Rotary Valve for Industrial Fluid Flow Control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

One Input One Output Cylindrical Rotary Valve as On / Off Valve

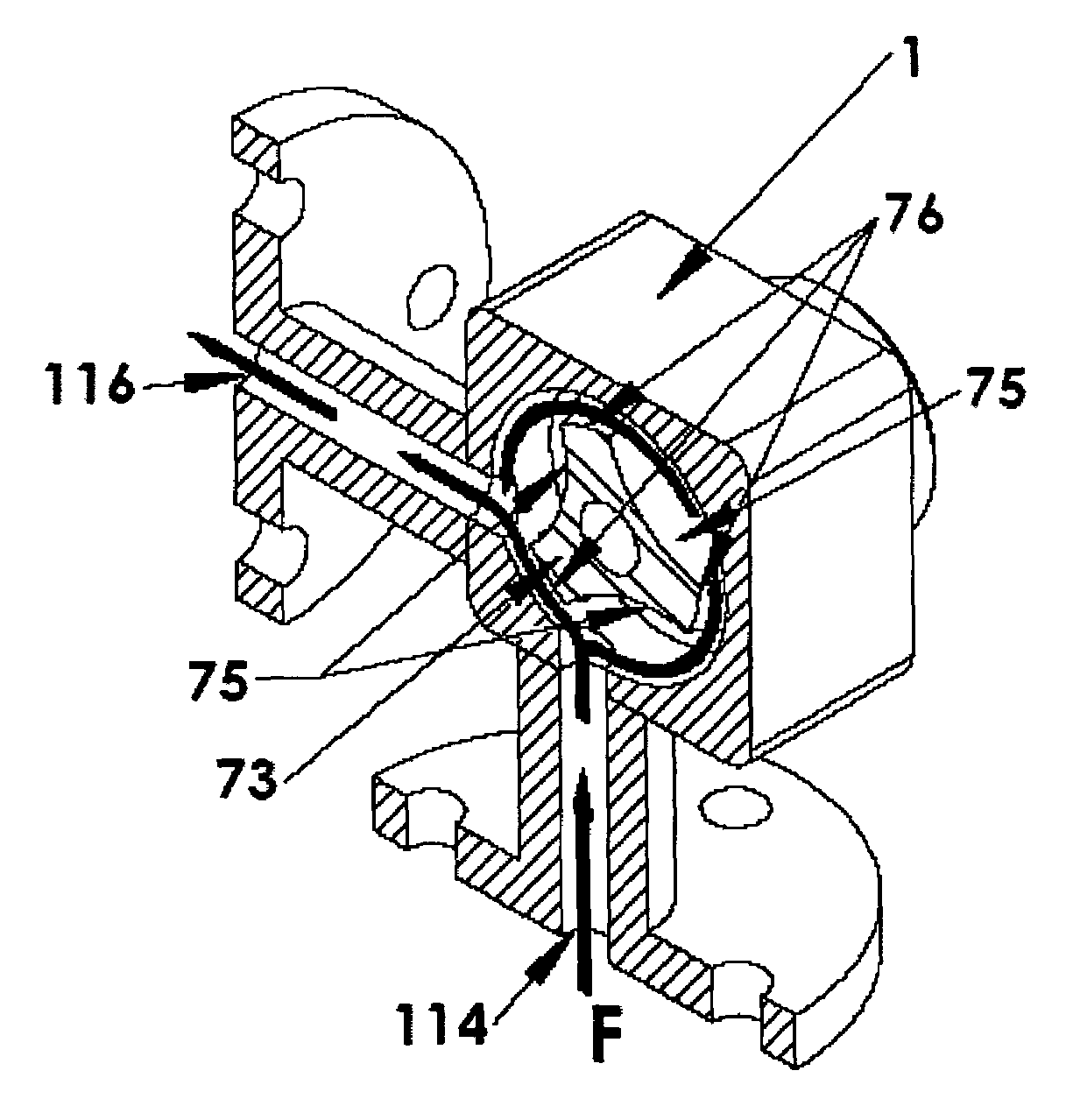

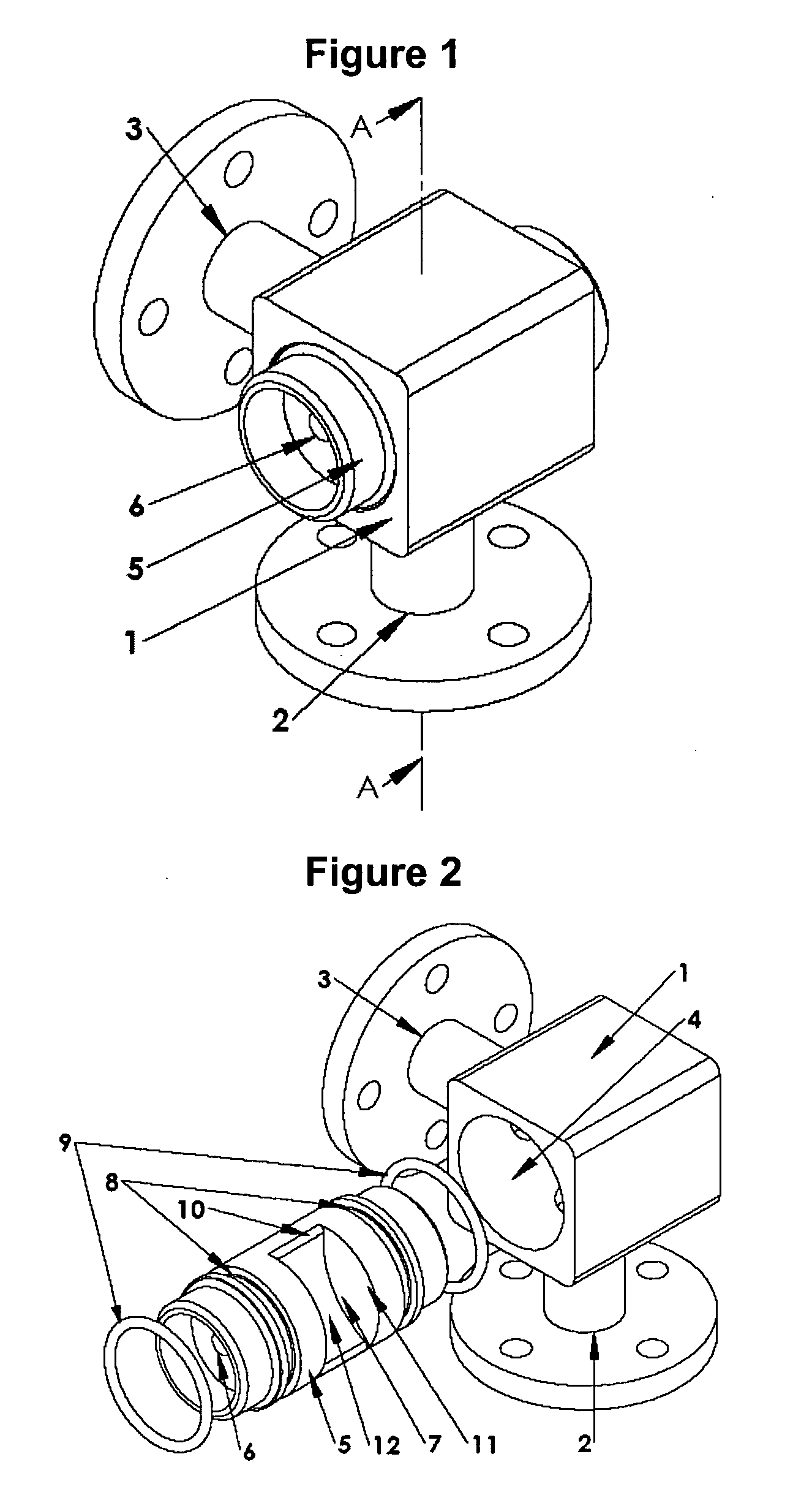

[0086]FIG. 1 and FIGS. 2 through 17 depict a first embodiment of the invention, namely a one input and one output configurable valve in use as a on / off (stop) valve.

[0087]FIG. 1 shows two port valve body 1 with inserted valve shaft 5. The valve body 1 has interchangeable input pipe 2 and output pipe 3, shown in this embodiment to be at 90 degrees from each other. The valve body houses a standard size valve shaft 5, with optional temperature control bore 6. To maintain the generality of the invention, the drive means for the valve is not shown, although a variety of accurate and robust means to control the rotation of the shaft will be known to those of skill in the art, who will be in a position to determine an appropriate drive means compatible with the tolerances of the proposed use. Also not shown is the specific element used to connect the temperature control core 6 with the temperature control fluid. There are well kn...

embodiment 2

Pulse Valve

[0099]FIG. 1 and FIGS. 18 through 27 disclose embodiments of the present invention configured to create a flow pulse in the fluid being controlled at the output of the valve body. The various embodiments demonstrate the design parameters that are available for use in the present invention. This embodiment includes a valve body 1 with input pipe 2, output pipe 3 as disclosed in FIG. 1. The exploded view in FIG. 18 shows the valve body 1 further provided with the hollow 4 in the valve body 1 sized to accept a standard radius cylindrical valve shaft 50. The cylindrical valve shaft may be equipped with a temperature control core 51. In this example, symmetrical crescent shaped conduits 52 are spaced evenly about the shaft. If required by the choice of material, seal channels 53 are cut around the valve shaft 50 on either side of the conduits 52 into which seals 54 are inserted. A self lubricating coating on the valve shaft 50 may also be provided.

[0100]The valve shaft 50 is i...

embodiment 3

Wave Valve.

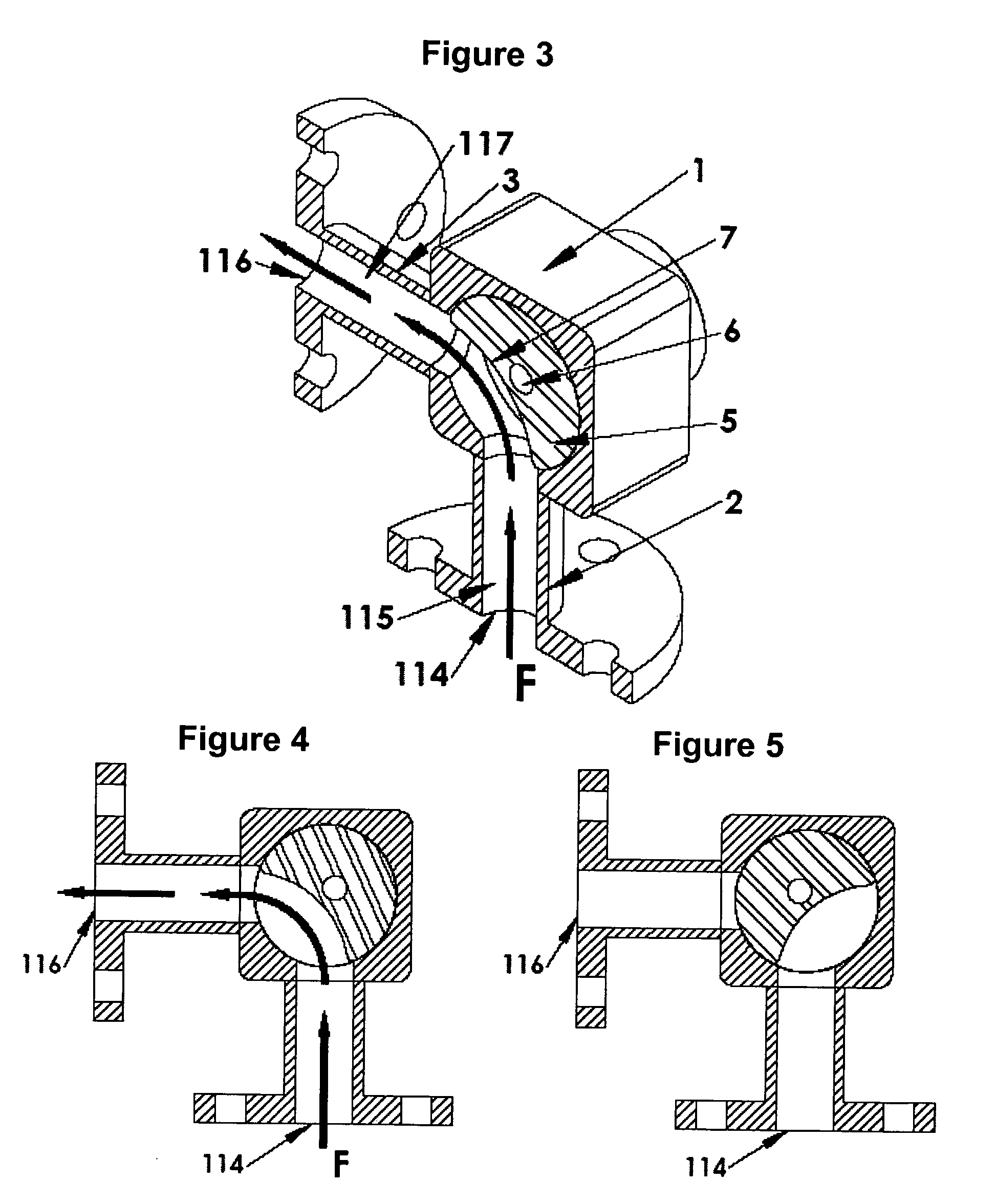

[0105]Yet another variation of the pulse valve is a “wave-valve” as shown in FIGS. 30, 31, 32A and 32B. In certain embodiments, it is desirable to create a known gap size in the clearance between the valve body (housing) and the valve shaft, in addition to the conduits previously described, so that fluid flow can be accurately controlled without entirely turning off fluid flow. This creates a “wave” or “offset pulse” in the fluid which is useful in certain applications. The prior art teaches away from intentionally inserting gaps into the space between the valve body and the valve shaft, to improve the seal and eliminate “leakage”. In contrast, certain wave valve embodiments of the invention allow a user to predetermine, and thereby quantify, the “leak” to suit a design purpose.

[0106]The overall wave valve configuration is similar to the pulse valve. FIG. 30 and FIG. 31 show two views of a three conduit wave type valve shaft 73, with optional temperature control core 73, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com