Fuel hose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

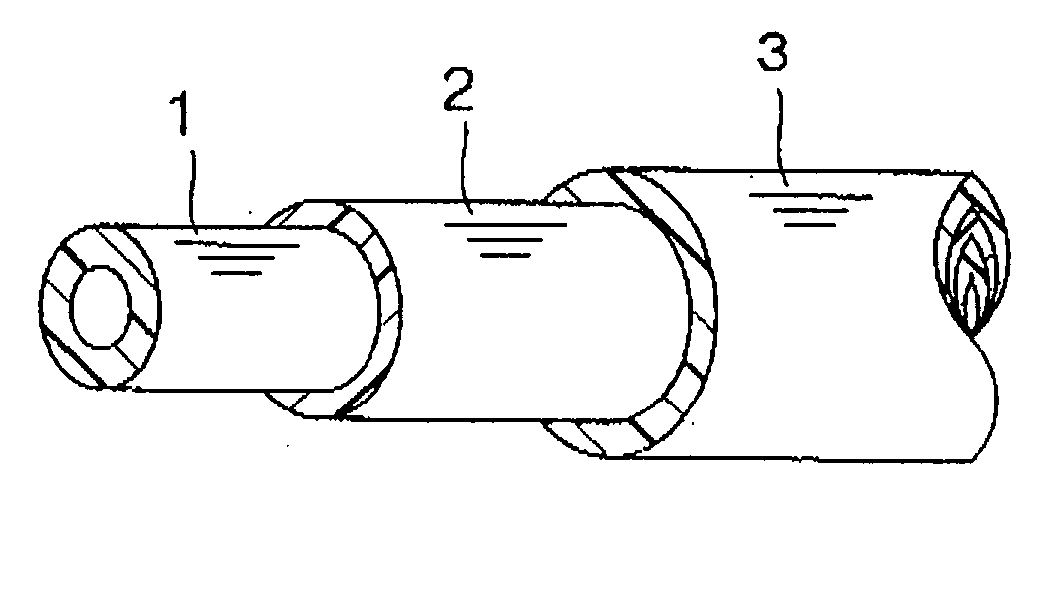

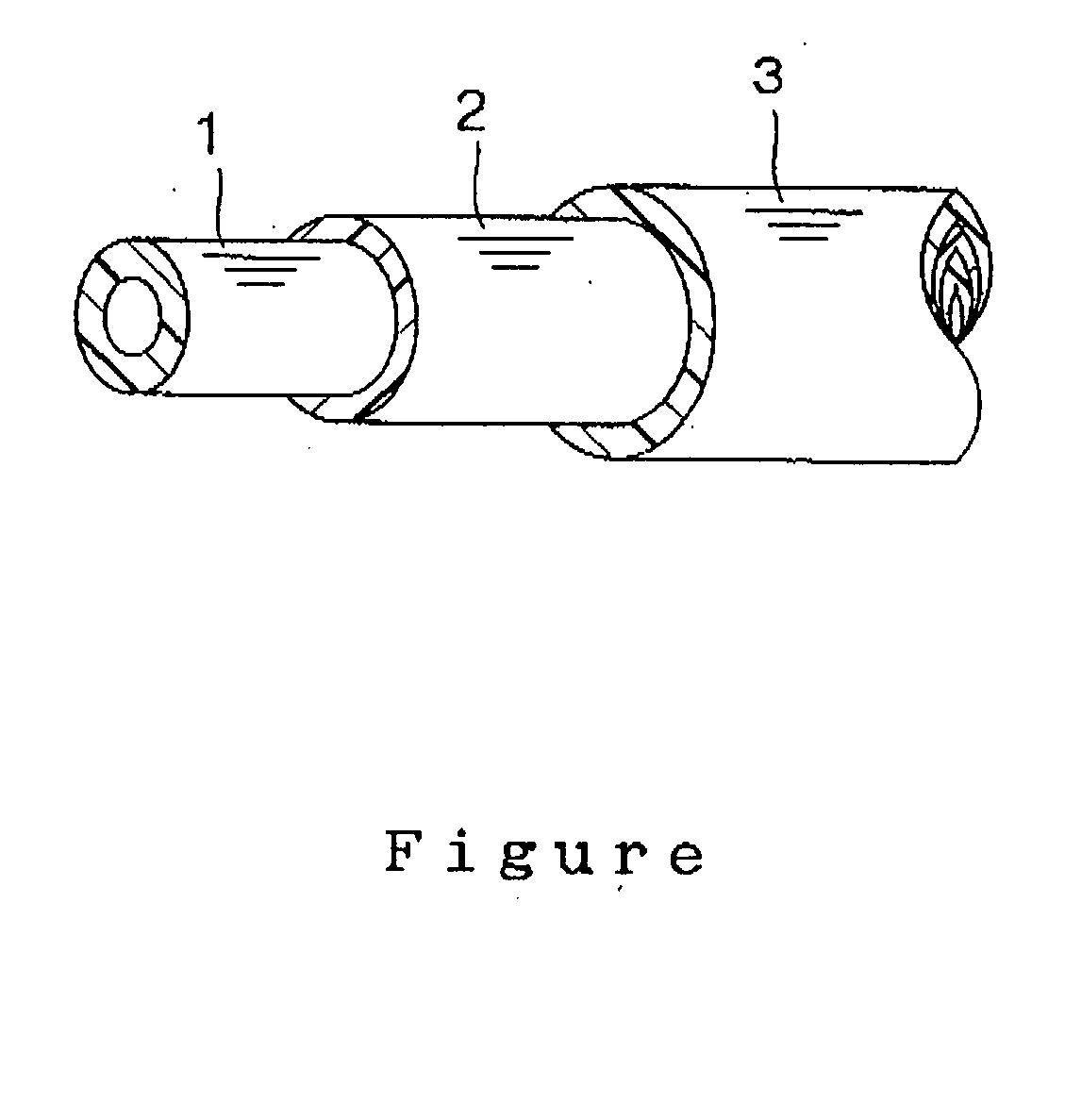

Image

Examples

example 1

[0047] [Preparation of Innermost Layer]

[0048] A material for an innermost layer was prepared by kneading 40 parts of ACM (DENKA ER-3400, available from DENKI KAGAKU KOGYO KABUSHIKI KAISHA), 60 parts of NBR (Nipol DN202 available from Zeon Corporation, bound acrylonitrile amount: 31 wt %), 50 parts of carbon black (SEAST 116, available from Tokai Carbon, Co., Ltd.), 1 part of a DBU salt (DA-500, available from Daiso Co., Ltd.), 1 part of a processing aid (LUNAC S-30, available from KAO Corporation), 20 parts of silica (Carplex 1120, available from SHIONOGI & CO., LTD.), 10 parts of a plasticizer (ADECASIZER RS-107, available from Asahi Denka Co., Ltd.), 2 parts of a vulcanizing agent (CN-25, available from DENKI KAGAKU KOGYO KABUSHIKI KAISHA), 0.5 parts of sulfur and 0.3 parts of a vulcanization accelerator aid (VULNOCAB-S, available from Ouchi Shinko Chemical Industrial Co., Ltd.) by means of a kneader. Thus obtained polymer rubber as a material for the innermost layer contained acr...

example 2

[0055] A material for an innermost layer was prepared by kneading 30 parts of ACM (DENKA ER-3400, available from DENKI KAGAKU KOGYO KABUSHIKI KAISHA), 70 parts of NBR (Nipol DN101, available from Zeon Corporation, bound acrylonitrile amount: 42.5wt %), 50 parts of carbon black (SEAST 116, available from Tokai Carbon, Co., Ltd.), 1 part of DBU salt (DA-500, available from Daiso Co., Ltd.), 1 part of processing aid (LUNAC S-30, available from KAO Corporation), 20parts of silica (Carplex 1120, available from SHIONOGI & CO., LTD.), 10 parts of a plasticizer (ADECASIZERRS-107, available from Asahi Denka Co., Ltd.), 2 parts of a vulcanizing agent (CN-25, available from DENKI KAGAKU KOGYO KABUSHIKI KAISHA), 0.5 parts of sulfur and 0.3 parts of a vulcanization accelerator aid (VULNOC AB-S, available from Ouchi Shinko Chemical Industrial Co., Ltd.) by means of a kneader. The thus obtained polymer rubber as a material for the innermost layer contained acrylonitrile at 29.8 wt %. Except for th...

example 3

[0056] A material for an innermost layer was prepared by kneading 70 parts of ACM (DENKA ER-3400, available from DENKI KAGAKU KOGYO KABUSHIKI KAISHA), 30 parts of NBR (Nipol DN009, available from Zeon Corporation, bound acrylonitrile amount: 50 wt %), 50 parts of carbon black (SEAST 116, available from Tokai Carbon, Co., Ltd.), 1 part of a DBU salt (DA-500, available from Daiso Co., Ltd.), 1 part of a processing aid (LUNAC S-30, available from KAO Corporation), 20 parts of silica (Carplex 1120, available from SHIONOGI & CO., LTD.), 10 parts of a plasticizer (ADECASIZER RS-107, available from Asahi Denka Co., Ltd.), 2 parts of a vulcanizing agent (CN-25, available from, DENKI KAGAKU KOGYO KABUSHIKI KAISHA), 0.5 parts of sulfur and 0.3 parts of a vulcanization accelerator aid (VULNOCAB-S, available from Ouchi Shinko Chemical Industrial Co., Ltd.) by means of a kneader. The thus obtained polymer rubber as a material for the innermost layer contained acrylonitrile at 15 wt %. Except for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com