Methods and instrumentation for during-synthesis monitoring of polymer functional evolution

a technology of functional evolution and monitoring method, applied in the direction of instruments, process and machine control, fluorescence/phosphorescence, etc., can solve the problems of drift and bias in empirical and inferential models, none of the streams of co-conversion continuous or substantially continuous, and the inability to measure the threshold characteristics of polymer stimuli responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

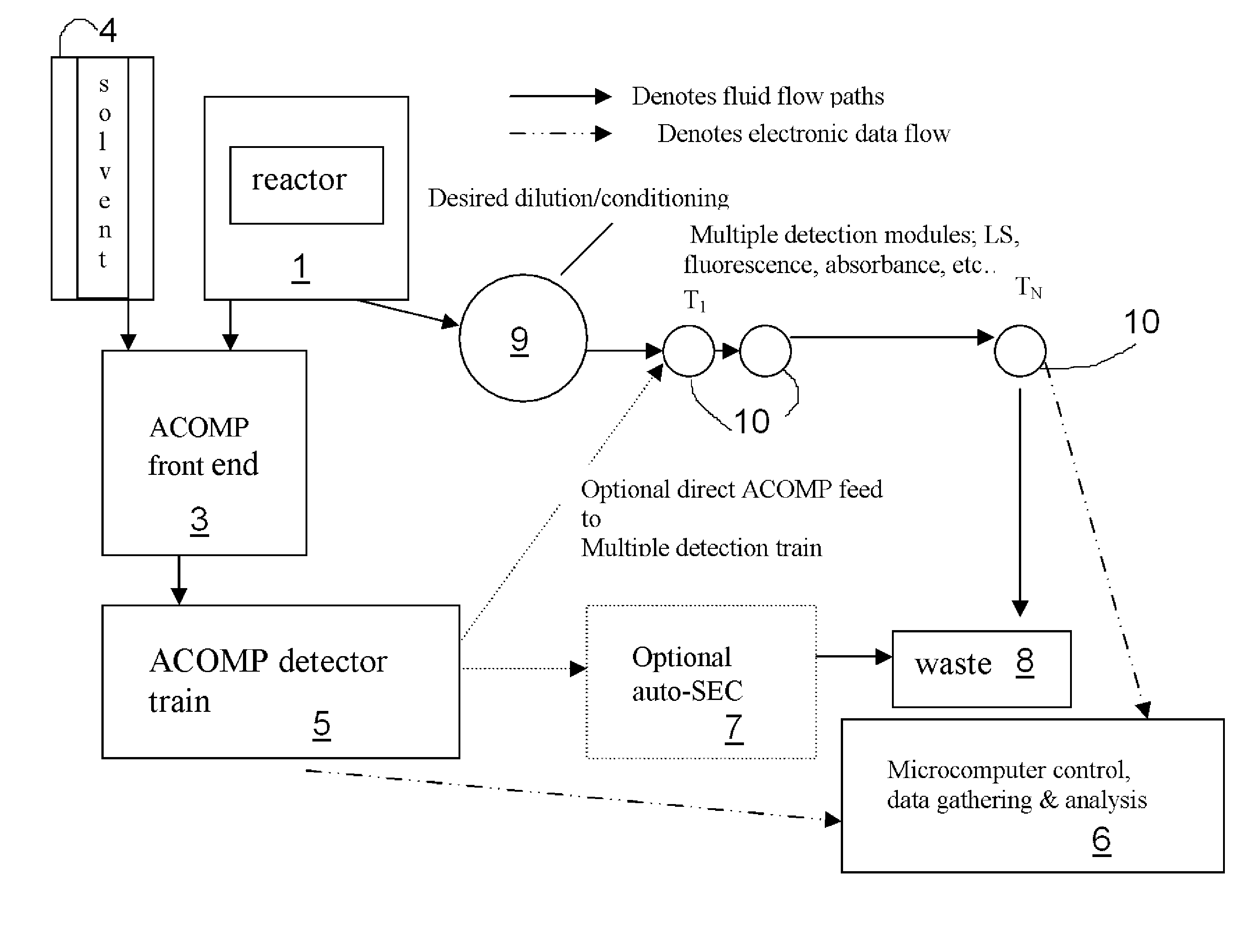

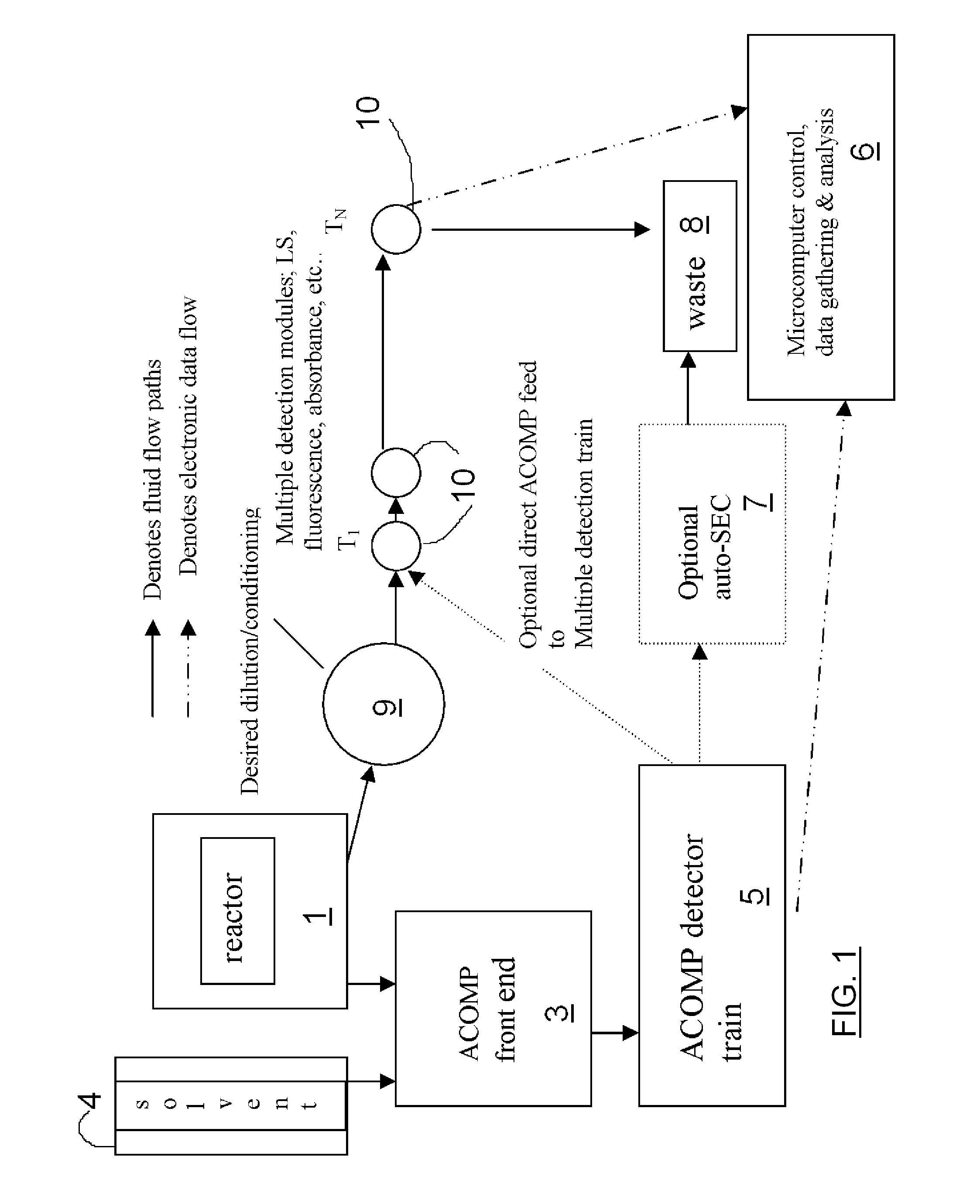

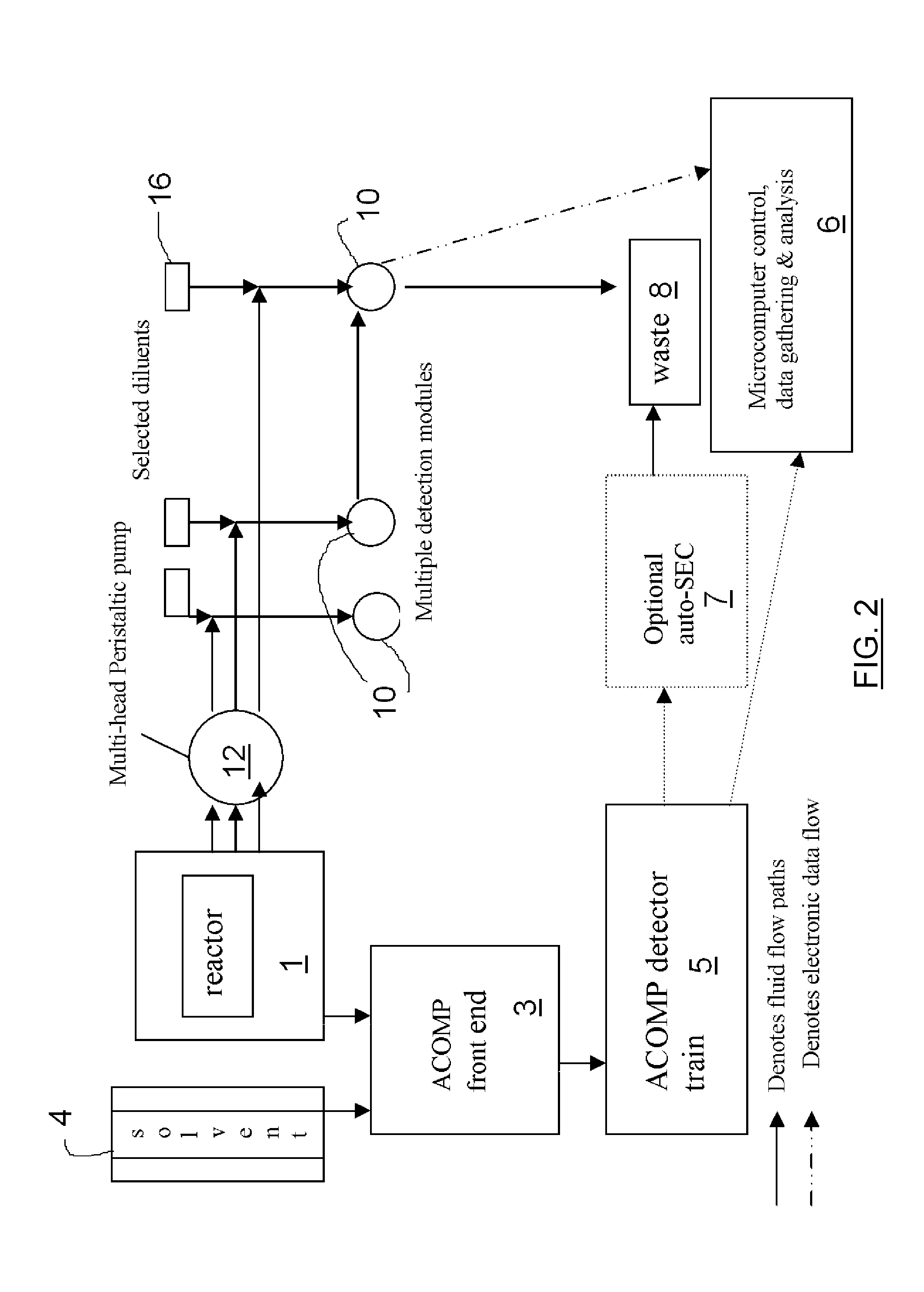

Embodiment Construction

[0101]Herein, ‘evolution of stimuli responsiveness’ refers to how the ability of polymers and / or colloids to go through phase and conformational transitions, associations with other molecules, synthetic and biomacromolecules, supramolecular and self-organizing assemblage, reactivities with other species, etc., as defined above, changes as the properties of the polymers and / or colloids themselves change during synthesis; i.e. how changing properties such as molecular mass, composition, comonomer sequentiality (e.g. block, gradient, random), grafting, cross-linking, microgelation, bioconjugation, association with nanoparticles, whether covalent or non-covalent, and post-polymer chemical and physical modifications (such modifications can include, but are not limited to quaternization, PEGylation, sulfonation, carboxylation, amination, ‘clicking’ on of any one or combination of functional groups or oligomers or polymers) etc. affect these types of stimuli responsiveness, and how the pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| volumes | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com