Pharmaceutical formulation for use in hiv therapy

a technology for hiv therapy and pharmaceutical formulations, applied in the field of pharmaceutical formulations, can solve the problems of lack of bioavailability, metallic taste, and criticized soft gel formulations, and achieve the effect of reducing the chance of degradation of drug constituents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

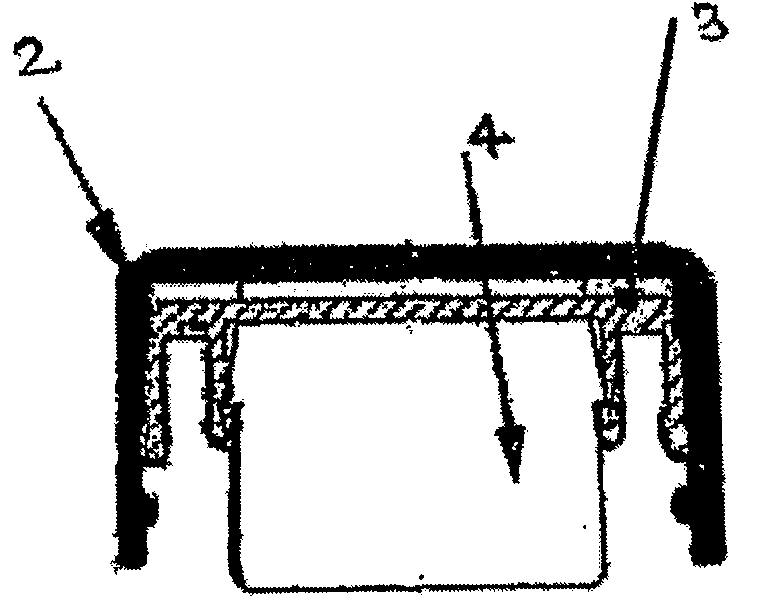

Image

Examples

example 1

Wet Granulation Process

[0077]

Ingredient% w / wLopinavir20.0Ritonavir5.0Poloxamer 12412.0Hypromellose (6 cps)58.0Colloidal silicon dioxide3.0Sodium stearyl fumarate2.0Dichloromethaneq.s.

[0078]Manufacturing Steps:[0079]a Lopinavir, Ritonavir and Poloxamer 124 were dissolved in dichloromethane;[0080]b. Colloidal silicon dioxide and hypromellose were sifted through a size 20 mesh;[0081]c. The mixture from step [b] was loaded into a rapid mixer granulator;[0082]d. The drug mixture of step [a] was added to the granulator and processed;[0083]e. The product was dried under vacuum at about 40° C.;[0084]f. The dry product was then milled in a multimill;[0085]g. Sodium lauryl sulfate was mixed with milled product and sifted for about 10 minutes;[0086]h. This sifted product was finally compressed into tablets.

example 2

[0087]

Ingredient% w / wLopinavir20.0Ritonavir5.0Glyceryl mono-oleate4.0Poloxamer 40763.0Colloidal silicon dioxide5.0Sodium stearyl fumarate2.0Talc1.0Methanolq.s.

[0088]Manufacturing Steps:[0089]a. Lopinavir, Ritonavir and glyceryl mono-oleate were dissolved in methanol;[0090]b. Colloidal silicon dioxide and Poloxamer 407 were sifted through a size 20 mesh;[0091]c. The mixture from step [b] was loaded into a rapid mixer granulator;[0092]d. The drug solution of step [a] was added to the granulator and processed;[0093]e. The product was dried under vacuum at about 40° C.;[0094]f. The dry product was then milled in a multimill;[0095]g. Sodium lauryl sulfate and talc was mixed with milled product and sifted for about 10 minutes;[0096]h. This sifted product was finally compressed into tablets.

example 3

[0097]

Ingredient% w / wLopinavir15.0Ritonavir3.75Glyceryl monooleate5.0Poloxamer 40715.0Hypromellose (3 cps)55.25Colloidal silicon dioxide3.0Hydrogenated cottonseed oil2.0Sodium lauryl sulfate1.0Methanolq.s.

[0098]Manufacturing Steps:[0099]a. Lopinavir, Ritonavir and glyceryl monooleate were dissolved in methanol;[0100]b. Colloidal silicon dioxide and hypromellose were sifted through a size 20 mesh;[0101]c. The mixture from step [b] was loaded into a rapid mixer granulator;[0102]d. The drug solution of step [a] was added to the granulator and processed;[0103]e. The product was dried under vacuum at about 45° C.;[0104]f. The dry product was then milled in a multimill;[0105]g. Sodium lauryl sulfate and hydrogenated cottonseed oil was mixed with milled product and sifted for about 10 minutes;[0106]h. This sifted product was finally compressed into tablets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com