Fixing device and mounting assembly comprising said fixing device

A technology for fixing devices and installing components, which is applied in the directions of transportation and packaging, antenna supports/installation devices, connecting components, etc., and can solve the problems of troublesome removal of installation modules, increased labor costs, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

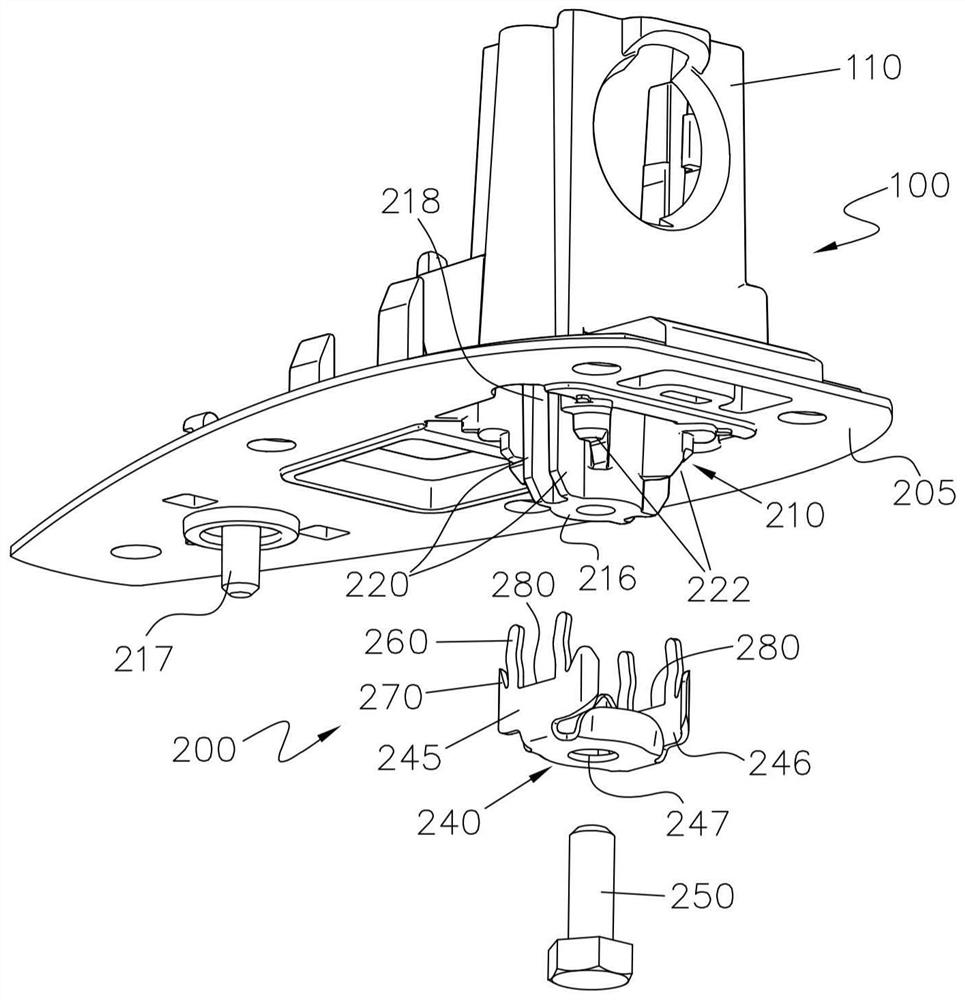

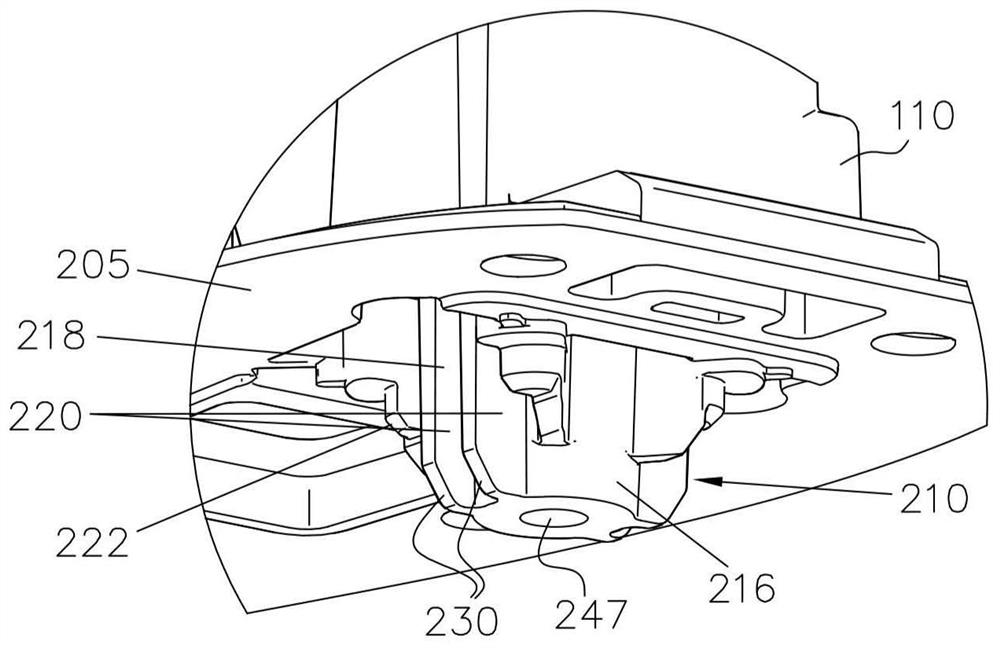

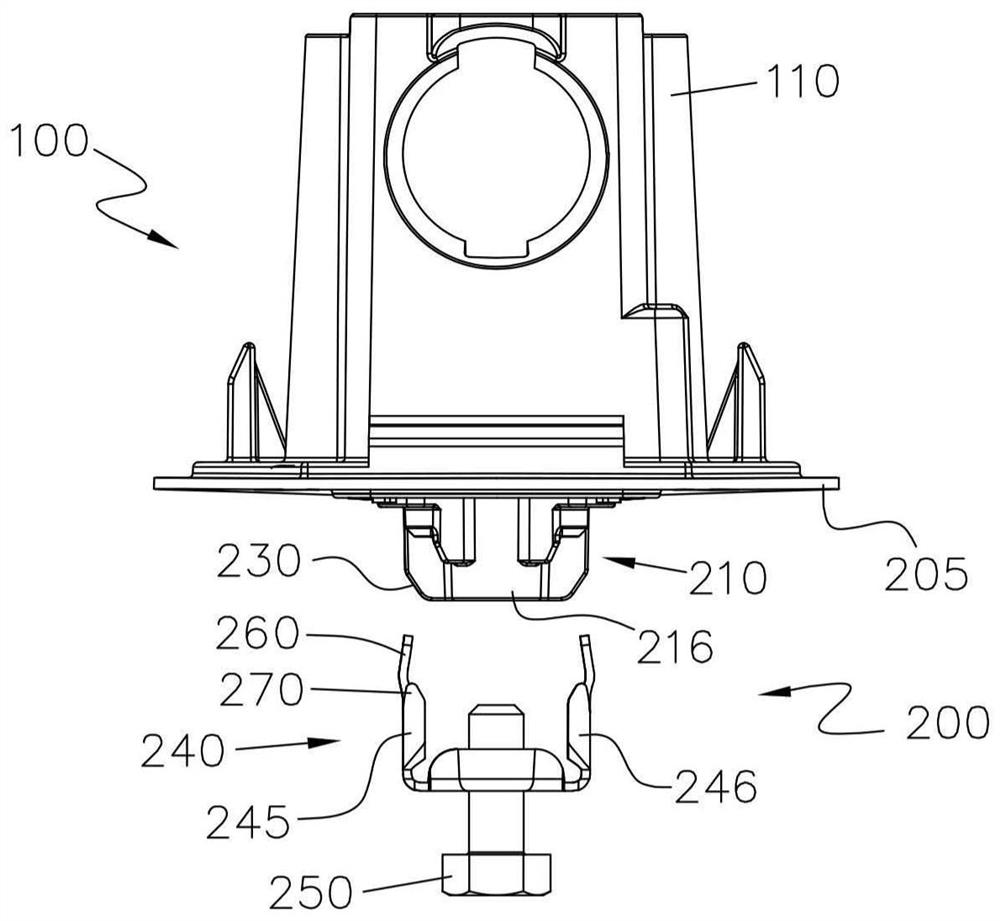

[0052] Disclosed below and in the accompanying drawings Figure 1 to Figure 14 Several non-limiting embodiments of the mounting assembly 100 of the present invention including a fixture are shown. In the illustrated embodiment, the securing device 200 is used to secure the mounting module (in this case the shark fin module 110 of the motor vehicle) to the vehicle surface (in this case the vehicle roof), such as Figure 1 to Figure 5 shown.

[0053] Fixture 200 includes base member 205 and bracket member 210 . The bracket member 210 has a first protruding portion 216 and the base member 205 has a second protruding portion 217 . Both protruding portions 216, 217 protrude downwards, such as figure 1 shown. In this embodiment, the first protruding portion 216 is made of aluminum and is part of the bracket member 210 . Other materials can be used. The first protruding portion 216 includes a chamfer 222, which will be described further below. The first protruding portion 216 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com