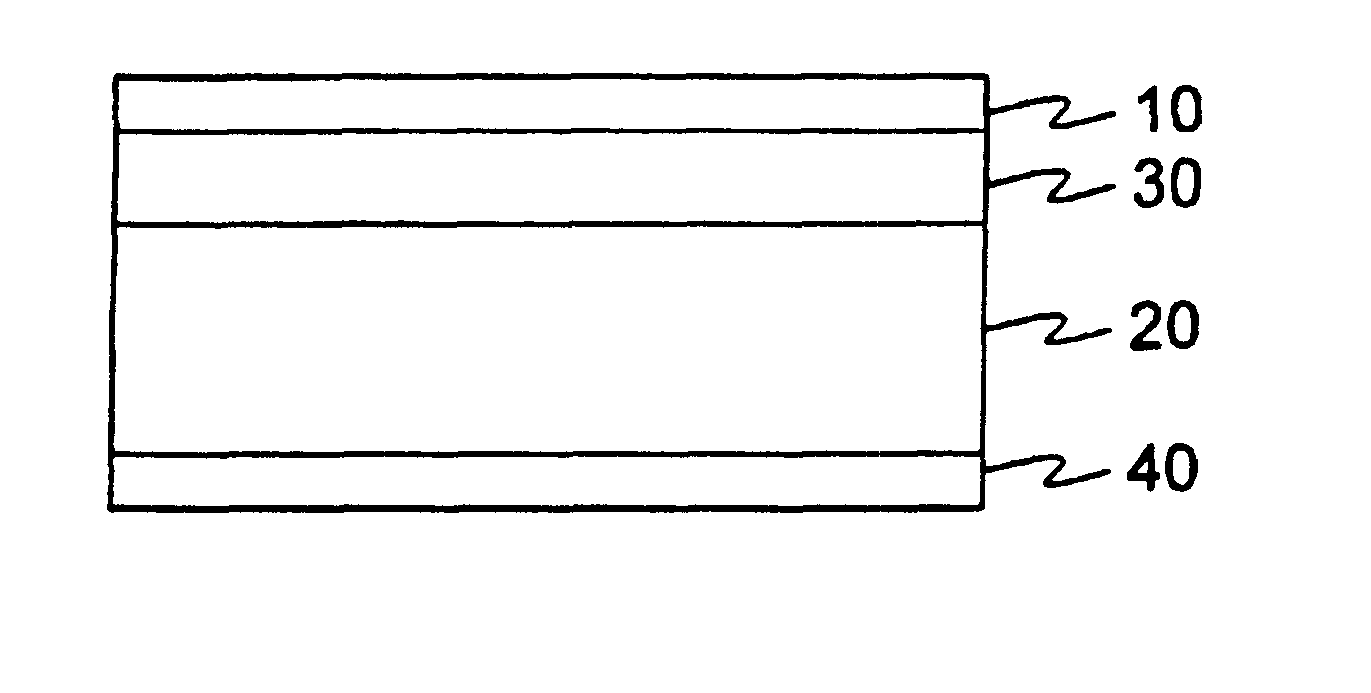

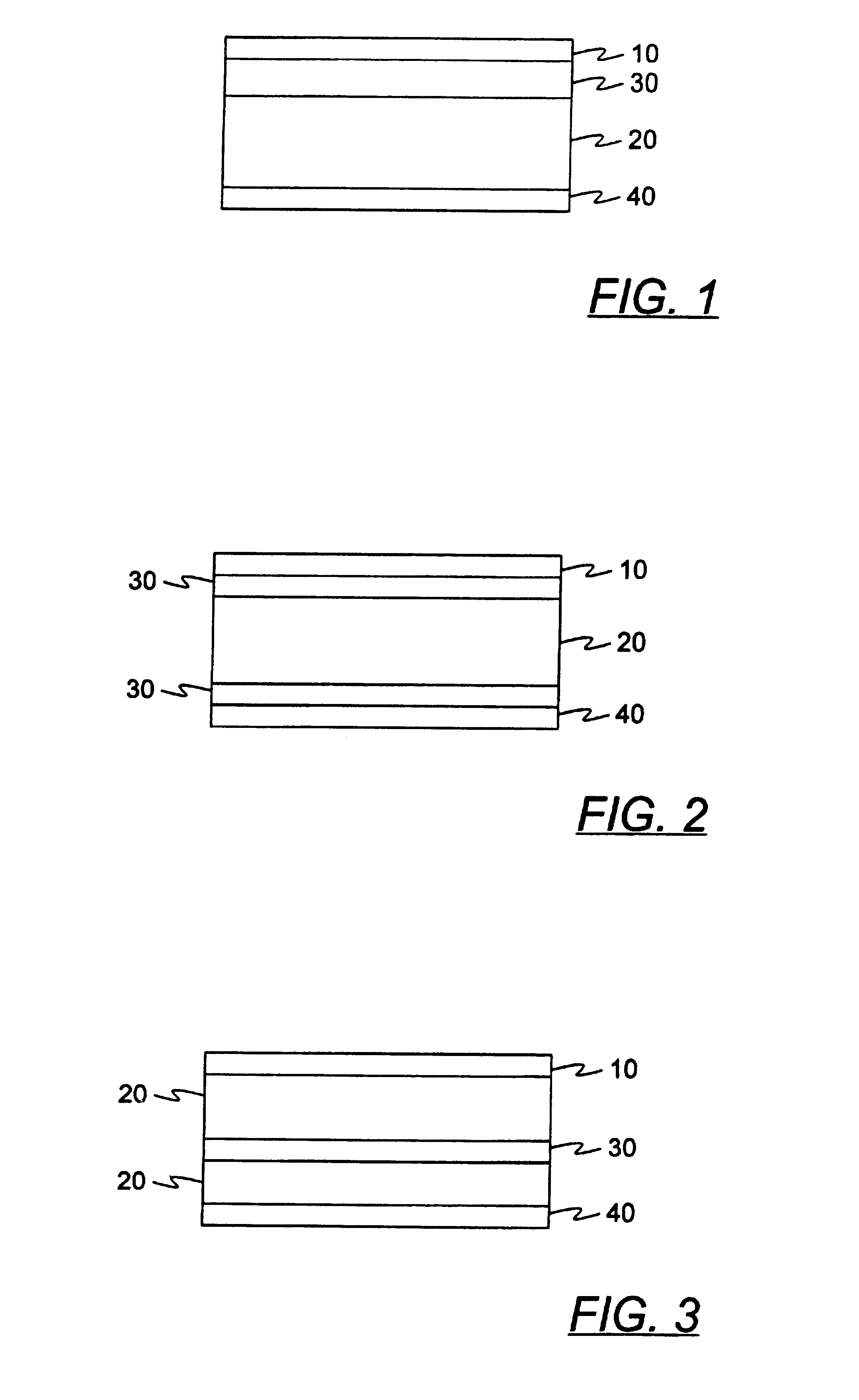

Experiments were conducted to analyze the properties of a film containing a layer of a metallocene-catalyzed polyethylene (PE) resin between slip and cling outer film layers. Films were constructed having a three layer construction, ABC, where the films were constructed with an outer slip layer, layer A, constructed from the resins set forth in Table 2.1. The LLDPE1 resin was a polyethylene hexene copolymer resin having a MI of 4 and a density of 0.941 g / cm.sup.3, the LLDPE2 resin was a polyethylene hexene copolymer resin having a MI of 2 and a density of 0.941 g / cm.sup.3, and the PP resin was a polypropylene hexene copolymer resin having a melt flow rate of 4 and a density of 0.90 g / cm.sup.3. The outer cling layer, layer C, was constructed from a polyethylene methyl acrylate (EMA; 28% methyl acrylate) copolymer resin having a MI of 5 and a density of 0.908 g / cm.sup.3. The inner core layer, layer B, was constructed from a metallocene-catalyzed LLDPE resin with a MI of 2.5 and a dens...

example 3

Experiments were conducted to analyze the properties of films utilizing a layer of a strain hardening resin possessing superior transverse direction tear properties along with a layer of a metallocene-catalyzed PE resin. This film construction can be used as the interior core of a multilayer film of the present invention, with the inclusion of an outer slip and an outer cling layer to complete the inventive film construction. Three films were prepared having a BCB film construction where the outer B layers were constructed with the metallocene-catalyzed PE resin used in Example 1, and the C core layer was a 2.0 MI LDPE resin, having a density of 0.921 g / cm.sup.3. The two resins were coextruded with the overall B resin content set forth in Table 3.1, that content being essentially evenly split between both outside film layers. The films were then tested for various properties as set forth in Table 3.1.

The films were also tested for performance in a stretch wrap tester as in Example 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com