Aromatic hydrocarbon based proton exchange membrane and direct methanol fuel cell using same

a proton exchange membrane and hydrocarbon based technology, applied in the direction of fuel cell details, ion-exchangers, electrochemical generators, etc., can solve the problems of affecting the establishment of fuel cell techniques, affecting the performance of the cell as a whole, and excessively high membrane cost, so as to improve the energy density improve the efficiency of the fuel cell, and reduce the size of the fuel cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0082] Working examples of the invention will be described hereinafter, but the invention is not limited to the examples.

examples 1 to 4

, and Comparative Examples 1 to 4

Evaluating Method / Measuring Method

[0083] The thickness of a proton exchange membrane was obtained by making a measurement using a micrometer (Mitutoyo Standard Micrometer 0-25 mm 0.01 mm). The proton exchange membrane was allowed to stand still in a measuring room wherein the room temperature and the humidity were controlled into 20° C. and 30±5 RH %, respectively, for 24 hours or more, and then the membrane was cut into a sample having a size of 5×5 cm. The thicknesses at 20 points therein were measured, and the average value thereof was defined as the film thickness.

[0084] The amount of acid-type functional groups present in an ion exchange membrane was measured as the ion exchange capacity (IEC). For sample preparation, a sample piece (5×5 cm) was first dried under the flow of nitrogen gas in an oven at 80° C. for 2 hours, and further the piece was allowed to stand still in a desiccator filled with silica gel for 30 minutes. Thereafter, the dry...

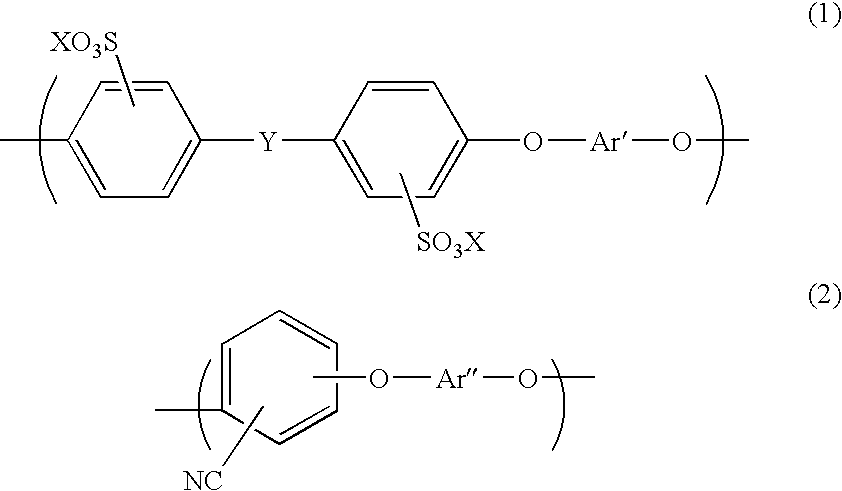

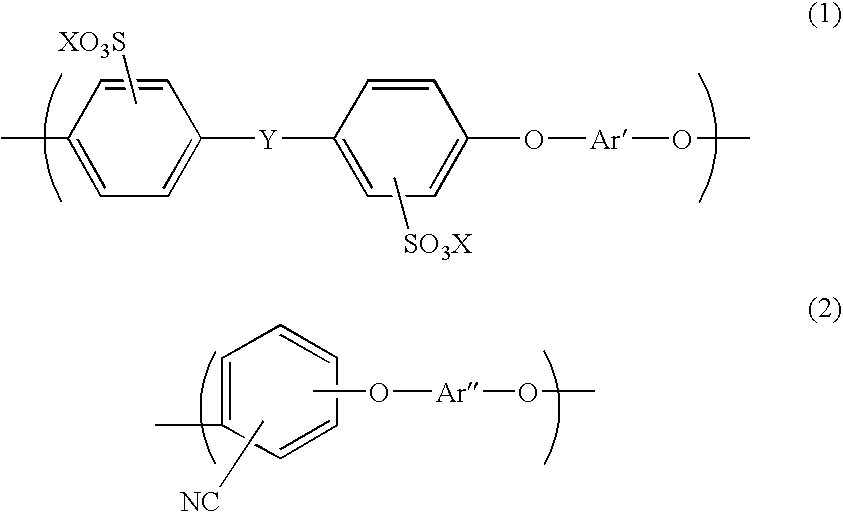

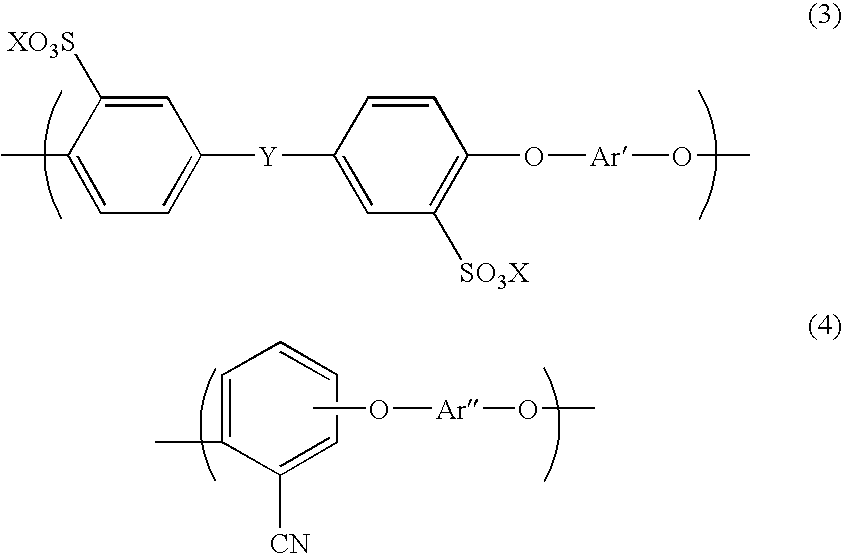

example 1

[0090] Prepared was a mixture of a disodium salt of 3,3′-disulfo-4,4′-dichlorodiphenylsulfone, 2,6-dichlorobenzonitrile, 4,4′-biphenol, and potassium carbonate to set the mol ratio therebetween into 1.00 / 5.62 / 6.62 / 7.62, and then 15 g of the mixture was weighed and put into a 100 mL four-necked flask, together with 3.50 g of a molecular sieve. Nitrogen was then caused to flow in the flask. NMP as a solvent was used. The solution was stirred at 155° C. for one hour, and then the reaction temperature was raised up to 190-200° C. The reaction was continued until the viscosity of the system was sufficiently raised (for about 4 hours). After the solution was naturally cooled, the molecular sieve, which precipitated, was removed, and a polymer was precipitated in a strand form in water. The resultant polymer was washed in boiled ultrapure water for 1 hour, and then dried. A 30% solution of the polymer in NMP was prepared. The polymer solution was cast into a thin film by casting, and dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com