Dressing bar for embedding abrasive particles into substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080]The entire content of U.S. Provisional Patent Application Nos. 61 / 174,472, filed Apr. 30, 2009; 61 / 187,658, filed Jun. 16, 2009; 61 / 220,149, filed Jun. 24, 2009; 61 / 221,554, filed Jun. 30, 2009; 61 / 232,425, filed Aug. 8, 2009; 61 / 232,525, filed Aug. 10, 2009; 61 / 248,194, filed Oct. 2, 2009; 61 / 267,031, entitled Dec. 5, 2009; and 61 / 267,030, filed Dec. 5, 2009, is hereby incorporated by reference.

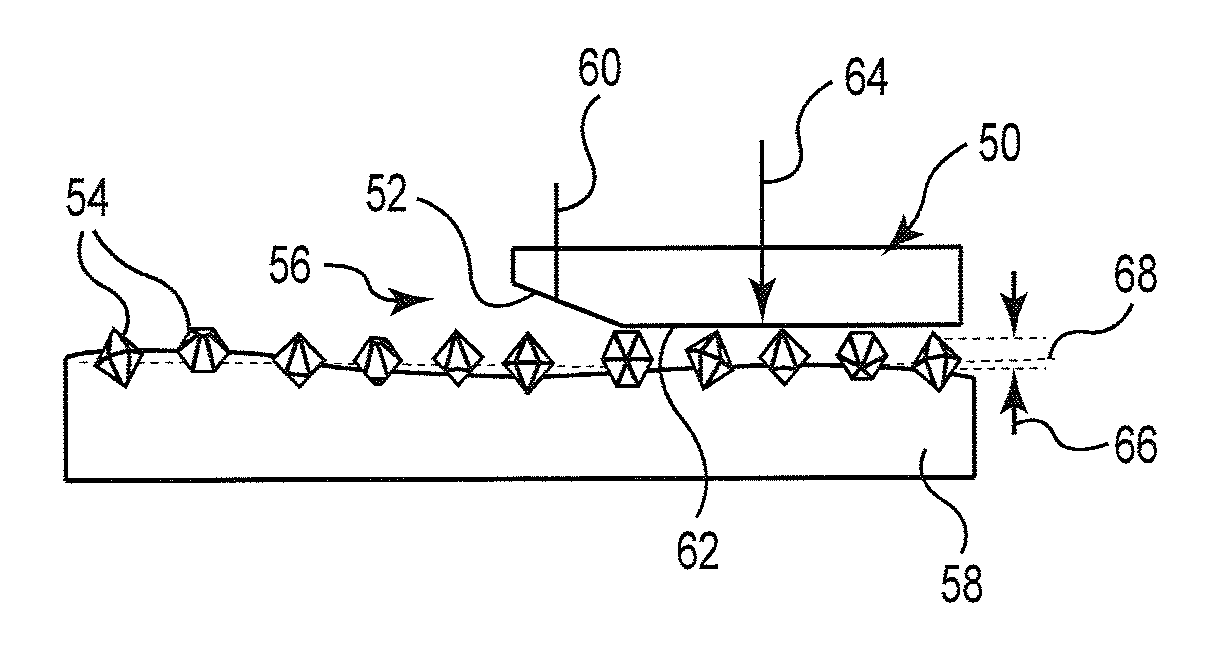

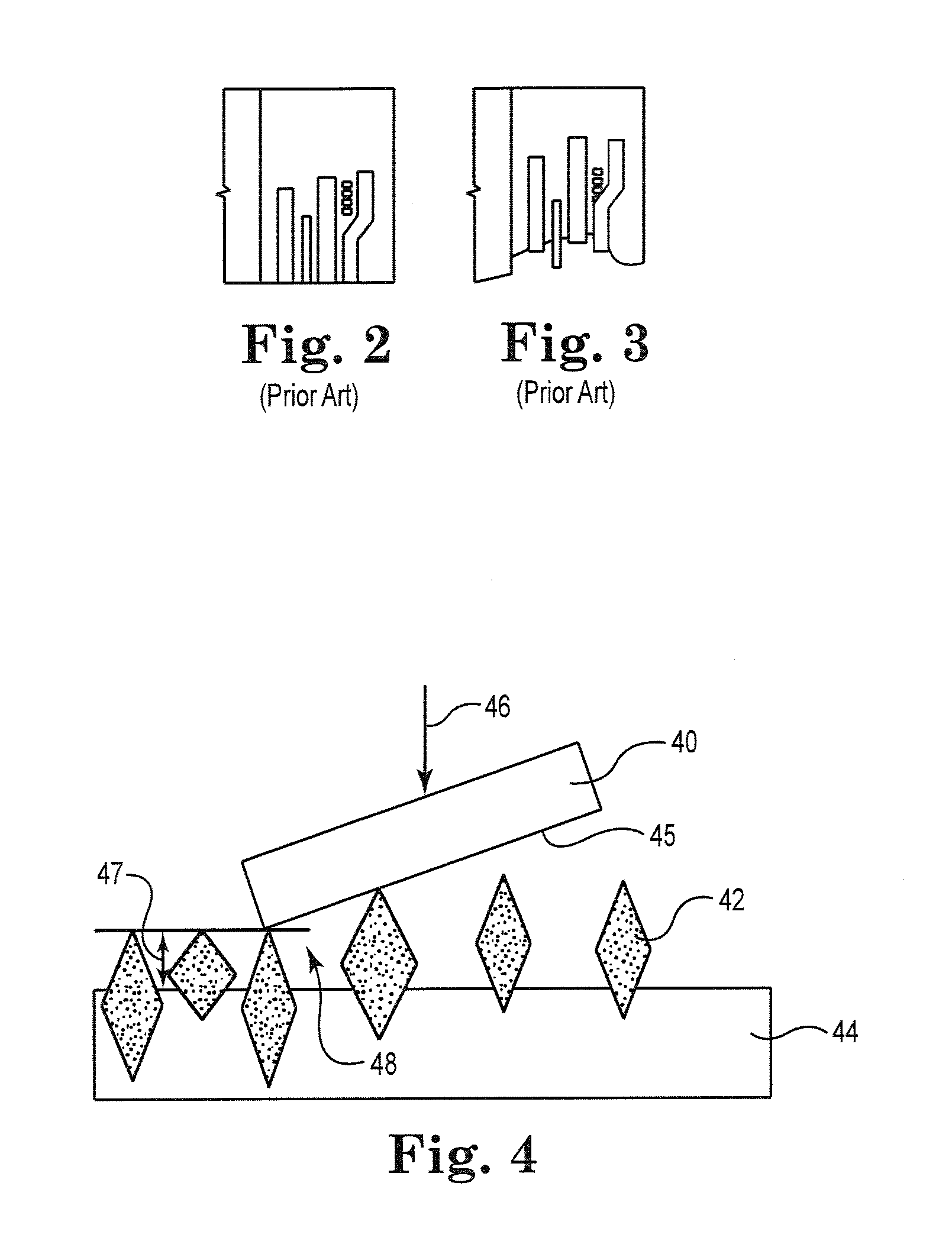

[0081]FIG. 4 is a schematic illustration of dressing bar 40 using progressive interference to embed abrasive particles 42 into substrate 44. Progressive interference refers to a tapering gap interface 48 between active surface 45 of the dressing bar 40 and the substrate 44. In the illustrated embodiment, the dressing bar 40 is at an angle with respect to the substrate 44 to progressively embed the abrasive particles 42 into the substrate 44, resulting in a constant clearance 47 of the abrasive particles 42 relative to the substrate 44. The interference can be adjusted by changing the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nanoscale particle size | aaaaa | aaaaa |

| Nanoscale particle size | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com