Lubricating Oil Composition

a technology of lubricating oil and composition, which is applied in the direction of lubrication of auxiliaries, machines/engines, mechanical equipment, etc., can solve the problems of increasing the level of haze and sediment, reducing the efficiency of lubricating oil, so as to achieve the effect of reducing copper corrosion and superior deposit control properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Methylene-Bridged Alkyl Phenol

[0106]A mixture of 95% para-substituted, branched dodecylphenol (1910 g), alkyl benzene sulfonic acid catalyst (19.1 g) and toluene (574 g) was heated to 110° C. over 60 minutes in a 5 L reactor under a blanket of nitrogen gas which remained throughout the reaction process. An aqueous formaldehyde solution (37%, 497 g) was added stepwise over 2 hours and 30 minutes. The temperature was increased to 120° C. and the contents of the reactor maintained at this temperature for 1 hour and 30 minutes. The contents were cooled to 90° C. and an aqueous NaOH solution (50%, 42 g) added over 35 minutes. The contents of the reactor were heated to 130° C. over 25 minutes, kept at this temperature for 2 hours and toluene stripped therefrom by vacuum distillation. The product was an alkylphenol-formaldehyde condensate in the form of a methylene-bridged alkylphenol in which x was from 0 to 22 or more, Mn (by GPC)=1600, Mw=2100, and residual monomer of dod...

example 2

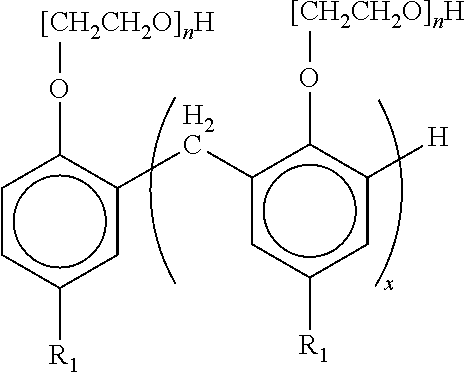

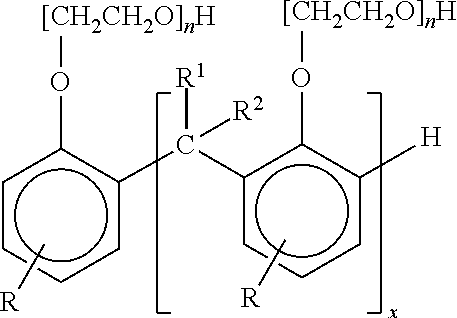

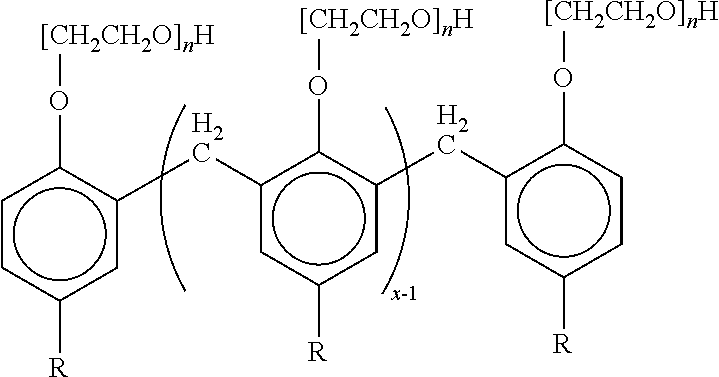

Preparation of Ethoxylated Methylene-Bridged Alkyl Phenol

[0107]Xylene (573 g) was added to Example 1 (2004 g), and then ethylene carbonate (1.02 equivalents per hydroxyl group, 645 g) at 90° C. over 35 minutes. The contents of the reactor were heated to reflux (150-160° C.). The ethylene carbonate was consumed over 4 hours, then xylene was stripped by vacuum distillation. The mixture had a molecular weight, as measured by GPC, of Mn=1700, Mw=2300, and residual monomer of dodecylphenol 13C NMR analysis of the mixture showed that it had the following properties with regard to the parameter n:

nmole %01196≧23

[0108]The temperature was lowered to 110° C. and group I, 150 neutral oil added (2278 g) and mixed for 1 hour to make an ethoxylated methylene-bridged alkylphenol mixture at 50% active ingredient (4556 g).

example 3

[0109]Heavy duty diesel lube oil formulation A was prepared containing ashless dispersant, metal containing detergent, zinc dialkyl dithiophosphate anti-wear agent, supplementary antioxidant, viscosity modifier and flow improver in a base oil. Heavy duty diesel lube oil formulation B (sulfated ash content=1.0%, TBN=12.3) was prepared with the same amount of all the additives except that 1.5 wt % active ingredient of the ethoxylated methylene bridged alkyl phenol mixture of Example 2 was added in place of 1.5 wt % of base oil. The weight ratio of the ashless detergent of Example 2 relative to the metal containing detergents in heavy duty diesel lube oil formulation B was 1.2 on an active ingredient basis.

[0110]Both products were tested in an OM501 LA heavy duty diesel deposit test and the merits produced are compared in Table I.

TABLE IPiston MeritsHeavy duty diesel formulation A21.7Heavy duty diesel formulation B31.4

[0111]Clearly, heavy duty diesel formulation B containing the ashles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight ratio | aaaaa | aaaaa |

| mass % | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com