Method for manufacturing solar cell with nano-structural film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]First, about the following description of the embodiment, it should be understood that when a layer (or a film) or a structure is deposited on or under another substrate, another layer (or film) or another structure, it can be directly disposed in the other substrate, layer (or film), or another structure, or indirectly disposed on more than one intermediate layers between both. Please refer to the location of each layer in brief description of the figures.

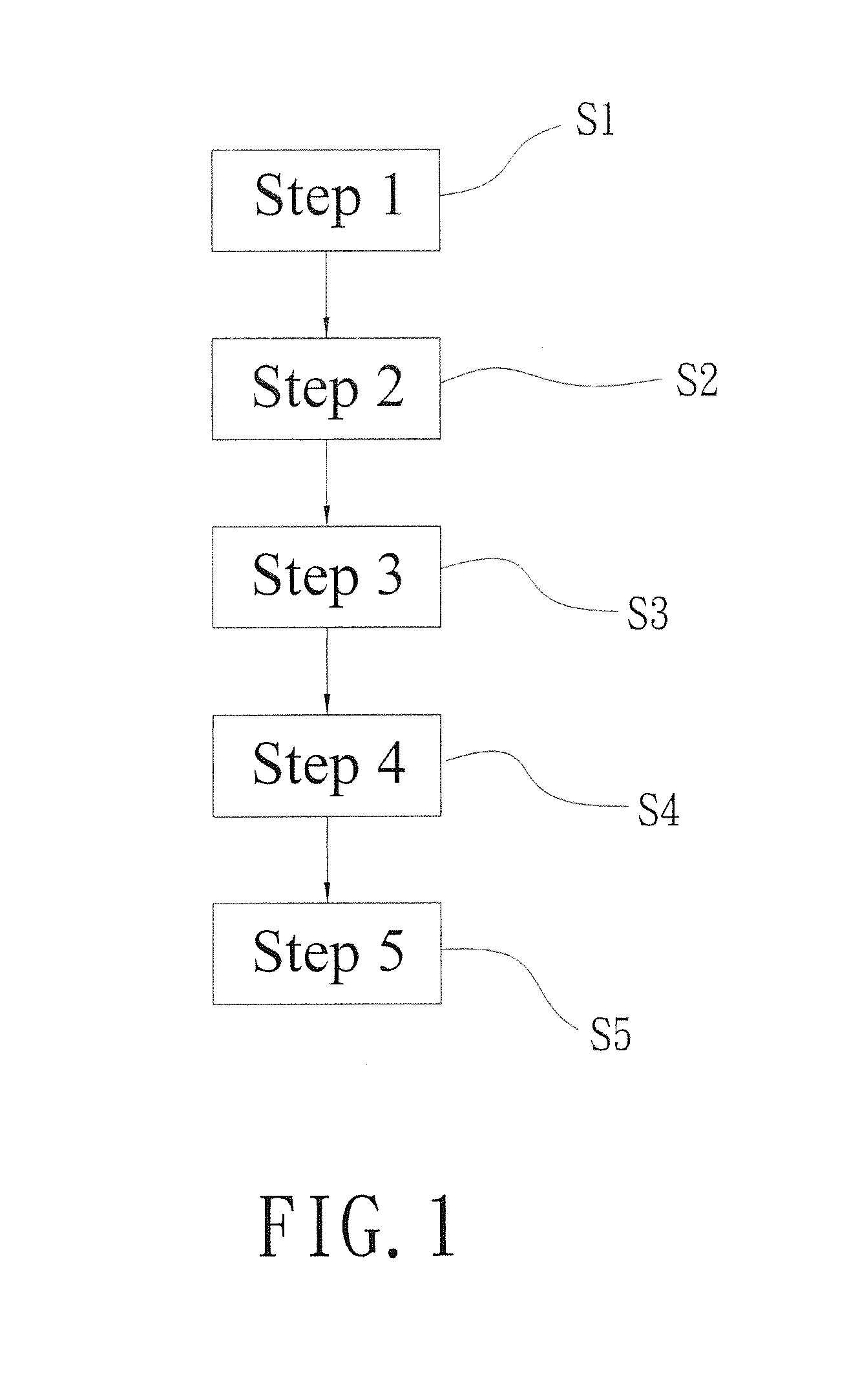

[0036]As referring to FIG. 1, a flow chart showing steps of an embodiment of a method for manufacturing a solar cell with a nanostructural film according to the present invention, wherein the first optical layer, second optical layer and adhesion layer in the embodiment of a method for manufacturing a solar cell are made of poly(dimethylsiloxane) (PDMS), the manufacturing method includes following steps.

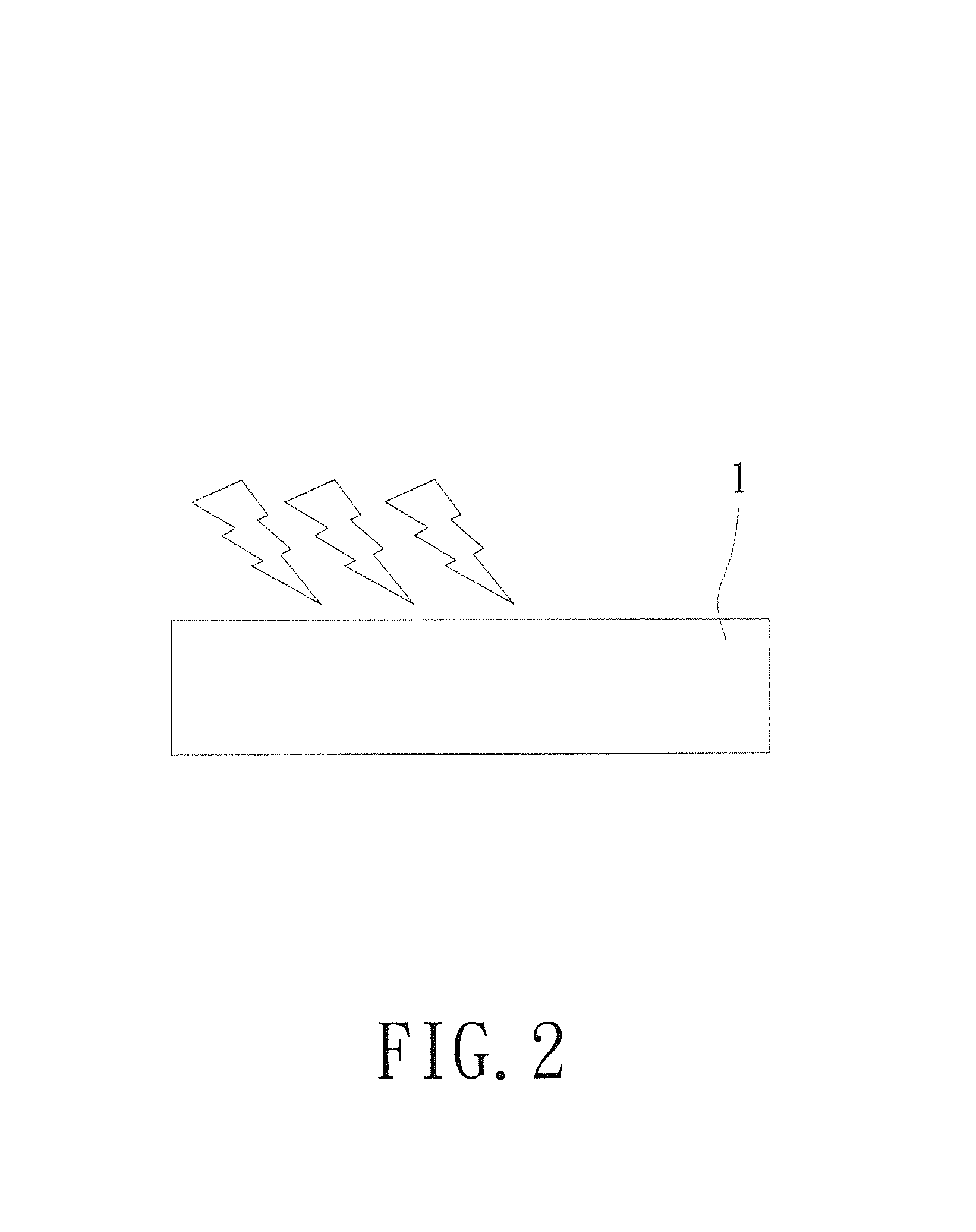

[0037]Step one (S1): treating a glass substrate (1) with UV ozone; as referring to FIG. 2, a schematic drawing showing a UV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com