Method and device for producing granulated polycrystalline silicon in a fluidized bed reactor

a technology of fluidized bed reactor and granulated polycrystalline silicon, which is applied in the direction of silicon compounds, lighting and heating apparatus, furnaces, etc., can solve the problems of reactor outages, reactor thermal loading, and disadvantageous increase of operating costs with such process management, so as to reduce the space-time yield of the reactor, reduce the economic viability of the method, and improve the effect of heat transpor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

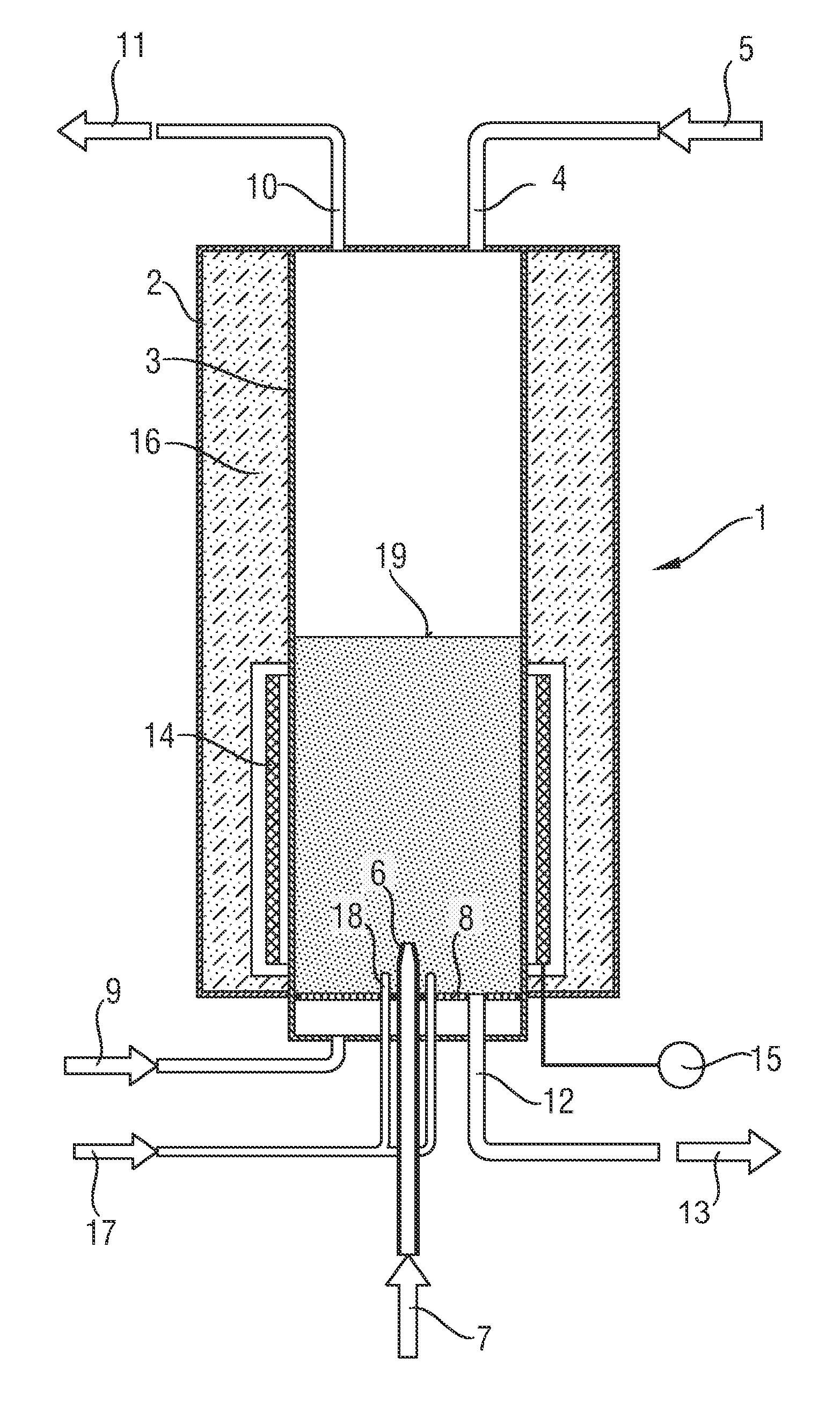

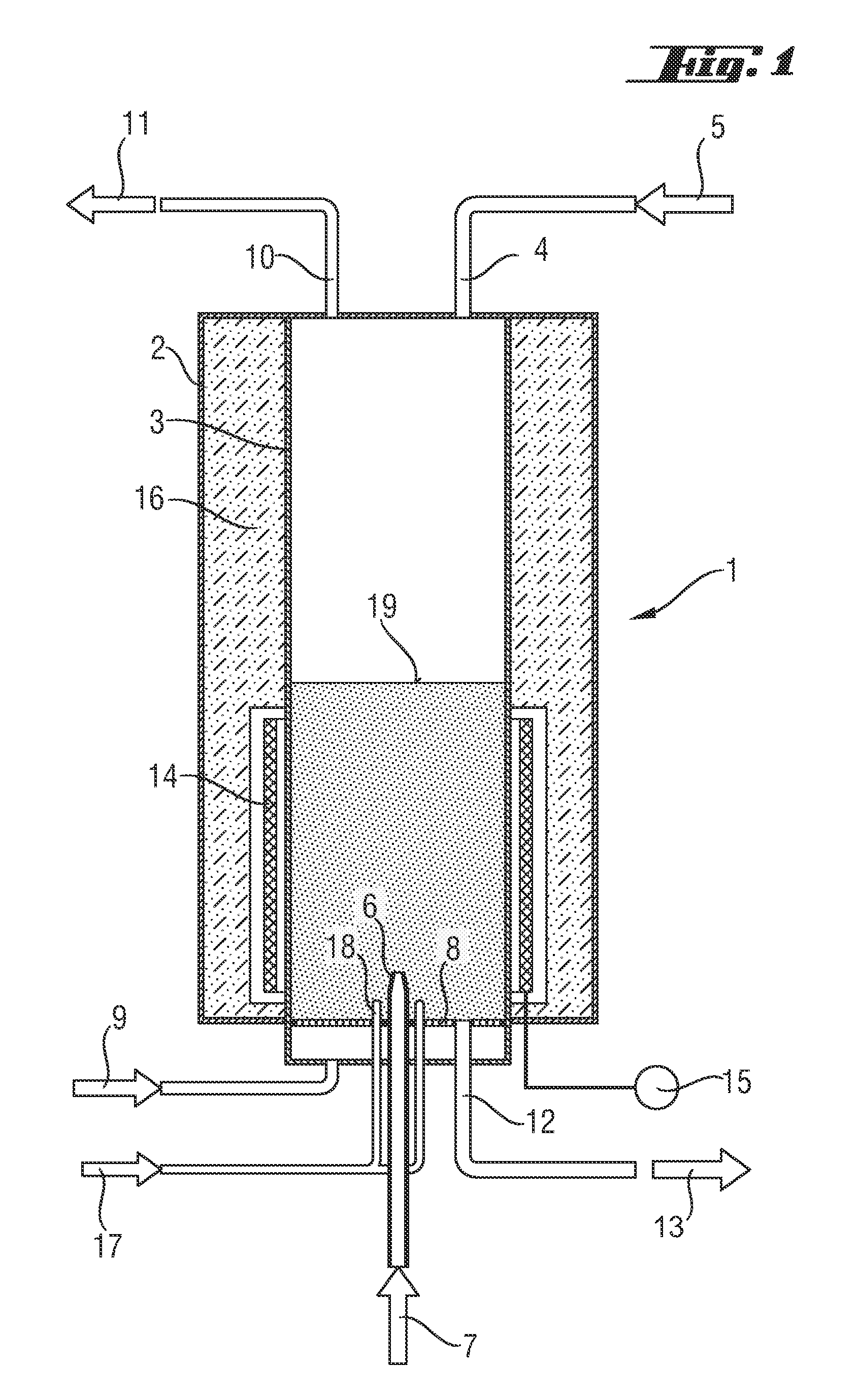

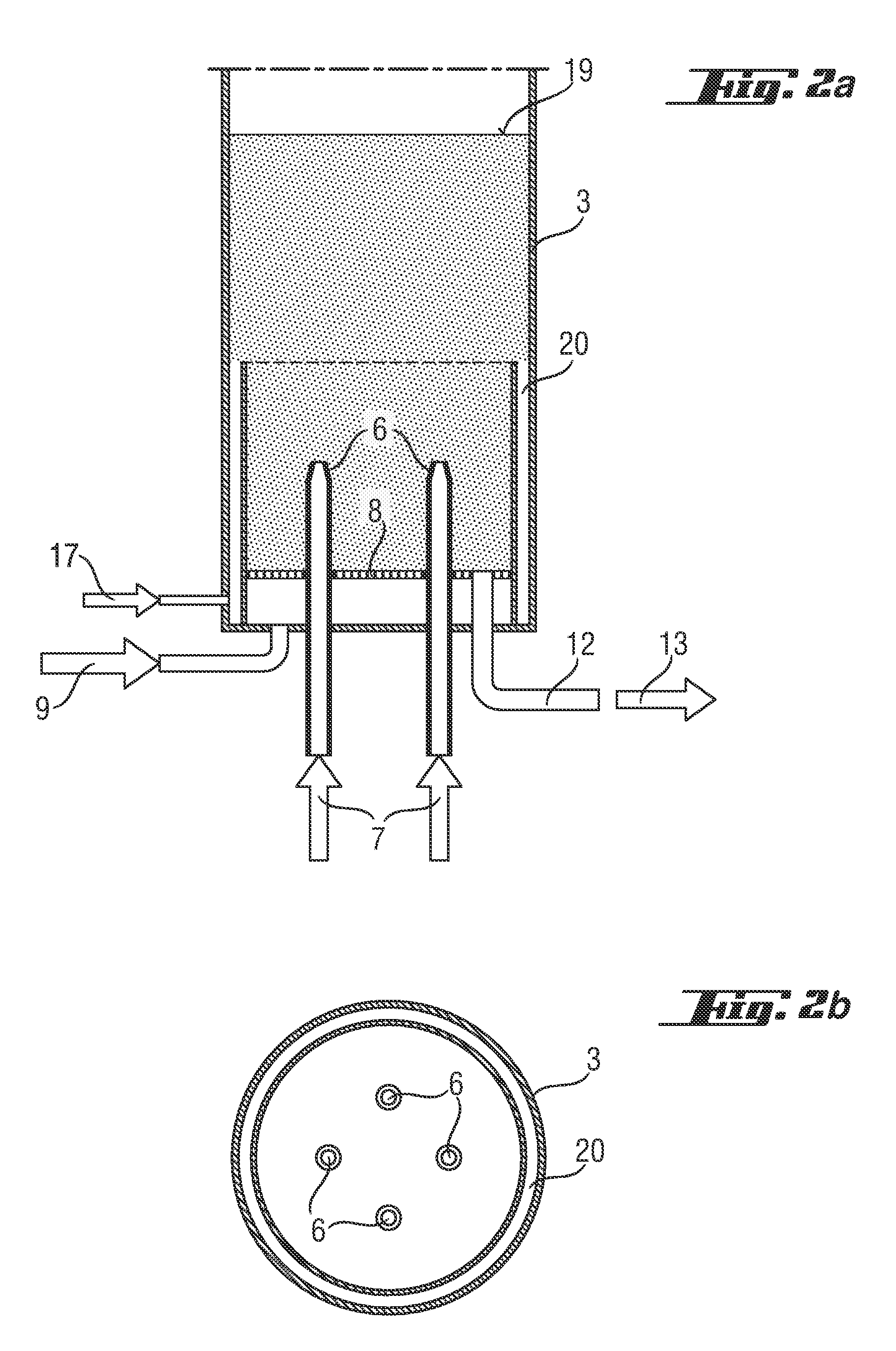

[0053]A pressure-proof steel vessel with an inner diameter of 770 mm contains the inner reactor tube, namely a quartz tube with an inner diameter of 600 mm and a length of 2200 mm. At the lower end of the quartz tube, a plate of quartz provided with openings forms the gas distributor for the fluidizing gas. Arranged in a central circle with a diameter of 250 mm, further quartz tubes with an inner diameter of 20 mm and a length of 250 mm project from the gas distributor plate into the inner reactor tube 4 as an inlet device for supplying the gas or gas mixture containing silicon. The quartz plate is furthermore provided with two openings to remove product.

[0054]A radiation heater is provided for introducing energy into the reactor by means of thermal radiation. It comprises plates of graphite annularly connected to one another, which surround the inner reactor tube without touching it. The radiation heater was supplied with electrical power via an adjustable voltage source. Its maxim...

examples 2 to 9

[0059]Similarly as in Example 1, with conditions otherwise remaining the same, the parameters operating temperature, nozzle wall temperature, reactor wall temperature and the reaction gas concentrations on the wall and on the nozzle were varied, and the maximum deposition / h on the wall and on the inlet device were determined. Tab. 1 lists the varied conditions and the maximum deposition of silicon on the wall. Tab. 2 lists the varied conditions and the maximum deposition of silicon on the inlet device.

[0060]

TABLE 1variation of the operating parameters andsilicon deposition on the reactor wall with a reactorpressure of 2 bar absoluteReaction gasOperatingReactor wallconcentrationWalltemperaturetemperaturelocally on thedepositionExample(° C.)(° C.)wall (mol. %)(μm / h)1 (C)9009100.10.8290091050.023 (C)9008000.12.04 (C)90080051.15 (C)100010100.11.061000101050.017 (C)10009000.12.58 (C)100090051.2995095020.02

[0061]

TABLE 2variation of the operating parameters andsilicon deposition on the noz...

examples 10 to 16

[0063]The following components were installed in the reactor according to Example 1:

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com