Safety protection structure and manufacturing method of flexible gas pipeline joint used in mine development

A technology of safety protection and production method, which is applied in the direction of pipes/pipe joints/fittings, hose connection devices, mechanical equipment, etc., which can solve problems such as time-consuming and laborious fixing and removal, flying air pipe ends, and safety cannot be guaranteed. Achieve the effect of convenient disassembly, simple structure and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

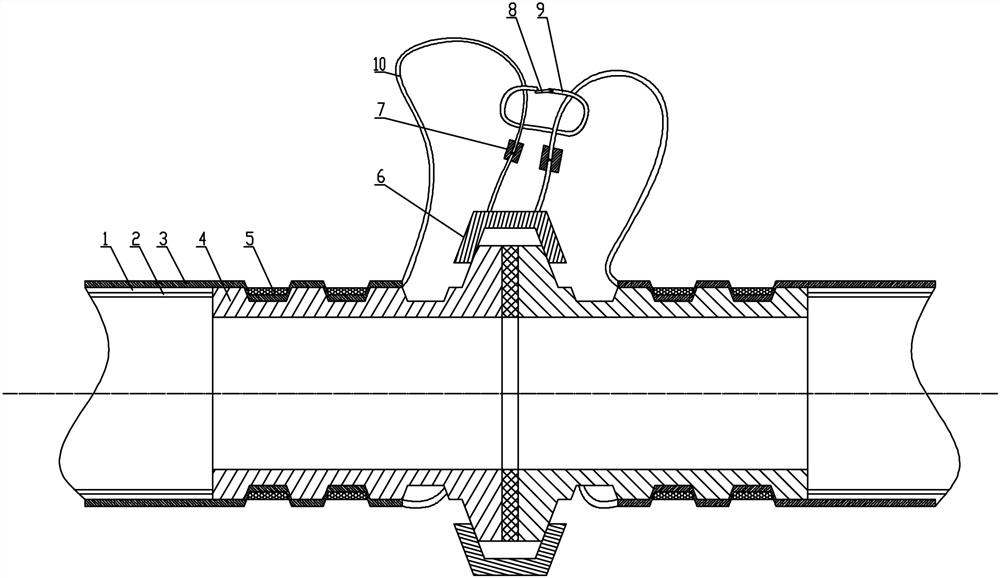

[0039] see Figure 1-9 , the mine adopts the safety protection structure of the flexible gas pipe joint, which includes a flexible gas pipe body, and the end part of the flexible gas pipe body is fixedly installed with a pipe joint 4 through a winding wire 5, and the ends of the two adjacent pipe joints 4 are installed. The head part is connected by the butt joints of the locking hoop 6, and is provided with a sealing gasket at the end faces of the two, and the outer casing 3 of the flexible gas delivery pipe body exceeds a length of the pipe joint 4, and the excess part is symmetrically cut and wound into a ring shape. Lap joints are connected by pressing the sleeve 7 at the lap joint to form a connecting ring 10 ; two adjacent connecting rings 10 are connected by a connecting buckle 9 . Through the safety protection structure of the above structure, it is arranged at the joint of the flexible gas delivery pipe, which can connect the two ends of the pipe joint reliably, there...

Embodiment 2

[0044] The production method of the safety protection structure of the flexible gas pipeline joint for mine development includes the following steps:

[0045] Step 1: Prepare two flexible gas pipe bodies that need to be docked;

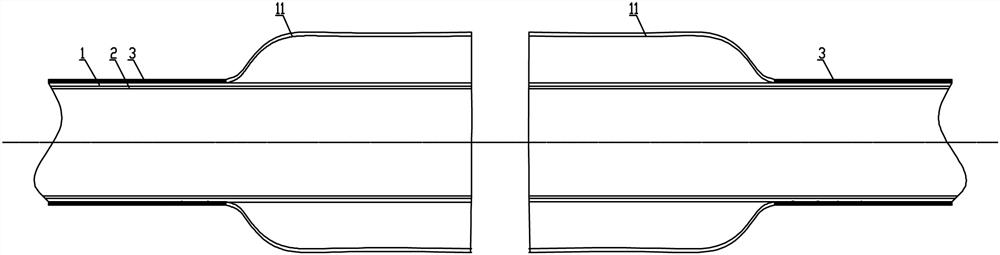

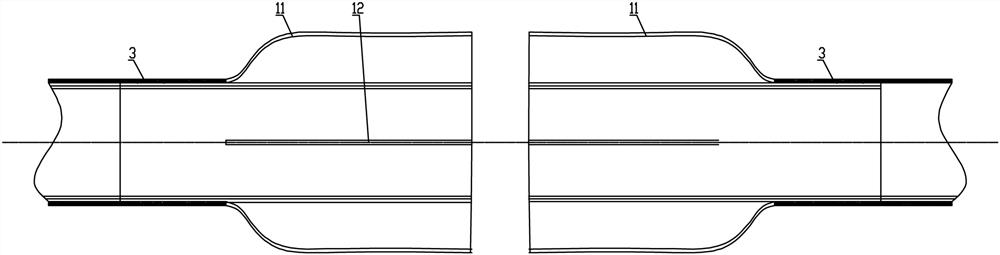

[0046] Step 2: Since the outer sleeve 3 is made of a braided layer of high-strength wear-resistant fiber material, which is wrapped on the outside of the pressure-bearing inner tube 1 and the air-tight inner tube 2, the ends of the outer sleeve 3 are symmetrically cut to form a shear incision 12;

[0047] Step 3: Cut and trim the end parts of the two flexible gas pipeline bodies to be connected, cut off the pressure-bearing inner tube 1 and the air-tight inner tube 2 at the cutting opening 12, and only keep the symmetrically cut outer sleeve 3. , so that the end portion of the outer casing 3 of the flexible gas delivery pipe body is beyond the pressure-bearing inner pipe 1 and the airtight inner pipe 2 within a section of length to form a reserved ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com