Drill bits and tools for subterranean drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]In the description which follows, like elements and features among the various drawing figures are identified for convenience with the same or similar reference numerals.

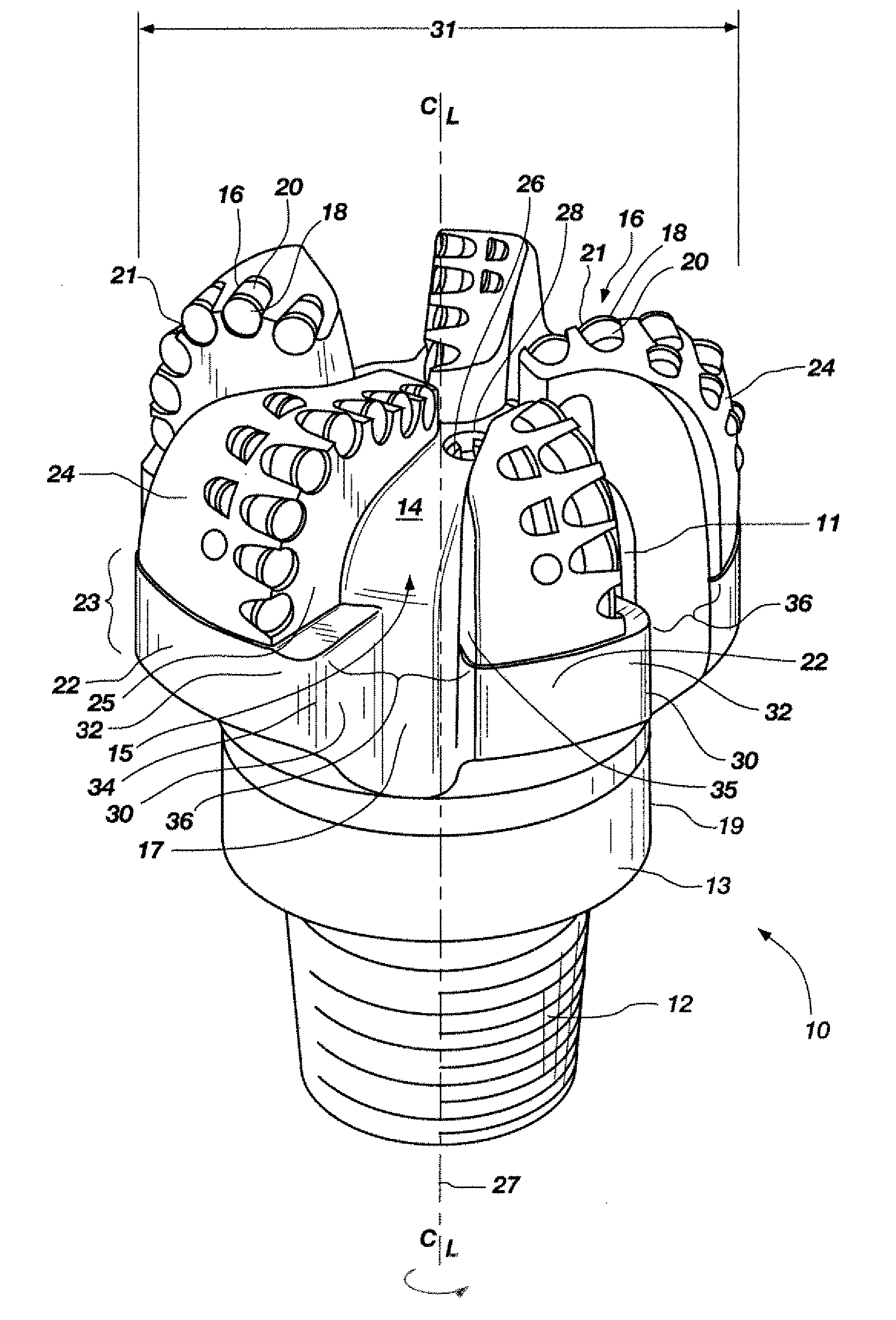

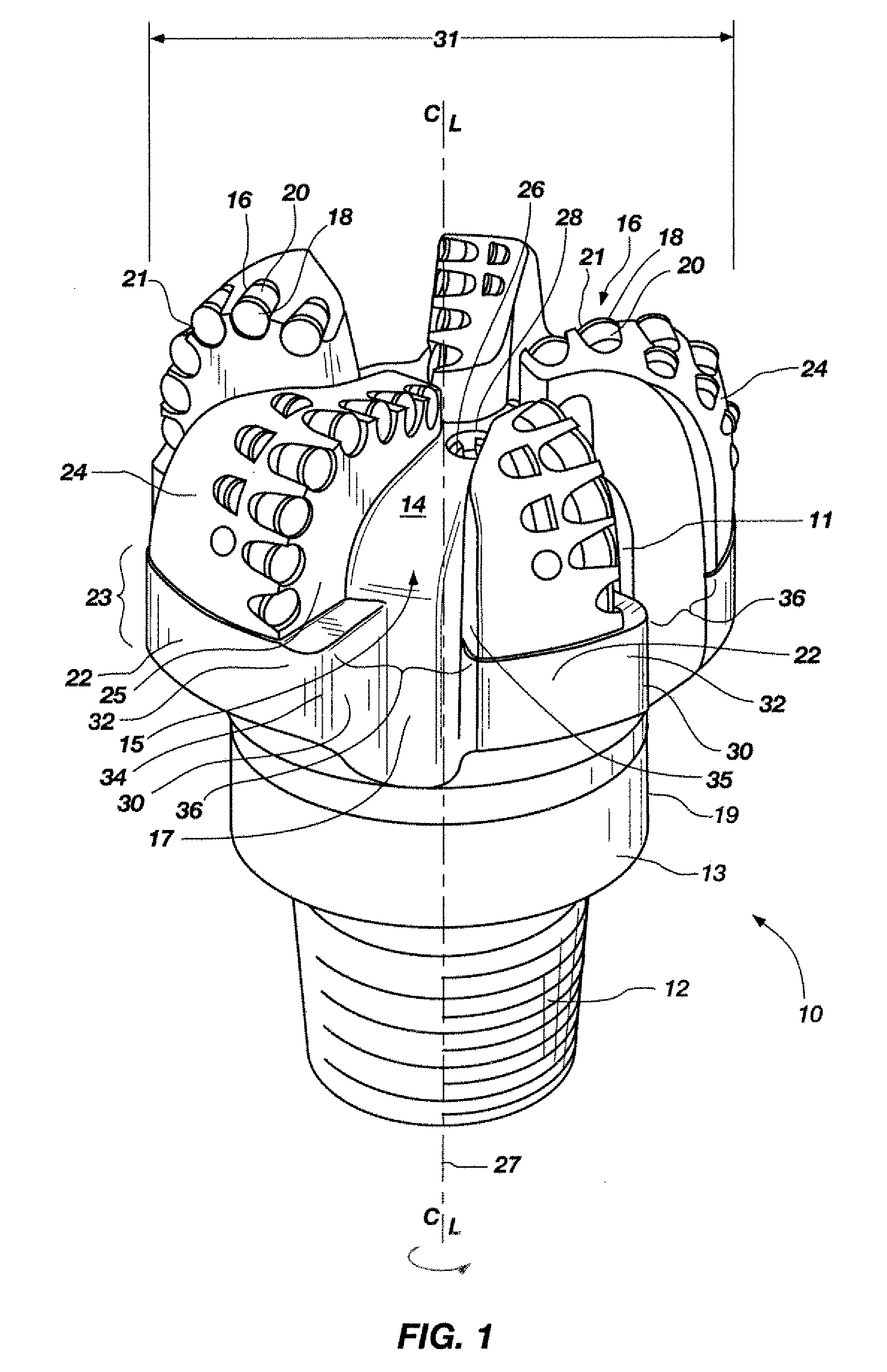

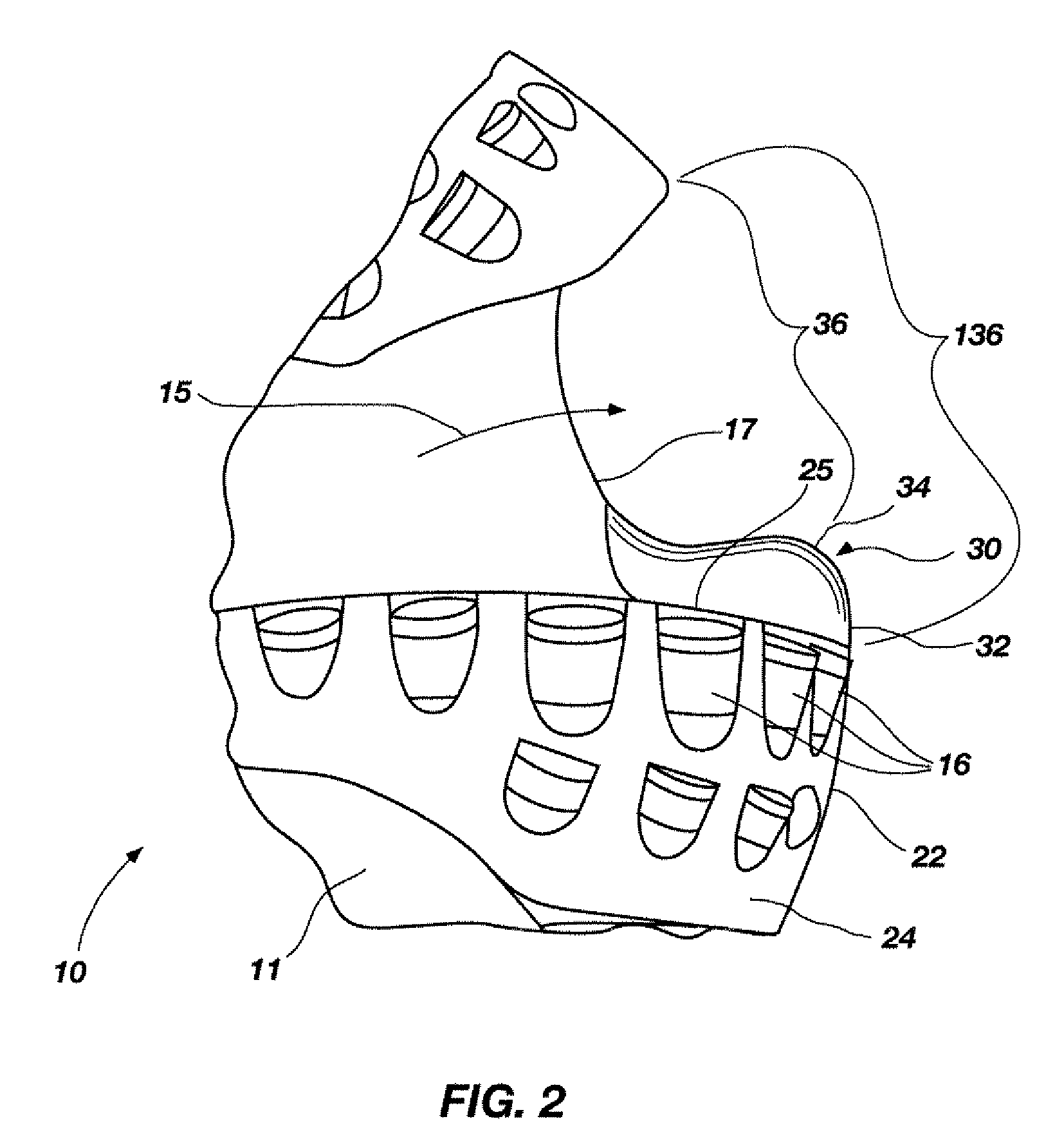

[0018]FIG. 1 shows a perspective, inverted (with respect to the usual orientation thereof during drilling) view of a drill bit 10 configured with extension pads 30, according to an embodiment of the invention. The drill bit 10 is configured as a fixed cutter rotary full bore drill bit, also known in the art as a “drag” bit. The drill bit 10 includes a bit crown or body 11 comprising, for example, tungsten carbide infiltrated with a metal alloy binder, a machined steel casting or forging, or a sintered tungsten or other suitable carbide, nitride or boride as discussed in further detail below, and coupled to a support 19. The support 19 includes a shank 13 and a crossover component (not shown) coupled to the shank 13 in this embodiment of the invention. It is recognized that the support 19 may be made from a uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com