Copper-contaning silica glass, method for producing the same, and xenon flash lamp using the same

a technology of copper condensate silica glass and xenon flash lamp, which is applied in the direction of glass making apparatus, manufacturing tools, discharge tube luminescnet screen, etc., can solve the disadvantages of laser excited by a lamp, high-power laser diodes are so expensive, and the laser energy efficiency is low disadvantageously, so as to improve the oscillation efficiency of laser energy, easy to obtain, and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

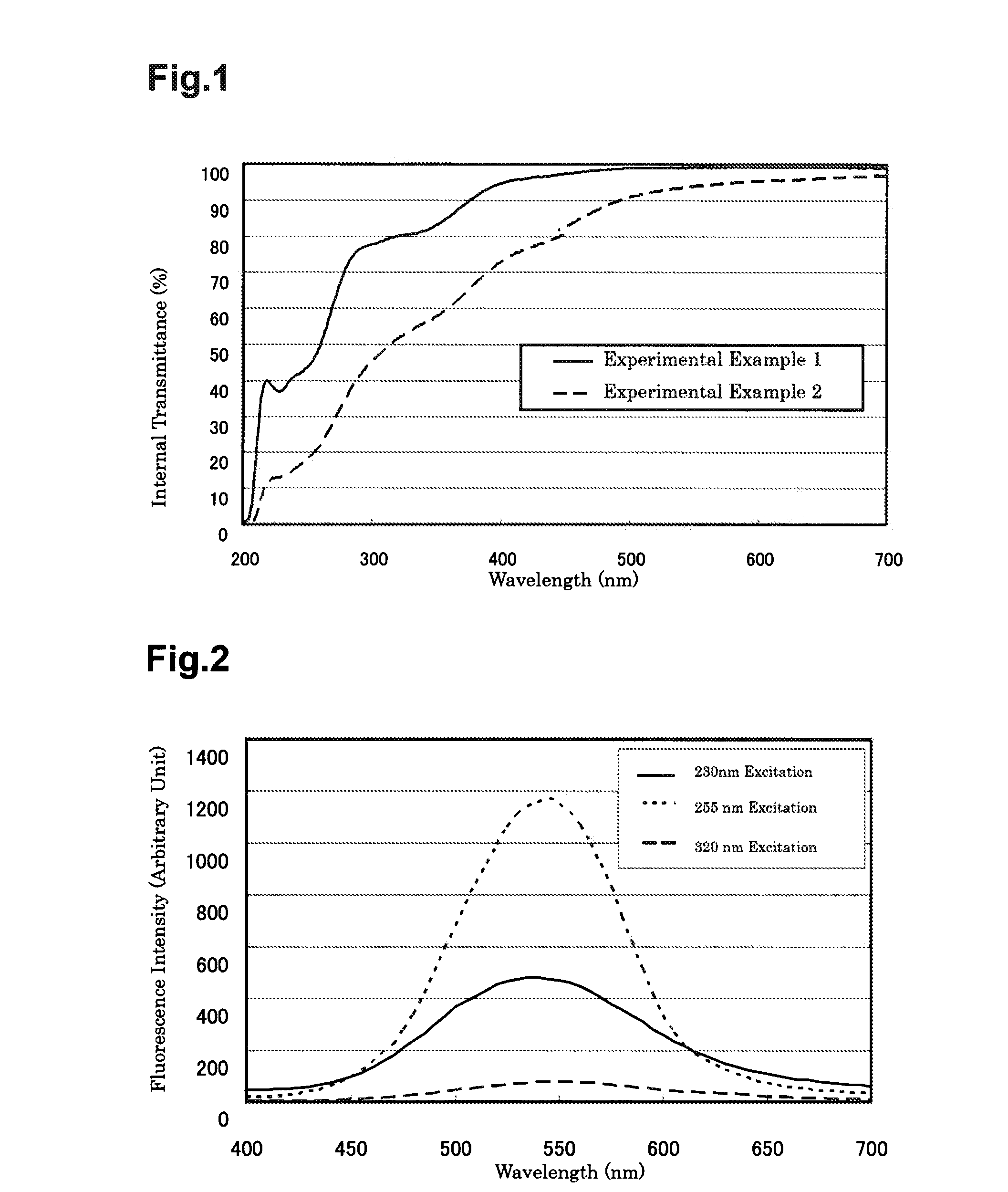

[0068]Silicon tetrachloride was introduced into an oxyhydrogen flame to produce silica particles, then the silica particles were deposited onto a rotating target, and thereby a silica porous body having an outside diameter of 250 mm, an inside diameter of 100 mm and a length of 800 mm was produced. The silica porous body was removed from the target, and then immersed in a copper (II) chloride solution having a copper (II) chloride concentration of 20 mg / L in which copper (II) chloride with purity of 99.999% was dissolved into pure water and was allowed to stand at a temperature of 25° C. for 100 hours, whereby copper doping operation was performed. Next, the silica porous body was taken out from the copper (II) chloride solution, and was dried in dry air at a temperature of 90° C. for 100 hours, After drying, the dried silica porous body was immersed into pure water and was allowed to stand at a temperature of 25° C. for 24 hours, the copper concentration having been averaged (unstu...

example 2

[0083]A cylindrical copper-doped silica glass having an outside diameter of 200 mm, an inside diameter of 100 mm and a length of 600 mm was obtained under the same conditions as in Example 1 except that a copper (II) chloride concentration in a copper (II) chloride solution was set to 4 mg / L when copper was doped.

[0084]The copper-doped silica glass was extended and cut in the same way as in Example 1 to produce copper-doped silica glass tubes each having an outside diameter of 20 mm, a thickness of 2.5 mm, and a length of 250 mm.

[0085]A copper concentration contained in the silica glass tube was 10 wtppm, each of the concentrations of Na, K, Mg, Ca and Al was less than 0.05 wtppm. The OH group concentration was 100 ppm. The internal transmittance per 2.5 mm thickness at a wavelength of 530 nm was 99.5%. The total cross-sectional area of bubbles each having a diameter of 0.08 mm or more which had been contained in 100 cm3 thereof was 0.01 mm2, and viscosity log η at a temperature of ...

example 3

[0089]A cylindrical copper-doped silica glass having an outside diameter of 200 mm, an inside diameter of 100 mm and a length of 600 mm was obtained under the same conditions as in Example 1 except that a copper (II) chloride concentration in a copper (II) chloride solution was set to 60 mg / L when copper was doped.

[0090]The copper-doped silica glass was extended and cut in the same way as in Example 1 to produce copper-doped silica glass tubes each having an outside diameter of 20 mm, a thickness of 2.5 mm, and a length of 250 mm.

[0091]A copper concentration contained in the silica glass tube was 150 wtppm, each of the concentrations of Na, K, Mg, Ca and Al was less than 0.05 wtppm. The OH group concentration was 100 ppm. The internal transmittance per 2.5 mm thickness at a wavelength of 530 nm was 96.5%. The total cross-sectional area of bubbles each having a diameter of 0.08 mm or more which had been contained in 100 cm3 thereof was 0.05 mm2, and viscosity log η at a temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com