Lithium secondary battery with high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

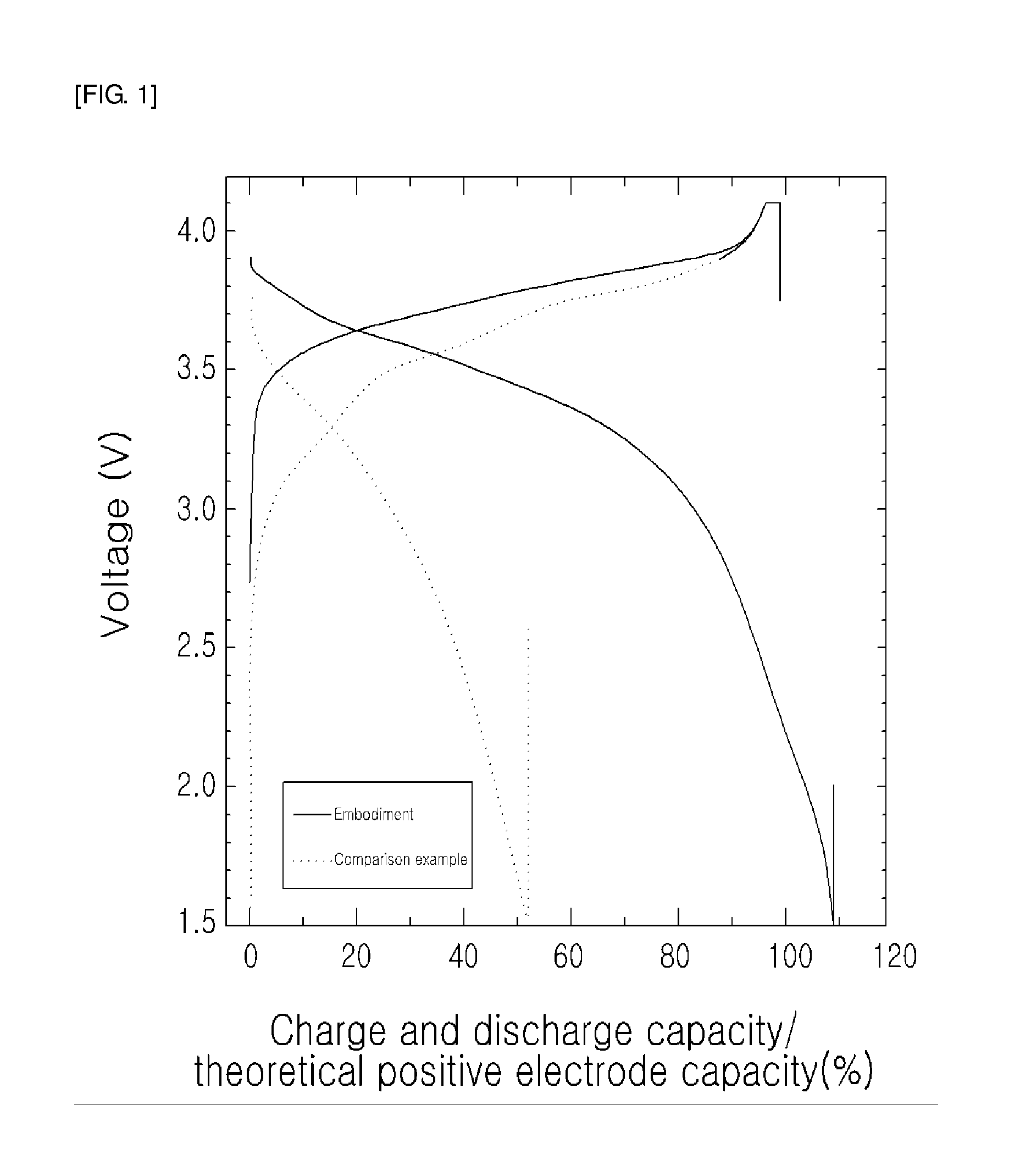

Image

Examples

embodiment

[0045]The positive electrode and the negative electrode of the lithium secondary battery were fabricated using the following method.

[0046](1) Manufacture of Negative Electrode

[0047]The negative electrode plate, including a copper (Cu) current collection plate of 10 μm in thickness and coating layers on both surfaces, was fabricated. Here, the coating layer was made of SiO having a capacity per unit weight of 1200 mAh / g and an initial irreversible capacity of 800 mAh / g, a carbon-based material having a capacity of about 300 mAh / g and an initial irreversible capacity of 30 mAh / g, a rubber component functioning as a binder, CMS, and conductive carbon acetylene black. In this case, SiO was 40%, the carbon-based material was 50%, the rubber component was 4%, CMC was 4%, and the conductive carbon acetylene black was 2%, of a total percentage of the coating layer. Further, the coating layer was controlled to have a reversible lithium storage and discharge ability of 3 mAh / cm2. Next, the ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com