Under bump metallization pad and solder bump connections

a technology of metallization which is applied in the direction of semiconductor devices, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problems of requiring a substantial requiring a large number of discrete steps, and the above-mentioned patents and prior art techniques for forming ubm pads and solder bumps are relatively complex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

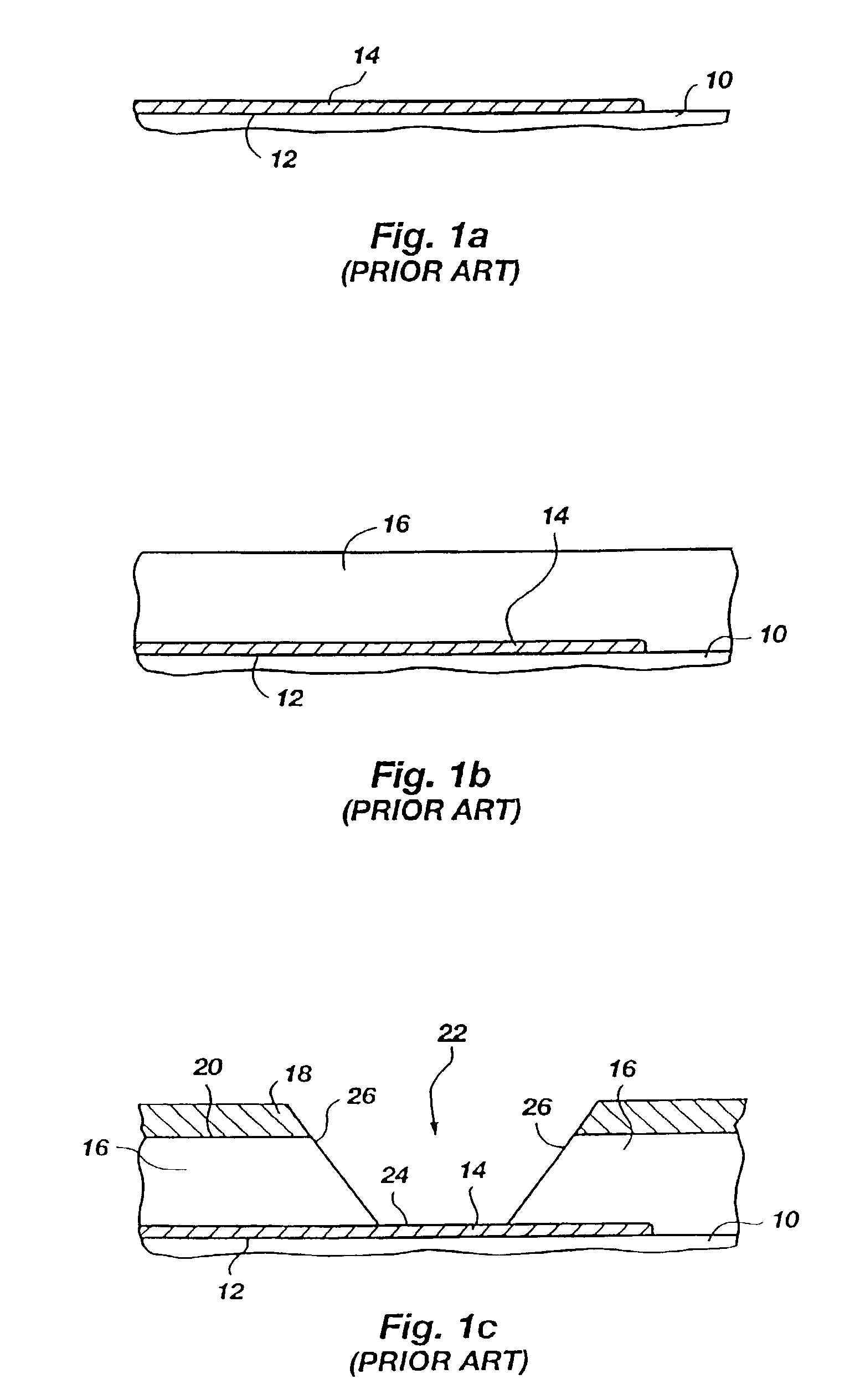

[0030]FIGS. 3a–3e illustrate a preferred method of forming UBM structures and flip chip solder bump connections in accordance with the present invention. FIG. 3a shows a first metal layer 70 applied over the passivation film face surface 60 as well as the via 62 of the structure shown in FIG. 2d. Metal layer 70 is preferably formed of Titanium (Ti), and is preferably between approximately 500 to 3000 Å thick. A second metal layer 72 is applied over the first metal layer 70 as illustrated in FIG. 3b. Second metal layer 72 is preferably formed of Nickel (Ni), and is preferably between 500 and 5000 Å thick. Although FIG. 3b illustrates first layer 70 and second layer 72 preferably as being discrete layers, the invention is not so limited and only a single layer comprised of a mixture of titanium and nickel may be used. The layers 70, 72 may be applied by any method as is known in the art, such as for example by chemical vapor deposition (CVD), physical vapor deposition (PVD) sputtering...

second embodiment

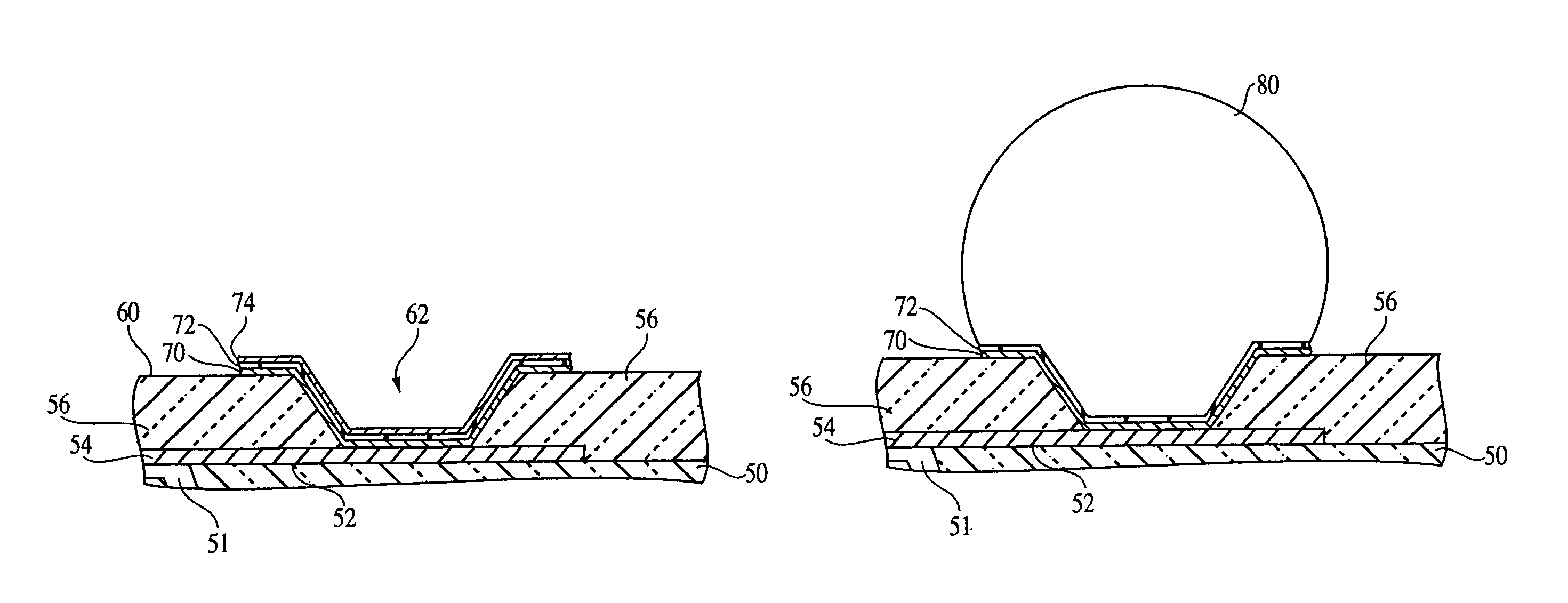

[0032]FIGS. 4a–4c illustrate a preferred method of forming a UBM pad and flip chip solder bump connections according to the present invention. In this embodiment it is preferable that the conductive traces or bond pads 54 on the semiconductor wafer face surface 52 are formed of copper. As shown in FIG. 4a, metal layer 82, preferably formed of gold (Au), silver (Ag) or palladium (Pd), is deposited or flashed over the passivation film face surface 60 as well as the via 62 of the structure shown in FIG. 2d. Metal layer 82 is preferably between 50 and 1000 Å thick.

[0033]A solder bump 80 is deposited on the layer 82 by any known industry technique, such as stenciling, screen printing, electroplating, electroless plating, evaporation, laser ball shooters, or the like as shown in FIG. 4b. Alternatively, solder bump 80 may also be formed utilizing a standard wire bonder as will be described below. When solder bump 80 is reflowed, the flash layer 82 will be consumed by solder ball 80, leavin...

third embodiment

[0034]FIGS. 5a–5c illustrate a preferred method of forming a UBM structure and flip chip solder bump connections according to the present invention. In this embodiment, a via 62 of the structure shown in FIG. 2d is plated with nickel (Ni) 84 as illustrated in 5a. It should be noted that although FIG. 5a shows the nickel plating as being at the same level as the top surface of passivation film 56, the upper surface of the nickel 84 may also be at a level which is higher or lower than the top surface of the passivation layer 56. Then, as shown in FIG. 5b, metal layer 86, preferably formed of gold (Au), is deposited or flashed over the plated nickel (Ni) 84. Although FIG. 5b shows the upper surface of metal layer 86 as being above the top surface of the passivation film 56, it could also be at the same level or below the level of the top surface of the passivation film 56.

[0035]A solder bump 80 is deposited on the layer 86 by any known industry technique, such as stenciling, screen pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com