Short-wavelength laser module and method of producing the same

a laser module and short-wavelength technology, applied in the direction of semiconductor lasers, active medium materials, instruments, etc., can solve the problems of lowering the output of blue light, losing long-term reliability, and lowering the output of optical outpu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

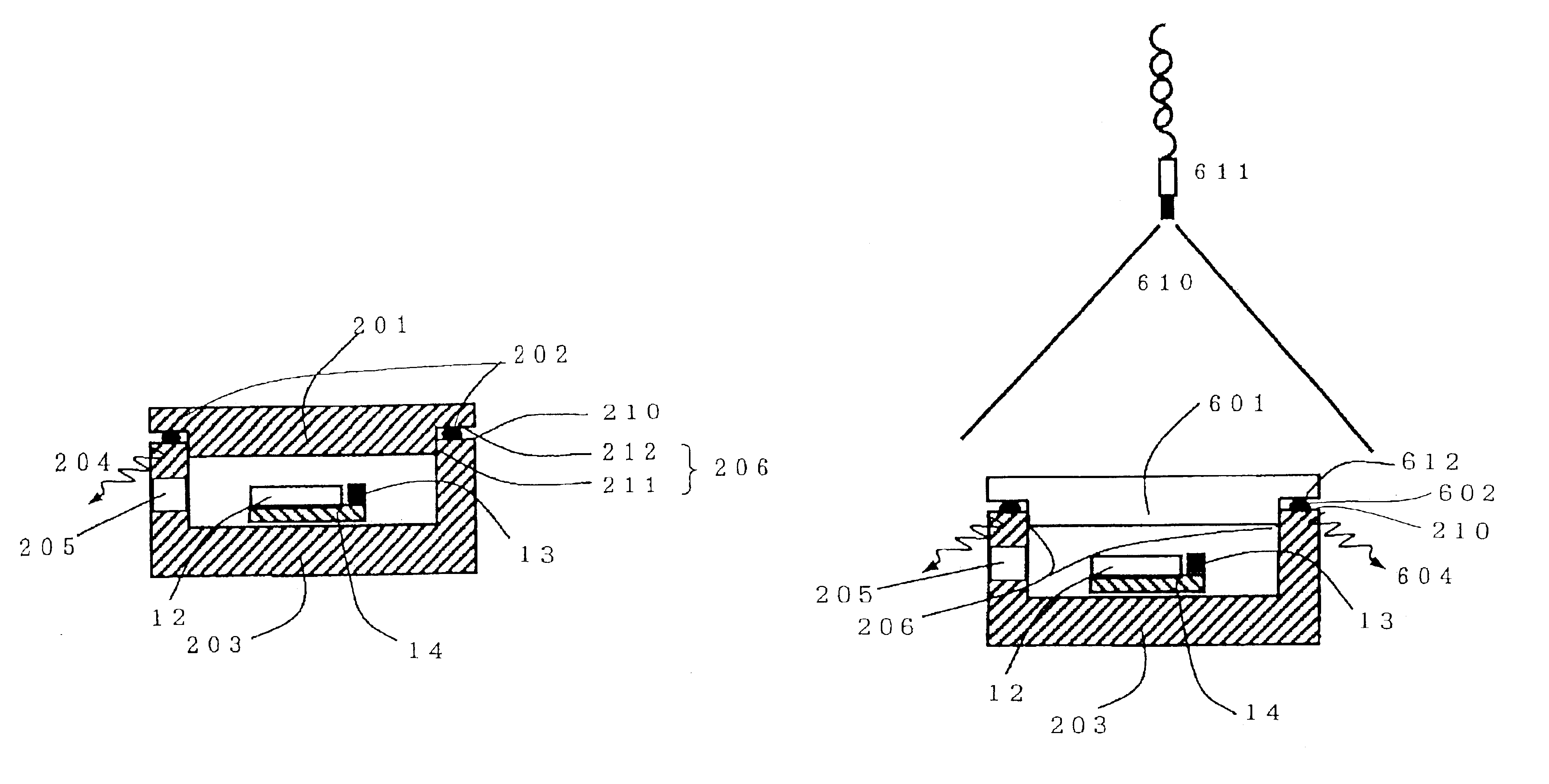

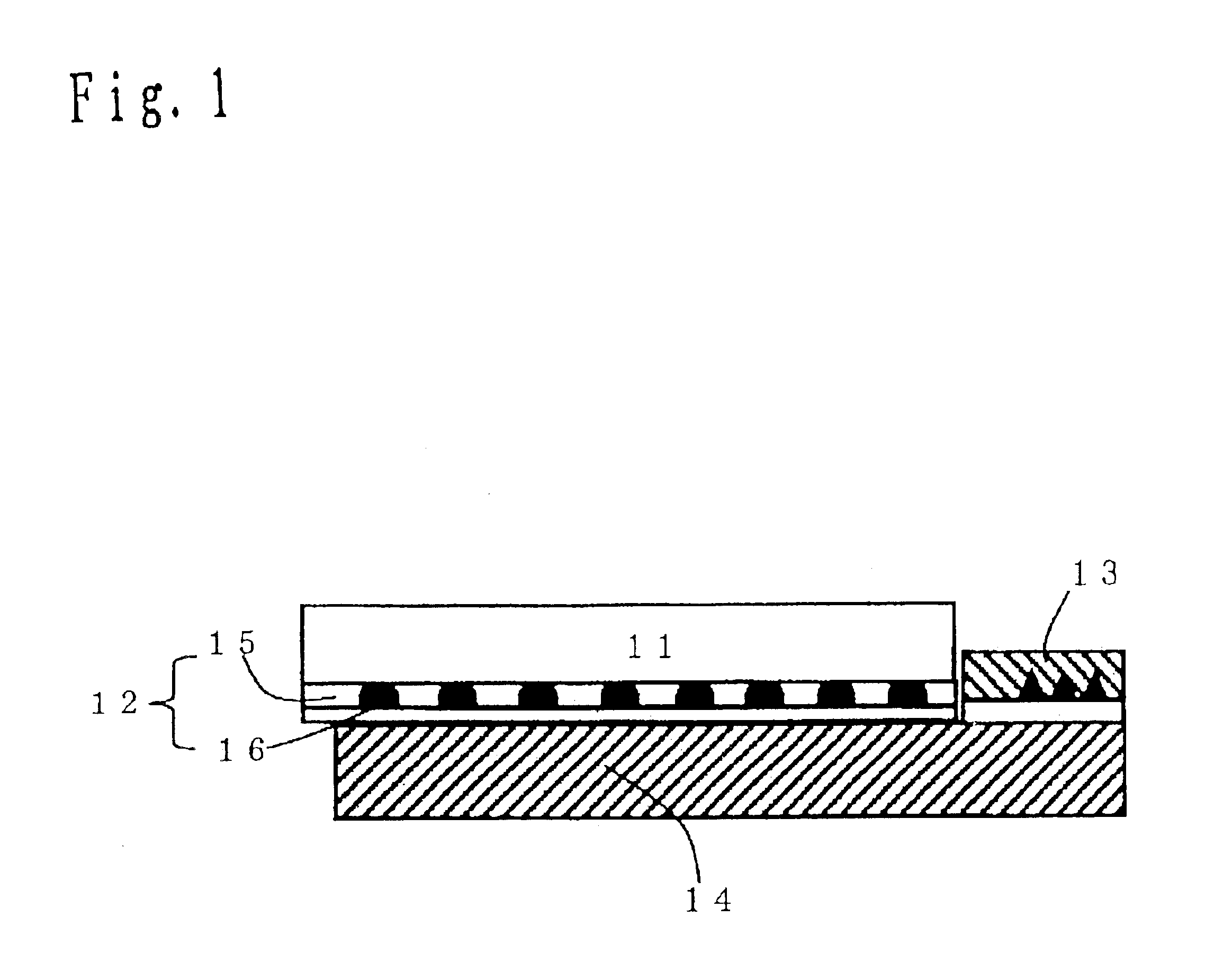

Image

Examples

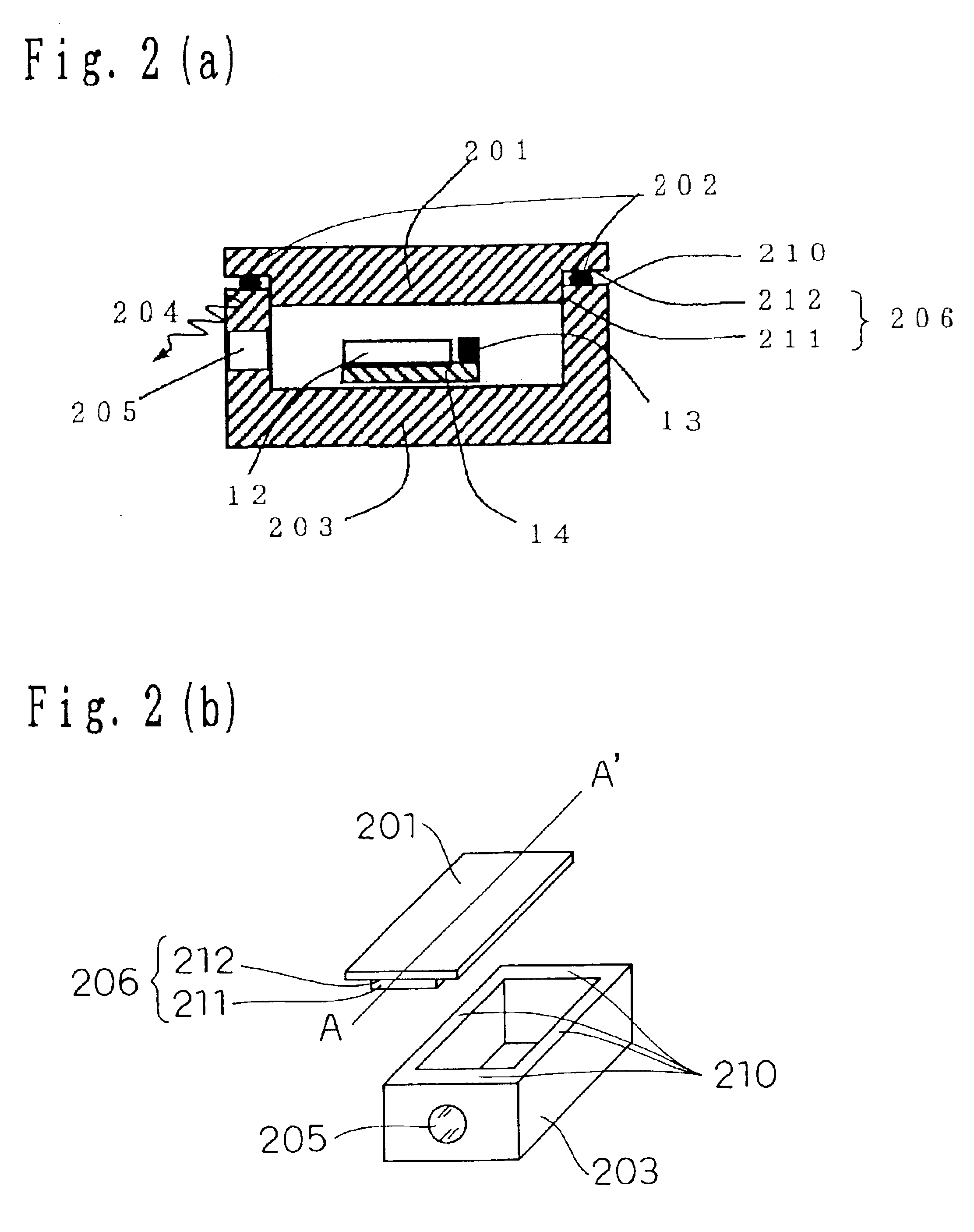

example 2

When the operating temperature and storage temperature of the SHG blue light source rise, it is necessary to set a heat treatment temperature so as to be higher than the operating temperature and storage temperature in order to prevent the generation of unnecessary gas; in addition, as the heat treatment process at that time, it is necessary to set a process wherein the influence due to thermal diffusion to the optical waveguide portion can be neglected. When using the SHG blue light source as an optical disc light source, it is necessary to use a heat treatment process of 85° C. or more, since the upper storage temperature is generally 85° C. The heat treatment process to eliminate unnecessary gas was carried out at 100° C. for 10 hours. The diffusion amount d at the waveguide due to heat diffusion at this time can be represented by d=2×[D(T)×t]1 / 2 (D: a diffusion constant and a function of T, T: a heat treatment temperature, and t: a heat treatment time).

Usually, the heat treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com