Analytical method and apparatus

an optical surface and analytical method technology, applied in the direction of measuring devices, scattering properties, instruments, etc., can solve the problems of limited technique, one-dimensional sensor area, spr-based methods used,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

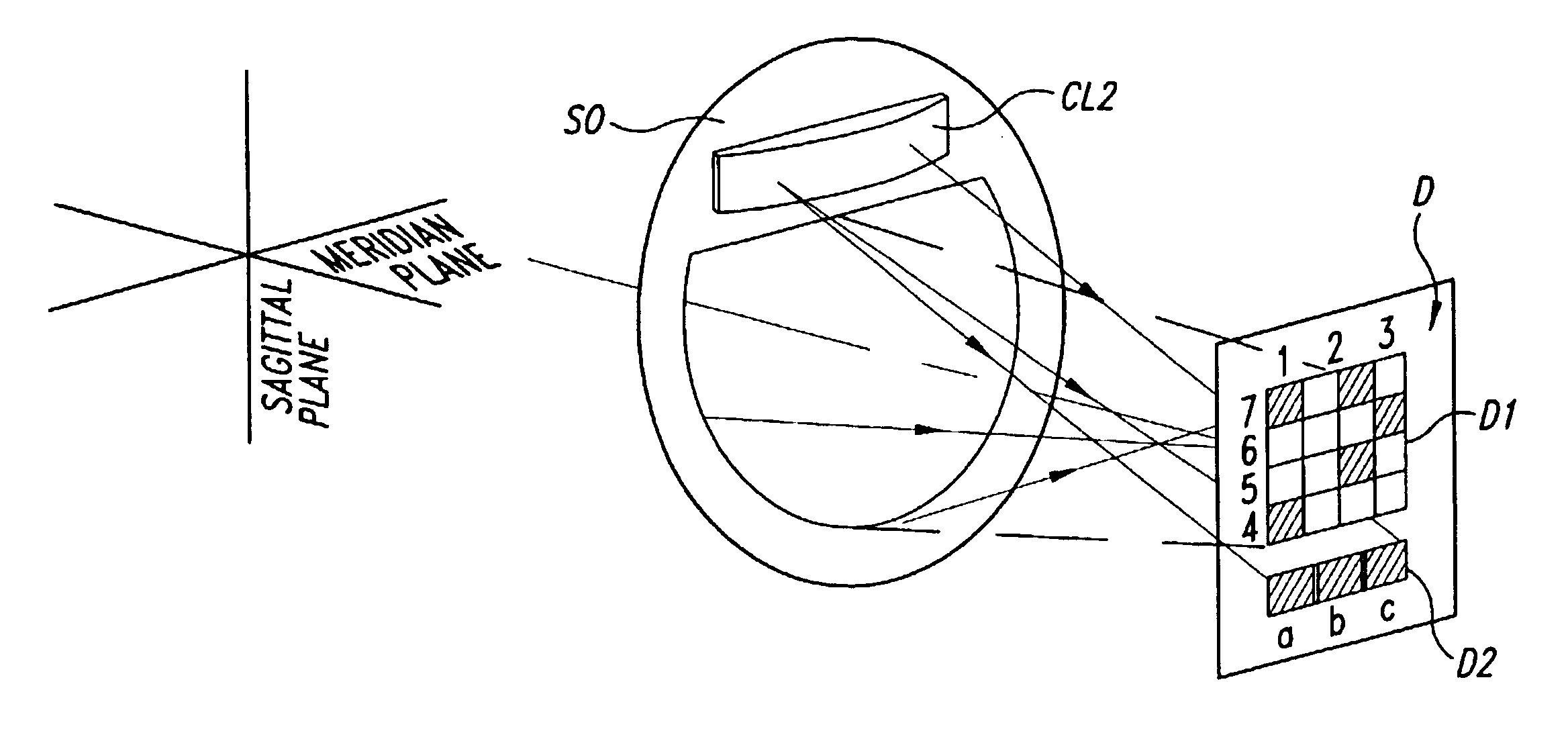

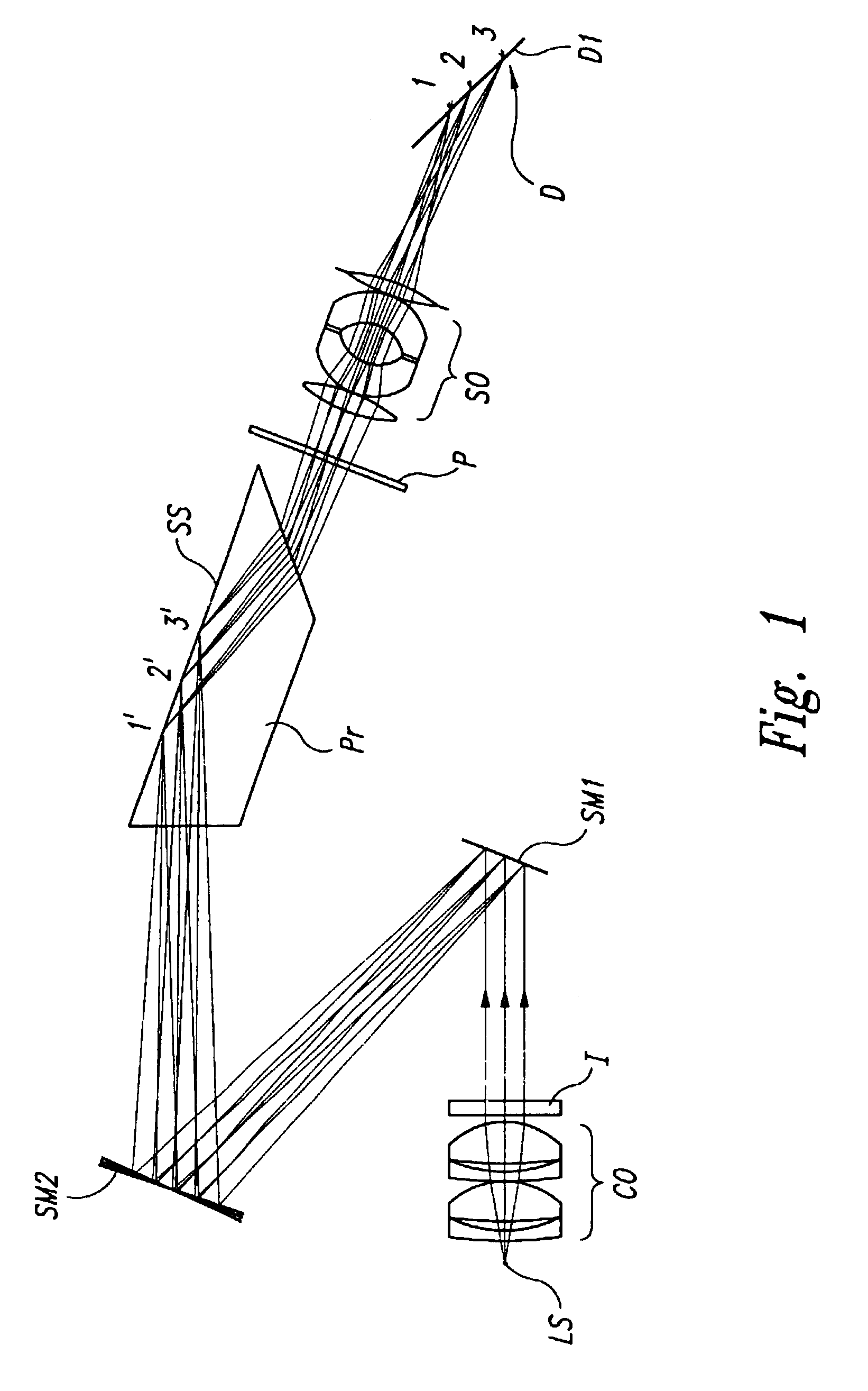

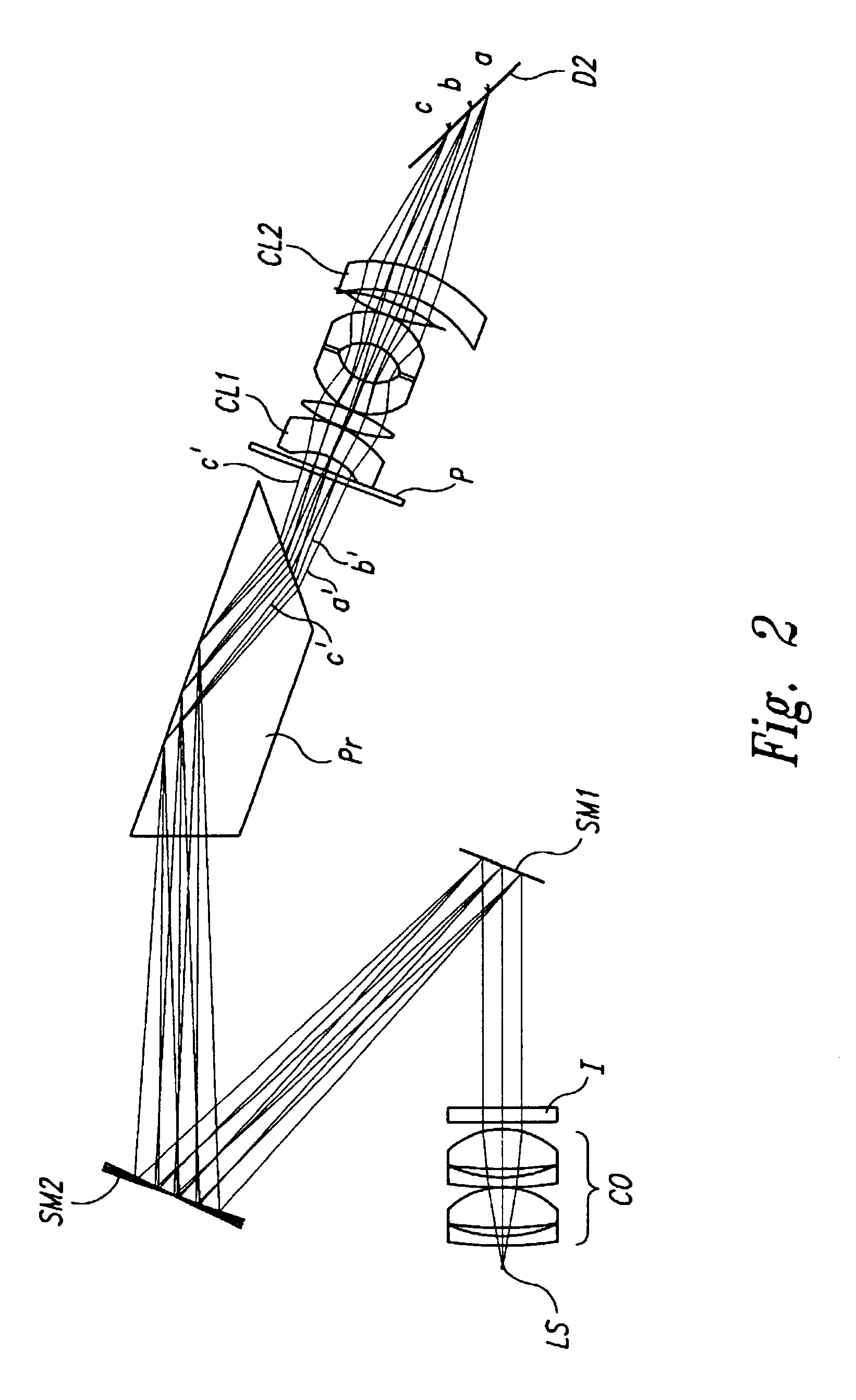

The principle of the present invention was verified as demonstrated in FIGS. 24a-24d, by use of a pivotally moving illumination system similar to the one described in FIG. 22, using a light emitting diode of center-wavelength 766 nm, lenses and a sheet-polarizer providing p-polarized collimated beam of diameter 8 mm, an interference filter of bandwidth 3 nm, an imaging embodiment according to FIGS. 3, 4, and 5, and a CCD-photodetector matrix connected to a video-recorder. The obscuration, imaged as the dark right part in FIGS. 24a-24d covering about 25% of the image, is positioned at the interference filter I, FIG. 23, decentered in relation to the beam cross-section, so that it covers about 15% of the beam width.

FIGS. 24a-24d show a series of SPR-images of a sensor surface exposed to rinse solution in a flow cell, the sensor surface consisting of sixteen zones of various refractive index (optical thickness), zone size 0.5 mm.times.0.5 mm, each image at a specific angle of incidence...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com