Dc-dc converter and manufacturing method thereof

a technology of dc-dc converter and manufacturing method, which is applied in the direction of electric variable regulation, process and machine control, instruments, etc., can solve the problems of high input voltage, high voltage cannot be applied to the element using silicon material, and high input voltage, so as to reduce the number of manufacturing steps and reduce the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

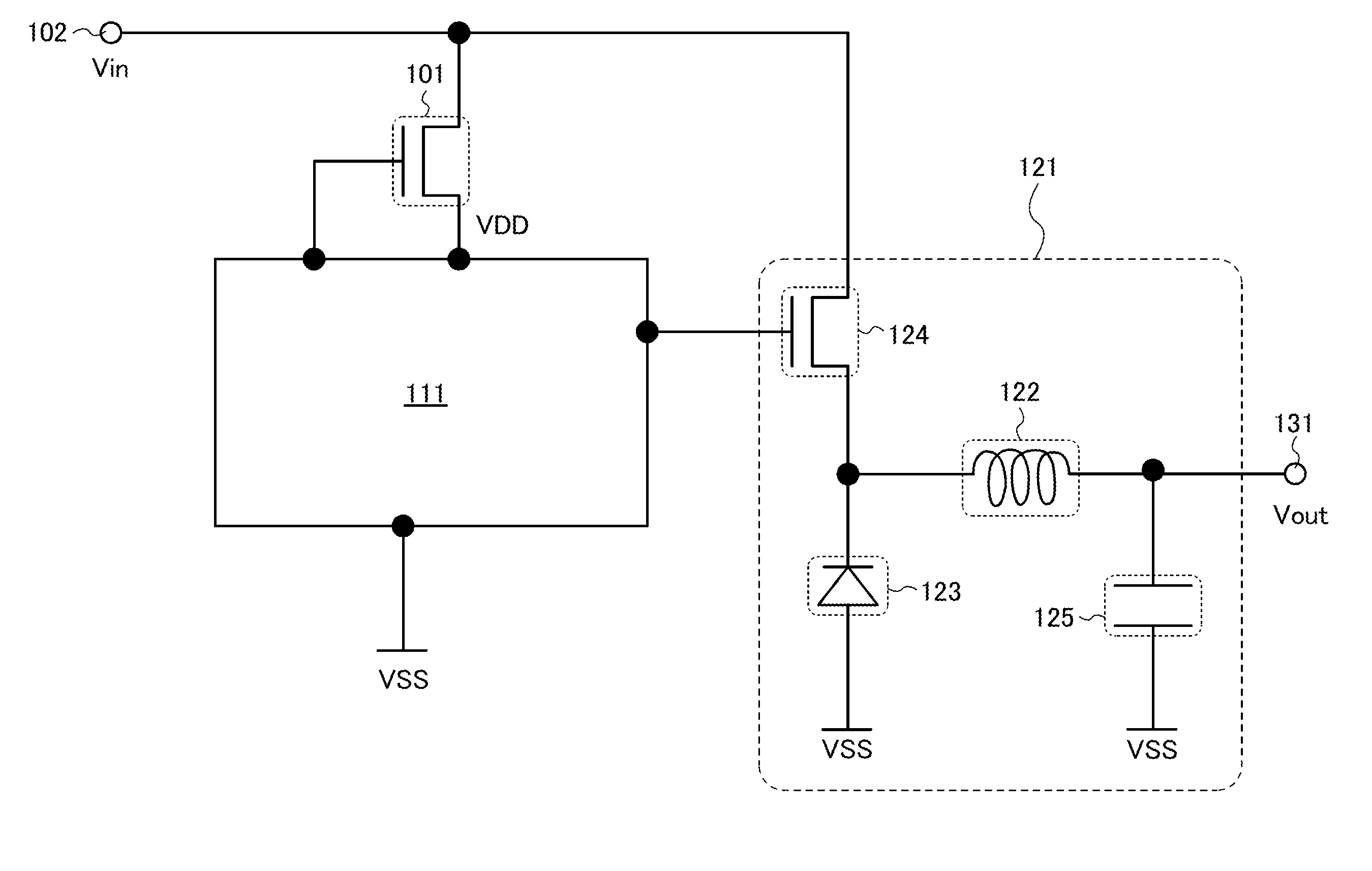

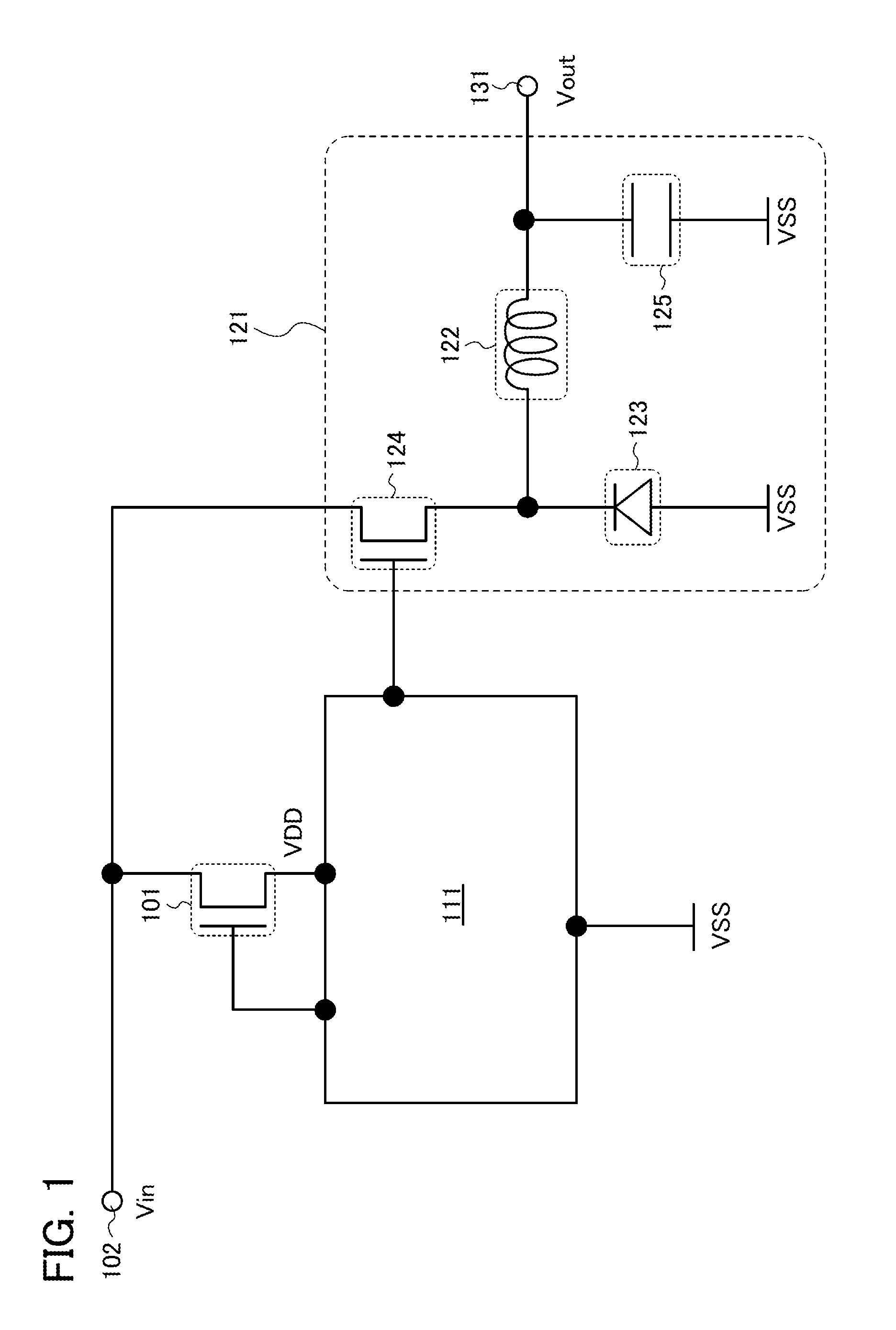

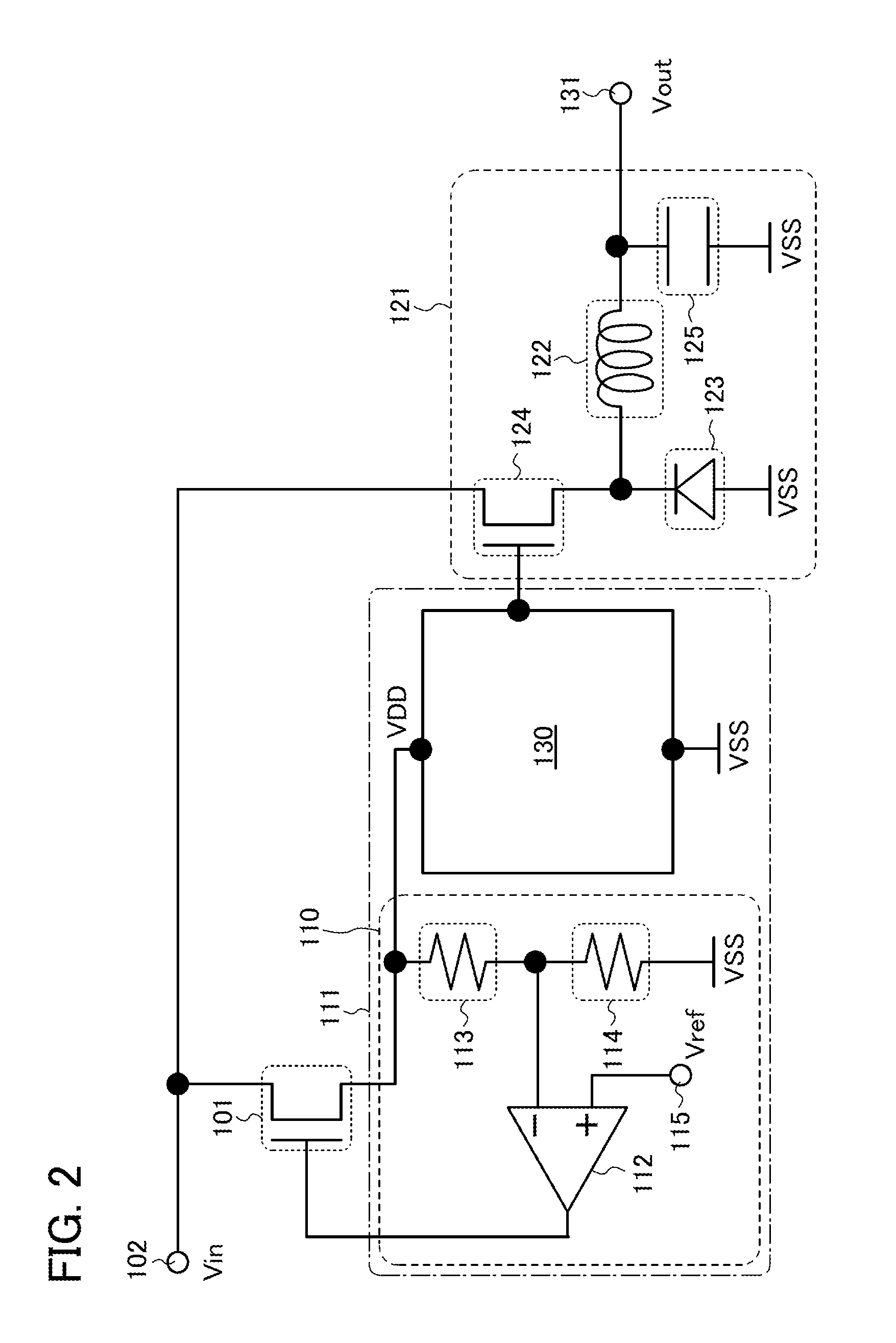

[0037]Embodiments of the invention disclosed in this specification will be hereinafter described with reference to the accompanying drawings. Note that the invention disclosed in this specification can be carried out in a variety of different modes, and it is easily understood by those skilled in the art that the modes and details of the invention disclosed in this specification can be changed in various ways without departing from the spirit and scope thereof. Therefore, the present invention is not construed as being limited to description of the embodiments. Note that, in the drawings hereinafter illustrated, the same portions or portions having similar functions are denoted by the same reference numerals, and repeated description thereof will be omitted.

[0038]Note that in the invention disclosed in this specification, a semiconductor device refers to an element or a device which functions by utilizing a semiconductor and includes, in its category, an electric device including an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com