Method of surface modifying graphene

a surface modification and graphene technology, applied in the field of surface modification methods, can solve the problems of poor performance of graphene dispersion in a coating process, limited dispersion effect, and disadvantages of graphene in actual applications, and achieve excellent dispersibility, reduce reaction waste generated in the method, and improve uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0034]Here, melamine is selected as the surface modifying agent.

[0035]First, graphene sheets are well mixed with melamine and then placed in the oven, which is evacuated to vacuum with a pressure less than 10−2 torr. Then, the oven is heated up to 200° C., and the surface cleaning step is performed on the graphene sheets for 3 hours to remove the impurity on the surface. The surface modifying step is performed. The oven is further heated up to 310° C. and kept at this temperature for 2 hours. As a result, the surface modifying agent sublimates and is adsorbed by the considerably clean surface of the graphene sheets. The graphene powder having modified surface is manufactured.

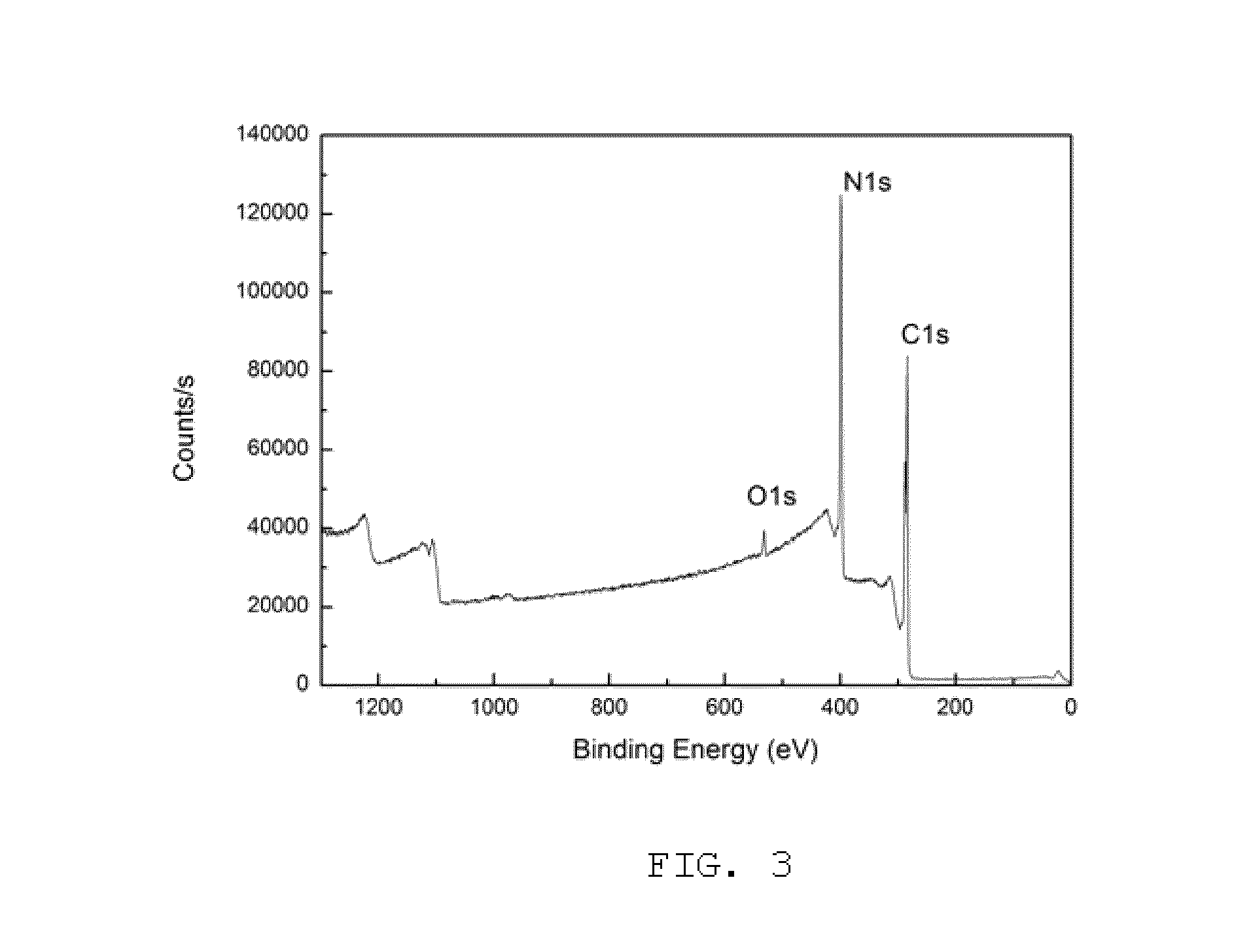

[0036]FIG. 3 shows an X-ray spectrum for the surface modified graphene powder, and it is clearly proved that the surface has a nitrogen containing functional group. FIG. 4 illustrates the state, in which the graphene powder is dispersed in water, and FIG. 5 is a view showing the original graphene sheets disperse...

example 2

[0037]This time, o-phthalate acid is selected as the surface modifying agent.

[0038]The graphene sheets is blended and mixed with o-phthalate acid, and the mixture is placed in the oven, which is evacuated to vacuum with a pressure less than 10−2 torr. The oven is heated up to 200° C., and the surface cleaning step is performed on the graphene sheets for 3 hours. The oven is further heated up to 400° C. and kept at this temperature for one hour such that the surface modifying agent sublimates and is adsorbed by the clean surface of the graphene sheets. The graphene powder having modified surface is obtained. FIG. 6 is an X-ray spectrum for the surface modified graphene powder. It is proved that the graphene powder actually has a good effect of dispersion in water.

[0039]From the above-mentioned, one aspect of the present invention is that the surface cleaning and adsorption steps are employed to modify the surface property of the graphene powder so as to facilitate the blending proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com