Sputtering cathode, sputtering device, and method for producing film-formed body

a sputtering cathode and film-forming technology, applied in the direction of plasma technique, light and heating apparatus, laminated elements, etc., can solve the problems of difficult film-forming on a flat boardlike body, inability to achieve a sufficiently high deposition rate, and low plasma density between the facing two targets, so as to reduce the risk of body damage, increase plasma density, and high deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

The First Embodiment

[Sputtering Device]

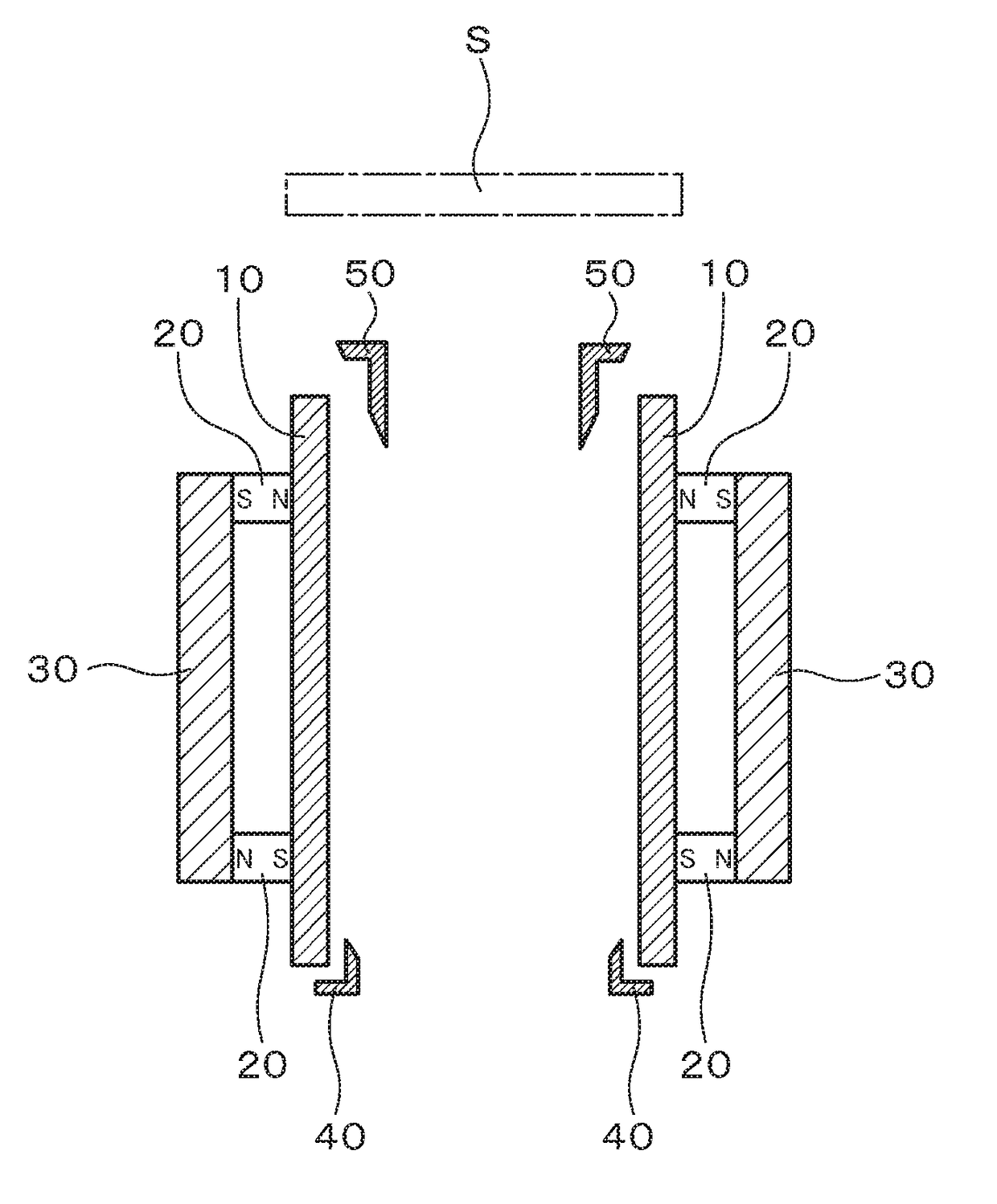

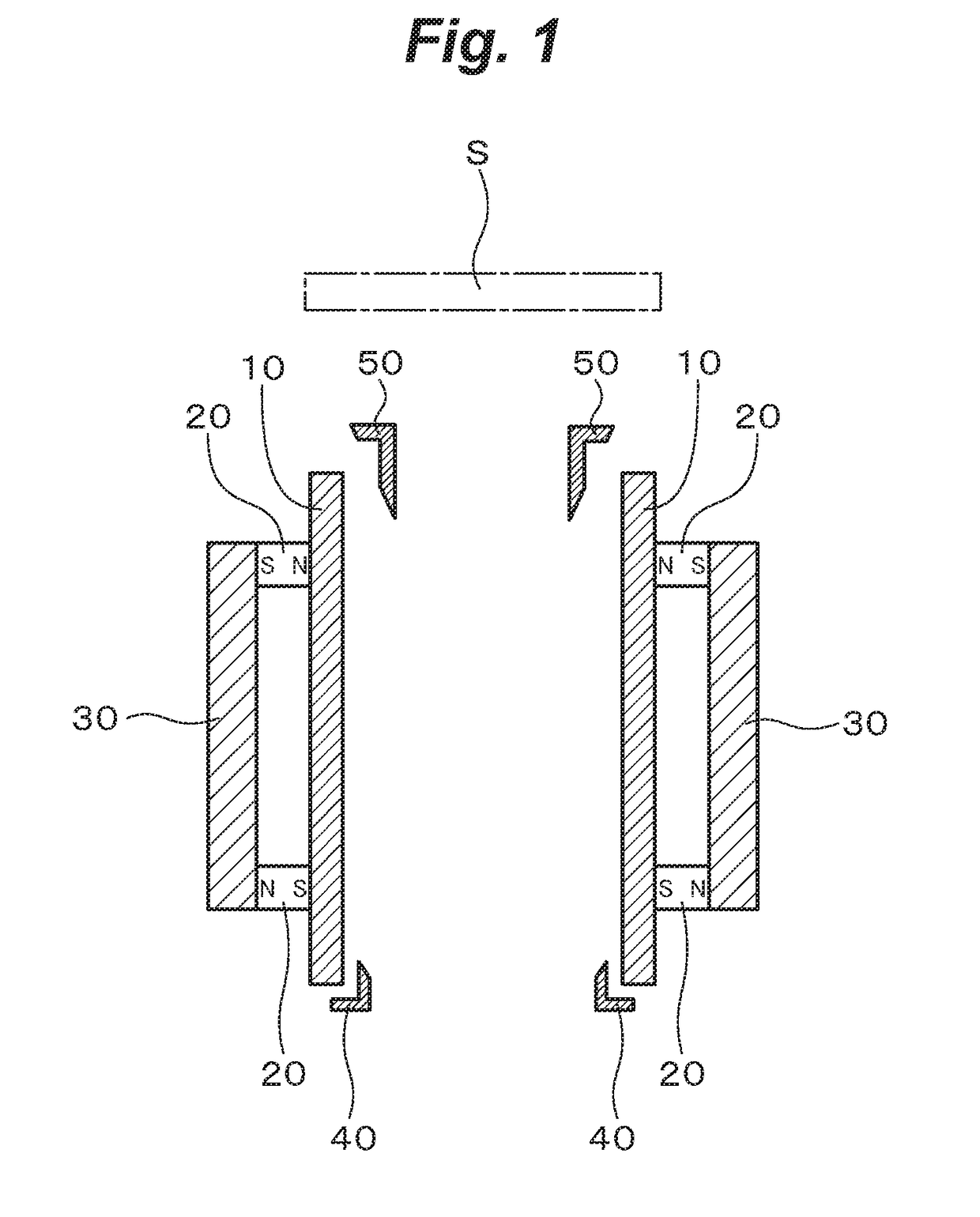

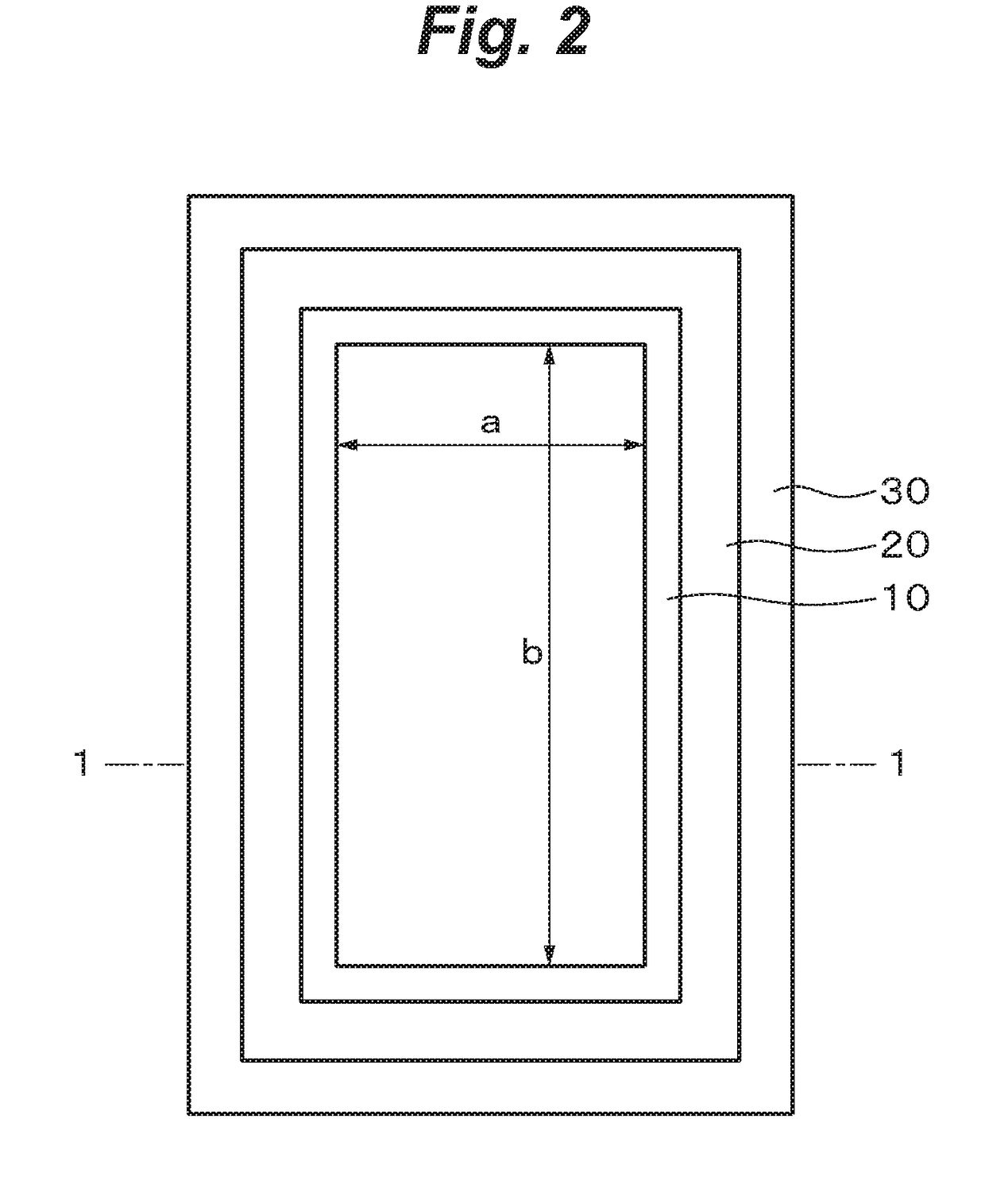

[0071]FIG. 1 and FIG. 2 are a longitudinal cross-sectional view and a plan view showing the sputtering device according to the first embodiment and show construction around a sputtering cathode and an anode disposed inside a vacuum chamber of the sputtering device. FIG. 1 is a cross-sectional view along the line 1-1 of FIG. 2.

[0072]As shown in FIG. 1 and FIG. 2, the sputtering device comprises a sputtering target 10 having a rectangular tubular shape in which the cross-sectional shape thereof is a rectangular, and an erosion surface faces inward, a permanent magnet 20 disposed outside the sputtering target 10 and a yoke 30 disposed outside the permanent magnet 20. The sputtering target 10, the permanent magnet 20 and the yoke 30 form the sputtering cathode. The sputtering cathode is generally fixed to the vacuum chamber in an electrically isolated state. The permanent magnet 20 and the yoke 30 form a magnet circuit. Although polarity of the per...

second embodiment

The Second Embodiment

[Sputtering Device]

[0082]In the sputtering device, the sputtering target 10 comprises the sputtering targets 10a, 10b, 10c and 10d shown in FIG. 9. Here, the sputtering targets 10a and 10b forming the long side sections facing each other are made of materials different from each other. Other construction of the sputtering device is as the same as the sputtering device according to the first embodiment.

[Method for Forming a Film by the Sputtering Device>

[0083]As the same as the first embodiment, film formation is performed in the film formation region of the substrate S by using the beams of sputtered particles 70 and 80. In this case, since the sputtering targets 10a and 10b are made of materials different from each other, constituent atoms of the beam of sputtered particles 70 and constituent atoms of the beam of sputtered particles 80 are different from each other. Therefore, the thin film F formed on the substrate S has the composition in which constituent at...

third embodiment

The Third Embodiment

[Sputtering Device]

[0085]FIG. 10 shows the sputtering device according to the third embodiment. In the sputtering device, as the same as the sputtering device according to the second embodiment, the sputtering target 10 comprises the sputtering targets 10a, 10b, 10c and 10d shown in FIG. 9, the sputtering targets 10a and 10c of the long side sections facing each other being made of materials different from each other. In addition, as shown in FIG. 10, in the sputtering device, a horizontal shield plate 90 held by a carrying mechanism not illustrated can be placed at a height between the height of the substrate S and the height of the light stopping shield 50 so as to stop the beam of sputtered particles 80 from the sputtering target 10c or the beam of sputtered particles 70 from the sputtering target 10a. Other construction of the sputtering device is as the same as the sputtering device according to the first embodiment.

[Method for Forming a Film by the Sputteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Distance | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com