Heat exchanger made of an aluminum alloy

a technology of aluminum alloy and heat exchanger, which is applied in the direction of manufacturing tools, soldering devices, light and heating equipment, etc., can solve the problems of inability to repair anymore, difficulty in adding additional steps, and defect that crevice corrosion is apt to take place at the boundary, so as to improve the corrosion resistance of the refrigerant passage component, improve the corrosion resistance, and reduce the self-corrosion resistance of the filler material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

First, the following shows an example for the first and second filler material.

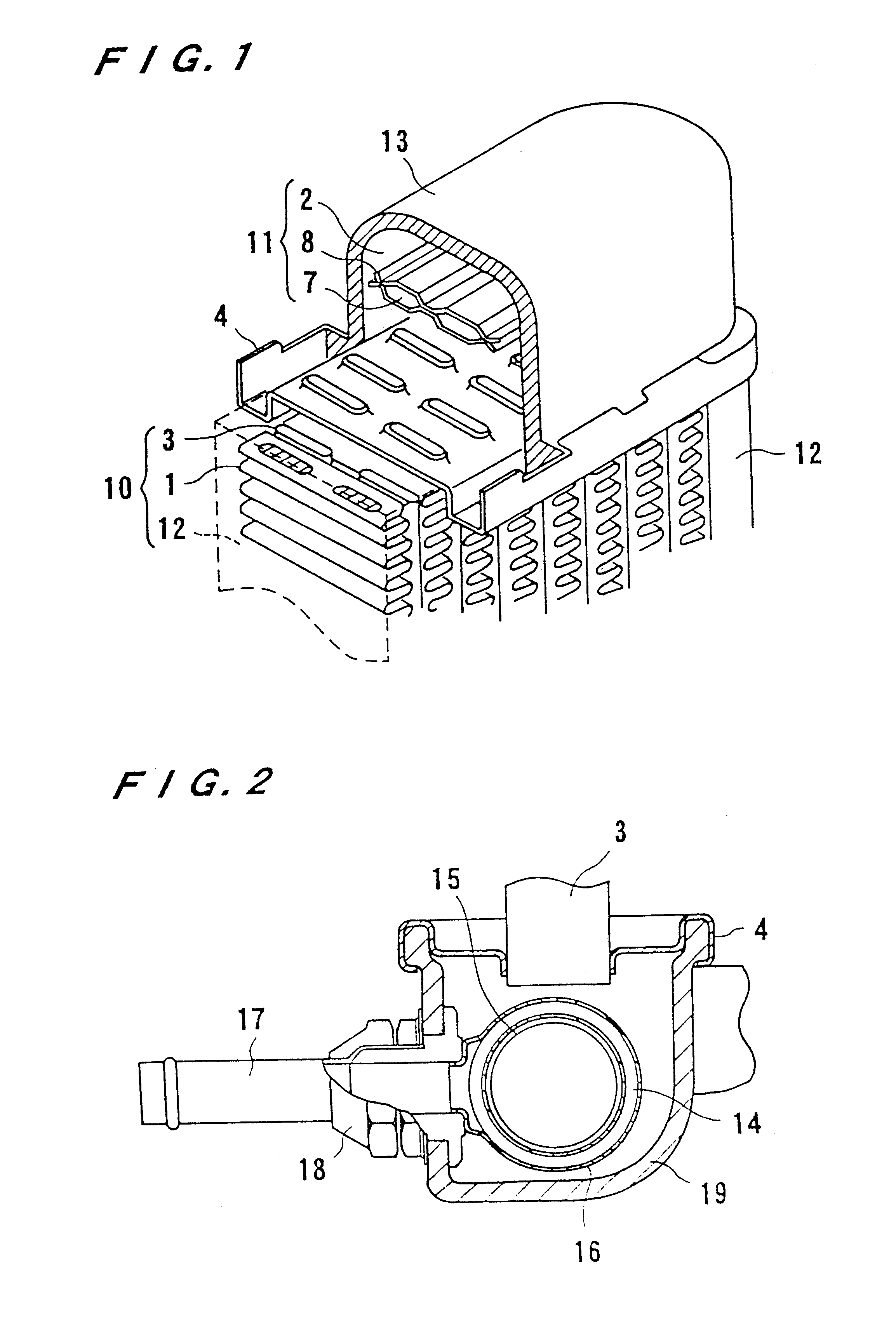

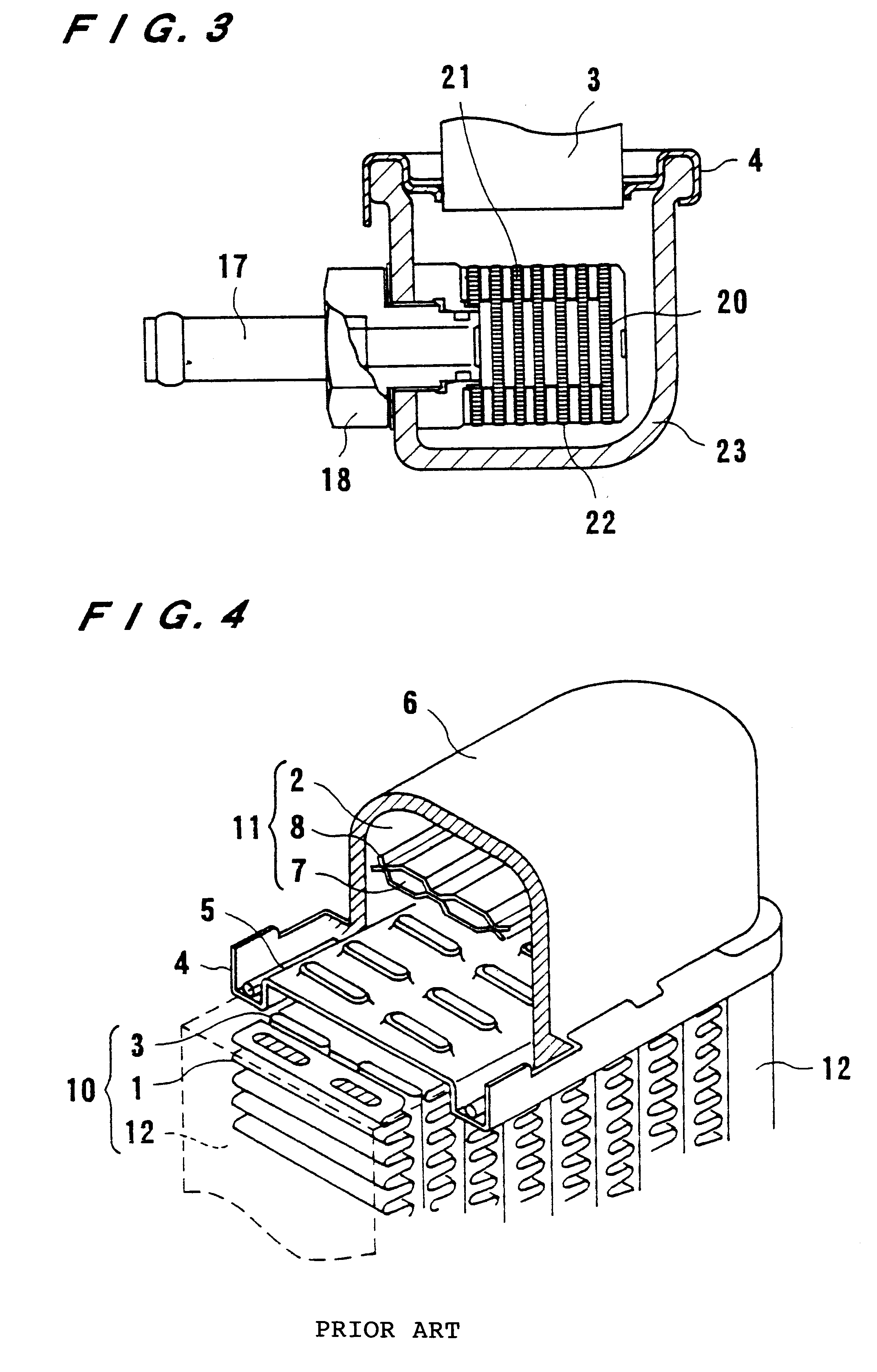

A heat exchanger wherein a radiator and an oil cooler were integrally formed as shown in FIG. 1 and the tank material was aluminum alloy brazing sheets was produced under heating conditions of 600.degree. C..times.5 min. Any packings were not used. The materials of the radiator are shown in Table 1. The tubes of the radiator were tubes electroseamed by using the tube material shown in Table 1. As the material for the oil cooler, brazing sheets having the following constitution were used. In their constitution, the brazing sheets were made by press molding O-material plates having a thickness of 0.6 mm, wherein the core material was an Al-0.5 wt % Si-0.3 wt % Fe-0.5 wt % Cu-1.1 wt % Mn alloy, the sacrificial material outside the core material of an Al-2 wt % Zn alloy was clad thereon, and the brazing alloy inside the core material shown in Table 2, was clad thereon in amounts of 10% for the total thickness...

example 2

The following shows an example for the third to sixth filler materials.

Each of brazing metals having compositions shown in Tables 4 and 5 was clad on one surface of a core material (Al-0.27 wt % Si-0.42 wt % Fe-1.1 wt % Mn-0.52 wt % Cu alloy), to prepare brazing sheets having the thickness of 0.50 mm. The brazing sheets were subjected to thermal refining under the specification of JIS grade H14 and the clad ratio of the filler material was 10%.

TABLE 5

Each of the above brazing sheets was subjected to the following brazing test by heating at a brazing temperature shown in Tables 6 and 7.

The brazing sheet was taken as a lower sheet and a sheet (thickness: 0.5 mm) of an Al-1.2 wt % Si-0.25 wt % Fe-0.4 wt % Cu-1.1 wt % Mn alloy-H14 material was taken as an upper sheet. The lower sheet was assembled with the upper sheet in the form of a T joint. A brazing portion of the T joint was coated with a liquid containing a potassium fluoride series flux at a concentration of 10% and heated in a N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com