Nano particle reinforced polymer element for stator and rotor assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]In the following description, numerous details are set forth to provide an understanding of the present invention. It should be understood by those of ordinary skill in the art that the present invention may be practiced without these details and that numerous variations or modifications from the described embodiments may be possible. The specific embodiments discussed herein are merely illustrative of specific ways to make and use the invention and do not delimit the scope of the present invention.

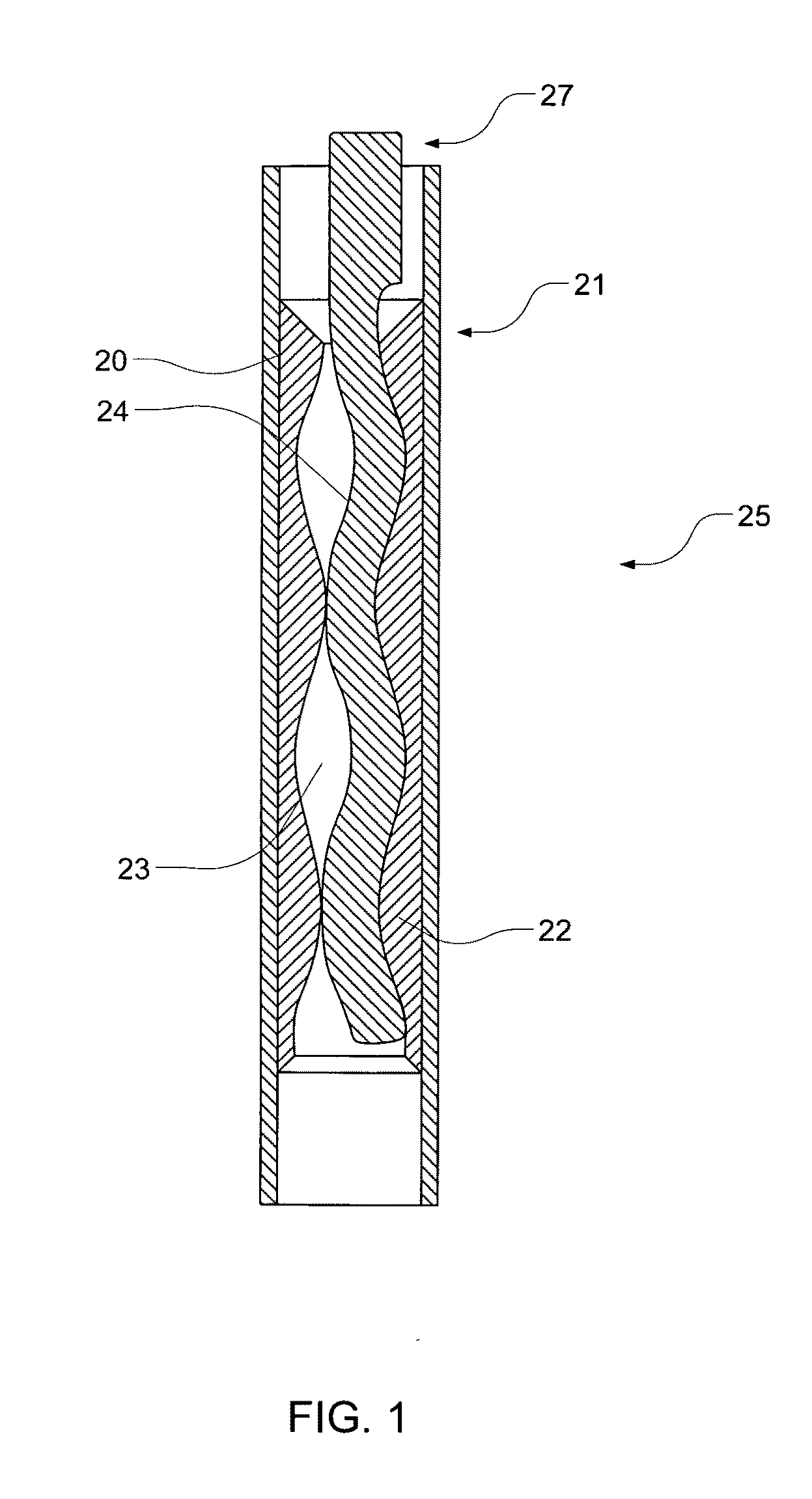

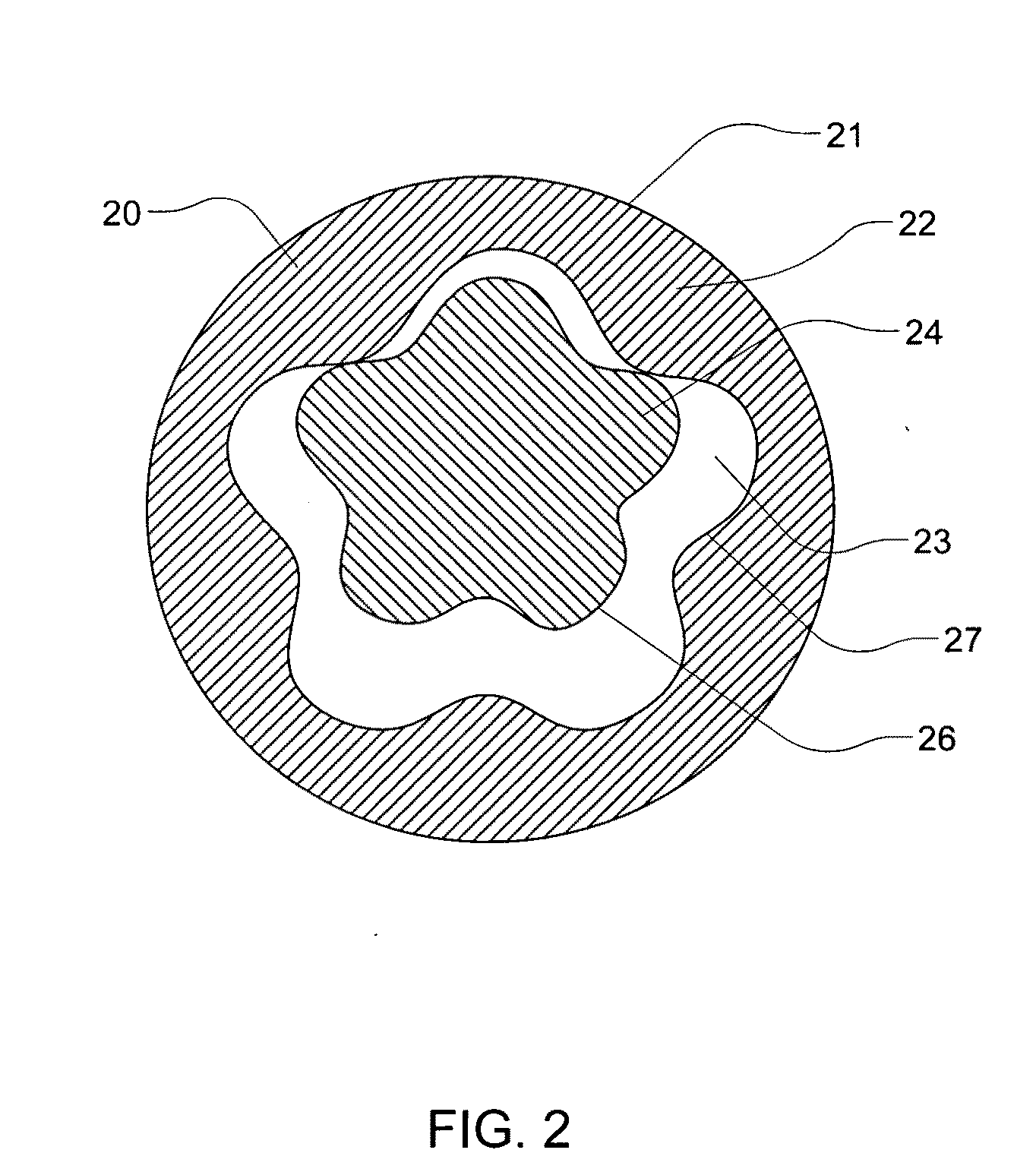

[0051]The present invention generally relates to a system and method of manufacture for an improved polymer element of a stator and rotor assembly. The system and method are useful, for example, with a variety of applications related to a power section of a positive displacement fluid motor or a progressive cavity pump or a fluid pulse generating device; for example, Halliburton's Pulsonix Deep Wave technology.

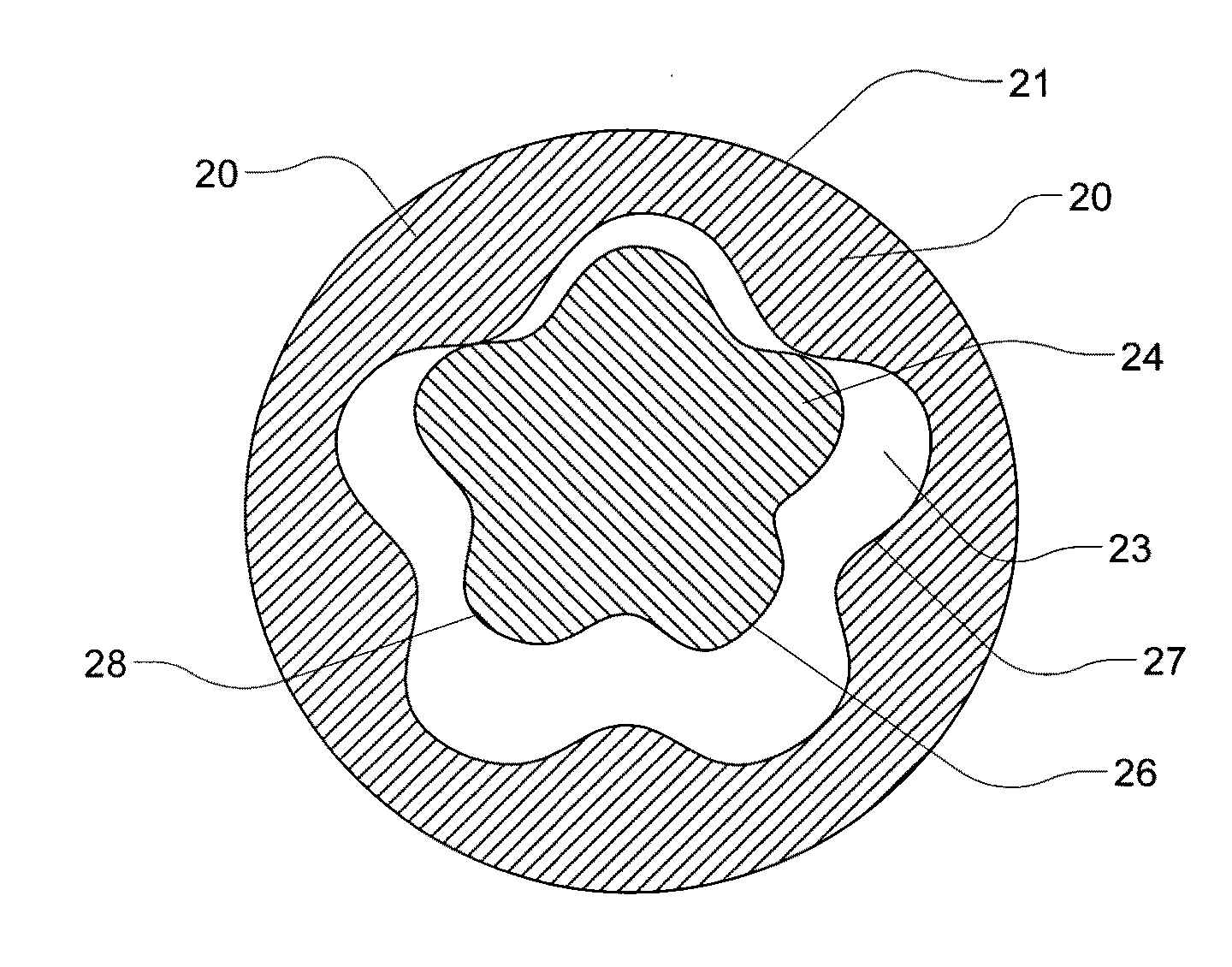

[0052]Referring generally to FIG. 1, a system 25 is illustrated according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nanoscale particle size | aaaaa | aaaaa |

| Nanoscale particle size | aaaaa | aaaaa |

| Nanoscale particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com