Casein active polypeptide nano-assembled health-care food and preparation method thereof

An active peptide and nano-assembly technology, applied in food science and other directions, can solve the problem of peptides being difficult to be effectively absorbed and unable to play a role, and achieve the effect of retaining activity, large chemical reactivity, and high hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

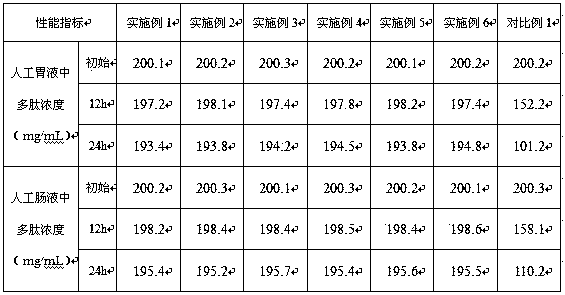

Examples

Embodiment 1

[0033] The preparation process is:

[0034] (1) Biomass nanocellulose was sterilized by ultraviolet radiation, and then repeatedly washed with deionized water until the pH value was 7 to obtain pretreated biomass cellulose; The diameter is 70nm and the average length is 1.3mm;

[0035] (2) Add the pretreated biomass cellulose and lecithin in step (1) into deionized water, and stir evenly to obtain a nanocellulose suspension; wherein, 33 parts by weight of pretreated biomass cellulose, lecithin 7 parts by weight, 60 parts by weight of deionized water;

[0036] (3) Add casein active peptides to the nanocellulose suspension prepared in step (2), disperse uniformly by ultrasonic, then freeze-dry, and grind into powder to obtain casein active peptide self-assembly powder; the ultrasonic frequency of ultrasonic dispersion The dispersing time is 38kHz, the dispersion time is 32min; the freeze-drying temperature is -34°C, and the freezing time is 25h; the parts by weight of each raw...

Embodiment 2

[0042] The preparation process is:

[0043] (1) Biomass nanocellulose was sterilized by ultraviolet radiation, and then repeatedly washed with deionized water until the pH value was 7 to obtain pretreated biomass cellulose; The diameter is 60nm, and the average length is 0.8mm;

[0044] (2) Add the pretreated biomass cellulose and lecithin in step (1) into deionized water, and stir evenly to obtain a nanocellulose suspension; wherein, 32 parts by weight of pretreated biomass cellulose, lecithin 7 parts by weight, 61 parts by weight of deionized water;

[0045] (3) Add casein active peptides to the nanocellulose suspension prepared in step (2), disperse uniformly by ultrasonic, then freeze-dry, and grind into powder to obtain casein active peptide self-assembly powder; the ultrasonic frequency of ultrasonic dispersion The dispersing time is 35kHz, the dispersion time is 35min; the freeze-drying temperature is -32°C, and the freezing time is 27h; the parts by weight of each ra...

Embodiment 3

[0051] The preparation process is:

[0052] (1) Biomass nanocellulose is sterilized by ultraviolet radiation, and then repeatedly washed with deionized water until the pH value is 7 to obtain pretreated biomass nanocellulose; biomass nanocellulose is obtained by separating wheat straw, with an average diameter of 90nm, the average length is 1.8mm;

[0053] (2) Add the pretreated biomass cellulose and lecithin in step (1) into deionized water, and stir evenly to obtain a nanocellulose suspension; wherein, 34 parts by weight of pretreated biomass cellulose, lecithin 9 parts by weight, 57 parts by weight of deionized water;

[0054] (3) Add casein active peptides to the nanocellulose suspension prepared in step (2), disperse uniformly by ultrasonic, then freeze-dry, and grind into powder to obtain casein active peptide self-assembly powder; the ultrasonic frequency of ultrasonic dispersion The dispersing time is 45kHz, the dispersion time is 25min; the freeze-drying temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com