Method for Growth of Gan Single Crystal, Method for Preparation of Gan Substrate, Process for Producing Gan-Based Element, and Gan-Based Element

a technology of gan single crystal and gan-based elements, which is applied in the direction of crystal growth process, polycrystalline material growth, chemically reactive gas growth, etc., can solve the problems of increasing the unit cost of production, difficult element processing, and deterioration of element characteristics, so as to improve the performance of gan-based elements and improve the fabrication steps of gan-based elements. , the effect of low d

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

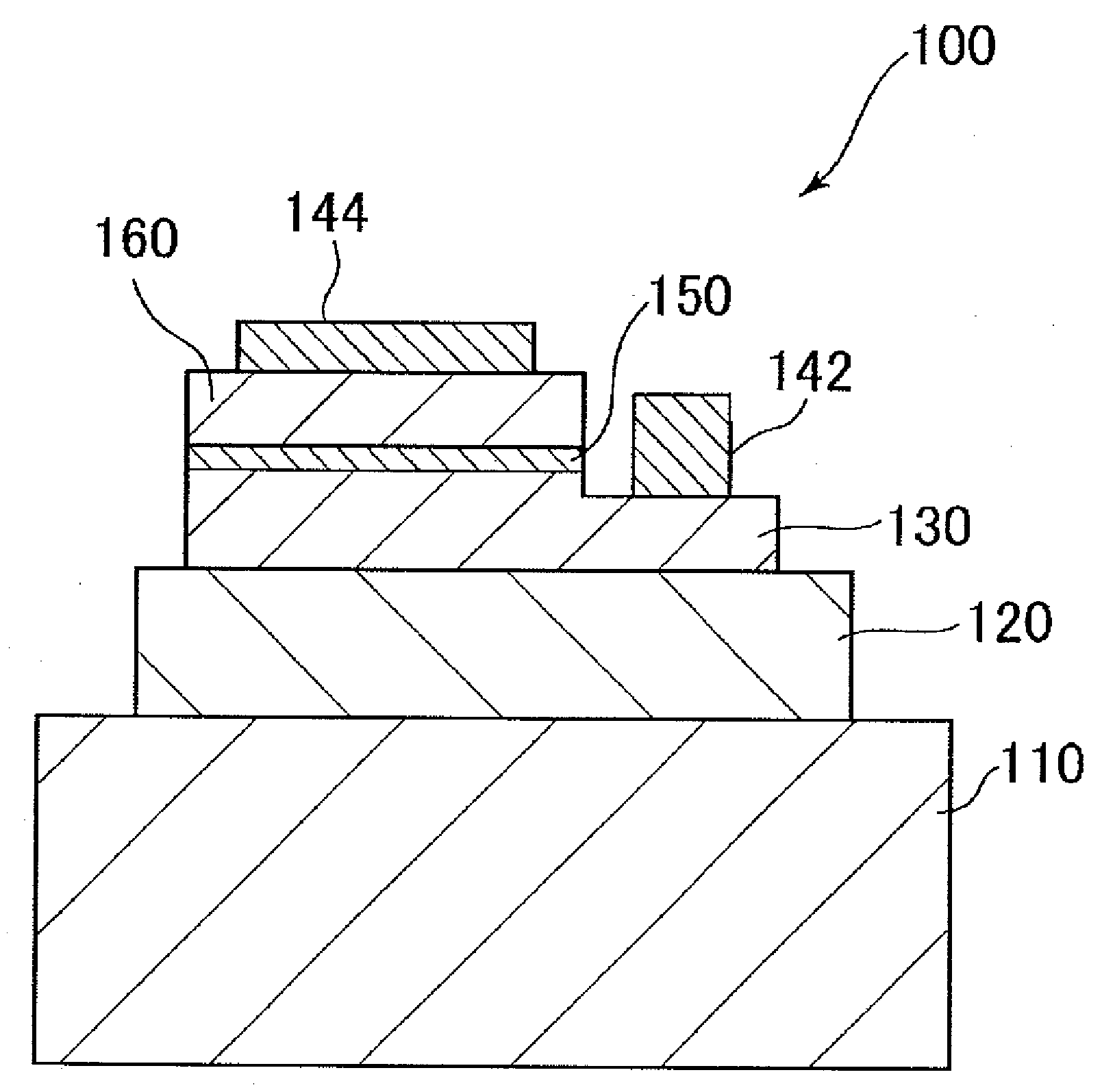

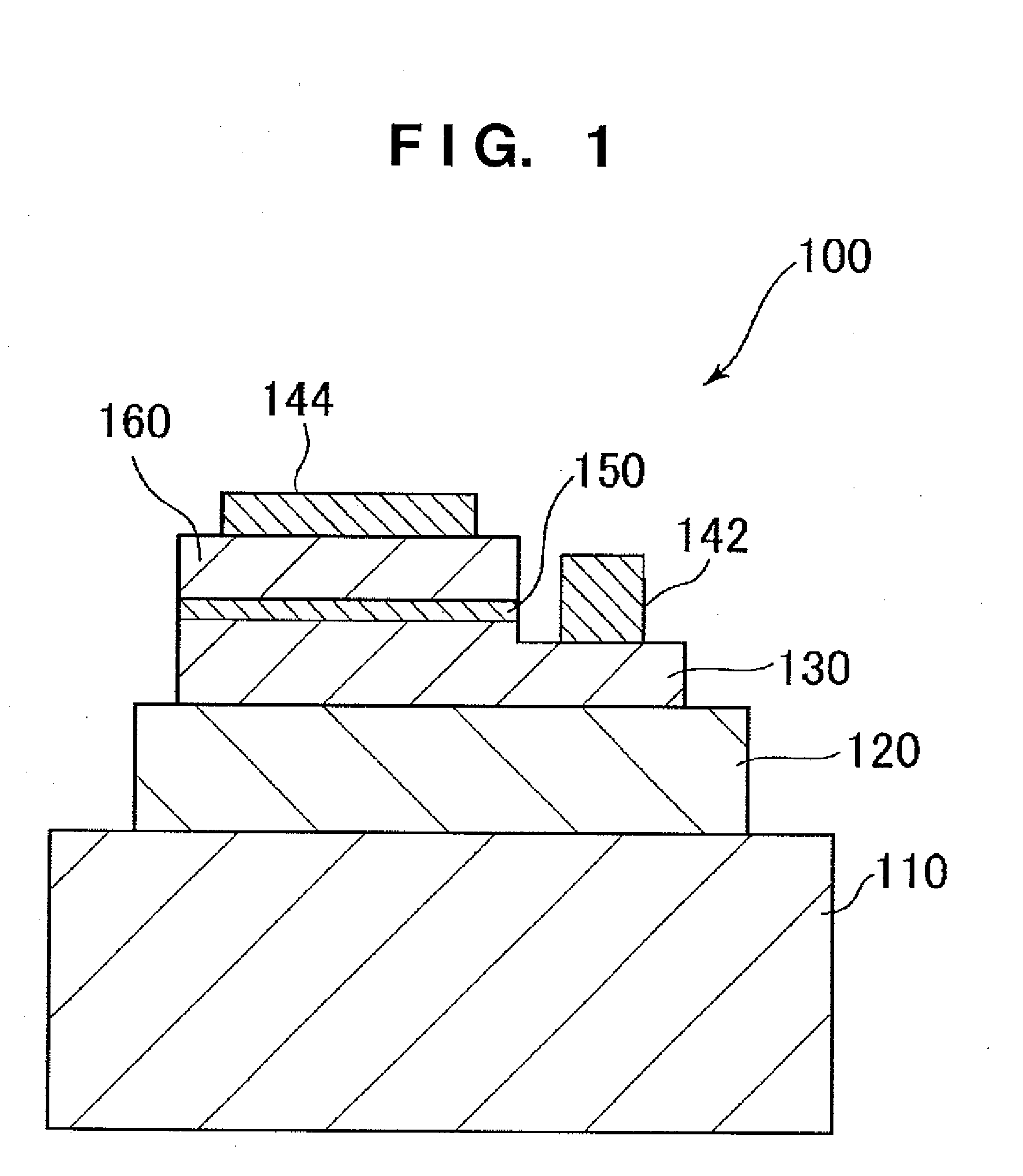

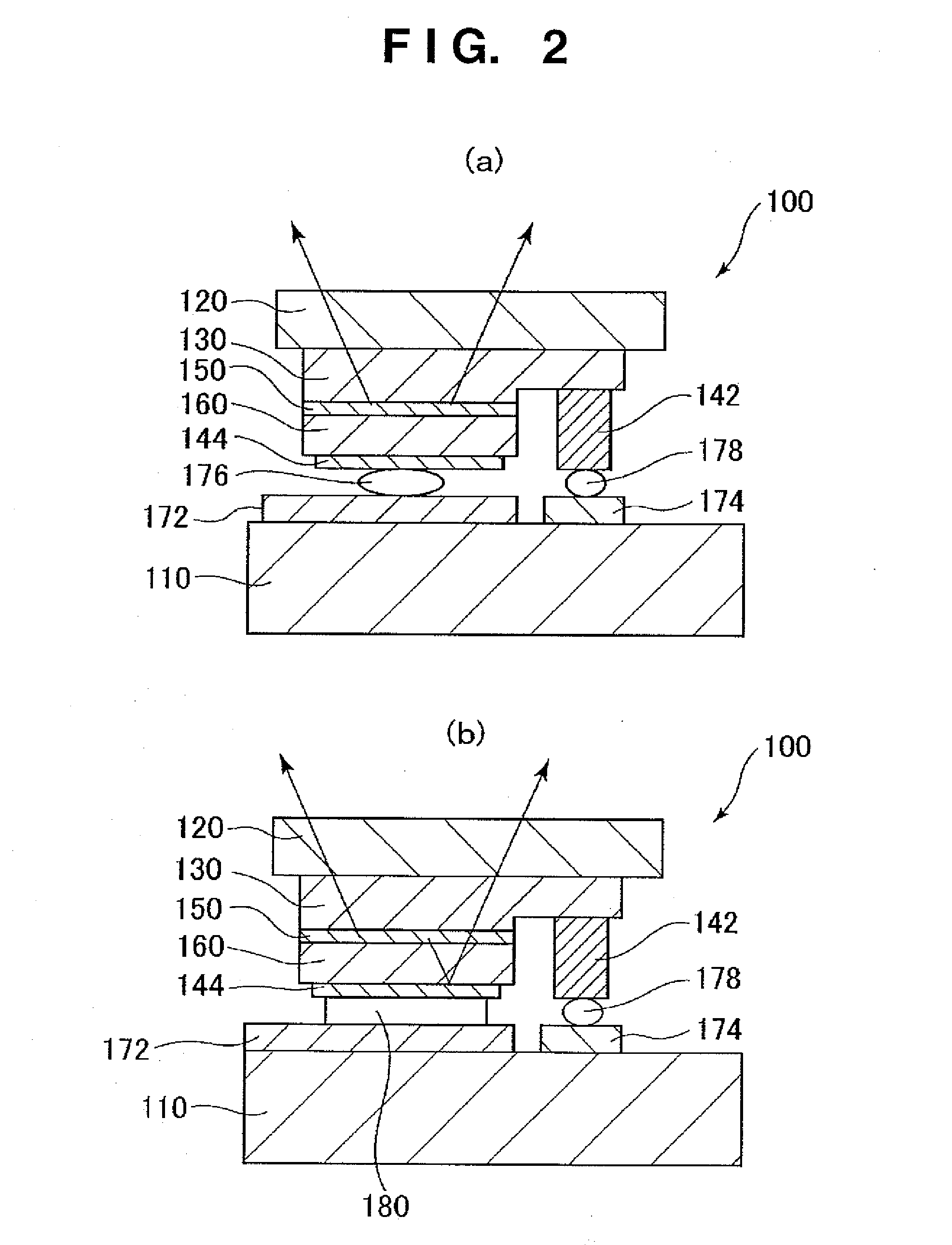

[0102]The present invention forms a metal buffer layer on a different kind of single-crystal substrate, a polycrystalline substrate, an amorphous substrate, or a metal substrate, in addition to a sapphire substrate and SiC substrate, by electron beam evaporation method (E-beam evaporator), thermal evaporation method (Thermal evaporator), sputtering method (Sputter), chemical vapor deposition method (Chemical Vapor Deposition), or metal organic chemical vapor deposition (MOCVD), and then grows single-crystal GaN on the metal buffer layer. It is the first attempt to use a metal as a buffer layer on various substrates, and fabricate a light emitting element or electronic element on the metal buffer layer. This makes it possible to provide various structures and various substrates of GaN-based light emitting elements in the future. Since the metal buffer layer is inserted in the interface between any of various substrates such as a sapphire substrate or SiC substrate and a GaN-based sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com