Container and Sealing Membrane for Packaging of Reactive Products

a technology of reactive products and containers, applied in the field of packaging products, can solve the problems of long-term chemical resistance to aggressive products, formulations pose significant challenges, and cannot be used in the presence of aggressive products, and achieve the effects of prolonging storage times, good sealing, and superior performance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

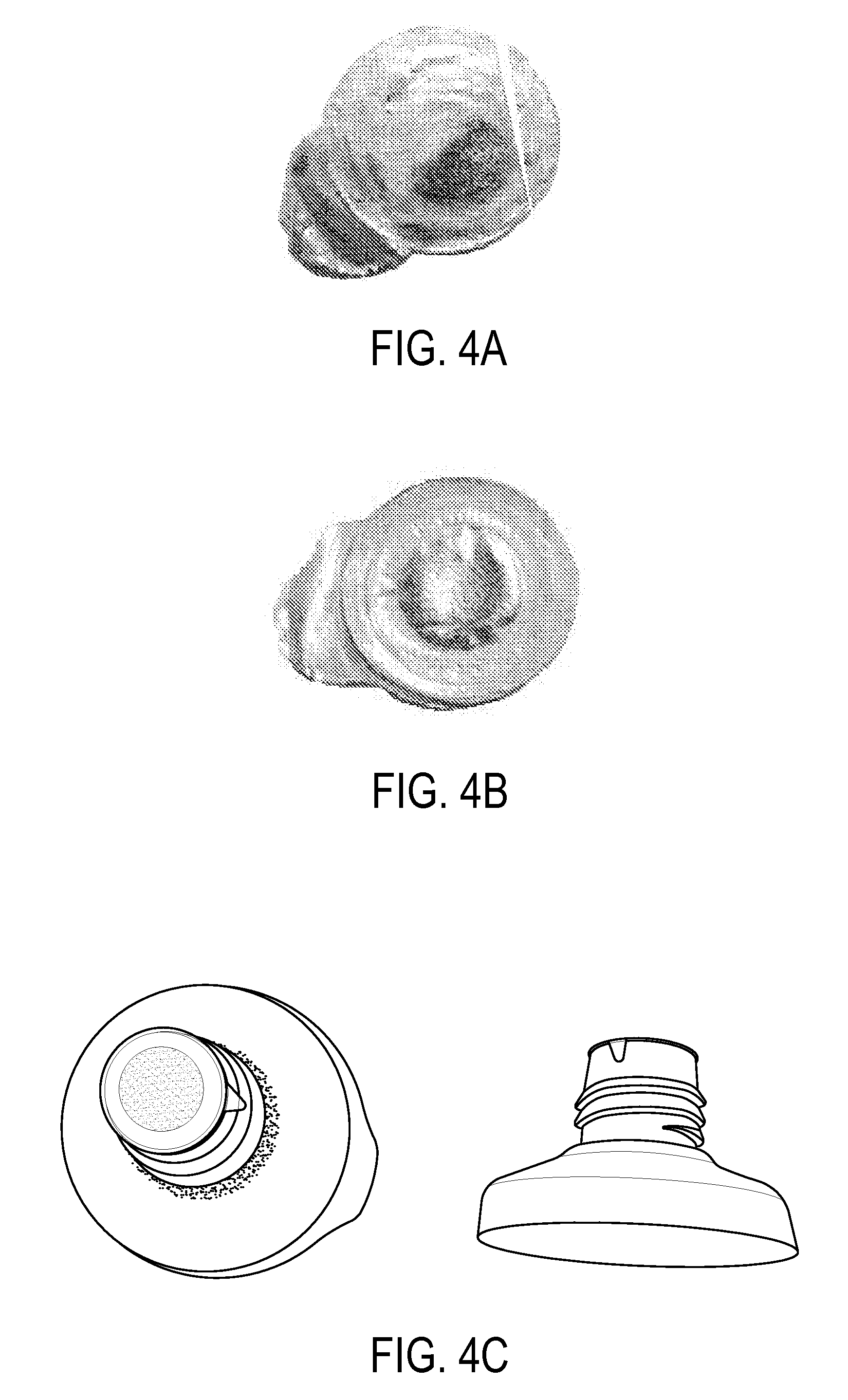

[0032]Replacement of the ionomer based seal membrane, described above in Comparative Example 1, with a seal membrane made of Aluthene® 40 II E 133 / 6 (Alcan Packaging, Selestat, France) resulted in successful storage of the same hair colorants tested in this comparative example, for comparable time periods at both ambient and elevated temperatures. The tested seal membrane comprises an inner layer comprising a blend of a low density polyethylene having a density of 0.92 g / cm3 and polypropylene as an anti-cohesion additive, and having a weight of 30 g / m2, a middle bather layer comprising soft aluminum having a thickness of 37 micrometers, an adhesive layer having a thickness of 3 micrometers, and an external layer made of a polyester film having a thickness of 12 micrometers. The sealing membrane and tubular container failure modes illustrated in FIGS. 4A, 4B, and 4C were not observed. The sealing membrane / container package was acceptable for storage of the aggressive hair colorant, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com