Powderfree medical glove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

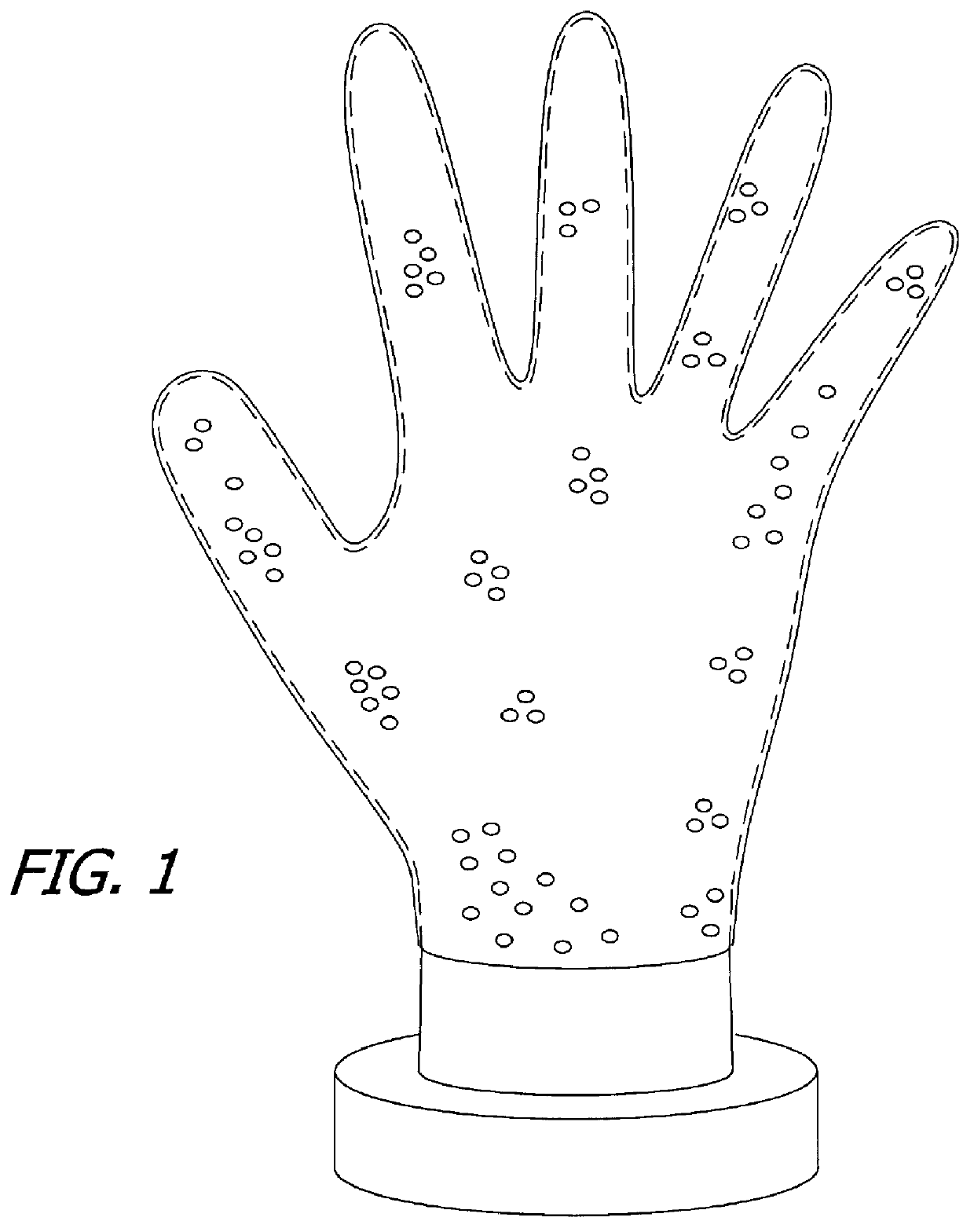

Image

Examples

example 2

A first layer PVC glove is formed and fused in like manner to that in Example 1. The film is cooled to between about 105.degree. C. to about 95.degree. C. The mold having the film on its surface is presented to a spray process that deposits a lognormal distribution of spray droplets with a 4.rho. region of droplet diameters ranging from about 30 microns to about 150 microns in major droplet diameter. The formula is constituted of an aqueous emulsion including a polyurethane dispersion, a surface hardener, a filler, and a thickener to form a spatter finish on the PVC layer. The coating air dries on the film to form a unitary structure. A cuff is then formed on the unitary structure between about 85.degree. C. to about 75.degree. C. The unitary structure is farther cooled to about 70.degree. C. and is stripped and everted to form a glove.

Composition of Formulae for Example 2:

example 3

A first layer PVC glove is formed and fused in like manner to that of Example 1. The film is cooled to between about 120.degree. C. to about 110.degree. C. The mold having the film on its surface is presented to a spray process that deposits a lognormal distribution of spray droplets with a 4.rho. region of droplet diameters ranging from about 30 microns to about 150 microns in major droplet diameter. The formula is constituted of an aqueous emulsion including a polyurethane dispersion, a surface hardener, a filler, and a thickener to form a spatter finish on the PVC layer. The coating air dries to form a unitary structure. A cuff is then formed on the unitary structure at 100.degree. C. to about 80.degree. C. The film is air cooled to approximately 75.degree. C. and the structure is stripped and everted to form a glove.

Composition of Formulae for Example 3:

example 4

A first layer PVC glove is formed and fused in like manner to that of Example 1. A cuff is then formed on the unitary structure between about 90.degree. C. to about 70.degree. C. The film is cooled to between about 80.degree. C. to about 65.degree. C. and the mold having the film on its surface is presented to a spray process. The spray process deposits a lognormal distribution of spray droplets with a 4.rho. region of droplet diameters ranging from about 10 microns to about 90 microns in major droplet diameter. The formula is constituted of an aqueous emulsion including a polyurethane dispersion, a surface hardener, a filler, and a thickener to form a spatter finish on the PVC layer. The coating air dries to form a unitary structure and the structure is stripped at 40.degree. C. and everted to form a glove.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com