Vehicle air-conditioning system employing tube-fin-type evaporator using hfo 1234yf material refrigerant

a technology of evaporator and tubefin, which is applied in the direction of indirect heat exchangers, light and heating apparatus, transportation and packaging, etc., can solve the problems of affecting the performance of the air conditioning system, restricting its use, and affecting the use of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

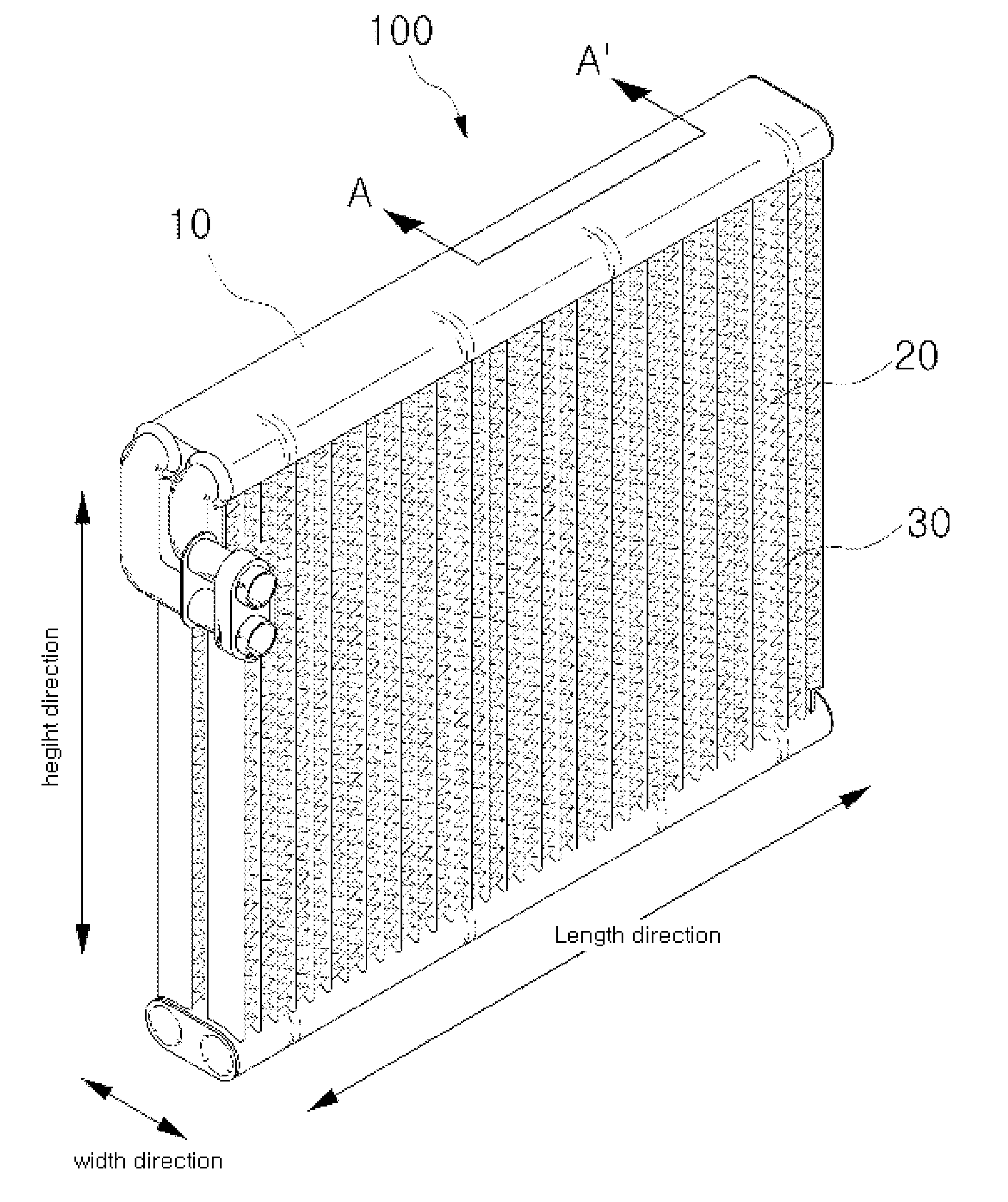

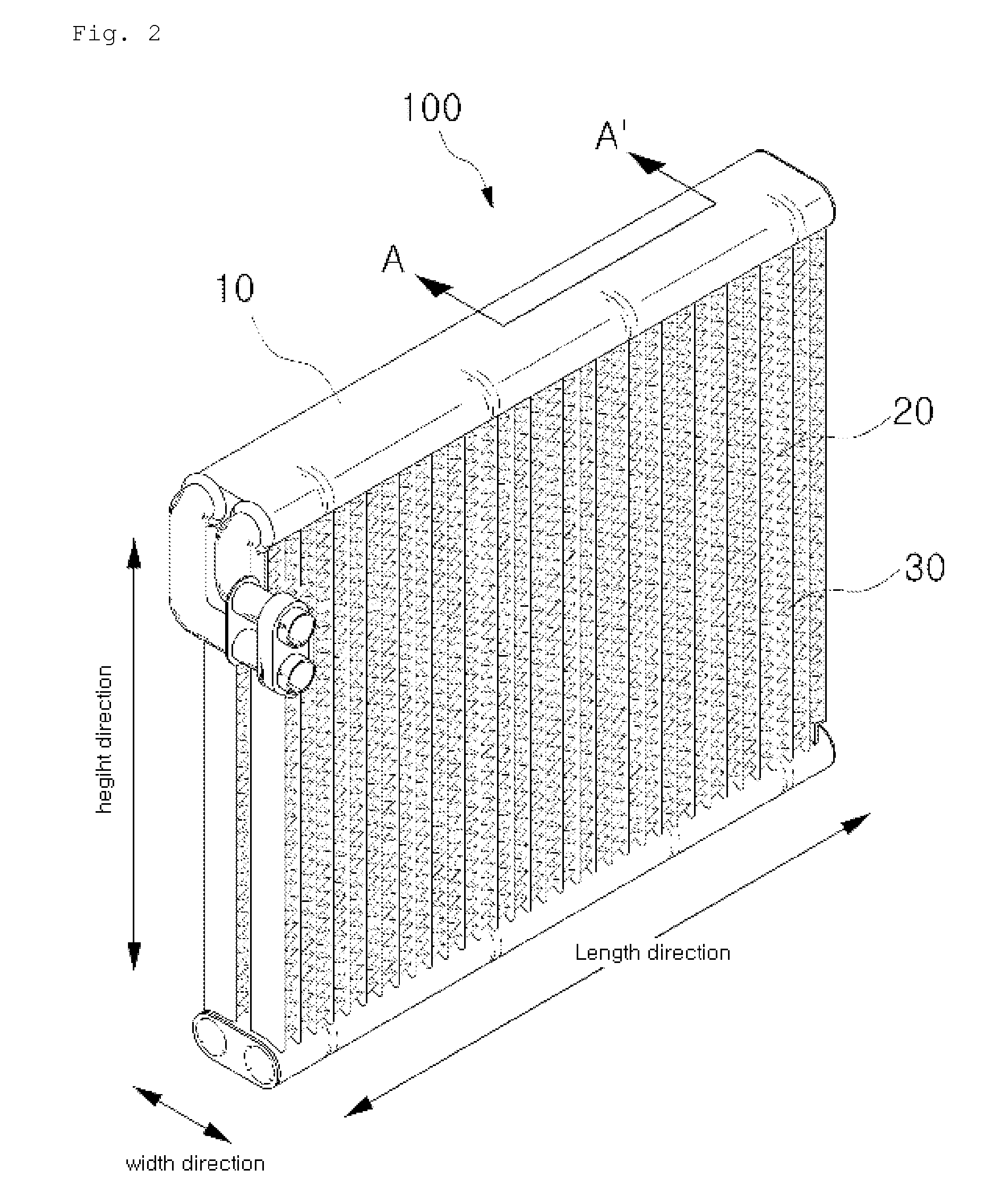

[0033]100: evaporator[0034]10: header tank[0035]20: tube[0036]30: fin

DESCRIPTION OF SPECIFIC EMBODIMENTS

[0037]The advantages, features and aspects of the invention will become apparent from the following description of the embodiments with reference to the accompanying drawings, which is set forth hereinafter.

[0038]FIG. 2 is a perspective view of a general tube-fin type evaporator. The general tube-fin type evaporator includes a plurality of tubes 20 which are arranged in parallel along an air-blowing direction to be spaced apart from each other at regular intervals; a fin 30 which is interposed between the tubes 20 so as to increase a heat exchange surface area with respect to air flowing between the tubes 20; and a pair of header-tanks 10 which are coupled to both ends of the tube 20 so that a heat exchange medium is flowed therethrough.

[0039]Generally, in the tube-fin type evaporator, refrigerant flow is divided into four passes or six passes. FIG. 3A is a schematic view showing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com