Gable assembly for use with a modular watercraft lift cover

a technology for modular watercraft and lift covers, which is applied in the direction of boat roofs, transportation and packaging, and construction. it can solve the problems of difficult design, manufacture and installation of boat lift covers for tidal lifts, high cost, and inconvenient configuration, and achieves a wide range of adjustment. , the effect of convenient configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

[0122]10B. Gable Assembly—Third Embodiment

[0123]10C. Gable Assembly—Fourth Embodiment

[0124]12. Deck Assembly

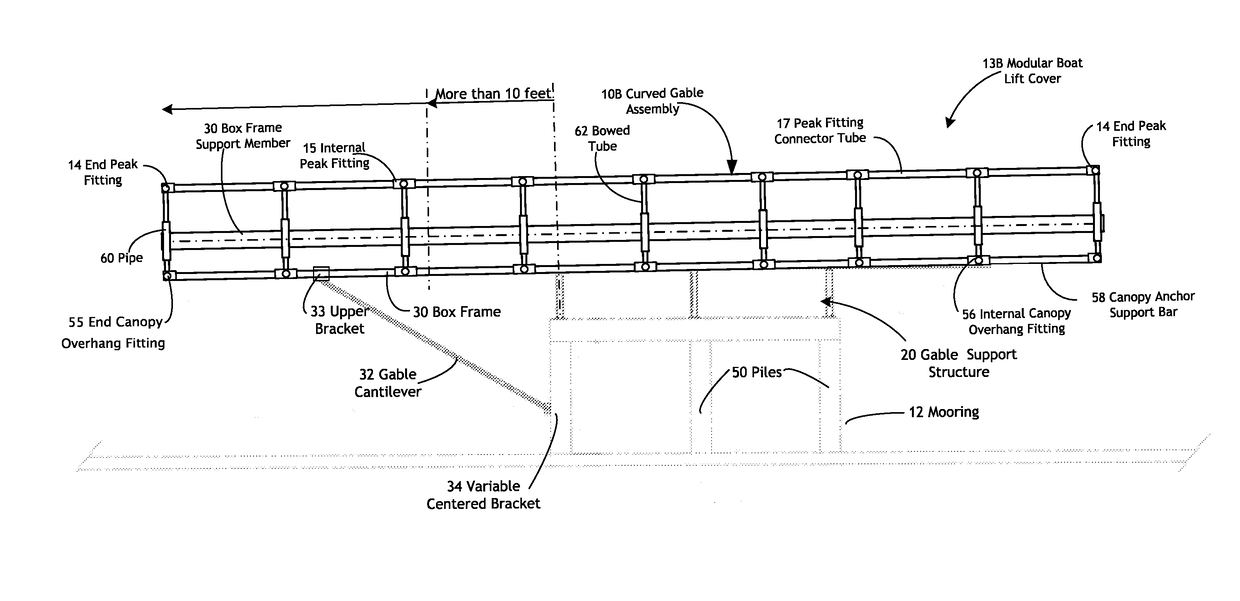

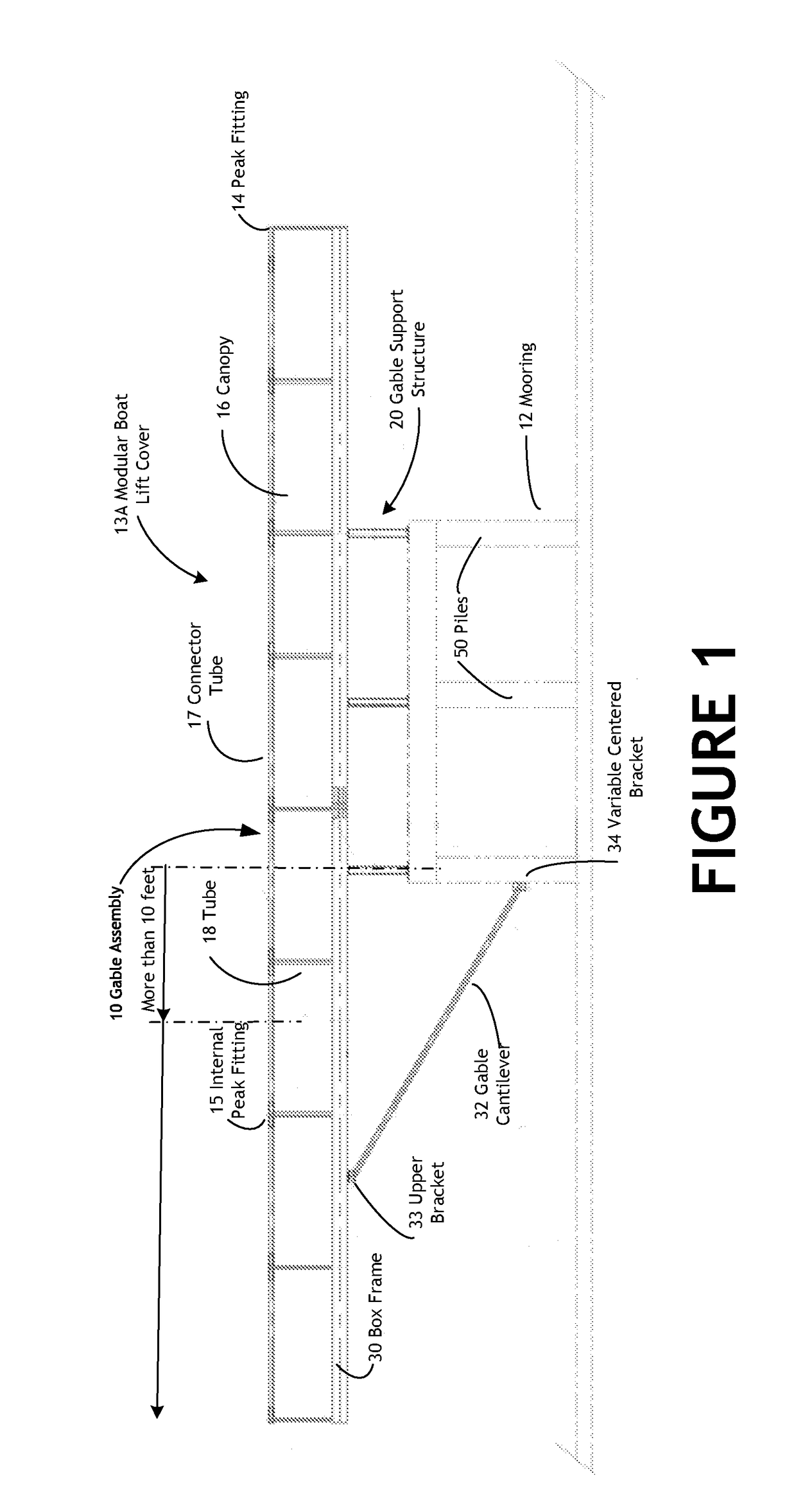

[0125]13A. Modular Boat Lift Cover (with linear tubes)

[0126]13B. Modular Boat Lift Cover (with linear tubes that become arcuate when stressed)

[0127]14. End Peak Fitting

[0128]15. Internal Peak Fitting

[0129]16. Canopy

[0130]17. Peak Fitting Connector Tube

[0131]18. Tube

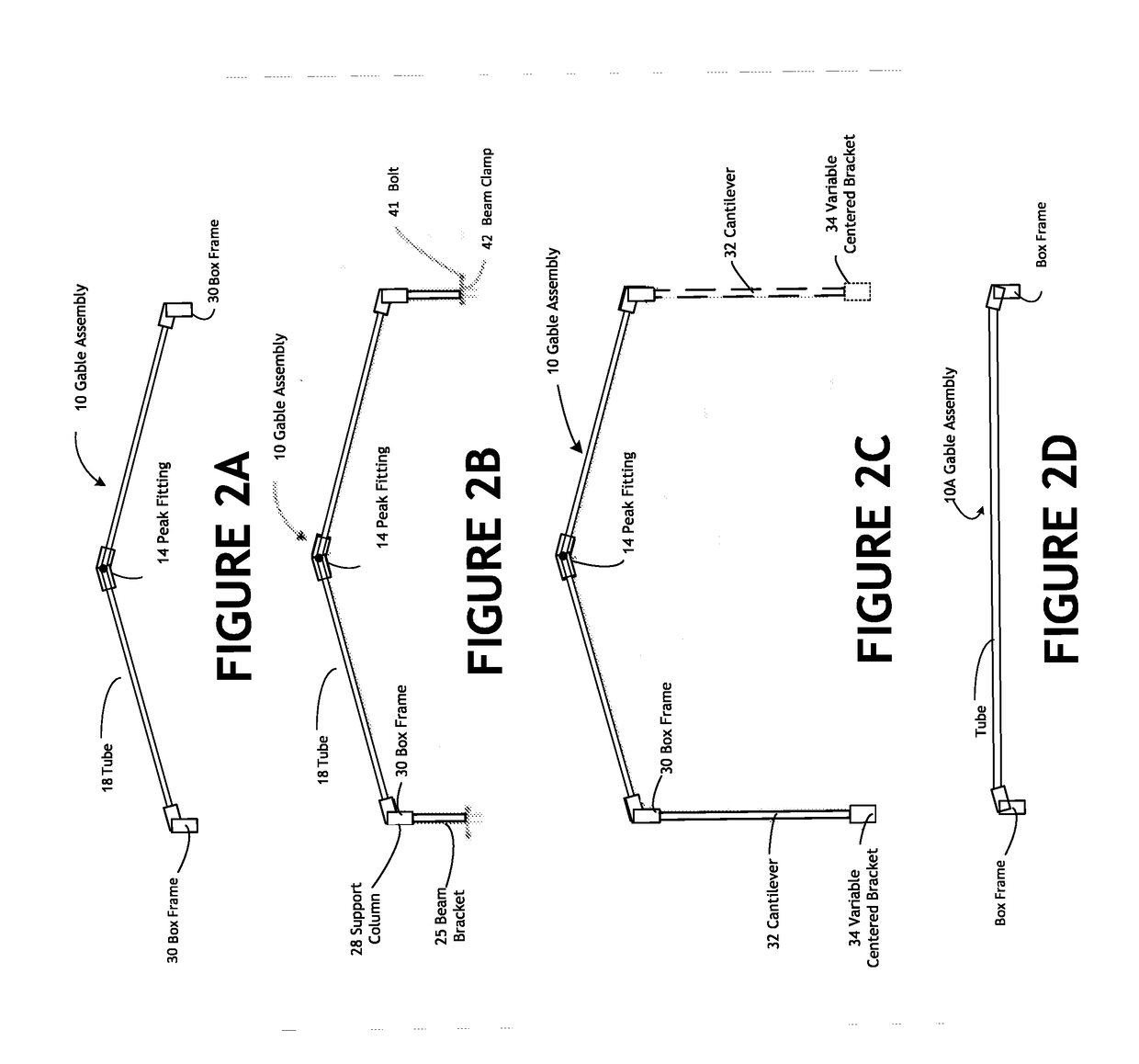

[0132]20. Adjustable Support Structure

[0133]25. Beam Bracket

[0134]27. Fastener Hole

[0135]28. Support Column

[0136]29. Clevis Pin

[0137]30. Box Frame Support Member

[0138]32. Cantilever

[0139]33. Upper Bracket

[0140]34. Variable Centered Bracket

[0141]37. Pipe Fitting

[0142]40A. Curved Gable Assembly

[0143]40B. Curved Gable Assembly

[0144]41. Bolt

[0145]42. Beam Clamp

[0146]44. I-Beam

[0147]45. U-Bolt

[0148]47. Knob

[0149]48. Elastic Cords

[0150]49. Box Frame End Cap

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com