Method to minimize brine contamination and/or gas migration during in situ trona solution mining

a technology of in situ solution and brine, which is applied in the direction of fluid removal, sealing/packing, borehole/well accessories, etc., can solve the problems of high cost of mechanical mining methods for trona, affecting the recovery of trona by these methods, so as to minimize the risk of brine contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

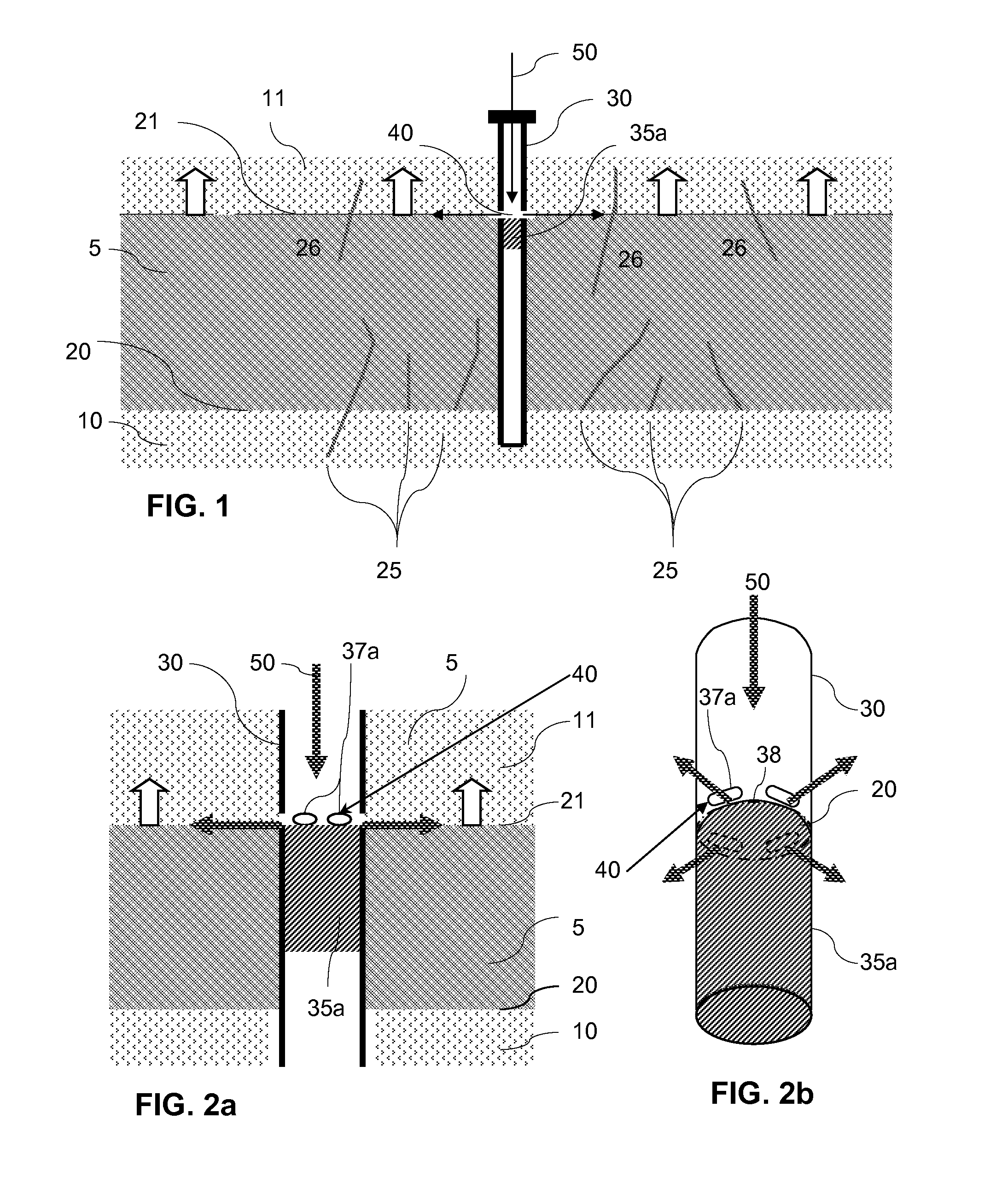

Image

Examples

example 1

[0538]Several small (¼-inch diameter) holes were drilled in a block of trona, and the exposed holes were covered by a piece of oil shale. A settable concrete mixture was injected into the holes and at the interface between the trona and the oil shale, and the trona / oil shale sandwiched assembly was submerged in water inside a beaker. After 24 hours, the concrete had hardened even while the assembly was being held in water. The concrete bonded the oil shale and to the trona surface with which it was in contact. Dissolution of the trona from trona block surfaces exposed to water initiated while the block was been submerged, and as trona dissolved around the concrete, a concrete ‘pad’ remained at the interface and continued to bond with the oil shale.

[0539]This disclosure of all patent applications, and publications cited herein are hereby incorporated by reference, to the extent that they provide exemplary, procedural or other details supplementary to those set forth herein.

[0540]Shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com