Multi-layer micro/nanofluid devices with bio-nanovalves

a nano-nanofluidic and multi-layer technology, applied in the field of micro/nanofluidic devices and systems, can solve the problems of extremely limited mass flow rate, and achieve the effect of economic, effective and efficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066]The following is a detailed description and explanation of the preferred embodiments of the invention and best modes for practicing the invention.

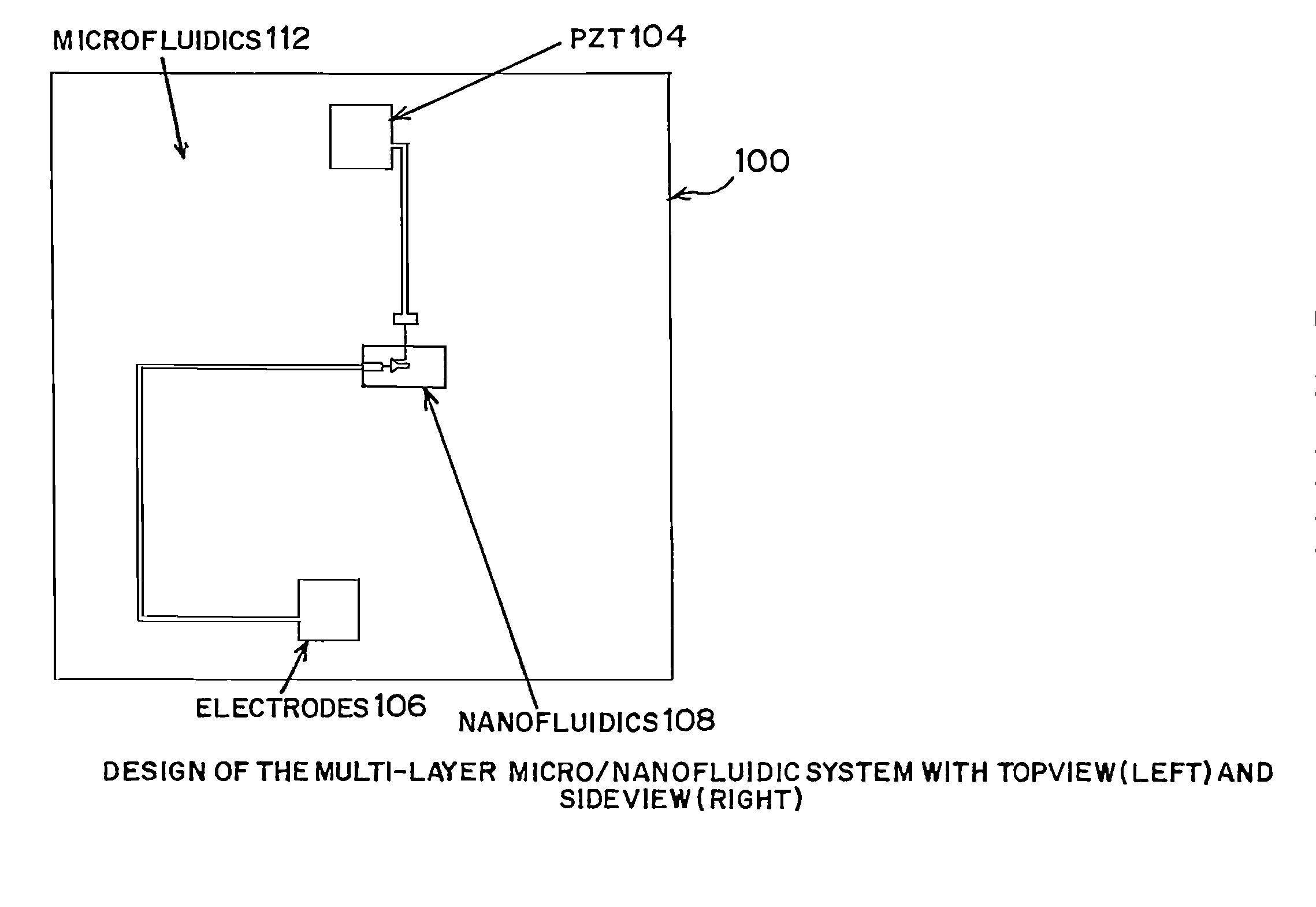

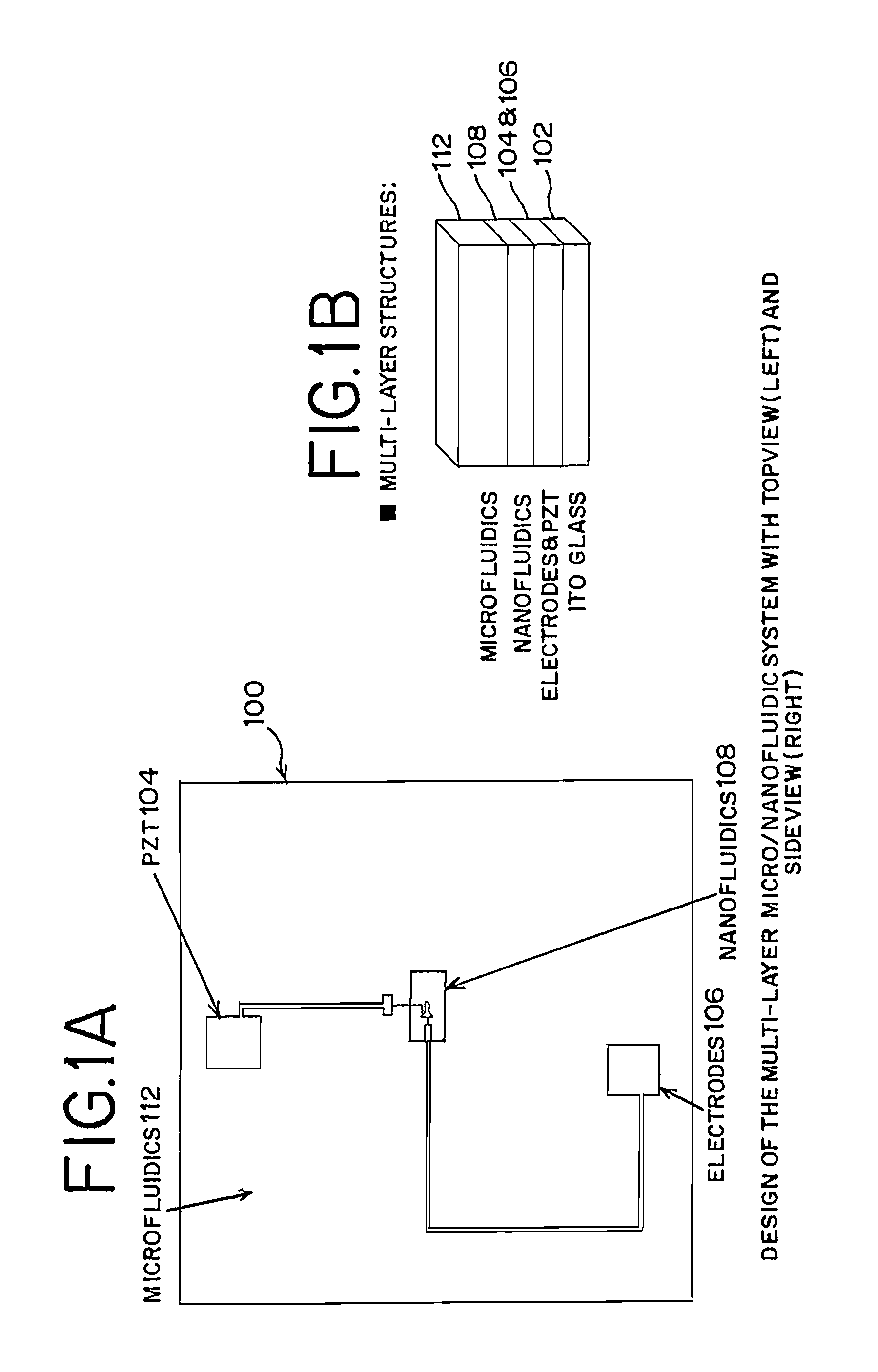

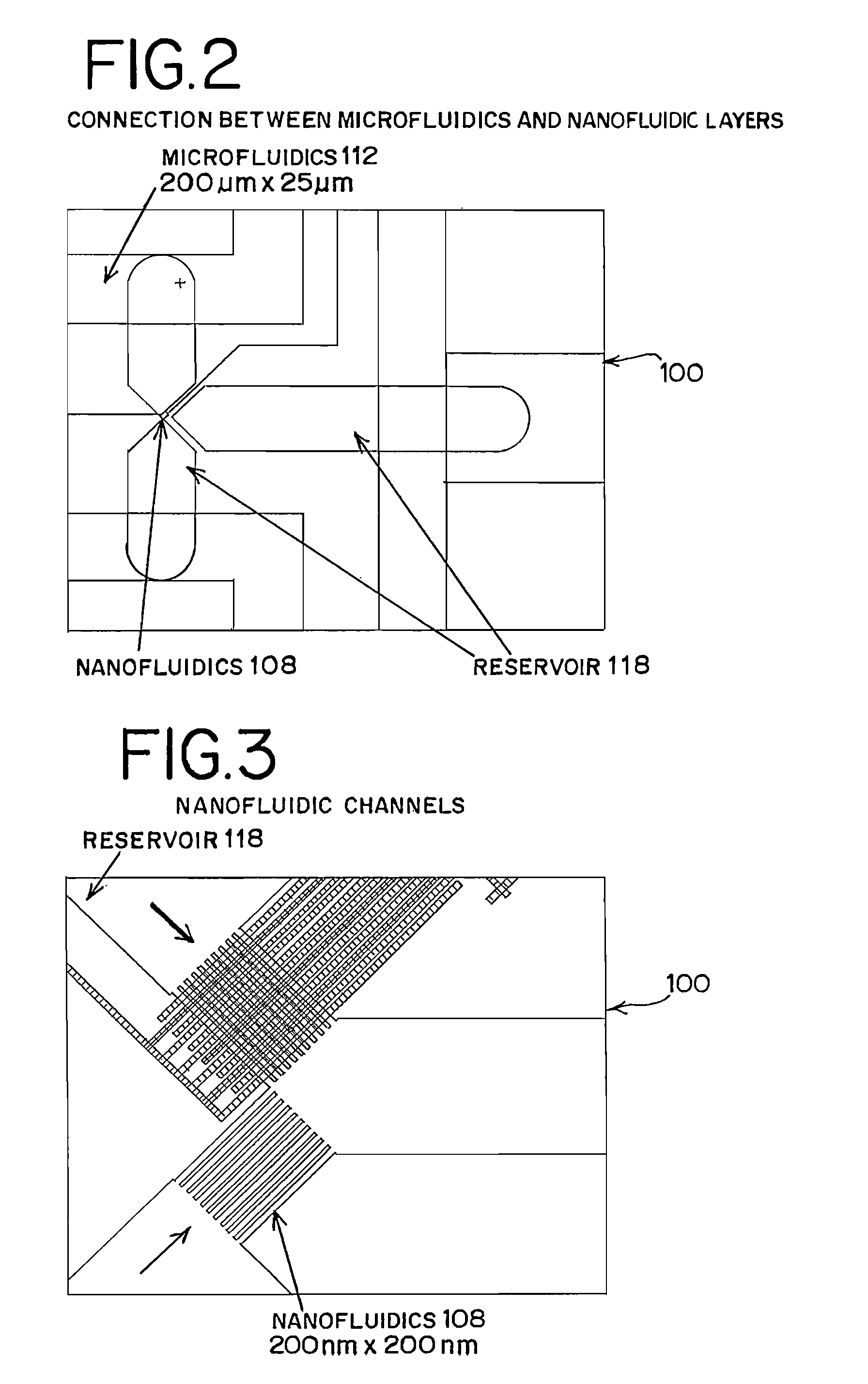

[0067]As shown in the drawings, a novel, multi-layer micro / nanofluidic flow device 100 (FIGS. 1A and 1B) is provided, which is also referred to as a multi-layered nanofluidic flow device. The multi-layer micro / nanofluidic flow device can comprise a substrate 102 made of indium tin oxide coated glass (ITO glass) upon which is stacked and positioned a layer 104 of lead zirconate titanate (Pb(ZrxTii-x)O3) (PZT). The multi-layer micro / nanofluidic flow device contains electrodes 106 connected to the PZT. A nanofluidics layer (nanofluidics) 108 with nanochannels 110 is stacked and positioned upon the PZT layer. A microfluidics layer (microfluidics) 112 with microchannels 114 is stacked and positioned upon the nanofluidics layer. Bio-nanovalves (biomolecular nanovalves) 116 in the nanochannels are activated by polarization of the PZT layer....

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluid flow rates | aaaaa | aaaaa |

| spacing distance | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com