Commercial production method for edible mushroom liquid culture bacteria, apparatus and automatic sterilized inoculator

A technology of liquid cultivation and production method, which is applied in the fields of botany equipment and method, application, gardening, etc., and can solve the problems that edible fungus liquid cultivation strains cannot be popularized and applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

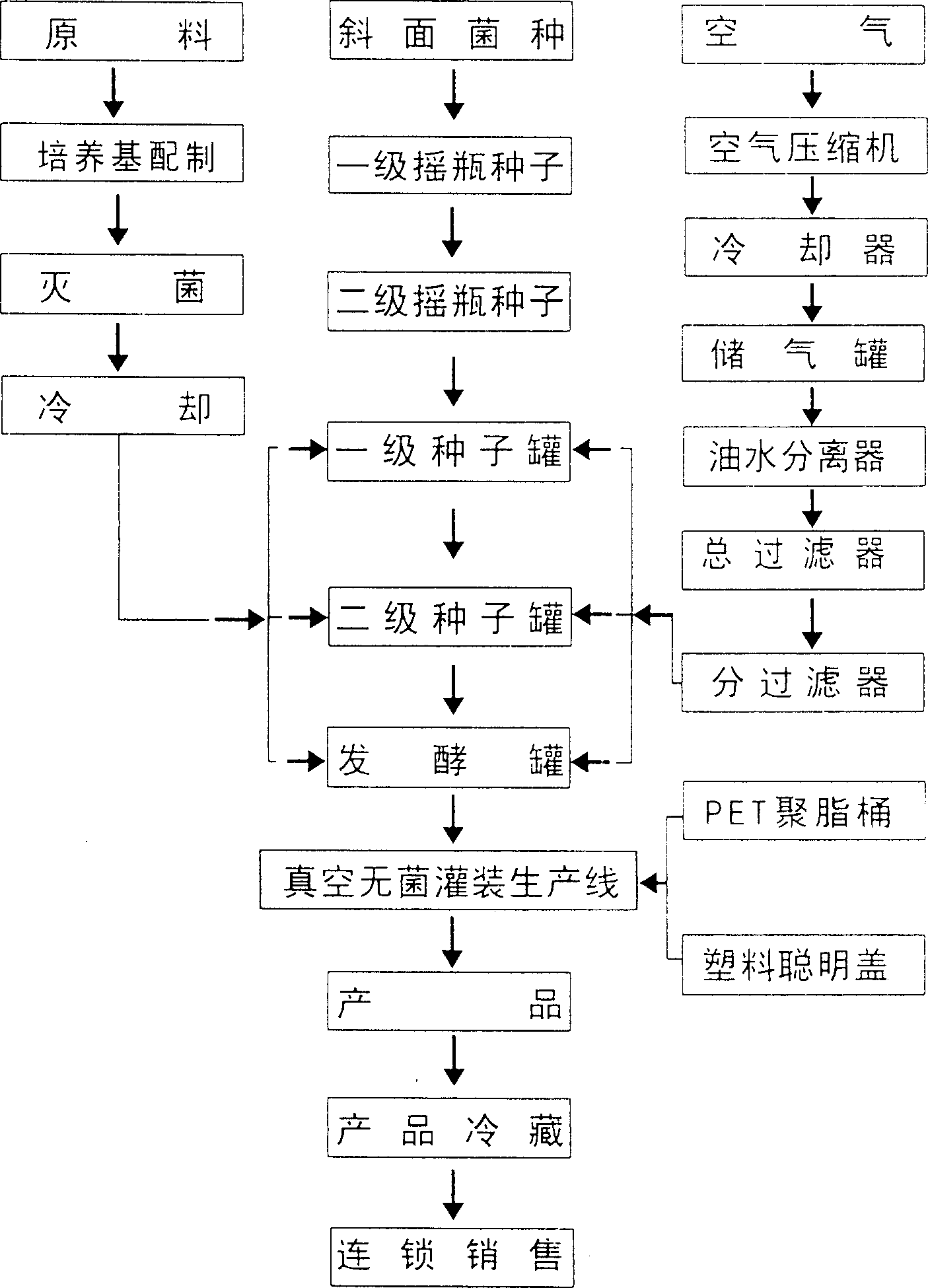

[0105] Such as figure 1 Shown: commercial production process of edible fungus liquid culture strains

[0106] Seed preparation

[0107] The purpose of seed preparation is to maximize the propagation of a sufficient number of robust, high-purity seeds; the quality of the seeds has a great impact on fermentation; the quality of the seeds depends on the strain itself on the one hand, and on the other hand determines in seed culture conditions;

[0108] 1. Seed requirements for submerged fermentation of edible fungi

[0109] (1) The bacteria grow vigorously and have strong vitality

[0110] The vigor of the seeds is related to the nutritional status and bacterial age of the culture medium; a nutrient-rich seed culture medium should be selected, preferably without a synthetic medium; the bacterial age of the seeds is usually controlled in the late logarithmic growth phase of the thalline; as Flammulina velutipes, The age of the seed bacteria is preferably 48-96 hours;

[0111]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com