Plasma processing apparatus and plasma processing method

a technology of plasma processing and processing apparatus, which is applied in the direction of water supply installation, transportation and packaging, service pipe system, etc., can solve the problems of severe requirements for plasma processing stability, and achieve the effect of conducting the control of temperature condition more accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

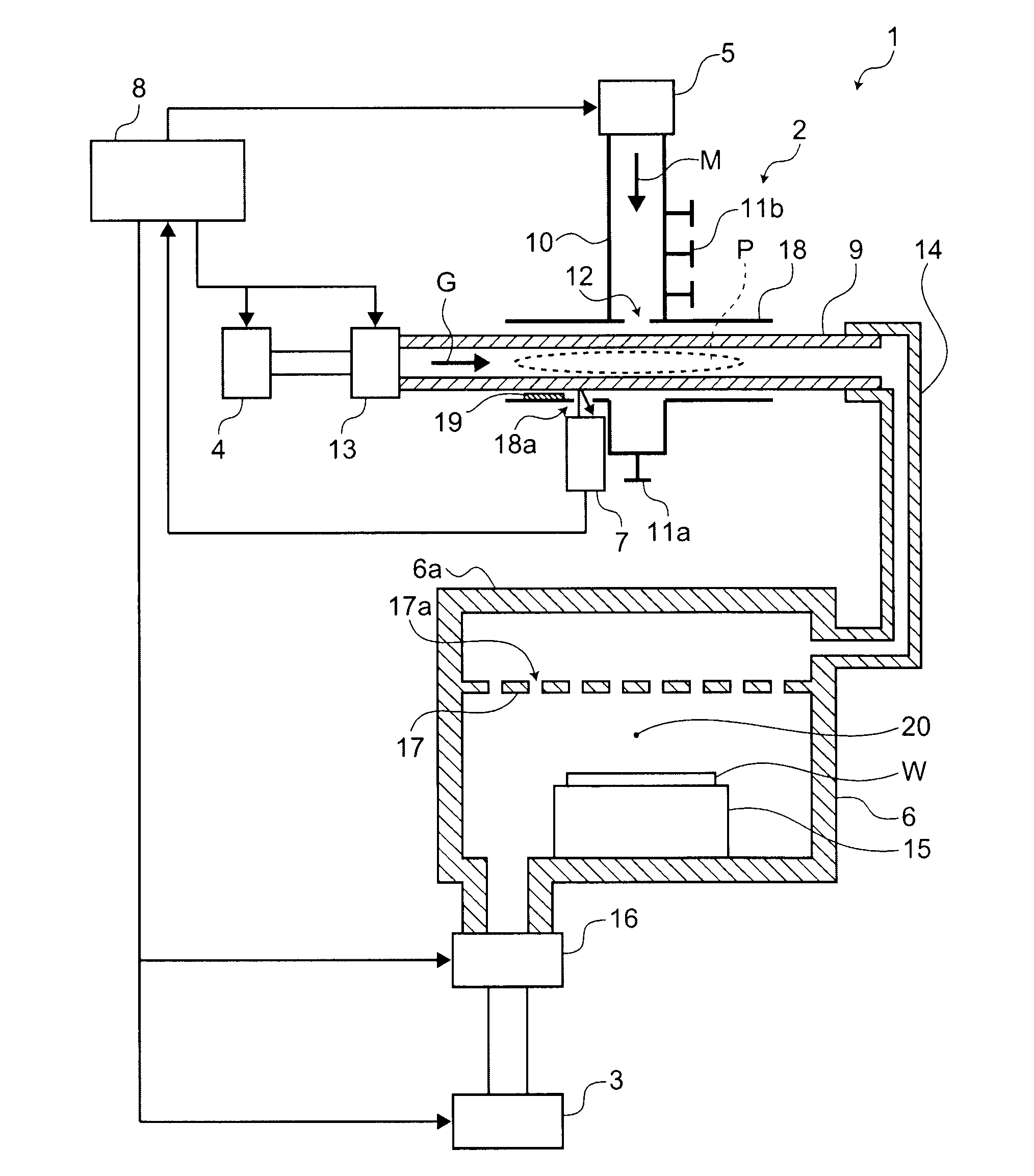

[0020]FIG. 1 is a schematic cross-sectional view for illustrating a plasma processing apparatus according to the invention.

[0021]The plasma processing apparatus 1 illustrated in FIG. 1 is a microwave-excitation type plasma processing apparatus, normally referred to as the “Chemical Dry Etching, (CDE) apparatus”. That is, the plasma processing apparatus 1 is an example of plasma processing apparatus which produces plasma products from the process gas through the use of plasma being exited and generated by microwave, and which performs the processing on an object to be processed.

[0022]As shown in FIG. 1, the plasma processing apparatus 1 includes a plasma-generating part 2, a depressurizing part 3, a gas-supplying part 4, a microwave-generating part 5, a processing vessel 6, a temperature-detecting part 7, a controlling part 8, and the like.

[0023]The plasma-generating part 2 is provided with a discharge tube 9 and an introduction waveguide 10.

[0024]The discharge tube 9 has a region ge...

second embodiment

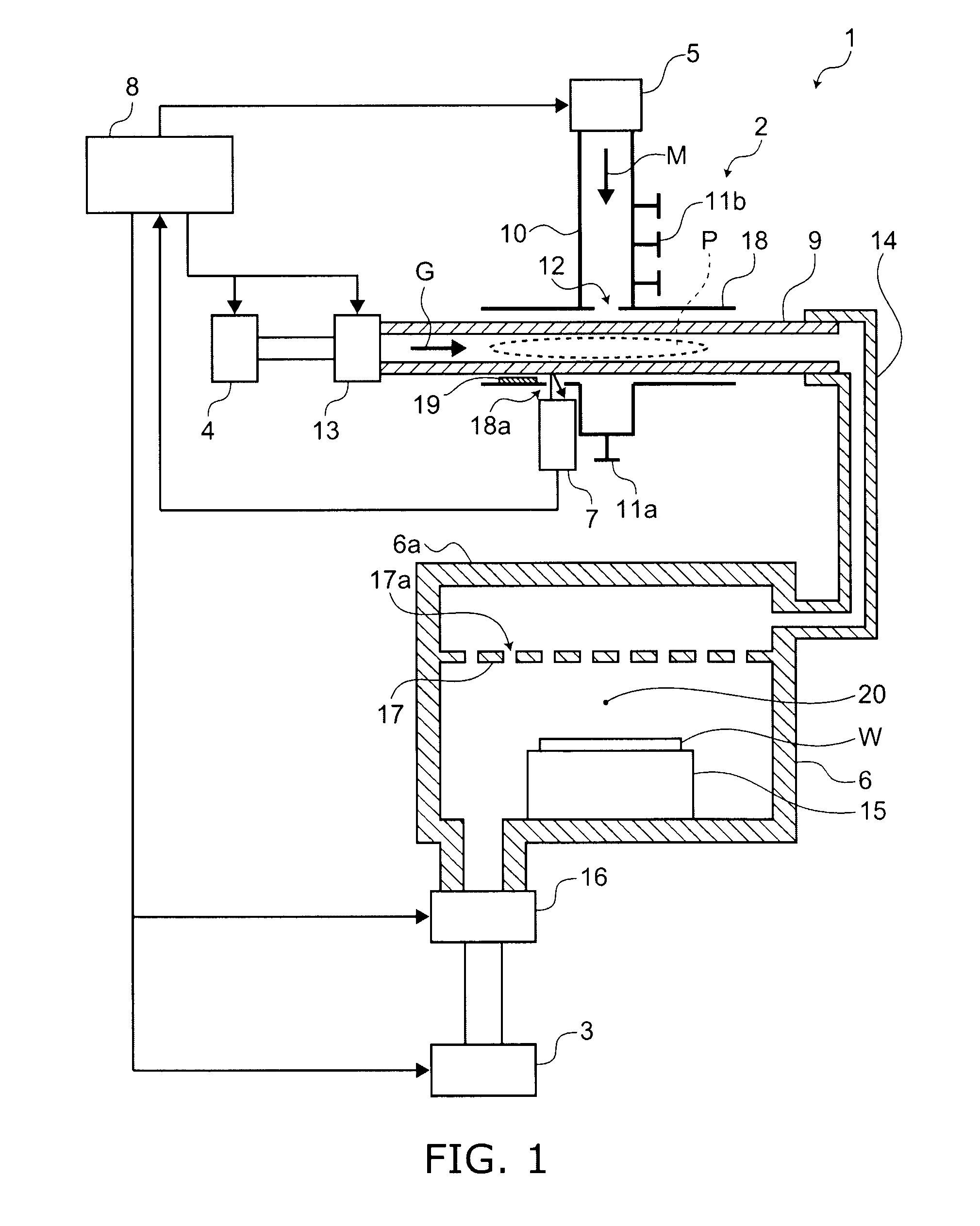

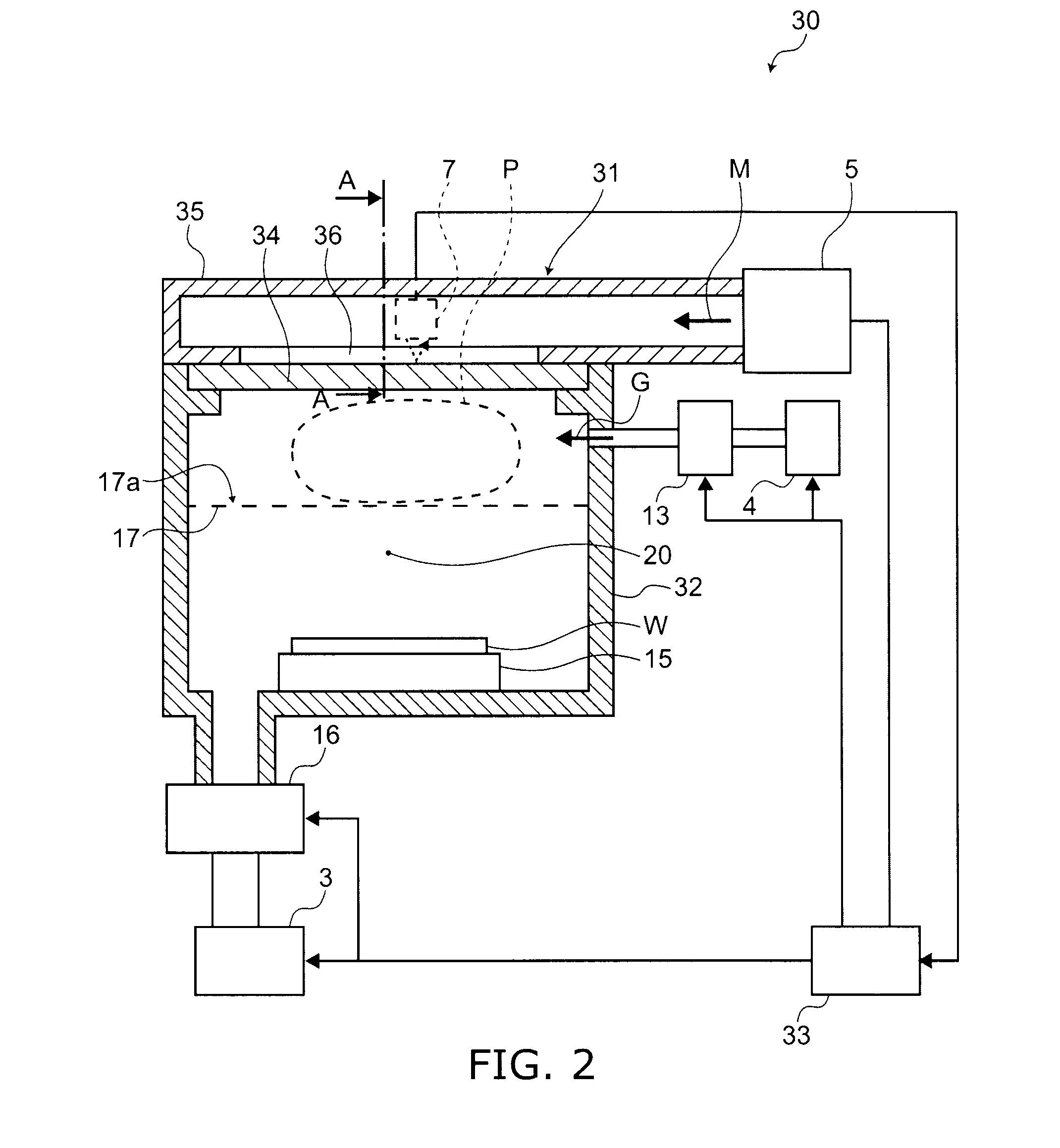

[0065]FIG. 2 is a schematic cross-sectional view for illustrating a plasma processing apparatus according to the invention.

[0066]FIG. 3 is A-A cross-sectional view of FIG. 2.

[0067]The plasma processing apparatus 30 illustrated in FIG. 2 is a microwave-excitation type plasma processing apparatus, normally called the “surface wave plasma (SWP) apparatus”. That is, the apparatus shown in FIG. 2 is an example of plasma processing apparatus which uses the plasma being excited and generated by microwave to produce the plasma products from the process gas, thus conducting the processing of the object to be processed.

[0068]As shown in FIG. 2, the plasma processing apparatus 30 includes a plasma-generating part 31, the depressurizing part 3, the gas-supplying part 4, the microwave-generating part 5, a processing vessel 32, the temperature-detecting part 7, a controlling part 33, and the like.

[0069]The plasma-generating part 31 generates the plasma P by supplying microwave (electromagnetic en...

third embodiment

[0107]FIG. 4 is a schematic cross-sectional view for illustrating a plasma processing apparatus according to the invention.

[0108]The plasma processing apparatus 40 illustrated in FIG. 4 is a capacitively coupled plasma (CCP) processing apparatus, normally called the “parallel-plate type reactive ion etching (RIE) apparatus”. That is, the apparatus shown in FIG. 4 is an example of plasma processing apparatus which uses the plasma generated by applying a high frequency power to the parallel plate electrodes to produce the plasma products from the process gas G, thus performing the processing on the object to be processed.

[0109]As shown in FIG. 4, the plasma processing apparatus 40 is provided with a plasma-generating part 43, the depressurizing part 3, the gas-supplying part 4, a power source part 44, a processing vessel 42, a temperature-detecting part 47, a controlling part 41, and the like.

[0110]The processing vessel 42 is in an approximately cylindrical shape closed at both ends, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com