Lubricating oil compositions comprising a molybdenum compound and a zinc dialkyldithiophosphate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

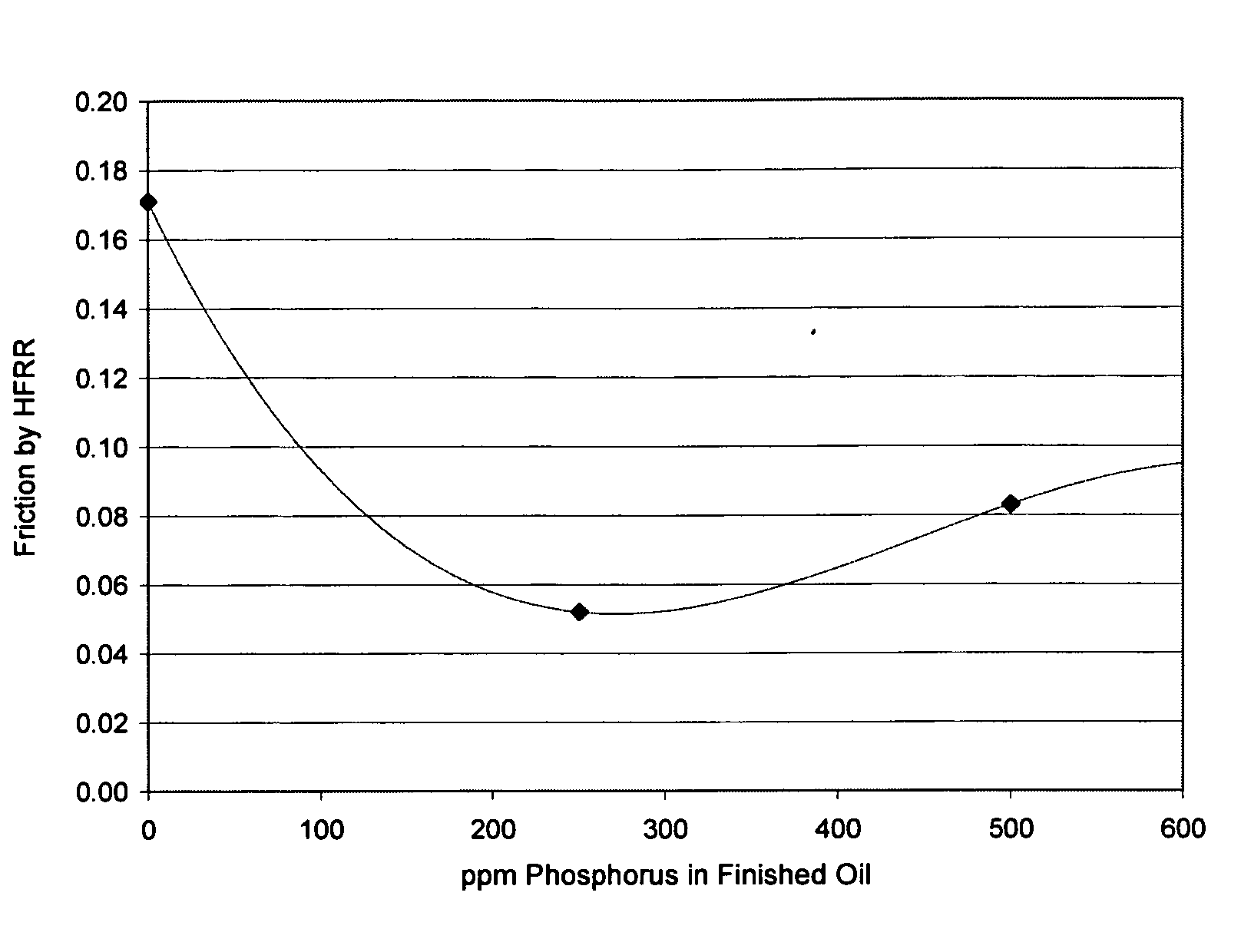

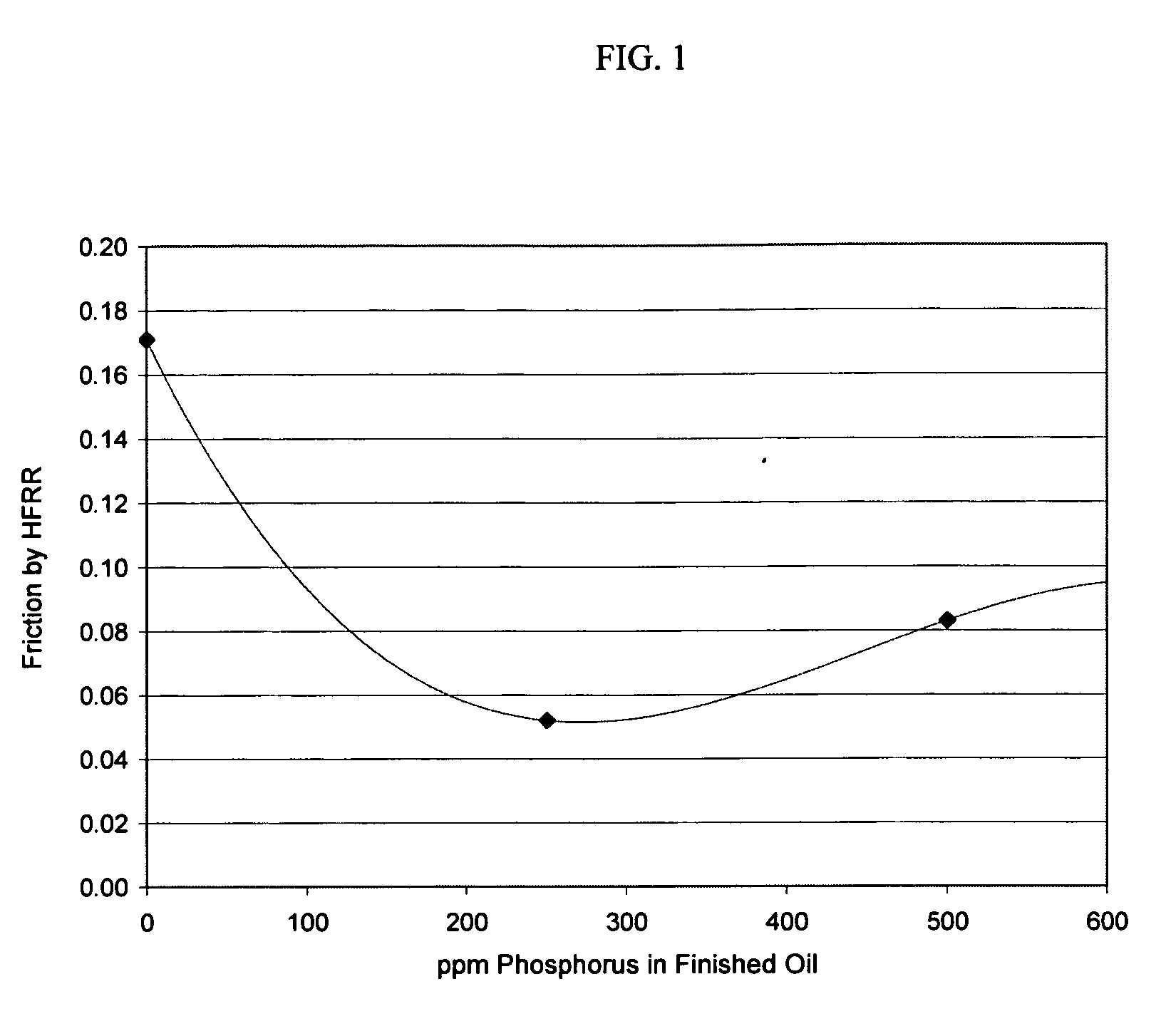

[0131]A lubricating oil composition was prepared and used for assessing boundary lubrication properties in the High Frequency Reciprocating Rig (HFRR) test (ASTM D 6079). The composition contained a major amount of a base oil of lubricating viscosity and the following additives, to provide an SAE 5W-20 finished oil;

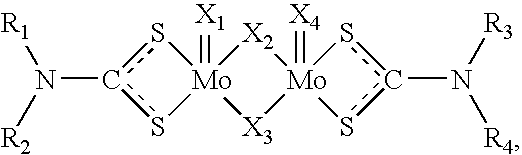

[0132](1) 700 ppm in terms of molybdenum content, of a molybdenum dithiocarbamate

[0133](2) 1 wt % of a borated bis-succinimide dispersant

[0134](3) 4 wt % of an ethylene carbonate post-treated bis-succinimide

[0135](4) 164 ppm in terms of calcium content, of a 17 TBN calcium sulfonate detergent

[0136](5) 2220 ppm in terms of calcium content, of a 148 TBN calcium salicylate

[0137](6) 1 wt % of an alkylated diphenylamine

[0138](7) 0.2 wt % of hindered phenol

[0139](8) 0.2 wt % of a pour point depressant

[0140](9) 4.8 wt % of a non-dispersant ethylene-propylene copolymer concentrate

[0141](10) 5 ppm in terms of Silicon content, of a foam inhibitor

[0142](11) The remainder was diluent...

example 2

[0143]A lubricating oil was prepared in accordance with the formulation of Example 1 except that 250 ppm in terms of phosphorus content of a zinc dialkyldithiophosphate was added. The composition contained 250 ppm phosphorus based on the total weight of the lubricating oil composition.

[0144]The zinc dialkyldithiophosphate is synthesized using a mixture of C4 and C6 secondary alcohols. The resulting zinc dialkyldithiophosphate is a zinc bis(O,O′-di-(2-butyl / 4-methyl-2-pentyl)dithiophosphate.

example 3

[0145]A lubricating oil was prepared in accordance with the formulation of Example 1 except that 500 ppm in terms of phosphorus content of the zinc dialkyldithiophosphate was added. The composition contained 500 ppm phosphorus based on the total weight of the lubricating oil composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com