LAYERED GaAs, METHOD OF PREPARING SAME, AND GaAs NANOSHEET EXFOLIATED FROM SAME

a nanosheet and gallium arsenide technology, applied in the field of layered gallium arsenide (gaas), can solve the problems of high limit in research on 2d materials, limited possibility of low-dimensional material development, and high cost, and achieve easy exfoliation into nanosheets, excellent electrical properties, and easy charge transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example 1

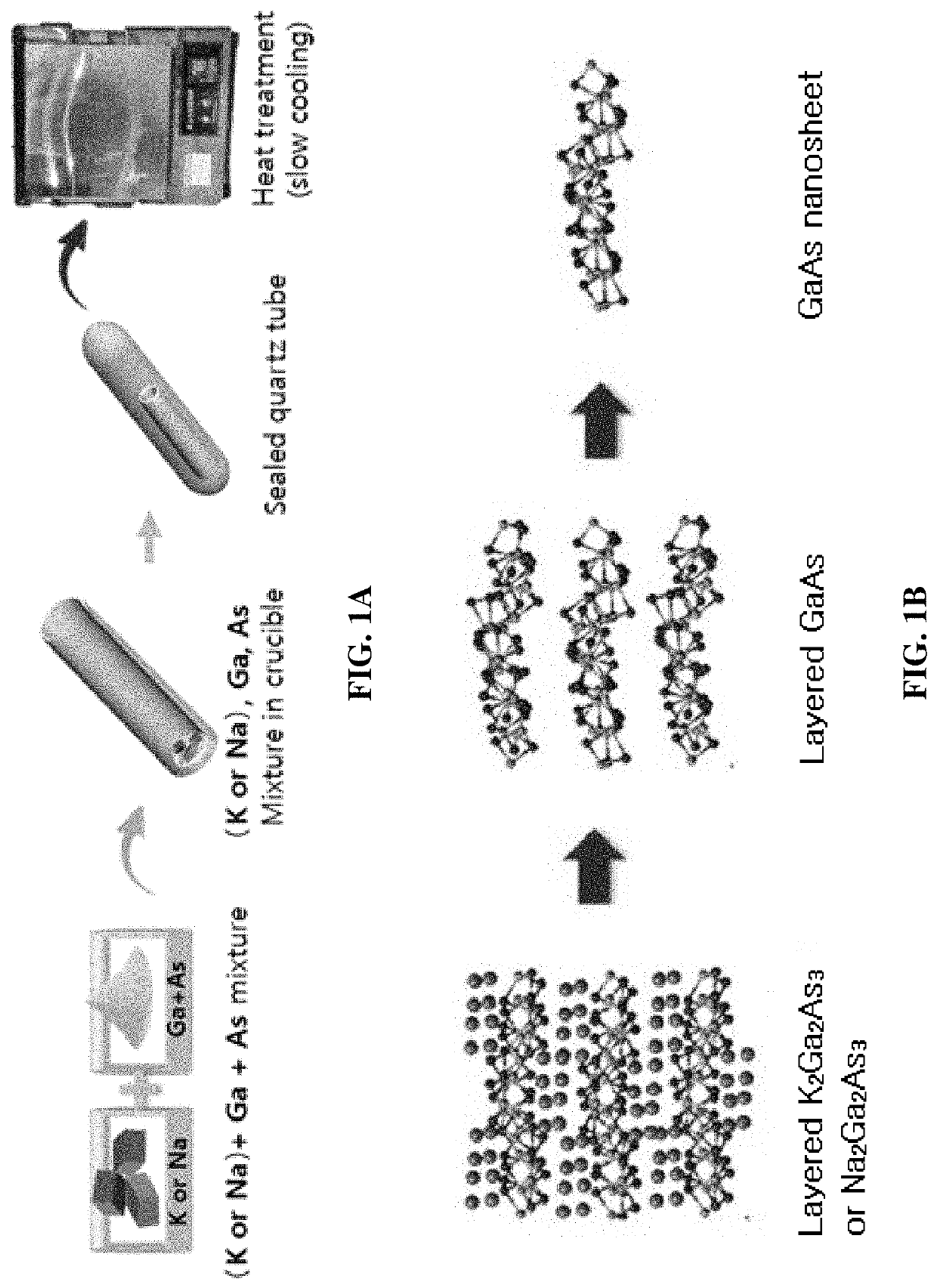

Preparation of Layered K2Ga2As3

[0074]A predetermined amount of K powder was mixed with a predetermined amount of Ga powder and As powder, and the mixtxure was sealed in a quart tube in an inert gas atmosphere. The quartz tube containing the sample was heat-treated for 10 hours at 750° C. Afterwards, the tube was cooled at a cooling rate of 0.5 to 3° C. / hr for K2Ga2As3 recrystallization, thereby obtaining a K2Ga2As3 single crystal having a monoclinic crystal structure with the P21 / c space group.

preparation example 2

Preparation of Layered Na2Ga2As3

[0075]A predetermined amount of Na powder was mixed with a predetermined amount of Ga powder and As powder, and the mixture was sealed in a quartz tube in an inert gas atmosphere. The quartz tube containing the sample was heat-treated for 10 hours at 750° C. Afterwards, the tube was cooled at a cooling rate of 1° C. / hr for Na2Ga2As3 recrystallization, thereby obtaining a Na2Ga2As3 single crystal having a monoclinic crystal structure with the P21 / c space group.

example 1

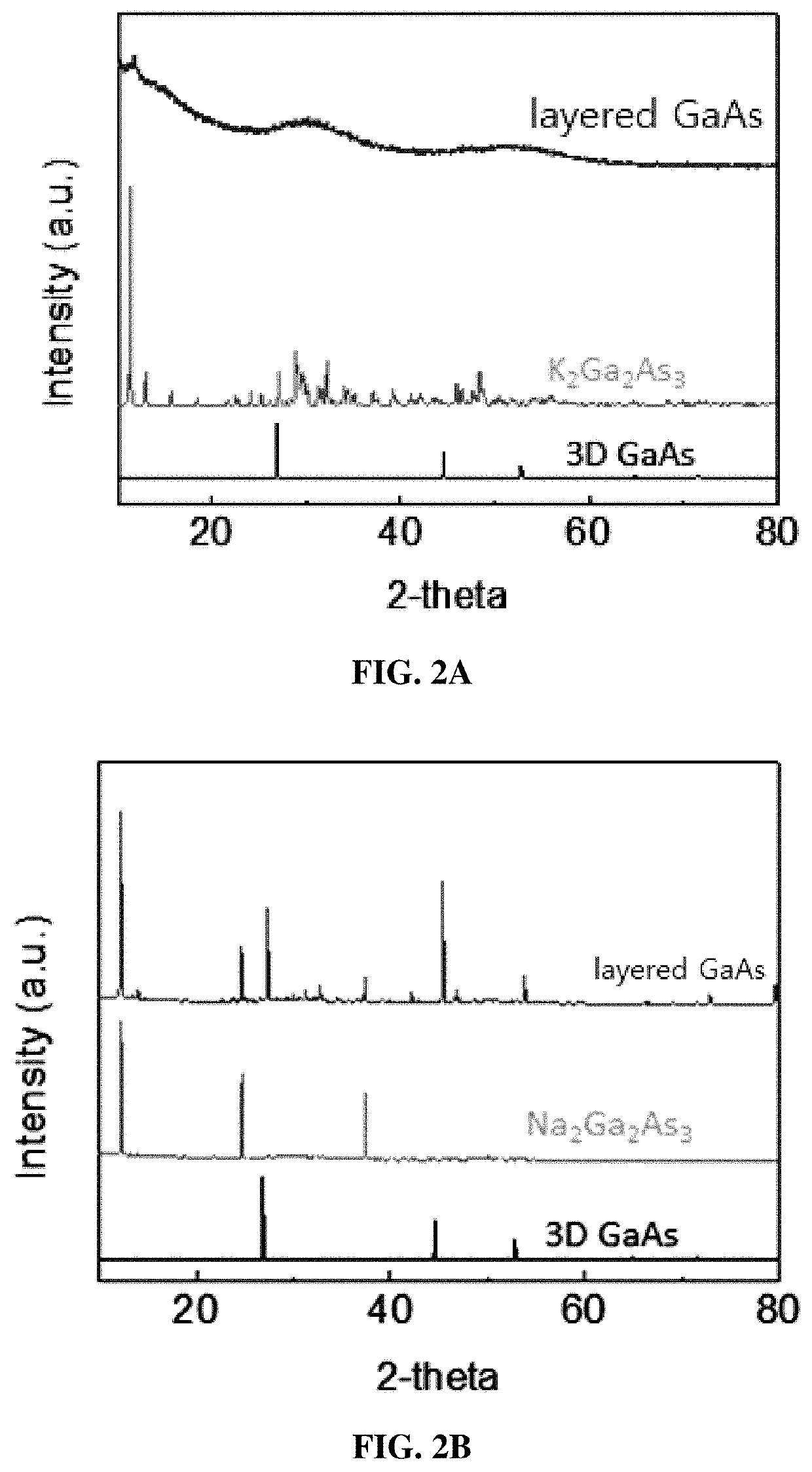

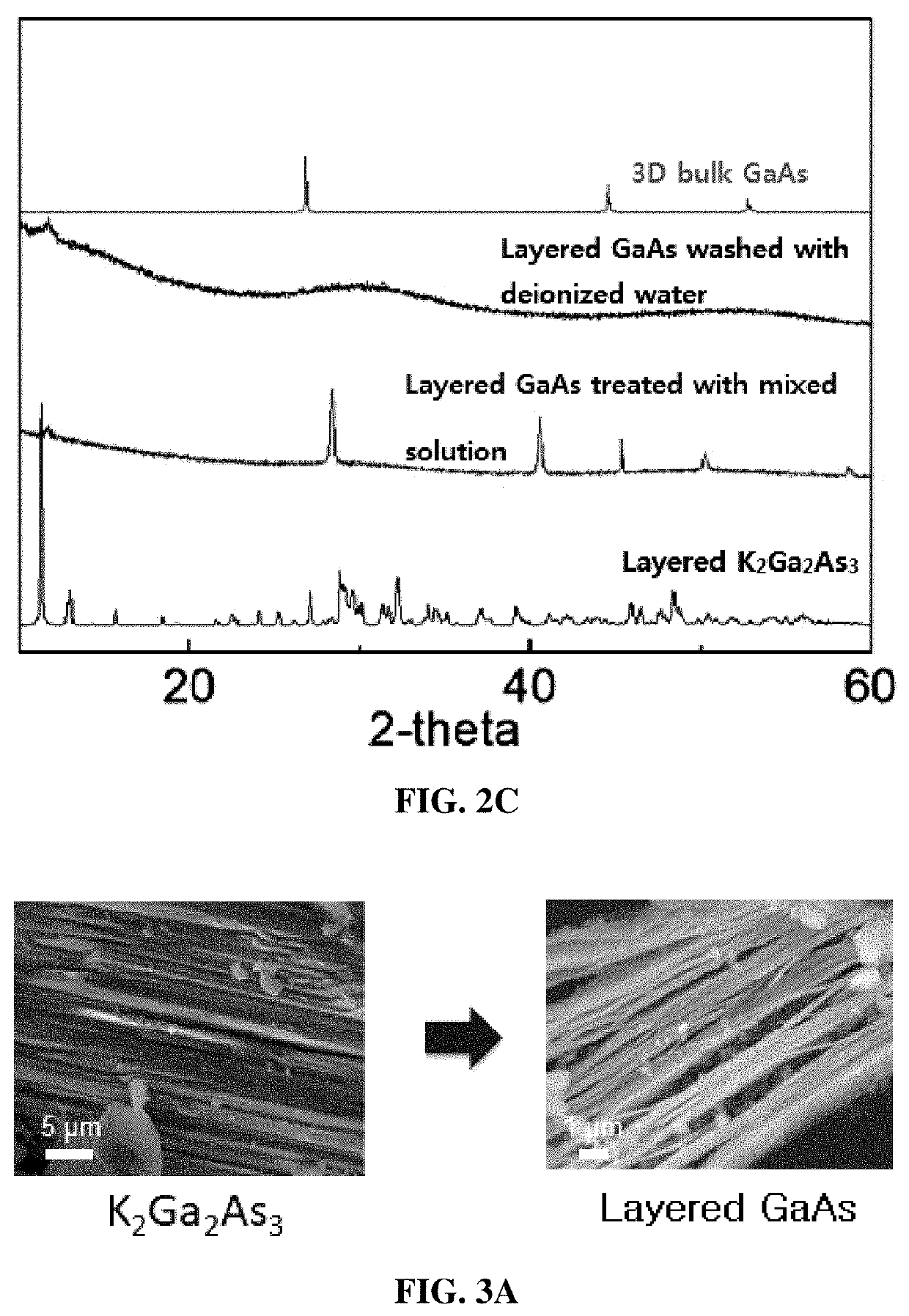

Preparation of Layered GaAs

[0076]The K2Ga2As3 prepared in Preparation Example 1 was mixed with deionized water, ethanol, and AlCl3 to remove K ions therefrom, and after washed with deionized water to remove KCl, layered GaAs having an amorphous structure was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com