Rapid Growth Method and Structures for Gallium and Nitrogen Containing Ultra-Thin Epitaxial Structures for Devices

a gallium and nitrogen technology, applied in the field of lighting techniques, can solve the problems of conventional edison light bulbs, low light intensity, and low light intensity, and achieve the effect of rapid growth of gallium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

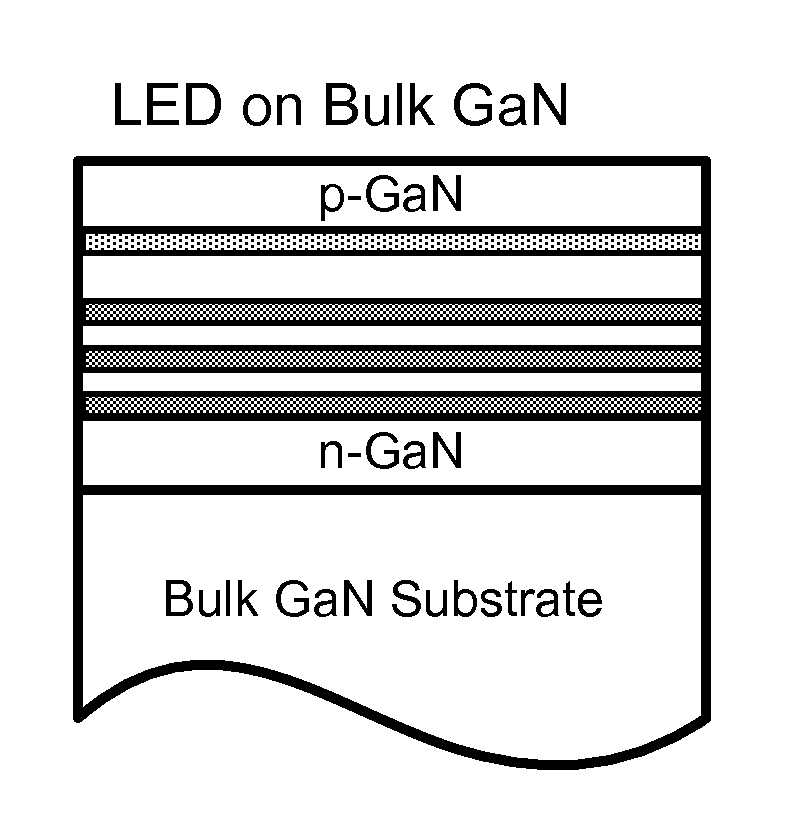

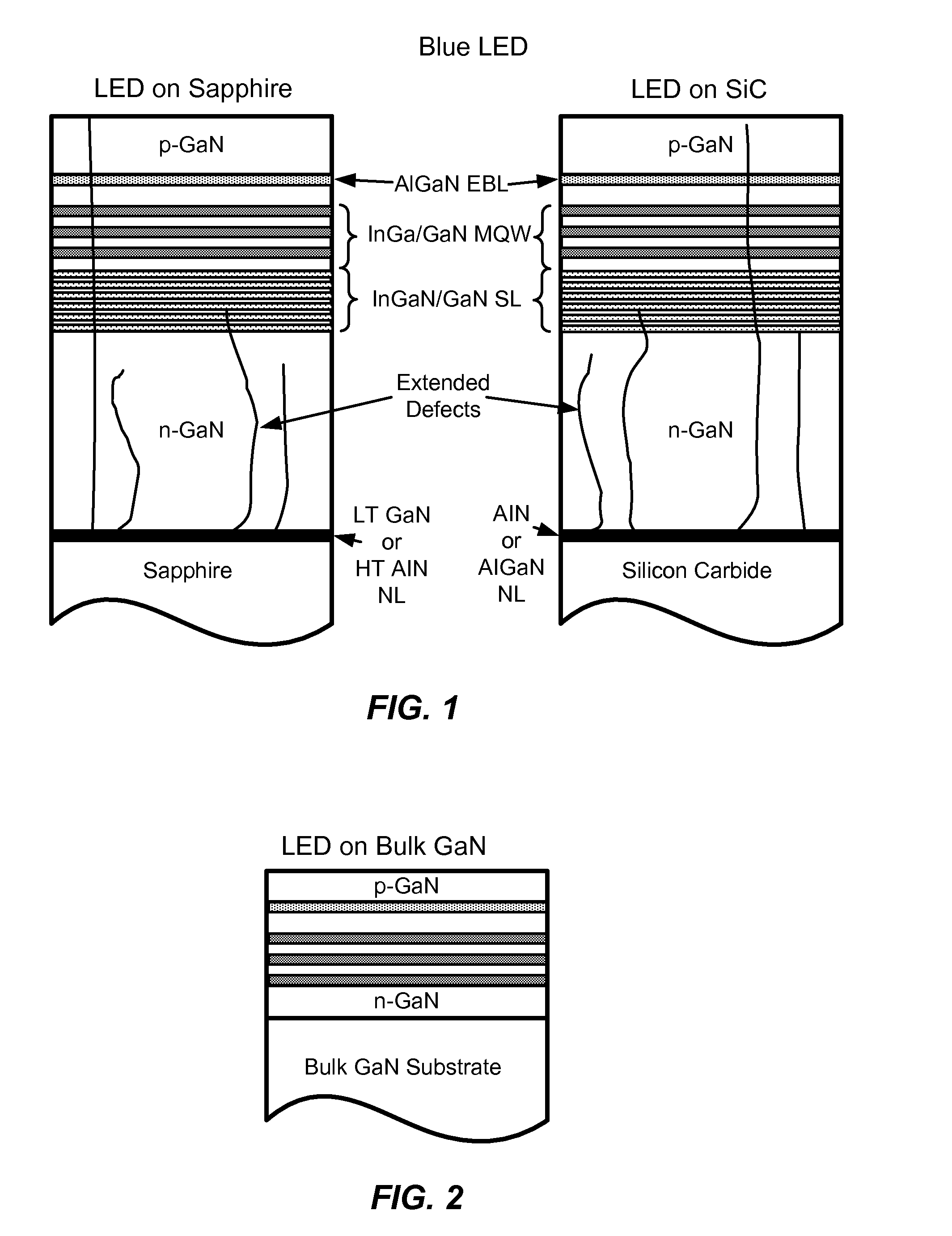

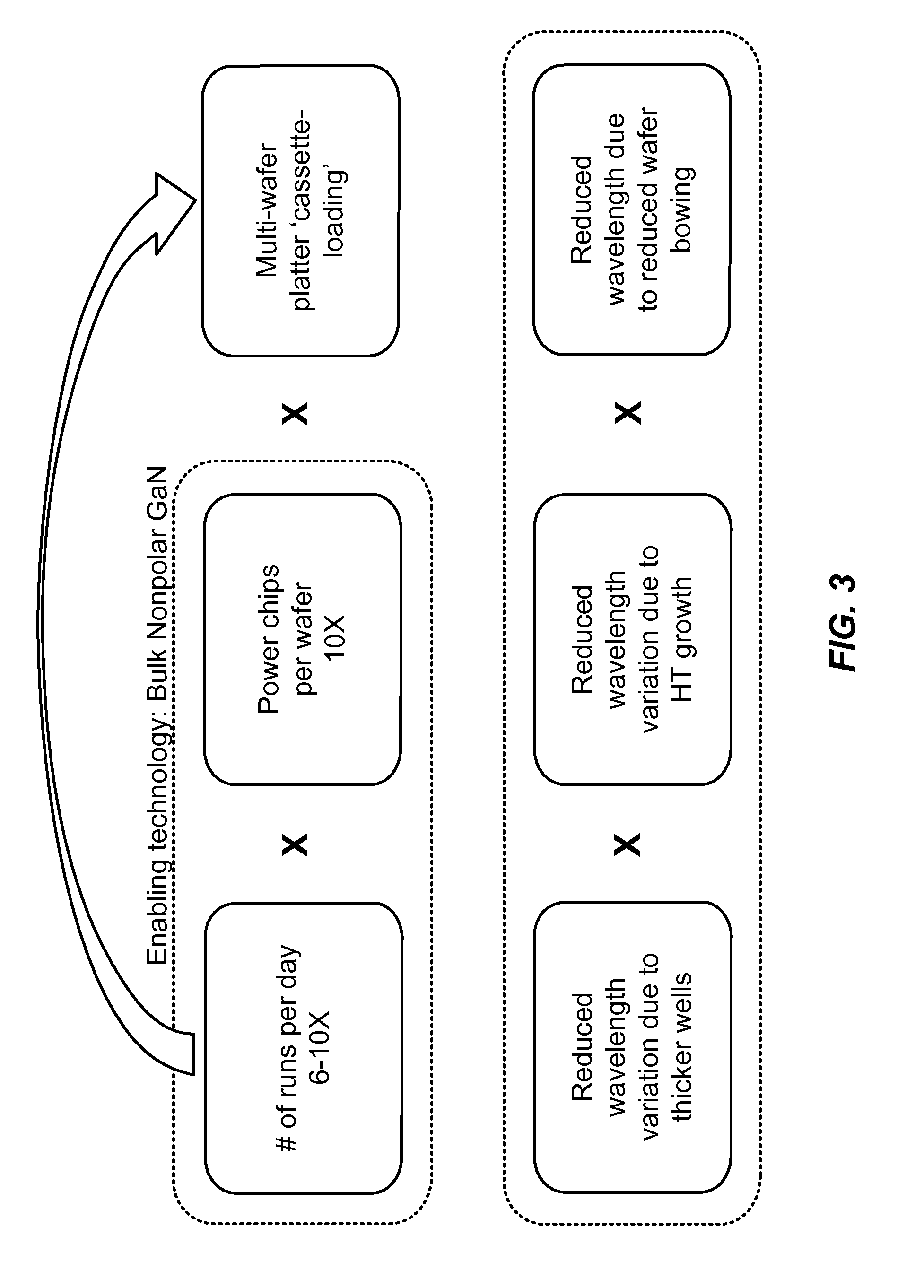

Image

Examples

example

[0098]To prove the principle and operation of the experiment, we performed certain experiments. We demonstrated high quality GaN epitaxial films at high growth rates of 4 microns per hour and greater. The experiment was performed using an atmospheric pressure MOCVD reactor configured with reactant gases, as noted. The chamber is configured to provide thermal energy to the growth as noted. The temperature of the reaction is measured by thermo-couples coupled to the susceptor, which holds the bulk wafer. It is believed that the temperature of the growth is slightly lower than those noted herein. Additionally, the experiment was performed using the following parameters.

1. Bulk wafer:

[0099]Non-polar, semipolar, or polar

[0100]GaN based material

[0101]Threading dislocation (TD) density<1E8 cm-2

[0102]Stacking fault (SF) density<1E4 cm-1

[0103]N-type Silicon Doping>1E17cm-3

2. N type epitaxial material:

[0104]Thickness of<2 um

[0105](Al,Ga,In) N based material

[0106]950 C

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com