Use of a duplex stainless steel object

a technology of stainless steel and object, applied in the field of objects, can solve problems such as failure, hydrogen induced stress corrosion cracking, impact on the strength and ductility of the duplex,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

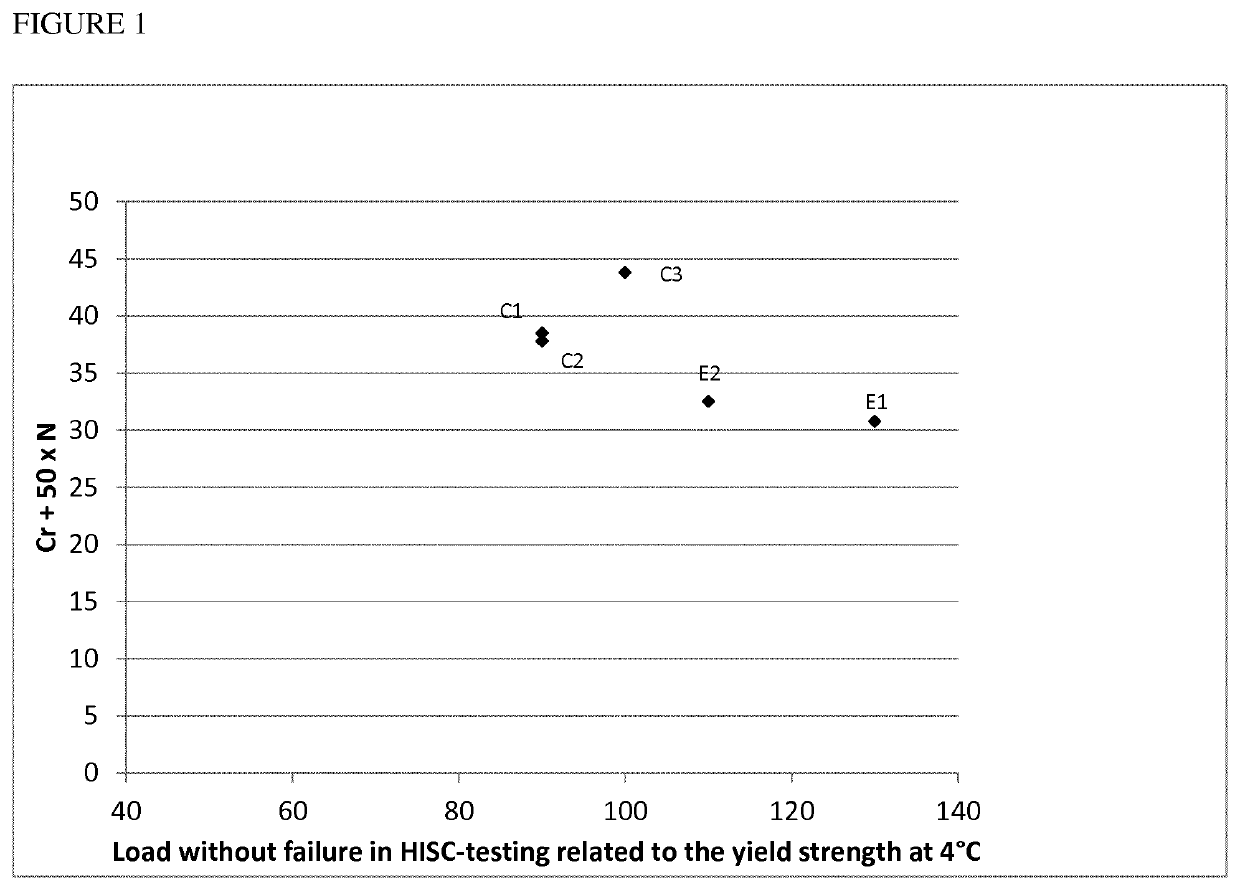

[0041]Five different heats with different compositions were melted as 270 kg heats in a high frequency induction furnace and cast to ingots using a 9″ mould. Table 1 shows the compositions of the duplex stainless steels used. Both inventive and comparative examples are shown below. In Table 1, the points E1 and E2 stand for Example 1 and Example 2 of the present disclosure, while the points C1-C3 stands for the comparative examples 1-3.

TABLE 1Chemical composition of different heatsHeatCSPSiMnCrNiMoNCuAlCr + 50NE10.0150.0090.0050.180.4523.796.592.96 0.140.10>0.00330.79E20.0090.0050.0040.230.4223.556.483.960.180.100.00732.55C10.0110.0050.0050.222.1327.027.213.970.230.100.01438.52C20.010.0050.0050.2223.84.733.970.280.100.01737.8C 30.0210.0100.0050.190.427.35.532.92 0.330.10 >0.00343.8

[0042]After casting, the mold was removed and the ingot was held at 1050° C. for 2 hours and then quenched in water. A sample for chemical analysis was taken from each ingot. The chemical analyses were per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com